Introduction

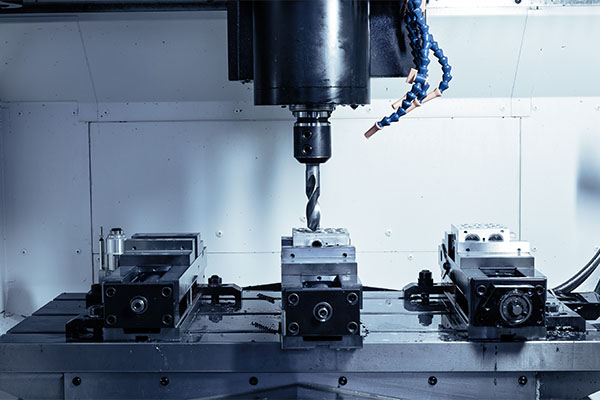

In this article, we’ll explore the seven key benefits of CNC machining and how they can significantly improve your manufacturing processes. Whether you’re looking for greater precision, efficiency, or cost savings, CNC machining offers unparalleled advantages in the world of manufacturing. By the end, you’ll understand why so many businesses, including factories, wholesalers, and distributors, are leveraging CNC technology to stay competitive.

1. What Are the 7 Key Advantages of CNC Machining?

CNC machining has become the gold standard in modern manufacturing. But what makes it so effective? Let’s dive into the seven key advantages that CNC machining brings to the table.

High precision and accuracy: One of the standout features of CNC machining is its precision. These machines operate based on pre-programmed instructions, which means every part is produced with minimal human input. This high level of automation reduces the potential for errors, making CNC machining ideal for industries that require tight tolerances.

Reduced production time: CNC machining speeds up the manufacturing process by automating multiple steps at once. What would typically require several manual operations can be accomplished in a fraction of the time.

Consistency and repeatability: Because CNC machines rely on precise programming, the output is highly consistent. This makes CNC machining perfect for both small and large production runs, where you need every part to meet exact specifications.

Cost-effectiveness: CNC machining’s efficiency and reduced human labor costs contribute to lower overall production costs. The ability to produce high-quality products in less time allows businesses to increase their profit margins.

Improved safety: By automating much of the work process, CNC machines help reduce the chances of human error and operator injuries, enhancing workplace safety.

Flexibility in material use: CNC machines can work with a variety of materials, including metals, plastics, and composites, making them highly versatile for different manufacturing needs.

Customization capabilities: CNC machining allows for tailored solutions to meet specific customer demands, from complex geometries to unique part designs.

Table 1: Key Advantages of CNC Machining

| Benefit | Description | Impact on Business |

|---|---|---|

| High precision and accuracy | Automated machines reduce human error and deliver high precision. | Ensures quality and tight tolerances for complex parts. |

| Reduced production time | CNC machines speed up the manufacturing process with automated functions. | Decreases lead times, boosting output efficiency. |

| Consistency and repeatability | Each part is produced with the same high quality every time. | Perfect for high-volume manufacturing runs. |

| Cost-effectiveness | Lower labor costs and faster production lead to cost savings. | Increases profitability through efficient resource use. |

| Improved safety | Reduced human interaction with machines lowers risk of injuries. | Provides a safer work environment for employees. |

| Flexibility in material use | CNC machining can handle a wide range of materials. | Enables the production of diverse parts and products. |

| Customization capabilities | Parts can be customized to meet specific needs. | Provides tailored solutions to meet customer demands. |

2. Why Is CNC Machining Ideal for Complex Parts?

Ready for the good part? CNC machining stands out when it comes to manufacturing complex parts. These machines can handle intricate and highly detailed designs with ease, making them the perfect choice for industries that need precision and complexity.

Ability to produce intricate designs: CNC machining can replicate even the most complex geometries with ease. The software used to program these machines can handle shapes and details that would be impossible or highly impractical to achieve through manual methods.

Versatility with materials: CNC machines are not limited to a single type of material. Whether you need metal, plastic, or composites, CNC machines can handle it all, offering flexibility in the types of parts you can produce.

Perfect for prototypes: CNC machining is excellent for rapid prototyping. You can quickly produce a model to test the design, ensuring it meets all specifications before moving forward with mass production. This iterative design process helps reduce risks and saves time in the long run.

