Introduction

In the world of CNC machining, aluminum casting plays a pivotal role in producing parts that are lightweight yet durable. When selecting materials for manufacturing, understanding the pros and cons of aluminum casting is essential. This article will explore the key advantages and drawbacks of using aluminum casting in CNC machining. By the end, you’ll have a clearer understanding of its potential, helping you decide if it’s the right choice for your next machining project.

1. What is Aluminum Casting in CNC Machining?

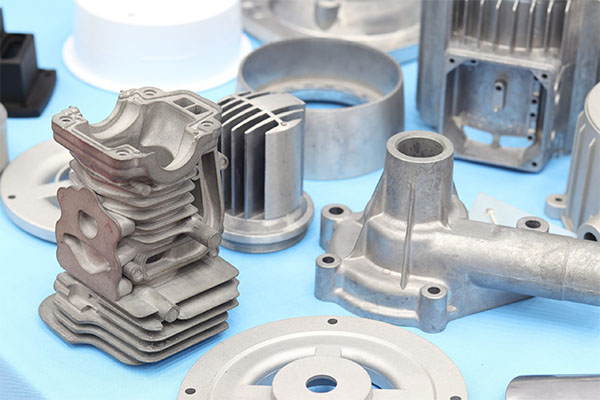

Aluminum casting in CNC machining involves pouring molten aluminum into a mold to create parts, which are then machined to precise specifications using CNC equipment. It’s a popular method due to aluminum’s favorable properties, including light weight, strength, and corrosion resistance. This process is essential in producing parts for industries such as automotive, aerospace, and electronics. Aluminum casting typically uses various methods, such as sand casting, die casting, and permanent mold casting, each suited for different types of parts and production volumes.

Aluminum casting is particularly valued for its ability to produce complex shapes with high precision. The versatility of aluminum alloys also allows for customization of physical properties, ensuring that parts meet specific performance criteria. Furthermore, aluminum’s excellent heat dissipation makes it ideal for components subjected to high thermal loads, such as engine blocks or heat sinks.

What’s the real story? The flexibility of aluminum casting not only reduces the overall weight of a component but also offers substantial cost savings in the long run due to reduced material waste and energy consumption during production. Let’s break down the casting process further and look at why it’s so widely used in CNC machining.

2. What Are the Benefits of Aluminum Casting for CNC Machining?

Aluminum casting offers several notable advantages in CNC machining. One of the most significant benefits is its lightweight nature, which makes it a go-to choice for industries that require high strength-to-weight ratios. For example, in the automotive industry, aluminum castings are used extensively in engine blocks, transmission housings, and wheels to reduce vehicle weight and improve fuel efficiency.

Another major benefit of aluminum casting is its resistance to corrosion, especially when used in environments exposed to moisture, chemicals, or harsh weather. This is particularly valuable for industries like aerospace, where components must endure extreme conditions without deteriorating.

This is where it gets interesting… Aluminum casting is also cost-effective. The material is relatively inexpensive, and casting methods like die casting and sand casting allow for mass production at lower costs. The ease with which aluminum can be cast into intricate shapes further reduces the need for secondary machining processes, saving both time and money.

| Benefits of Aluminum Casting | Explanation |

|---|---|

| Lightweight | Ideal for industries like automotive and aerospace that prioritize reducing weight. |

| Corrosion Resistance | Perfect for environments exposed to moisture, chemicals, and other corrosive elements. |

| Cost-Effective | Inexpensive material and efficient manufacturing methods lower production costs. |

| High Strength-to-Weight Ratio | Allows for strong components without adding significant weight, improving overall performance. |

3. What Are the Drawbacks of Aluminum Casting for CNC Machining?

While aluminum casting offers numerous benefits, it does have its drawbacks. One key limitation is the potential for casting defects. Issues like porosity, cracks, and shrinkage can occur during the casting process, which may require additional machining or post-processing to correct. This can lead to increased production costs and delays, especially when dealing with high-precision parts.

Another disadvantage is the relatively low strength of aluminum compared to other metals, such as steel. While aluminum’s strength is sufficient for many applications, it may not be ideal for components that will undergo heavy stress or high-impact forces. For instance, in situations where extreme strength is required, aluminum parts may need to be reinforced or combined with other materials.

