Introduction

CNC machined aluminum parts have become a crucial element in a wide range of industries, from aerospace to automotive manufacturing. In this guide, we will delve into what CNC machined aluminum parts are, how they are made, their advantages, and the industries that rely on them. We’ll also discuss the factors that influence their cost, and the future trends in CNC machining technology. Let’s explore why CNC machined aluminum parts have become so essential in modern manufacturing.

1. What Are CNC Machined Aluminum Parts?

CNC machined aluminum parts are components made from aluminum through the process of CNC (Computer Numerical Control) machining. This process involves using automated machines controlled by a computer to remove material from a solid aluminum block, shaping it into the desired part. What’s the real story? This method allows for precise control over the dimensions of each part, ensuring high-quality, consistent results. CNC machining is especially popular because of its versatility, precision, and the durability of aluminum, making it ideal for a wide range of applications.

Aluminum is lightweight, durable, and resistant to corrosion, which makes it an ideal material for CNC machining. It’s also one of the most widely used materials in manufacturing. The process is used to create parts with tight tolerances, which is essential for industries that demand high levels of accuracy. Whether it’s aerospace components, automotive parts, or industrial machinery, CNC machined aluminum parts are integral to the manufacturing process.

Table 1: Common Applications of CNC Machined Aluminum Parts

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Aircraft components | Lightweight, high strength |

| Automotive | Engine components | Durability, high precision |

| Electronics | Casings for electronics | Heat resistance, cost-effective |

| Medical | Surgical instruments | Sterilizable, corrosion-resistant |

2. How Does CNC Machining Work for Aluminum?

CNC machining of aluminum starts with a digital design that is input into the CNC machine. The machine then precisely cuts, drills, mills, or turns the aluminum to create the desired shape. Here’s the kicker… The CNC machine follows the design instructions with incredible precision, creating parts that fit the exact specifications. This makes CNC machining ideal for complex geometries and intricate designs.

The process typically involves several stages, including setup, tool selection, programming, and actual machining. After the design is input into the CNC system, the machine begins the work, often using multiple tools to cut the aluminum into different shapes. Some parts may require secondary operations such as finishing, polishing, or coating to enhance their properties.

Table 2: Steps in the CNC Machining Process

| Step | Description |

|---|---|

| 1. Design | Create a digital 3D model of the part |

| 2. Setup | Prepare the CNC machine and tools |

| 3. Machining | Cut, mill, drill, or turn the aluminum |

| 4. Secondary Operations | Finishing and coating for added durability |

3. What Are the Benefits of CNC Machined Aluminum Parts?

CNC machined aluminum parts come with several significant benefits, which is why they are preferred in many industries. Ready for the good part? CNC machining offers exceptional precision, allowing for tight tolerances that are difficult to achieve with other manufacturing methods. This is critical for industries like aerospace and automotive, where even the smallest error can result in significant problems.

Another major benefit is the cost-effectiveness of CNC machining, particularly in mass production. Once a design is created and programmed, it can be reproduced many times with little variation, reducing the overall cost per part. Additionally, aluminum’s lightweight nature combined with its strength and resistance to corrosion makes it an excellent choice for many applications.

Table 3: Advantages of CNC Machined Aluminum Parts

| Benefit | Description |

|---|---|

| Precision | High accuracy and tight tolerances |

| Cost-Effective | Lower cost per part in mass production |

| Durability | Resistant to corrosion and wear |

| Lightweight | Ideal for applications requiring low weight |

4. What Industries Use CNC Machined Aluminum Parts?

CNC machined aluminum parts are used across many industries, each with specific requirements for their components. This is where it gets interesting… In the aerospace industry, the lightweight nature of aluminum is crucial for reducing weight without sacrificing strength, which is essential for fuel efficiency and performance. Similarly, in the automotive industry, CNC machined aluminum parts are used for engine components, body panels, and even suspension parts.

Electronics and medical industries also rely on CNC machined aluminum parts for creating durable, heat-resistant housings for devices, as well as medical instruments that need to be corrosion-resistant and easily sterilizable.

