Introduction

Aluminium CNC machining is a process that involves using computer numerical control (CNC) machines to precisely cut, shape, and finish aluminium materials. This process is widely used in manufacturing industries to produce high-quality, durable, and precise parts. In this article, we will explore the key processes involved in aluminium CNC machining, the benefits it offers, the tools used in the process, and much more. By the end of this article, you will have a comprehensive understanding of aluminium CNC machining and its significance in various industries.

1. What is Aluminium CNC Machining?

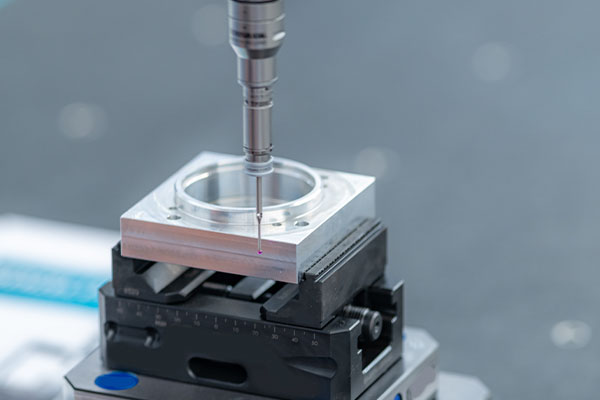

Aluminium CNC machining is the process of using CNC technology to cut, mill, drill, or shape aluminium materials into specific parts or products. This method offers high precision and accuracy, making it ideal for industries requiring complex geometries and fine details. But here’s the kicker, CNC machining allows for automation, reducing the need for manual labor and significantly increasing production efficiency.

One of the main reasons aluminium is favored in CNC machining is its lightweight properties, which make it easier to handle and process. Additionally, aluminium’s excellent thermal conductivity and corrosion resistance are key advantages for industries like aerospace, automotive, and electronics, where performance and durability are paramount.

CNC machining works by utilizing a pre-programmed computer software that controls the movement of machinery such as mills, lathes, and drills. These machines follow the exact specifications defined in the design file to create the final product. This precision ensures that even the most intricate and complex designs are reproduced accurately.

Table 1: Key Features of Aluminium CNC Machining

| Feature | Description |

|---|---|

| Precision | High tolerance and accuracy in part manufacturing |

| Materials | Works well with various aluminium alloys |

| Speed | Quick production times with reduced errors |

| Automation | Reduces need for manual labor, improving efficiency |

| Corrosion Resistance | Ideal for use in harsh environments |

2. What are the Key Processes in Aluminium CNC Machining?

The aluminium CNC machining process encompasses various techniques that allow manufacturers to shape aluminium with extreme precision. These processes include CNC milling, turning, drilling, grinding, and electrical discharge machining (EDM). Ready for the good part? Each process serves a unique function, and together they allow for the production of high-quality, complex parts.

CNC milling is one of the most common processes used in aluminium machining. It involves using rotating tools to remove material from the workpiece, creating specific shapes and finishes. CNC turning, on the other hand, is used to create cylindrical parts by rotating the workpiece while a cutting tool is applied to it.

Drilling and tapping are also essential processes, especially when creating parts with holes or threads. CNC grinding is typically used for polishing or achieving extremely smooth finishes. Lastly, EDM uses electrical discharges to remove material from the workpiece and is ideal for creating complex geometries or small holes.

Table 2: Key Processes in Aluminium CNC Machining

| Process | Description |

|---|---|

| CNC Milling | Rotating tools to remove material and shape parts |

| CNC Turning | Produces cylindrical parts by rotating the workpiece |

| Drilling & Tapping | Creates holes or threaded holes in the material |

| CNC Grinding | Smoothes or polishes the aluminium surface |

| EDM | Uses electrical discharges to remove material |

3. What Are the Benefits of Aluminium CNC Machining?

Aluminium CNC machining offers several benefits, making it a preferred method for many industries. So, why does this matter? One of the key benefits is its ability to produce parts with high precision and tight tolerances. This means that each part is made to exact specifications, ensuring that it fits perfectly within an assembly or system.