Increased accuracy for complex parts: When working with complex parts, accuracy is paramount. CNC machining can handle high-precision parts with intricate details, making them ideal for sectors like aerospace, automotive, and medical device manufacturing.

Table 2: CNC Machining for Complex Parts

| Feature | Description | Applications |

|---|---|---|

| Ability to produce intricate designs | CNC machines handle complex geometries with high precision. | Aerospace, automotive, medical devices. |

| Versatility with materials | CNC machines can work with a wide range of materials. | Flexible use in various industries. |

| Rapid prototyping | Quickly create prototypes to test designs before mass production. | Ideal for product development and testing. |

| Increased accuracy for complex parts | CNC machining offers high precision even for detailed parts. | Critical for high-precision industries. |

3. How Does CNC Machining Increase Efficiency in Manufacturing?

This is where it gets interesting… CNC machining isn’t just about precision; it’s also about efficiency. This automated process significantly enhances productivity, giving businesses a competitive edge in fast-paced manufacturing environments.

Faster production speeds: CNC machines can run continuously, processing parts much faster than manual operations. Additionally, the automation reduces setup times, enabling faster turnarounds on orders.

Reduced downtime: With fewer manual interventions required, CNC machines are less prone to unexpected downtime. This leads to smoother production flows and a more reliable manufacturing process.

Increased capacity for large runs: CNC machines excel at both small and large-scale productions. Their ability to maintain precision over long production runs ensures high output without sacrificing quality.

Minimized human error: Human error is an inherent part of manual machining, but CNC machines minimize this risk by operating based on pre-programmed instructions. This reduces the need for rework and improves overall workflow.

Streamlined production processes: With CNC machining, multiple steps can be completed simultaneously, which helps streamline the production process and reduces the need for manual intervention at each stage.

Table 3: How CNC Machining Improves Efficiency

| Efficiency Factor | Description | Impact on Business |

|---|---|---|

| Faster production speeds | CNC machines can process parts at a much quicker rate than manual methods. | Reduces production time, boosting throughput. |

| Reduced downtime | CNC machines require fewer manual adjustments, reducing the chances of stoppages. | More consistent and reliable production. |

| Increased capacity for large runs | CNC machines can handle both small and large batch productions effectively. | Enhances ability to scale production with consistency. |

| Minimized human error | Automated systems reduce the potential for mistakes. | Reduces the need for rework and scrap material. |

| Streamlined production processes | Multiple steps can be done in one go, streamlining workflow. | Improves overall production speed and efficiency. |

4. How Does CNC Machining Improve Quality Control?

Here’s the kicker… When it comes to quality control, CNC machining is a game-changer. These automated systems offer unparalleled consistency, which leads to high-quality output across every part manufactured.

Consistency across the production line: CNC machines operate based on computer programming, ensuring that every part produced is identical in size, shape, and tolerance. This consistency helps businesses maintain high-quality standards in every batch.

Advanced monitoring and feedback systems: Many CNC machines come with built-in sensors and monitoring systems that track performance and detect errors in real-time. This means issues can be identified and addressed immediately, preventing defective parts from making it into production.

Reduced rework: Because of the high accuracy of CNC machines, parts are less likely to require rework. This reduces the amount of material wasted and saves time in the manufacturing process.

Accurate dimensional control: CNC machining ensures that every part meets exact specifications. For industries that demand high precision, such as aerospace or medical devices, this level of accuracy is crucial.

Table 4: CNC Machining and Quality Control

| Quality Control Feature | Description | Impact on Business |

|---|---|---|

| Consistency across production | Each part is produced to the same exact specifications. | Maintains high product quality, especially for large runs. |

| Advanced monitoring and feedback | Built-in sensors detect errors in real-time. | Prevents defective parts, improving overall quality. |

| Reduced rework | Higher precision reduces the need for rework. | Saves time and reduces material waste. |

| Accurate dimensional control | CNC machines provide highly precise dimensions. | Ensures that parts meet exact industry standards. |

5. What Are the Cost Benefits of CNC Machining?

What’s the real story? CNC machining may have higher upfront costs, but it delivers long-term cost savings that more than make up for the initial investment. Here’s how:

Lower labor costs: CNC machines reduce the need for skilled labor, as operators mainly monitor and supervise the machines rather than performing manual tasks. This can lead to significant savings in labor costs.

