Introduction

When it comes to precision manufacturing, aluminum CNC machining is a go-to solution for creating custom parts. The ability to shape aluminum with high accuracy is essential in industries like automotive, aerospace, and electronics. In this article, we will explore the various aspects of aluminum CNC machining services, its benefits, applications, and how you can select the right machining service for your needs.

1. What is Aluminum CNC Machining?

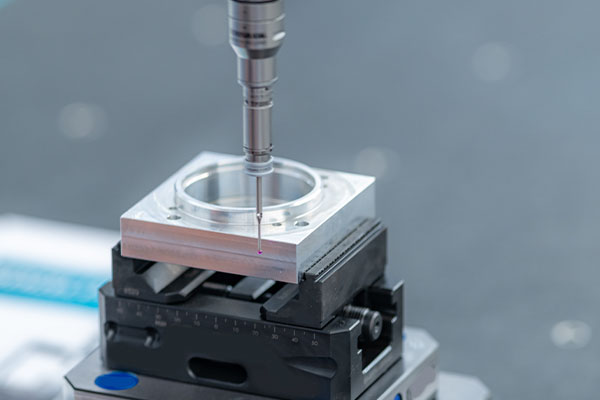

Aluminum CNC machining refers to the process of using computer-controlled machines to cut, mill, and shape aluminum into specific parts or components. This process allows for highly accurate and repeatable results, making it ideal for industries requiring precision parts. But here’s the kicker—CNC machining gives manufacturers the ability to create complex shapes and intricate designs that would be nearly impossible with traditional methods.

In CNC machining, a design is first created using computer-aided design (CAD) software. This design is then translated into machine code, allowing the CNC machine to execute the necessary cuts and movements to produce the desired part. The use of aluminum in CNC machining is widespread due to its favorable properties, including its strength-to-weight ratio, corrosion resistance, and machinability.

Aluminum is used in various forms, such as sheets, plates, bars, and billets, which are fed into CNC machines. The machining process involves cutting, drilling, and milling to shape these materials into precise parts. Whether it’s for prototypes or mass production, CNC machining can handle both with exceptional speed and accuracy.

2. Why Choose Aluminum for CNC Machining?

Choosing aluminum for CNC machining comes with several advantages. First, aluminum is a lightweight material, which makes it highly valuable in industries like aerospace and automotive, where reducing weight is crucial. This allows for the creation of parts that are not only strong but also lightweight, contributing to improved fuel efficiency and performance.

In addition to its strength-to-weight ratio, aluminum is known for its excellent corrosion resistance. This makes it an ideal choice for products exposed to harsh environments, such as automotive parts and outdoor equipment. Aluminum’s ability to resist rust and corrosion means that the final products can withstand long-term use, even in challenging conditions.

Aluminum is also an excellent conductor of heat and electricity, which makes it useful in industries like electronics. It is easy to machine, which allows manufacturers to achieve precise cuts and shapes with minimal effort. Additionally, aluminum can be easily anodized or painted, offering a range of finishing options for a polished, durable final product.

3. How Does CNC Machining Work for Aluminum Parts?

CNC machining works for aluminum parts by using a computer-controlled machine to perform precise cutting, drilling, and milling operations. The process begins with a design created in CAD software, which is then converted into machine-readable code (G-code). This G-code directs the CNC machine’s movements, instructing it to make the necessary cuts and shapes.

Aluminum parts are typically produced by feeding raw aluminum stock (such as a billet or sheet) into a CNC machine. The machine then uses various tools, including drills, lathes, and mills, to shape the material. For example, in milling, the machine’s cutting tool rotates to remove material from the workpiece, while in drilling, a rotating tool is used to create holes.

The beauty of CNC machining is its precision. The machine can follow the G-code with extreme accuracy, producing parts with tight tolerances. This ensures that the final product meets the required specifications and can be replicated consistently for mass production. CNC machining also offers flexibility, as it can handle complex geometries and intricate details with ease.

4. What Are the Different Types of Aluminum CNC Machining Services?

When it comes to aluminum CNC machining, there are several types of services that cater to different manufacturing needs. These include milling, turning, drilling, and custom machining services. But here’s the real story—each of these services is designed for specific applications, and knowing which one to choose is key to achieving the best results.

- Milling: In aluminum milling, a rotating cutter is used to remove material from a workpiece to create precise shapes. It’s suitable for complex geometries and is widely used in industries like automotive and aerospace.

- Turning: In turning, the workpiece is rotated while a cutting tool is applied to remove material. This process is ideal for producing cylindrical parts, such as shafts or bushings.