Table 4: Industries and Applications of CNC Machined Aluminum Parts

| Industry | Application |

|---|---|

| Aerospace | Aircraft components |

| Automotive | Engine blocks, body panels |

| Electronics | Casings for computers, mobile devices |

| Medical | Surgical tools, implants |

5. What Are the Types of CNC Machined Aluminum Parts?

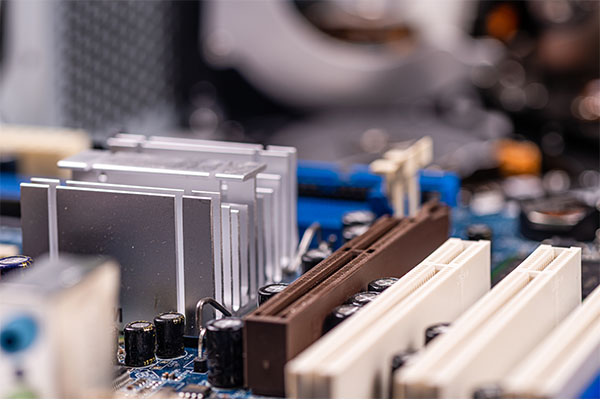

CNC machining is used to create a wide variety of aluminum parts. Some common types include housings, brackets, and heat sinks. What’s the real story? CNC machined aluminum parts can be customized for specific applications, from intricate and highly detailed designs for electronics to larger, more robust parts for the automotive and aerospace industries.

The versatility of CNC machining allows it to produce parts with complex geometries that are difficult to achieve with traditional machining methods. Whether it’s a small, precise component or a large, structural part, CNC machining can handle it all.

Table 5: Types of CNC Machined Aluminum Parts

| Part Type | Description |

|---|---|

| Housings | Protective enclosures for electronics |

| Brackets | Support structures for various applications |

| Heat Sinks | Components for heat dissipation in electronics |

| Custom Parts | Tailored components for specific needs |

6. How Are CNC Machined Aluminum Parts Customized?

Customization of CNC machined aluminum parts is a key feature of the process. Here’s the kicker… Whether you need a completely new part or a modification to an existing design, CNC machining allows for flexibility in creating custom components that meet specific requirements. This customization can include changes to dimensions, shapes, or even material specifications.

The CNC software plays a pivotal role in making these adjustments. By simply modifying the digital design, manufacturers can quickly adapt to new requirements without the need for major changes to the production process.

Table 6: Examples of CNC Machining Customizations

| Customization Type | Example |

|---|---|

| Shape | Custom contours for a unique design |

| Dimensions | Tailoring size to fit specific applications |

| Material | Choosing the right aluminum alloy for specific needs |

7. What Are the Common Materials Used for CNC Machined Parts?

CNC machining is not limited to aluminum, although it is one of the most popular materials used. Other common materials include steel, plastic, and titanium. But here’s the kicker… Aluminum is favored for many applications due to its unique combination of lightweight properties and strength, making it suitable for a wide range of industries, especially when weight reduction is crucial.

Each material has its own advantages, and choosing the right one depends on the specific requirements of the project, including strength, weight, and resistance to heat and corrosion.

Table 7: Common Materials for CNC Machined Parts

| Material | Benefits |

|---|---|

| Aluminum | Lightweight, corrosion-resistant, cost-effective |

| Steel | Strong, durable, good for high-stress parts |

| Plastic | Lightweight, cost-effective, versatile |

| Titanium | Strong, heat-resistant, lightweight |

8. How Do Tolerances and Precision Affect CNC Machining?

CNC machining is renowned for its precision, with parts often being produced to tolerances of 0.001 inches or finer. What’s the real story? The importance of tolerance and precision cannot be overstated, especially in industries like aerospace, where parts must meet exact specifications to ensure safety and performance. Higher precision results in higher quality parts and ensures that components fit together properly in their final assembly.

While achieving high precision in CNC machining is generally not an issue, maintaining it throughout the production process is essential. For example, fluctuations in temperature or material inconsistencies can affect precision and, therefore, the overall quality of the parts.

Table 8: CNC Machining Tolerances

| Tolerance | Application |

|---|---|

| 0.001″ | Precision parts for aerospace and medical |

| 0.005″ | General CNC machining for automotive and electronics |

| 0.010″ | Larger parts with less critical tolerance |

9. What Are the Challenges in CNC Machining of Aluminum Parts?

CNC machining is an efficient process, but it does come with challenges. This is where it gets interesting… Aluminum is softer than other metals like steel, which can make it more prone to wear and tear on the machining tools. Additionally, aluminum’s tendency to form burrs and chips during machining can lead to surface finish issues if not properly controlled.

Moreover, managing heat during machining is crucial. Aluminum tends to heat up quickly during the cutting process, which can cause thermal deformation and affect the precision of the finished part.