Another significant benefit is the speed and efficiency of the process. CNC machines can operate 24/7, producing parts at a much faster rate than traditional methods. Additionally, aluminium’s inherent properties, such as its lightweight nature and resistance to corrosion, make it ideal for applications in harsh environments.

The versatility of aluminium CNC machining is also worth noting. The process can be used to create a wide range of parts, from small components to large structures. This flexibility allows for the production of customized parts for various industries, such as aerospace, automotive, electronics, and medical devices.

Table 3: Benefits of Aluminium CNC Machining

| Benefit | Description |

|---|---|

| High Precision | Tolerances within thousandths of an inch |

| Speed and Efficiency | Quick production times and continuous operation |

| Corrosion Resistance | Ideal for industries where materials face harsh conditions |

| Versatility | Can create parts for various industries and applications |

4. What Types of Tools Are Used in Aluminium CNC Machining?

The tools used in aluminium CNC machining are vital to achieving precision and ensuring the quality of the finished part. Some of the most commonly used tools include CNC mills, lathes, and cutting tools such as drills and end mills. But here’s the kicker, using the right tool for the right material and job is crucial to achieving optimal results.

CNC mills are used for cutting and shaping aluminium into desired forms, while CNC lathes are ideal for creating cylindrical parts. For cutting, end mills are commonly used as they are versatile and can be employed for a variety of machining operations. Drills are used for creating holes, and other custom tooling options are available depending on the complexity of the part being produced.

Tool coatings are often applied to reduce wear and extend tool life. These coatings protect the tools from heat and friction, ensuring they remain effective for longer periods and reducing the need for frequent replacements.

Table 4: Common Tools in Aluminium CNC Machining

| Tool Type | Description |

|---|---|

| CNC Mills | Used for cutting and shaping aluminium |

| CNC Lathes | Ideal for producing cylindrical parts |

| End Mills | Versatile tool for various machining operations |

| Drills | Used to create holes in aluminium parts |

| Custom Tools | Specialized tooling for complex machining tasks |

5. How Do Aluminium Properties Affect CNC Machining?

Aluminium is a popular material for CNC machining due to its unique properties. One of its most important characteristics is its softness, which makes it easier to machine than harder metals like steel. However, this softness can also lead to certain challenges during machining. For instance, aluminium can be prone to material deformation when not processed properly.

The material’s thermal conductivity also plays a significant role. Aluminium tends to heat up quickly during machining, which can lead to tool wear if not managed correctly. To mitigate this, cooling methods such as flood cooling or mist cooling are often used to maintain temperature control during machining.

Another factor to consider is the material’s cutting speed and feed rate. Aluminium requires higher cutting speeds compared to other materials, but the feed rate needs to be adjusted to avoid overloading the cutting tool.

Table 5: Properties of Aluminium and Their Impact on CNC Machining

| Property | Impact on CNC Machining |

|---|---|

| Softness | Easier to machine, but prone to deformation |

| Thermal Conductivity | Requires effective cooling methods to avoid overheating |

| Cutting Speed | High cutting speeds needed, but requires careful feed rate management |

6. How Does CNC Machining Improve Aluminium Part Quality?

CNC machining significantly enhances the quality of aluminium parts. With its high precision, CNC machining ensures that parts are manufactured to tight tolerances, leading to minimal deviation from the design specifications. This is particularly important in industries such as aerospace, where even the slightest error can have serious consequences.

Moreover, CNC machining improves surface finish. The process is capable of producing parts with smooth, uniform surfaces, reducing the need for additional finishing operations. This is crucial for parts that need to meet aesthetic standards or those used in high-performance applications where surface smoothness is key.

The precision and repeatability of CNC machines also ensure consistent product quality, making it ideal for mass production. Each part produced will be identical to the next, reducing the risk of defects and ensuring that every product meets the required standards.

7. What Are the Common Applications of Aluminium CNC Machining?

Aluminium CNC machining has a wide range of applications across various industries, making it a highly versatile method for creating precision parts. From the automotive sector to aerospace and electronics, aluminium parts produced through CNC machining are integral to the functionality and performance of many products. But here’s the kicker—aluminium’s lightweight yet durable nature makes it the perfect material for industries where weight, strength, and precision are critical.