- Drilling: Drilling is the process of creating holes in aluminum parts. CNC drilling allows for highly accurate hole placement and is often used in electronics, automotive, and construction.

- Custom CNC Services: For specialized needs, custom CNC services are available. These services may involve a combination of different machining processes, or even specific adaptations of the CNC machine, to meet the exact requirements of a project.

Understanding which service is best for your aluminum part is essential for achieving the desired performance and cost-effectiveness. Each service has its own strengths and is suited to different manufacturing needs.

5. What Are the Advantages of Using CNC Machining for Aluminum?

The advantages of using CNC machining for aluminum are vast. CNC machining allows for a high degree of precision and repeatability, ensuring that each part is identical and meets the required specifications. This is particularly important in industries that require tight tolerances, such as aerospace and medical device manufacturing.

Another key advantage is the ability to produce complex shapes and geometries that are difficult or impossible to achieve with traditional machining methods. CNC machines can create intricate details with ease, making it ideal for applications that require detailed and functional designs.

CNC machining also offers fast turnaround times. Since the process is automated, production can be completed quickly, reducing lead times for custom parts. This is particularly beneficial for industries that need to quickly prototype or produce parts in small to medium quantities.

6. How Do You Choose the Right CNC Aluminum Machining Service?

Choosing the right CNC aluminum machining service is crucial for ensuring the quality and efficiency of your production. There are several factors to consider when selecting a machining provider. First, consider the provider’s experience and expertise in aluminum machining. A company with a proven track record will have the necessary skills to handle complex aluminum parts and ensure high-quality results.

Next, consider the machinery and technology used by the service provider. CNC machining requires advanced equipment, so it’s essential to work with a provider that has state-of-the-art machines capable of achieving the required tolerances and precision.

Another key factor is customer service. A good machining service should provide clear communication, quick responses, and a willingness to work with you to meet your specific needs. Make sure the provider is open to discussing your project in detail and is committed to delivering the best possible outcome.

7. What Are the Common Applications of Aluminum CNC Machined Parts?

Aluminum CNC machined parts are used in a wide range of industries due to aluminum’s versatility. In the automotive industry, aluminum is used to produce lightweight, high-strength parts that help improve fuel efficiency and performance. Components like engine blocks, transmission parts, and wheels are commonly made from aluminum.

In the aerospace industry, aluminum’s strength-to-weight ratio makes it ideal for components such as aircraft fuselages, wings, and landing gear. The ability to machine aluminum with high precision ensures that these parts can withstand the demands of high-speed flight while remaining lightweight.

Aluminum is also widely used in medical devices, where its corrosion resistance and biocompatibility make it an excellent material for implants, surgical instruments, and diagnostic equipment. In the electronics industry, aluminum is used to produce heat sinks, enclosures, and other parts that require excellent thermal conductivity.

8. How Can You Improve the Quality of CNC Machined Aluminum Parts?

Improving the quality of CNC machined aluminum parts starts with selecting the right materials. Using high-quality aluminum ensures that the final part will have the desired mechanical properties, such as strength, durability, and resistance to corrosion.

Another important factor is machine calibration. CNC machines must be regularly calibrated to maintain accuracy. If a machine is miscalibrated, it can produce parts that don’t meet the required specifications. Regular maintenance and checks are essential for ensuring that the machines perform optimally.

Tooling also plays a critical role in the quality of the final part. Choosing the right cutting tools and ensuring they are sharp and in good condition can help improve the surface finish and overall quality of the part. Additionally, optimizing machining parameters such as feed rate and cutting speed can further enhance the quality of CNC machined aluminum parts.

9. What Are the Cost Factors in Aluminum CNC Machining?

The cost of aluminum CNC machining depends on several factors, including the complexity of the part, the quantity of parts needed, and the type of aluminum material used. The more complex the design, the longer it will take to machine, which can increase the cost. Custom machining services, which involve specialized tooling or processes, can also add to the cost.

Material costs also play a significant role in the overall price. High-grade aluminum alloys may cost more than standard aluminum, but they may also offer improved mechanical properties. Volume is another factor—ordering in bulk typically results in lower per-unit costs.

Labor and machine time also contribute to the cost. CNC machines are efficient, but they still require skilled operators to monitor and maintain them. The more time it takes to produce a part, the higher the cost will be.

10. How Long Does It Take to Machine Aluminum Parts?

The time it takes to machine aluminum parts depends on the size and complexity of the part. Simple, straightforward parts can be machined quickly, often within a few hours. However, more intricate parts with complex geometries or tight tolerances can take longer to produce.