Table 9: Common Challenges in CNC Machining Aluminum

| Challenge | Solution |

|---|---|

| Tool Wear | Use high-quality carbide tools |

| Heat Generation | Implement coolant systems during machining |

| Surface Finish | Use proper finishing techniques |

10. How Is Quality Control Managed in CNC Machining?

Maintaining high-quality standards is essential in CNC machining. Ready for the good part? Quality control involves a series of inspections and tests to ensure that each part meets the required specifications. This can include visual inspections, dimensional checks, and functional testing.

Some manufacturers also follow international quality standards, such as ISO certifications, to ensure that their CNC machined aluminum parts meet the highest standards of quality. Automated inspection systems can also be used to check parts for defects at various stages of production.

Table 10: Quality Control Processes in CNC Machining

| Process | Description |

|---|---|

| Visual Inspection | Checking for surface defects and imperfections |

| Dimensional Checks | Ensuring that the part meets the required dimensions |

| Functional Testing | Verifying that the part performs as intended |

Conclusion

CNC machined aluminum parts play a crucial role in many industries, offering precision, durability, and versatility. The process of CNC machining ensures that these parts are manufactured to tight tolerances and can be customized for various applications. Whether you are in aerospace, automotive, electronics, or another industry, CNC machined aluminum parts are likely an integral part of your manufacturing process. By understanding the CNC machining process, its benefits, and how to choose the right parts, you can improve your production efficiency and ensure the quality of your products.

11. What Are the Costs of CNC Machined Aluminum Parts?

The cost of CNC machined aluminum parts can vary depending on a number of factors, and understanding these variables is crucial for businesses looking to optimize their manufacturing budget. But here’s the kicker… One of the most significant factors affecting the cost is the complexity of the part being produced. More intricate designs require more time and effort to machine, which increases labor and tool wear, thus driving up the cost. For example, parts with complex geometries or tight tolerances may take longer to machine and require specialized tools, which results in higher prices.

Another key element that influences the cost is the material itself. Different aluminum alloys come with varying prices depending on their properties and availability. Additionally, the size of the order can play a significant role in the overall cost. Larger orders typically benefit from economies of scale, reducing the per-unit cost. The volume of production and whether you’re ordering a prototype or mass-production parts also impacts the pricing. Prototype orders generally cost more per unit due to the setup costs involved, while mass production tends to bring the cost down.

The choice of the machining process itself also plays a role. For instance, 5-axis CNC machines are more expensive to operate than standard 3-axis machines, but they offer greater precision and the ability to work with more complex designs. These machines require skilled operators and higher maintenance costs, which are reflected in the final price.

Table 11: Factors Affecting the Cost of CNC Machined Aluminum Parts

| Factor | Influence on Cost |

|---|---|

| Part Complexity | More intricate designs lead to higher costs due to longer machining times |

| Material Type | Aluminum alloys with unique properties may cost more |

| Order Volume | Larger quantities reduce the cost per unit due to economies of scale |

| Production Process | Advanced machines and processes increase costs due to specialized tools and expertise |

12. How Can You Improve the Efficiency of CNC Machining?

Improving the efficiency of CNC machining is vital for reducing costs and enhancing the speed of production without sacrificing quality. Ready for the good part? There are several strategies manufacturers can adopt to optimize their CNC machining processes. One approach is to invest in automation, such as robotic arms and automatic tool changers. This can significantly speed up the production process, reduce human error, and lower labor costs.

Another efficiency boost comes from optimizing the programming and toolpaths. By carefully designing the machining operations and optimizing tool movements, operators can minimize machine downtime and reduce the amount of material waste. For example, utilizing a “best fit” toolpath can ensure that the cutting tool makes the most efficient movements while minimizing the time spent on each part.

Material selection also plays a role in machining efficiency. Choosing aluminum alloys that are easier to machine can reduce cutting times and tool wear. Additionally, selecting parts with less intricate designs, when possible, can decrease the complexity of the machining process, leading to faster production times and lower costs.

Finally, regular maintenance of CNC machines is crucial to prevent breakdowns and ensure that the equipment is running at optimal performance. Preventative maintenance helps avoid costly repairs and unscheduled downtimes, which can disrupt the production process.

Table 12: Strategies to Improve CNC Machining Efficiency

| Strategy | Benefit |

|---|---|

| Automation | Speeds up production and reduces human error |

| Toolpath Optimization | Minimizes machine downtime and material waste |

| Material Selection | Reduces cutting time and tool wear |

| Regular Maintenance | Prevents breakdowns and ensures optimal performance |

13. What Are the Sustainability Considerations for CNC Machining?

Sustainability is becoming an increasingly important factor in all manufacturing processes, and CNC machining is no exception. What’s the real story? CNC machining can be quite resource-intensive, but there are ways to reduce its environmental impact. One of the most effective methods is recycling. Aluminum is a highly recyclable material, and many CNC machining operations recycle scrap aluminum to reduce waste and lower material costs. In fact, aluminum can be recycled indefinitely without losing its quality, making it an excellent choice for sustainable manufacturing.