Less waste and scrap material: The precision of CNC machines ensures that there’s minimal material waste. This means businesses can make the most of their raw materials, further reducing costs.

Fewer errors and rework: The high accuracy of CNC machines means fewer parts will need to be scrapped or reworked. This reduces the need for extra materials and labor to fix mistakes.

Faster production time: Faster production speeds allow businesses to produce more parts in less time, increasing their output and profitability.

Table 5: CNC Machining Cost Benefits

| Cost Benefit | Description | Impact on Business |

|---|---|---|

| Lower labor costs | CNC machines automate much of the work, requiring less manual labor. | Reduces the overall cost of production. |

| Less waste and scrap material | Precision machining reduces material wastage. | Maximizes the use of raw materials, cutting down costs. |

| Fewer errors and rework | The precision of CNC machines minimizes the need for rework. | Saves time, materials, and labor costs. |

| Faster production time | CNC machines speed up the manufacturing process. | Boosts output and profit margins. |

6. How Does CNC Machining Minimize Waste in Manufacturing?

What’s the real story? Waste is a significant concern in any manufacturing process, and minimizing it is key to improving both efficiency and profitability. CNC machining plays a pivotal role in reducing material waste, thanks to its precision and automation capabilities.

Efficient material use: CNC machines are programmed to use exactly the amount of material needed to create the desired part. Unlike traditional machining methods, which often require larger chunks of material to be cut down, CNC machining ensures that the material is used as efficiently as possible.

Precision reduces waste: CNC machines are capable of working with high precision, which minimizes scrap material and reduces the chances of creating defective parts. The more precise the machine, the less material is wasted, which is especially important when working with expensive raw materials.

Recycling and reusing materials: Many CNC operations incorporate recycling programs to reuse materials left over from production. This not only helps reduce waste but also saves money by maximizing the use of every material batch. In industries like aerospace, where raw materials can be costly, this is an essential practice.

Minimizing human error: Traditional methods can be prone to human error, leading to parts being scrapped and resources being wasted. With CNC machining, errors are reduced, and parts are created to exact specifications, ensuring that there is less need for rework or rejection of materials.

Table 6: CNC Machining Waste Reduction

| Waste Reduction Factor | Description | Impact on Business |

|---|---|---|

| Efficient material use | CNC machines use only the amount of material needed to create each part. | Reduces costs by minimizing material waste. |

| Precision reduces waste | High accuracy ensures that parts are created with minimal scrap. | Decreases production costs and raw material use. |

| Recycling and reusing materials | Leftover materials can be recycled and reused in future projects. | Saves costs and reduces environmental impact. |

| Minimizing human error | Automated processes reduce the likelihood of mistakes in production. | Reduces waste and rework due to human error. |

7. What Materials Can Be Processed with CNC Machining?

Ready for the good part? One of the greatest strengths of CNC machining is its versatility when it comes to materials. Whether you’re working with metals, plastics, or composites, CNC machines can handle a wide variety of materials to meet the needs of different industries.

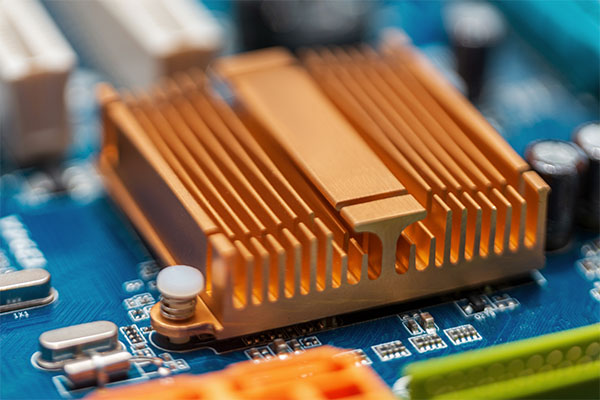

Metals: CNC machining is commonly used to work with a variety of metals such as aluminum, steel, titanium, and copper. These materials are frequently used in aerospace, automotive, and medical device manufacturing due to their strength, durability, and heat resistance.

Plastics: CNC machines can also process a wide range of plastics, from softer polymers like acrylic to more rigid and durable options like nylon or PVC. Plastics are often used in industries that require lightweight, non-corrosive materials, such as consumer products, electronics, and packaging.