In the aerospace industry, for example, aluminium parts made through CNC machining are used in aircraft components such as engine parts, fuselage sections, and structural supports. The lightweight properties of aluminium help reduce the overall weight of the aircraft, improving fuel efficiency without sacrificing strength.

Similarly, in the automotive industry, aluminium is commonly used for making engine components, body panels, and wheels. It’s used in electric vehicles (EVs) to reduce weight and increase energy efficiency. Aluminium CNC machining allows manufacturers to create custom parts with precise specifications to ensure optimal vehicle performance.

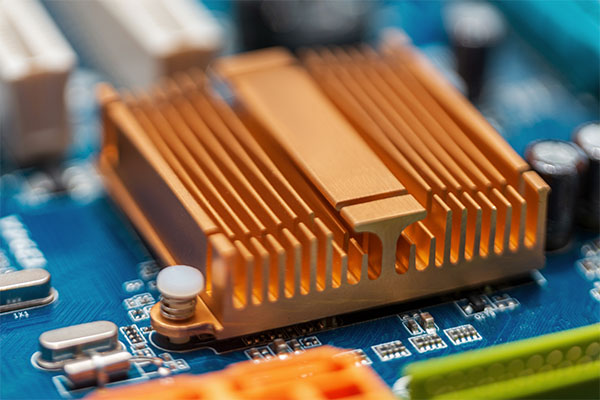

In electronics, CNC-machined aluminium is often used for enclosures and housings for devices such as computers, smartphones, and telecommunications equipment. The material’s thermal conductivity helps dissipate heat, ensuring that sensitive electronic components remain cool during operation.

Table 6: Common Applications of Aluminium CNC Machining

| Industry | Application Example |

|---|---|

| Aerospace | Aircraft engine parts, fuselage sections |

| Automotive | Engine components, body panels, wheels |

| Electronics | Enclosures and housings for computers, smartphones |

| Medical Devices | Surgical tools, diagnostic equipment |

| Industrial Machinery | Custom parts for machines and equipment |

8. What Materials are Compatible with Aluminium CNC Machining?

While aluminium is a popular material in CNC machining, it is not the only material that can be effectively processed. Other materials such as steel, titanium, and plastics can also be machined using CNC technology, but aluminium stands out due to its favorable properties. So, why does this matter? The choice of material impacts the machining process, including tool selection, machining speed, and final part characteristics.

Aluminium alloys are commonly used in CNC machining because they are lightweight, corrosion-resistant, and offer good strength. Some popular aluminium alloys used in CNC machining include 6061, 7075, and 2024, each offering different strength, corrosion resistance, and machinability characteristics.

Comparing aluminium to other metals, it’s clear that aluminium’s advantages include easier machining and faster processing times. In contrast, materials like steel and titanium require more effort to machine due to their higher hardness. This makes aluminium a more cost-effective option for many machining projects, especially in industries where weight reduction is critical, such as aerospace and automotive manufacturing.

Table 7: Comparison of Aluminium and Other Materials in CNC Machining

| Material | Machinability | Corrosion Resistance | Cost Effectiveness |

|---|---|---|---|

| Aluminium | Easy | Excellent | High |

| Steel | Medium | Good | Medium |

| Titanium | Hard | Excellent | High |

| Plastics | Very Easy | Varies | Low |

9. How Does Tool Wear Affect Aluminium CNC Machining?

Tool wear is a common challenge in CNC machining, particularly when machining materials like aluminium. As tools wear down, they can lose their effectiveness, leading to reduced part quality, increased production time, and higher costs. This is where managing tool wear becomes essential to maintaining the efficiency and accuracy of the CNC machining process.

One of the most common types of tool wear is flank wear, where the tool’s cutting edge becomes rounded, resulting in a loss of cutting performance. This is particularly noticeable when machining aluminium, as the material can cause tools to wear faster due to its relatively soft nature. Regular inspection of cutting tools is crucial to identifying wear early and ensuring that tools are replaced or re-sharpened before part quality is compromised.

To combat tool wear, manufacturers often use cutting fluids or coolants to reduce friction and heat generation. This helps extend tool life and ensures smoother cuts. Additionally, tool coatings such as TiN (Titanium Nitride) or TiAlN (Titanium Aluminium Nitride) can be applied to reduce wear and increase tool longevity.