For small quantities or prototypes, CNC machining may take anywhere from a few days to a week. For mass production, the process can be sped up through efficient scheduling and optimized machine settings. However, it’s important to balance speed with quality to ensure the parts meet the necessary specifications.

11. What Are the Challenges in Aluminum CNC Machining?

Aluminum CNC machining presents several challenges. One of the primary challenges is material-related. While aluminum is relatively easy to machine, it can also be prone to burr formation, which can affect the quality of the final part. Careful control of cutting parameters is necessary to avoid this issue.

Another challenge is ensuring the machine’s accuracy over long production runs. As machines operate, they can experience slight wear and tear, which can affect precision. Regular maintenance and calibration are essential to mitigate this problem.

Handling small or intricate aluminum parts can also be challenging, as these parts may be difficult to secure properly during machining. Specialized fixtures or clamping methods may be required to hold these parts in place.

12. How Can You Ensure Accuracy in Aluminum CNC Machining?

Accuracy in aluminum CNC machining starts with proper machine calibration. Regular checks and maintenance ensure that the machine is performing at its best and producing parts with tight tolerances. Using high-quality CNC machines equipped with advanced features like automatic tool changers and high-speed spindles can also improve accuracy.

Another factor is the use of CAD software to design parts with precise dimensions. This allows for detailed planning and ensures that the part meets all required specifications. During machining, using the right tooling and cutting parameters will help achieve the desired level of accuracy.

13. What Are the Different Finishing Options for Aluminum CNC Machined Parts?

After machining, aluminum parts often undergo finishing processes to improve their appearance, durability, and performance. One of the most common finishes is anodizing, which adds a protective layer to the aluminum and enhances its corrosion resistance. Anodizing also allows for color customization.

Powder coating is another popular option, offering a durable and aesthetically pleasing finish. It is often used in automotive and consumer goods applications. Polishing and brushing can also be used to improve the surface finish, providing a sleek, smooth appearance.

Other surface treatments include chemical milling, which removes material from the surface of the part to improve its finish, and laser engraving, which can add text or designs to the surface.

14. What Should You Know About Post-Machining Services for Aluminum?

Post-machining services are crucial for ensuring that aluminum parts are fully functional and ready for use. Assembly and part fitting are often necessary, especially for parts that need to be combined with other components. CNC machining services may offer these services as part of a package.

Packaging and shipping are also important aspects of post-machining. Proper packaging ensures that parts are protected during transport, while efficient shipping methods ensure that parts arrive on time.

Post-machining inspections are also vital. Parts should be inspected for quality, including checking for dimensional accuracy, surface finish, and functional testing. Ensuring that all parts meet the required specifications is critical before they are shipped out for use.

15. How Does CNC Machining for Aluminum Compare to Other Materials?

Aluminum has several advantages over other materials like steel or plastic when it comes to CNC machining. It is lighter and more corrosion-resistant, making it ideal for industries where weight reduction and durability are key factors. Aluminum is also easier to machine than steel, resulting in shorter lead times and lower production costs.

However, aluminum is not as strong as steel, which may be a limitation in some applications. While aluminum offers excellent machinability and performance in many industries, steel may be preferred for parts that require higher tensile strength.

Conclusion

Aluminum CNC machining is an essential process for producing high-quality, precision parts in industries like automotive, aerospace, and medical devices. The versatility, cost-effectiveness, and performance advantages of aluminum make it an ideal choice for many applications. By understanding the process, benefits, and challenges of CNC machining for aluminum, you can make informed decisions when selecting the right service provider for your manufacturing needs.

FAQ Section

Q1: What is aluminum CNC machining?

Aluminum CNC machining is a process that uses computer-controlled machines to cut, mill, drill, and shape aluminum into custom parts and components with high precision.

Q2: How does CNC machining work for aluminum parts?

CNC machining for aluminum involves translating a CAD design into machine-readable code, which directs the CNC machine to cut and shape aluminum material into the required part.

Q3: What are the benefits of aluminum in CNC machining?

Aluminum offers a lightweight, corrosion-resistant material with excellent machinability, making it ideal for precision parts in industries like automotive, aerospace, and medical devices.

Q4: How can I choose the right CNC machining service for aluminum?

When choosing a CNC machining service, consider the provider’s experience, the quality of their equipment, and their ability to meet your specific machining requirements.

Q5: What are the typical applications of aluminum CNC machined parts?

Aluminum CNC machined parts are widely used in the automotive, aerospace, medical, and electronics industries due to aluminum’s strength, durability, and versatility.