Composites: Composites are becoming increasingly popular in industries like aerospace and automotive due to their lightweight and strong properties. CNC machining can handle composite materials like carbon fiber, fiberglass, and carbon composites, allowing manufacturers to produce parts that are both strong and lightweight.

Wood and other materials: CNC machines are not limited to just metals and plastics. They can also work with materials like wood, foam, and ceramics, making them ideal for industries such as furniture manufacturing, signage, and product prototyping.

Table 7: Materials Processed with CNC Machining

| Material Type | Examples | Common Industries |

|---|---|---|

| Metals | Aluminum, Steel, Titanium, Copper | Aerospace, Automotive, Medical Devices |

| Plastics | Acrylic, Nylon, PVC, Polycarbonate | Consumer Products, Electronics, Packaging |

| Composites | Carbon Fiber, Fiberglass, Carbon Composites | Aerospace, Automotive |

| Wood and Other Materials | Wood, Foam, Ceramics | Furniture Manufacturing, Prototyping |

8. Why Is CNC Machining a Great Option for Prototyping?

But here’s the kicker… CNC machining is not just for mass production—it’s also an excellent tool for rapid prototyping. Whether you’re testing out new product designs or fine-tuning existing ones, CNC machining offers several benefits when it comes to prototyping.

Speed: CNC machining can quickly turn around prototypes, allowing businesses to test ideas in a short amount of time. Unlike traditional prototyping methods, which can take days or weeks, CNC machining can produce a prototype in a matter of hours.

Accuracy: The precision offered by CNC machining makes it ideal for producing prototypes that closely match the final product. This allows for thorough testing and validation before moving into full-scale production.

Cost-effective: With the ability to use real production materials, CNC prototyping is often more cost-effective than other methods like 3D printing. Since CNC machines can work with a variety of materials, businesses can test their prototypes under real-world conditions.

Iteration flexibility: CNC machining allows for easy design iterations. If a prototype doesn’t work as expected, you can quickly adjust the design and produce a new one. This rapid iteration process helps businesses perfect their products before entering full-scale manufacturing.

Table 8: CNC Machining for Prototyping

| Advantage | Description | Impact on Business |

|---|---|---|

| Speed | CNC machines can produce prototypes quickly, often within hours. | Accelerates product development and time-to-market. |

| Accuracy | CNC machining provides high precision, ensuring prototypes match design specs. | Ensures reliable testing and validation of designs. |

| Cost-effective | Producing prototypes using actual production materials is cheaper than other methods. | Reduces prototyping costs and material waste. |

| Iteration flexibility | Easy to make adjustments and rework designs. | Allows for rapid testing and product refinement. |

9. How Does CNC Machining Offer Customization for Your Projects?

Here’s the deal… CNC machining offers remarkable customization options, which makes it the perfect choice for businesses with specific needs or those looking to create unique, high-quality parts.

Tailored solutions: CNC machining allows manufacturers to produce parts with highly specific dimensions and features. Whether it’s a custom part for an industrial machine or a unique design for a consumer product, CNC machines can accommodate almost any specification.

Variety of options: CNC machines can produce a wide range of part shapes, sizes, and geometries, allowing businesses to create everything from simple components to complex, multi-part assemblies. The flexibility in the design process means that no project is too complicated.

Adaptability for small-batch production: CNC machining is ideal for both small and large runs of custom parts. Whether you need a single prototype or a small batch of custom parts, CNC machines can produce high-quality pieces without the need for expensive molds or tooling.

Faster turnaround times for custom designs: CNC machining can produce custom parts faster than traditional methods, enabling businesses to meet tight deadlines and quickly respond to customer demands.

Table 9: CNC Machining for Customization

| Customization Benefit | Description | Impact on Business |

|---|---|---|

| Tailored solutions | CNC machines can produce parts to exact specifications. | Allows businesses to meet specific customer needs. |

| Variety of options | Capable of creating a wide range of part shapes and sizes. | Provides flexibility in product design and production. |

| Adaptability for small-batch production | CNC machining is ideal for low-volume custom production. | Enables businesses to create custom parts without large-scale investments. |

| Faster turnaround times | CNC machines can quickly produce custom parts for fast market response. | Increases business agility and ability to meet customer demands. |

10. How Does CNC Machining Contribute to Sustainability?

What’s the big deal? In today’s environmentally-conscious world, sustainability is more important than ever. CNC machining helps businesses reduce their environmental footprint while maintaining high production standards.