Table 8: Types of Tool Wear in CNC Machining

| Type of Tool Wear | Description |

|---|---|

| Flank Wear | Wear on the tool’s cutting edge, reducing cutting efficiency |

| Notch Wear | Occurs at the tool’s edge, leading to edge breakdown |

| Crater Wear | Material is displaced on the tool surface, affecting part quality |

| Adhesive Wear | Material transfer from workpiece to tool surface |

10. How Do CNC Machining Techniques Optimize Aluminium Production?

CNC machining techniques are constantly evolving, and with advancements in automation and software, aluminium production has become more efficient than ever. Automation in CNC machining allows for faster and more consistent production, reducing the chances of human error and improving overall efficiency. This is where it gets interesting—by integrating automated systems, manufacturers can streamline operations, reduce waste, and cut production costs.

Advanced CNC systems are also capable of executing complex operations with minimal setup time, allowing manufacturers to produce a wide variety of parts without the need for constant machine recalibration. This is especially beneficial for small-batch production runs or custom parts, where high precision and speed are crucial.

Another optimization technique is the use of multi-axis CNC machines. These machines allow for more complex geometries and shapes to be machined in a single setup, reducing the need for multiple operations and improving overall part quality. Multi-axis machining also enhances the machining of intricate parts, making it ideal for industries like aerospace, where precision and complexity are essential.

Table 9: Advantages of Advanced CNC Machining Techniques

| Technique | Advantage |

|---|---|

| Automation | Reduces human error, increases production speed |

| Multi-Axis Machining | Allows complex geometries in a single setup |

| Advanced Software | Enables faster machine setup and better precision |

| Integrated Systems | Improves workflow and reduces setup time |

11. What Are the Challenges in Aluminium CNC Machining?

While aluminium CNC machining offers numerous benefits, it is not without its challenges. One of the main challenges faced by manufacturers is material deformation. Aluminium’s relatively soft nature can lead to warping, especially when machining large or thin-walled parts. This can be mitigated by using proper fixturing and ensuring the part is securely held during the machining process.

Another challenge is the generation of heat during machining. Aluminium tends to heat up quickly, which can lead to tool wear and reduced accuracy if not properly managed. The use of cooling methods such as flood cooling or mist cooling can help control the temperature and prevent overheating.

Burr formation is also a common issue when machining aluminium. Burrs are small, unwanted protrusions that form around the edges of cut parts. These can be removed through additional finishing processes like deburring, but they add time and cost to production. To minimize burr formation, manufacturers use specific cutting techniques and tool geometries that reduce the chances of burrs forming.

Table 10: Common Challenges in Aluminium CNC Machining

| Challenge | Description |

|---|---|

| Material Deformation | Warping or bending due to aluminium’s softness |

| Heat Generation | Overheating of the material during machining |

| Burr Formation | Unwanted protrusions that need to be removed |

| Tool Wear | Loss of cutting efficiency due to prolonged use |

12. What Are the Costs of Aluminium CNC Machining?

The costs associated with aluminium CNC machining vary depending on several factors, including the complexity of the part, the volume of parts being produced, and the type of machine used. CNC machining typically involves an upfront cost for machine setup, tooling, and labor, but once set up, the cost per part can decrease significantly for large-volume production runs.

Aluminium is generally considered a cost-effective material for machining, especially when compared to harder metals like titanium or steel. However, the cost of machining can still be influenced by factors such as the required tolerances, material waste, and additional finishing processes. For example, parts that require tighter tolerances or complex geometries may require more expensive tooling and longer machining times, increasing costs.

Another cost factor to consider is the maintenance of CNC equipment. While automation and advanced CNC systems offer significant cost savings in terms of labor and production time, regular maintenance is necessary to ensure the machines continue to operate efficiently and produce high-quality parts.

Table 11: Cost Factors in Aluminium CNC Machining

| Factor | Impact on Cost |

|---|---|

| Part Complexity | More intricate designs require higher costs |

| Production Volume | Larger volumes reduce cost per part |

| Tolerances & Finish | Tight tolerances and finishes increase production costs |

| Tooling & Maintenance | Regular maintenance and specialized tools add costs |

13. How to Choose the Right CNC Machine for Aluminium Parts?

Choosing the right CNC machine for aluminium parts depends on several factors, including part complexity, production volume, and the desired level of precision. CNC mills and lathes are the most commonly used machines for aluminium machining, but selecting between them depends on the specific needs of the project.