But here’s the kicker… The casting process itself can be expensive, particularly for small production runs. The molds used in casting can be costly to manufacture, and the process itself may not be as efficient for low-volume production compared to other methods like machining from solid stock.

| Drawbacks of Aluminum Casting | Explanation |

|---|---|

| Casting Defects | Issues like porosity and cracks may require additional machining or post-processing. |

| Low Strength | Not ideal for components that require extremely high strength or resistance to heavy stress. |

| High Setup Costs | Molds for casting can be expensive to manufacture, making it less cost-effective for small production runs. |

4. How Does Aluminum Casting Compare to Other Materials in CNC Machining?

When comparing aluminum casting to other materials in CNC machining, it becomes clear why aluminum is such a popular choice, but it’s not without its competition. Steel, for example, is often used for its superior strength and durability. However, steel is much heavier than aluminum, which can be a disadvantage in applications that prioritize lightweight components.

Plastic materials are also sometimes used in CNC machining, particularly for parts that do not require the high strength and heat resistance that aluminum provides. However, plastics are generally not as durable or capable of withstanding extreme conditions, making aluminum a better choice for components that need to perform under stress, such as engine parts or structural components in airplanes.

Ready for the good part? Aluminum’s versatility is one of its strongest suits. While other materials may outperform aluminum in specific applications, aluminum’s combination of light weight, strength, and cost-efficiency make it an all-around excellent material for CNC machining.

| Material Comparison | Aluminum | Steel | Plastic |

|---|---|---|---|

| Strength | Moderate | High | Low |

| Weight | Light | Heavy | Very Light |

| Corrosion Resistance | High | Moderate | Low |

| Cost | Low | High | Low |

5. What Are the Common Methods of Aluminum Casting in CNC Machining?

Aluminum casting in CNC machining can be accomplished using several different methods. Each method offers distinct advantages and is suited for different types of components and production volumes. The most common casting methods include:

- Sand Casting: This is one of the oldest and most versatile casting methods, where a mold is created using a mixture of sand, clay, and water. It’s ideal for low to medium production runs and can be used for creating large and complex parts.

- Die Casting: In this process, molten aluminum is injected into a metal mold under high pressure. Die casting is ideal for producing high-volume parts with tight tolerances and smooth surfaces.

- Investment Casting: This involves creating a mold by coating a wax pattern with a ceramic shell. It’s perfect for producing complex and detailed parts, though it can be more expensive than other methods.

What’s the real story? The method chosen depends on the part’s design, production volume, and the required finish. Each method has its strengths and weaknesses, and understanding these nuances can help manufacturers choose the best option for their specific needs.

| Casting Method | Ideal For | Advantages | Disadvantages |

|---|---|---|---|

| Sand Casting | Low to medium production runs | Flexible, low cost | Rough finish, limited precision |

| Die Casting | High-volume production | High precision, smooth surface | Higher initial cost, limited to small parts |

| Investment Casting | Complex parts with fine details | High detail and accuracy | Expensive, not suited for large parts |

6. How Do Aluminum Casting Processes Affect CNC Machining?

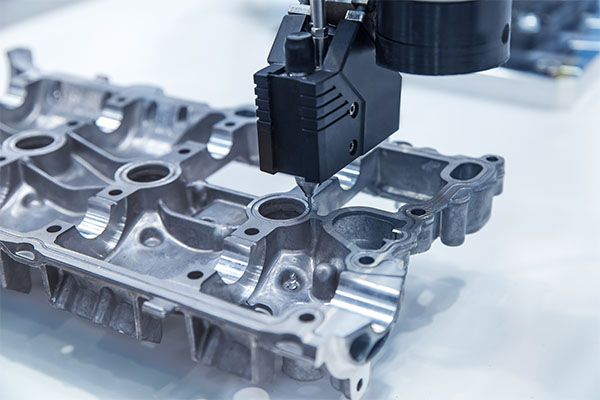

The aluminum casting process significantly impacts the subsequent CNC machining operations. Cast aluminum parts often require additional machining to achieve the final dimensions and surface finish required. The casting process can result in rough surfaces, uneven thicknesses, and other imperfections that need to be addressed during CNC machining.