Reduced material waste: Thanks to CNC’s high precision, only the exact amount of material needed is used, which significantly reduces waste. This efficiency helps lower the environmental impact associated with material waste in manufacturing.

Energy efficiency: CNC machines are designed for efficiency, consuming less power compared to older, less efficient machines. This reduced energy consumption contributes to the overall sustainability of the manufacturing process.

Longer lifespan of tools and parts: CNC machines can operate for longer periods before requiring tool replacements, which means fewer discarded tools and parts. This is particularly valuable in industries that rely on expensive or rare materials.

Recycling and reusing materials: Many CNC operations encourage the recycling of leftover materials, such as metal shavings or plastic scrap. This contributes to a circular economy and helps minimize waste.

Table 10: CNC Machining and Sustainability

| Sustainability Factor | Description | Impact on Business |

|---|---|---|

| Reduced material waste | High precision ensures that only the necessary amount of material is used. | Minimizes material waste and reduces costs. |

| Energy efficiency | CNC machines are designed to use energy more efficiently. | Lowers energy consumption and reduces operational costs. |

| Longer lifespan of tools | CNC machines require fewer replacements, reducing waste. | Reduces costs and environmental impact of tool disposal. |

| Recycling and reusing materials | Leftover materials can be recycled or reused. | Supports sustainable manufacturing practices. |

11. How Safe Is CNC Machining for Operators?

Ready for the good part? CNC machining is not only efficient and precise, but it is also safe for operators. The automation of the process minimizes human interaction with dangerous machinery, reducing the risk of accidents and injuries.

Automated safety features: Many CNC machines come equipped with built-in safety features, such as emergency stop buttons, protective barriers, and safety sensors. These features ensure that operators are protected from moving parts and hazardous conditions.

Reduced risk of human error: Because CNC machines operate based on pre-programmed instructions, there is less room for human error that could lead to accidents or safety issues. Operators primarily oversee the process, which greatly minimizes the potential for mistakes.

Operator training and safety protocols: Operators are trained to handle the machines safely, and companies often implement safety protocols to ensure that everyone adheres to proper procedures. This emphasis on safety culture helps maintain a safe working environment.

Table 11: CNC Machining and Operator Safety

| Safety Feature | Description | Impact on Business |

|---|---|---|

| Automated safety features | CNC machines have built-in safety features like emergency stops and barriers. | Reduces risk of accidents and enhances workplace safety. |

| Reduced risk of human error | CNC machines are automated, minimizing human error and accidents. | Decreases the chances of injury and damage to equipment. |

| Operator training and safety protocols | Operators undergo extensive training and adhere to strict safety protocols. | Ensures compliance with safety standards and regulations. |

12. How Does CNC Machining Reduce Lead Times?

But here’s the kicker… When it comes to manufacturing, time is money. CNC machining dramatically reduces lead times, allowing businesses to get their products to market faster and more efficiently.

Streamlined production processes: CNC machines can complete multiple tasks at once, reducing the number of steps required to manufacture a part. This helps cut down production time and gets the product to the customer faster.

Quick setup times: CNC machines are often quicker to set up than traditional manufacturing equipment. This means that businesses can change production schedules or respond to urgent orders more efficiently.

Continuous production: CNC machines can operate around the clock, enabling continuous production without breaks. This constant production cycle significantly reduces lead times and helps companies meet tight deadlines.

Table 12: CNC Machining and Lead Time Reduction

| Lead Time Factor | Description | Impact on Business |

|---|---|---|

| Streamlined production processes | CNC machines can handle multiple steps in one process, speeding up production. | Reduces production time, enabling faster deliveries. |

| Quick setup times | CNC machines require minimal setup, allowing for fast changeovers. | Increases responsiveness to changing demands. |

| Continuous production | CNC machines can operate 24/7, reducing downtime. | Ensures constant production and faster product turnaround. |

13. What Are the Limitations of CNC Machining?

What’s the real story? While CNC machining offers numerous benefits, it’s important to understand its limitations so that businesses can make informed decisions.

Initial setup costs: CNC machining can be expensive to set up initially. The machines themselves can have a high upfront cost, and programming the machines to perform specific tasks requires skilled operators and engineers.