Another aspect of sustainability is energy consumption. CNC machines, especially older models, can consume a significant amount of energy. Investing in energy-efficient machinery and implementing practices to reduce energy consumption, such as optimizing machine operations and using energy-saving settings, can help lower the environmental footprint of the process.

Lastly, the use of eco-friendly cutting fluids and lubricants can reduce the environmental impact of machining. Traditional cutting fluids may contain harmful chemicals, but there are now biodegradable alternatives that minimize the toxicity of waste products. By opting for these sustainable practices, manufacturers can contribute to reducing the environmental impact of CNC machining operations.

Table 13: Sustainability Practices in CNC Machining

| Practice | Environmental Benefit |

|---|---|

| Recycling Aluminum | Reduces waste and lowers material costs |

| Energy Efficiency | Reduces energy consumption and lowers carbon footprint |

| Eco-friendly Cutting Fluids | Minimizes the environmental impact of waste fluids |

14. What Are the Future Trends in CNC Machining of Aluminum Parts?

The future of CNC machining looks promising, with new technologies and innovations driving the industry forward. This is where it gets interesting… One of the most notable trends is the increasing use of artificial intelligence (AI) and machine learning in CNC machining. AI can help optimize the machining process by predicting tool wear, adjusting cutting parameters in real time, and automating quality control, which ultimately leads to higher efficiency and better results.

Another significant trend is the development of more advanced materials. New aluminum alloys and composite materials are being engineered to provide even greater strength, durability, and resistance to extreme conditions. These materials offer new possibilities for CNC machining, allowing manufacturers to produce more innovative parts for industries like aerospace, automotive, and electronics.

Additive manufacturing, also known as 3D printing, is another area that is expected to revolutionize the CNC machining process. While traditionally separate processes, additive manufacturing is now being integrated with CNC machining to produce hybrid parts that combine the best aspects of both methods. This allows for faster production times, reduced waste, and the ability to create more complex geometries that would otherwise be difficult or impossible to achieve.

Table 14: Future Trends in CNC Machining of Aluminum Parts

| Trend | Description |

|---|---|

| AI Integration | Optimizing processes and enhancing quality control |

| Advanced Materials | New alloys and composites with improved properties |

| Additive Manufacturing | Combining 3D printing with CNC machining for faster, more complex parts |

15. How Do You Choose a CNC Machining Service Provider?

Selecting the right CNC machining service provider is crucial for ensuring that you get the quality and precision you need. What’s the real story? One of the first factors to consider is the provider’s experience and expertise in working with CNC machined aluminum parts. An experienced provider will have a better understanding of material properties, machining techniques, and industry-specific requirements.

Another important consideration is the capabilities of the provider’s equipment. Ensure that the provider uses modern CNC machines that are capable of producing parts with the precision you need. Additionally, look for a provider that offers a range of services, including custom machining, rapid prototyping, and finishing options, as this will give you flexibility in your production needs.

Finally, consider the provider’s quality control processes. A good CNC machining service should have stringent quality assurance procedures in place to ensure that every part meets your specifications. This includes regular inspections, testing, and certifications such as ISO 9001, which indicate a commitment to quality.

Table 15: Factors to Consider When Choosing a CNC Machining Provider

| Factor | Consideration |

|---|---|

| Experience | Expertise in CNC machining and working with aluminum |

| Equipment | Modern CNC machines capable of precision work |

| Quality Control | Strong quality assurance processes and certifications |

FAQ Section

Q1: What are CNC machined aluminum parts?

CNC machined aluminum parts are components made from aluminum using a CNC machine, which shapes the material precisely to meet specific design requirements.

Q2: How does CNC machining work for aluminum?

CNC machining involves a computer-controlled machine that cuts, drills, and shapes aluminum to create the desired part with high precision.

Q3: What are the main benefits of CNC machined aluminum parts?

The benefits include high precision, durability, cost-effectiveness, and lightweight properties, making them ideal for many industries.

Q4: What industries use CNC machined aluminum parts?

Industries such as aerospace, automotive, electronics, and medical use CNC machined aluminum parts for various components due to their strength and lightweight nature.

Q5: What factors affect the cost of CNC machined aluminum parts?

Factors include material choice, part complexity, production volume, and the level of precision required for the parts.