For large parts or high-volume production, a CNC mill is often preferred due to its versatility and ability to handle a wide range of operations. On the other hand, for smaller or cylindrical parts, a CNC lathe may be the better choice.

It’s also important to consider the machine’s precision and tolerance capabilities. High-precision machines are essential for industries like aerospace, where even slight variations can impact the performance of the part.

Table 12: Types of CNC Machines for Aluminium Parts

| Machine Type | Best For |

|---|---|

| CNC Mills | Large parts, complex geometries, high-volume production |

| CNC Lathes | Small parts, cylindrical shapes, precision turning |

| Multi-Axis CNC Machines | Complex parts requiring multiple operations |

14. What Are the Latest Trends in Aluminium CNC Machining?

The field of aluminium CNC machining is constantly evolving with new technologies and techniques aimed at improving efficiency, precision, and sustainability. One significant trend is the increased use of automation and artificial intelligence in machining processes. These technologies allow machines to adjust their operations in real-time, improving production speed and reducing human error.

Another trend is the focus on sustainable practices. Manufacturers are now looking for ways to reduce energy consumption and material waste during the machining process. This includes using energy-efficient CNC machines and optimizing cutting techniques to reduce scrap.

Advancements in material science are also influencing aluminium CNC machining. New aluminium alloys are being developed to offer better strength, corrosion resistance, and machinability, allowing manufacturers to create more durable and high-performing parts.

Table 13: Current Trends in Aluminium CNC Machining

| Trend | Description |

|---|---|

| Automation & AI | Use of smart machines to optimize production |

| Sustainable Practices | Reducing waste and energy consumption in machining |

| New Aluminium Alloys | Development of stronger and more durable materials |

15. How to Maintain Aluminium CNC Machining Equipment?

Maintaining CNC machining equipment is crucial to ensuring its longevity and performance. Regular maintenance routines, such as cleaning, lubricating, and checking machine alignment, can help prevent unexpected breakdowns and maintain consistent production quality.

It’s also important to monitor tool wear and replace tools when necessary to avoid poor-quality parts and ensure smooth operations. Regularly checking the calibration of the CNC machine is also essential for maintaining precise measurements and tolerances.

Table 14: Maintenance Checklist for CNC Machining Equipment

| Task | Frequency |

|---|---|

| Clean Machine | Daily or after each shift |

| Lubricate Moving Parts | Weekly |

| Check Alignment | Monthly |

| Inspect Tools | After each job or daily |

| Calibrate Machine | Annually |

Conclusion

In this article, we’ve covered the key aspects of aluminium CNC machining, including its processes, benefits, tools, and how it impacts part quality. From the cutting-edge technology behind CNC machines to the unique properties of aluminium, it’s clear that CNC machining plays a vital role in various industries. Whether you are manufacturing aerospace components, automotive parts, or custom machinery, understanding the ins and outs of aluminium CNC machining can help you achieve superior results and improve production efficiency.

FAQ Section

Q1: What is Aluminium CNC Machining?

Aluminium CNC machining is a manufacturing process that uses computer-controlled machines to shape and cut aluminium materials into specific parts with high precision and accuracy.

Q2: How does CNC machining work for aluminium?

CNC machining uses pre-programmed software to control machine tools, shaping aluminium into parts with extreme precision. The process can include milling, turning, drilling, and grinding.

Q3: What are the advantages of using aluminium for CNC machining?

Aluminium is lightweight, corrosion-resistant, and easy to machine, making it ideal for producing parts that need to perform well in harsh environments, such as aerospace or automotive applications.

Q4: What tools are used in Aluminium CNC machining?

CNC mills, lathes, drills, and end mills are commonly used in aluminium CNC machining. These tools help shape the material into precise parts according to design specifications.

Q5: How can I reduce costs when machining aluminium?

To reduce costs, optimize part designs to minimize material waste, use efficient CNC machines, and select the appropriate tooling to extend tool life and minimize maintenance.