This is where it gets interesting… Aluminum casting is particularly beneficial in reducing the overall material waste compared to other manufacturing methods, like machining from solid stock. By casting the part in its near-net shape, manufacturers only need to remove minimal material to reach the desired final form, saving both time and money in machining.

| Impact of Casting on CNC Machining | Explanation |

|---|---|

| Rough Surfaces | Cast aluminum parts often require post-machining to achieve a smooth finish. |

| Material Waste | Aluminum casting minimizes material waste by forming parts close to their final shape. |

| Tool Wear | The hardness of cast aluminum may cause additional wear on cutting tools during machining. |

7. What Types of CNC Machining Are Suitable for Aluminum Casting?

Aluminum casting can be used in various CNC machining processes, including milling, turning, drilling, and tapping. Milling and turning are particularly useful for shaping cast aluminum parts into precise components, while drilling and tapping are often required for creating holes and threads.

Ready for the good part? The compatibility of aluminum casting with CNC machining makes it an ideal choice for producing complex parts with intricate designs, such as engine components, housings, and brackets, all of which require precise measurements and high tolerances.

| CNC Machining Types | Suitable for Aluminum Casting |

|---|---|

| Milling | Excellent for shaping aluminum castings into precise dimensions. |

| Turning | Ideal for cylindrical parts, such as shafts and gears. |

| Drilling and Tapping | Common for parts requiring holes and threaded connections. |

8. How Do Surface Finishes Affect Aluminum Casting Parts in CNC Machining?

The surface finish of aluminum casting plays a crucial role in the performance and aesthetic appeal of the final part. Anodizing, powder coating, and painting are common surface treatments used to improve the surface of aluminum castings.

But here’s the kicker… The right surface finish can enhance the part’s durability, corrosion resistance, and appearance. For example, anodizing increases the thickness of the aluminum oxide layer, offering improved corrosion resistance and a more aesthetically pleasing finish.

| Surface Finishes | Benefits | Common Uses |

|---|---|---|

| Anodizing | Improves corrosion resistance and appearance | Aerospace, automotive |

| Powder Coating | Provides a durable, weather-resistant finish | Outdoor equipment, machinery |

| Painting | Enhances appearance, but less durable than anodizing | Consumer goods, decorative items |

9. What Are the Environmental Considerations of Aluminum Casting for CNC Machining?

Aluminum casting is generally more environmentally friendly compared to other metals, due to aluminum’s high recyclability. However, there are still environmental challenges associated with the casting process, including energy consumption and waste generation.

What’s the real story? Despite these challenges, advancements in aluminum casting techniques, such as improved recycling methods and energy-efficient technologies, are helping to reduce the environmental footprint of the process.

| Environmental Considerations | Explanation |

|---|---|

| Energy Consumption | The melting and casting process requires substantial energy, particularly for aluminum. |

| Recycling | Aluminum is highly recyclable, reducing the need for raw material extraction. |

| Waste Generation | The casting process can generate waste materials, though this is being minimized with modern techniques. |

10. What Are the Key Considerations for Choosing Aluminum Casting for CNC Machining Projects?

When deciding whether aluminum casting is the right choice for a CNC machining project, several factors should be taken into account. These include the strength requirements of the part, the expected production volume, and the level of precision needed. For high-volume, precision parts, die casting might be the best choice, whereas sand casting might be more appropriate for larger, less intricate parts.

This is where it gets interesting… The overall cost of the project will depend on these factors, and the best casting method will be the one that aligns with the specific needs of your project.

| Key Considerations | Explanation |

|---|---|

| Strength Requirements | Aluminum casting can handle moderate strength requirements but may not be suitable for extreme applications. |

| Production Volume | High-volume production benefits from methods like die casting, which reduces per-part costs. |

| Precision Needs | Parts requiring tight tolerances may benefit from die casting or investment casting. |

11. How Do Tolerances and Specifications Affect Aluminum Casting in CNC Machining?

The tolerances and specifications required for aluminum casting play a crucial role in determining the casting method and the need for post-processing. Parts with tight tolerances may require more sophisticated casting methods, such as die casting or investment casting, to ensure that the part dimensions are within acceptable limits.

What’s the real story? Choosing the right aluminum casting method ensures that the part meets the necessary tolerance specifications without unnecessary additional machining.

| Tolerance Considerations | Explanation |

|---|---|

| Tight Tolerances | Require high-precision methods like die casting or investment casting. |

| Looser Tolerances | Can be accommodated with sand casting, though post-machining may still be necessary. |

12. What Are the Challenges in Machining Aluminum Castings?

While aluminum casting offers numerous benefits, machining aluminum castings can present challenges. One challenge is the hardness of the aluminum after casting, which can lead to increased wear on machining tools. Additionally, surface defects such as porosity and cracks may require additional machining or repair.