Size constraints: While CNC machines can handle a variety of materials, there are limitations to the size of the parts they can produce. Large components may require specialized machines or additional equipment.

Material limitations: Although CNC machining is versatile, it cannot handle all materials. Certain highly abrasive materials may cause excessive wear on tools, and softer materials may not be suitable for the high-precision nature of CNC machining.

Table 13: Limitations of CNC Machining

| Limitation | Description | Impact on Business |

|---|---|---|

| Initial setup costs | CNC machines are expensive to purchase and set up. | High initial investment required for businesses. |

| Size constraints | CNC machines may not be suitable for producing extremely large parts. | Requires additional equipment for large-scale parts. |

| Material limitations | Some materials are not ideal for CNC machining due to wear or precision needs. | Limits material options for certain applications. |

14. How Can CNC Machining Help Your Business Stay Competitive?

What’s the big deal? In a rapidly evolving manufacturing landscape, staying competitive is key. CNC machining gives businesses a significant edge over competitors in both efficiency and quality.

Faster time-to-market: CNC machining reduces production lead times, allowing businesses to get products to market faster than competitors who rely on manual methods or slower processes.

High-quality, consistent output: The precision and automation of CNC machining ensure that businesses consistently produce high-quality products, making it easier to meet customer demands and build trust.

Flexibility to adapt: CNC machining offers flexibility, allowing businesses to pivot quickly and respond to changing market needs, whether it’s adjusting product designs or increasing production volume.

Table 14: CNC Machining and Competitiveness

| Competitive Advantage | Description | Impact on Business |

|---|---|---|

| Faster time-to-market | CNC machining speeds up production, allowing for faster deliveries. | Helps businesses respond quickly to market demands. |

| High-quality, consistent output | Precision ensures that every product meets high standards. | Increases customer satisfaction and loyalty. |

| Flexibility to adapt | CNC machines can quickly adapt to new designs or production needs. | Allows businesses to stay agile and competitive. |

15. What Are the Future Trends in CNC Machining?

This is where it gets interesting… CNC machining continues to evolve, with advancements in technology driving the future of the industry. Let’s take a look at some of the exciting trends shaping the future of CNC machining.

Automation and AI integration: As automation becomes more sophisticated, CNC machines will incorporate more AI to improve efficiency, reduce human error, and optimize production processes.

Additive manufacturing integration: The combination of CNC machining and 3D printing is opening up new possibilities for producing complex parts that were previously impossible or costly to create.

Smart machines: The future of CNC machining lies in smarter machines with advanced sensors and connectivity, enabling manufacturers to monitor and adjust operations in real-time for better efficiency and quality control.

Sustainability initiatives: The demand for eco-friendly manufacturing processes is growing, and CNC machining is becoming more sustainable by reducing energy consumption, waste, and material usage.

Table 15: Future Trends in CNC Machining

| Trend | Description | Impact on Business |

|---|---|---|

| Automation and AI integration | The use of AI and automation to optimize CNC machine performance. | Improves efficiency and reduces errors. |

| Additive manufacturing integration | Combining CNC with 3D printing to create more complex parts. | Enables new production possibilities and innovation. |

| Smart machines | Machines with sensors and connectivity for real-time monitoring. | Increases operational efficiency and reduces downtime. |

| Sustainability initiatives | Incorporating eco-friendly practices in CNC machining processes. | Reduces environmental impact and improves business sustainability. |

FAQ Section

Q1: What is CNC machining?

CNC machining is a computer-controlled process that uses pre-programmed instructions to control the movement of tools in manufacturing machines. This results in high precision and repeatability.

Q2: How does CNC machining work?

CNC machining works by taking a design from a CAD (computer-aided design) file and using that file to guide automated machines in the process of cutting, shaping, and finishing materials.

Q3: What are the benefits of using CNC machining over traditional methods?

CNC machining offers higher precision, faster production speeds, less waste, and reduced labor costs, making it more efficient and cost-effective than traditional manual machining.

Q4: Can CNC machining handle complex parts?

Yes, CNC machining is ideal for creating complex parts with intricate designs, ensuring high precision even for the most detailed parts.

Q5: What types of materials can CNC machines work with?

CNC machines can process a wide variety of materials, including metals, plastics, and composites, making them highly versatile for different manufacturing needs.