What’s the real story? While these challenges can be mitigated with the right tools and techniques, it’s important to be aware of them when planning aluminum casting CNC machining projects.

| Challenges in Machining | Explanation |

|---|---|

| Tool Wear | Aluminum casting can cause increased wear on cutting tools, requiring more frequent tool replacements. |

| Porosity and Cracks | Defects that occur during casting may require additional steps to fix before machining. |

13. What Is the Future of Aluminum Casting in CNC Machining?

The future of aluminum casting in CNC machining looks promising, with innovations in aluminum alloys and casting technologies paving the way for improved performance. New developments in casting techniques are helping to reduce defects and improve precision, making aluminum even more viable for CNC machining.

Ready for the good part? As demand for lighter, more durable components grows, the role of aluminum casting in CNC machining is expected to increase, especially in industries like automotive and aerospace.

| Future of Aluminum Casting | Explanation |

|---|---|

| New Alloys | Advances in aluminum alloys will improve performance and versatility. |

| Improved Techniques | Innovations in casting and machining technologies will enhance precision and reduce defects. |

14. How Can You Improve the Quality of Aluminum Casting in CNC Machining?

Improving the quality of aluminum casting in CNC machining involves using the right materials, choosing the appropriate casting method, and implementing strict quality control measures. Ensuring that the aluminum alloy used is of high quality, along with investing in advanced casting techniques, will minimize defects and reduce the need for rework.

But here’s the kicker… Implementing regular quality checks during the casting and machining processes ensures that parts meet the necessary specifications and maintain high standards.

| Improving Quality | Explanation |

|---|---|

| High-Quality Materials | Using superior aluminum alloys helps ensure better casting quality. |

| Advanced Casting Techniques | Reducing defects and improving part quality by using methods like die casting. |

15. How Can Aluminum Casting Be Used in Complex CNC Machining Projects?

Aluminum casting is especially useful for CNC machining complex parts, such as those used in automotive engines or aerospace components. The ability to cast intricate designs and features directly into the part reduces the need for additional machining steps, saving both time and cost.

This is where it gets interesting… Complex CNC machining projects benefit from aluminum casting due to the material’s lightweight, corrosion-resistant properties, making it the perfect choice for parts requiring strength without adding unnecessary weight.

| Complex CNC Projects | Explanation |

|---|---|

| Automotive Engines | Aluminum castings are commonly used for engine blocks and transmission housings. |

| Aerospace Components | The strength-to-weight ratio makes aluminum ideal for aircraft structural parts. |

Conclusion

Aluminum casting plays a crucial role in CNC machining, offering both advantages and challenges. Its lightweight properties, corrosion resistance, and cost-effectiveness make it a popular choice for various industries, including automotive, aerospace, and electronics. However, the potential for casting defects and the need for precision machining can be challenges that require careful consideration.

With the right casting method and post-machining processes, aluminum casting can provide high-quality, durable components for your CNC machining projects. By understanding the pros and cons, you can make informed decisions that will ensure the success of your next project.

FAQ Section

- Q1: What is aluminum casting in CNC machining?

Aluminum casting in CNC machining involves pouring molten aluminum into a mold to create parts, which are then machined to precise specifications using CNC equipment. - Q2: How does aluminum casting compare to other casting methods?

Aluminum casting offers benefits like low weight and high strength but may face challenges such as casting defects. It is often compared to methods like sand casting or die casting for different manufacturing needs. - Q3: What industries use aluminum casting in CNC machining?

Industries like automotive, aerospace, and electronics frequently use aluminum casting in CNC machining for parts requiring lightweight, durable, and corrosion-resistant materials. - Q4: How can I improve the quality of aluminum casting in CNC machining?

To improve quality, focus on selecting the right alloy, implementing strict quality control measures, and using advanced finishing techniques such as anodizing and powder coating. - Q5: What are the challenges when machining aluminum castings?

Challenges in machining aluminum castings include handling surface defects, ensuring proper tolerances, managing tool wear, and using the correct equipment for efficient machining.