Introduction

CNC machining aluminum is a key manufacturing process used to create precise, custom aluminum parts for various industries. Whether you’re in aerospace, automotive, or electronics, aluminum is often the material of choice due to its lightweight and durable properties. In this comprehensive guide, we will explore everything you need to know about CNC machining aluminum, from understanding the basic process to troubleshooting common issues. Let’s dive in.

1. What is CNC Machining Aluminum?

CNC machining aluminum refers to the process where a computer-controlled machine cuts and shapes aluminum material according to digital designs. It is an essential technique in modern manufacturing, offering high precision and the ability to produce complex parts with ease. CNC stands for Computer Numerical Control, which means the machine follows specific coded instructions to execute tasks like drilling, milling, and turning aluminum pieces.

Why is aluminum so widely used in CNC machining? Well, it’s because aluminum is both lightweight and incredibly durable, making it perfect for various applications like aerospace components, automotive parts, and even medical devices. In addition, aluminum is resistant to corrosion, ensuring longevity in products made from this material.

What’s the real story behind CNC machining aluminum? The ability to control the machining process with great precision ensures that manufacturers can meet the tight tolerances required for high-quality parts, all while reducing the potential for human error. This is where it gets interesting – the rise of CNC technology has dramatically improved the speed, accuracy, and overall efficiency of aluminum fabrication.

2. Why Choose Aluminum for CNC Machining?

Aluminum offers a variety of benefits that make it ideal for CNC machining. Here’s the deal – it’s lightweight, strong, and easy to machine. These attributes make aluminum an excellent choice for industries where weight reduction and strength are crucial, such as in the aerospace and automotive sectors.

But there’s more! Aluminum also provides good thermal and electrical conductivity, which is particularly beneficial in electronics. Additionally, it’s non-magnetic, making it safe for applications in sensitive equipment.

The versatility of aluminum allows it to be used in countless applications, including the manufacturing of frames, panels, housings, and brackets. So, why do manufacturers choose aluminum time and again? Simply put, its cost-effectiveness, strength-to-weight ratio, and machinability make it a go-to material for precision manufacturing.

Table 1: Benefits of Aluminum in CNC Machining

| Benefit | Description |

|---|---|

| Lightweight | Reduces overall weight of finished products |

| Strength | Offers durability and strength for various applications |

| Corrosion Resistance | Protects against environmental wear and tear |

| Machinability | Easy to machine, saving time and costs |

| Conductivity | Ideal for electronic and thermal applications |

3. How Does CNC Machining Aluminum Work?

The CNC machining process for aluminum involves several key stages. Ready for the good part? Let’s break down each step:

- Design – The first step is creating a digital design using CAD software. This design will serve as a blueprint for the CNC machine to follow.

- Setup – Next, the machine is set up with the proper tooling. Depending on the complexity of the design, different tools (such as drills, lathes, or mills) are used to shape the aluminum.

- Machining – The machine follows the instructions in the CAD file, performing precise cutting, drilling, and milling operations to create the final part.

- Finishing – After the aluminum is machined, it may undergo finishing processes like polishing or anodizing to enhance its appearance and durability.

In this process, the use of a computer-controlled system ensures consistent quality and minimal human intervention. The ability to produce parts with incredibly tight tolerances is one of the standout features of CNC machining.

Table 2: Steps in CNC Machining Aluminum

| Step | Description |

|---|---|

| Design | Create a digital design using CAD software |

| Setup | Configure the CNC machine with the right tools |

| Machining | Execute precise cutting, milling, and drilling |

| Finishing | Apply finishing processes like polishing or anodizing |

4. What Are the Key Benefits of CNC Machining Aluminum?

CNC machining aluminum is not only precise but also highly efficient. What’s the real benefit here? It offers manufacturers the ability to produce complex shapes quickly and at high volumes, making it an attractive option for industries requiring mass production.

Additionally, CNC machining aluminum is cost-effective because it reduces material waste. Since the process is automated, there’s less room for human error, which can save time and money. The precision achieved in CNC machining allows for tight tolerances, which is especially important in industries like aerospace, where accuracy is paramount.

So, what sets CNC machining aluminum apart? It’s all about efficiency, precision, and flexibility. The ability to quickly create intricate designs with minimal waste is a huge advantage for manufacturers, helping them meet deadlines and reduce costs.

Table 3: Advantages of CNC Machining Aluminum

| Advantage | Description |

|---|---|

| High Precision | Achieves tight tolerances for complex designs |

| Cost-Effective | Reduces material waste and minimizes human error |

| Flexibility | Allows for rapid production of custom parts |

| Speed | Faster than traditional manufacturing methods |

5. What Types of Aluminum Are Used in CNC Machining?

Aluminum comes in many grades, each offering different properties suited for specific applications. Here’s the kicker – understanding which aluminum grade to choose can make all the difference in the outcome of your project.

Common aluminum grades include 6061, 7075, and 2024. 6061 is versatile and easy to machine, making it suitable for most applications. 7075, on the other hand, is known for its high strength and is often used in aerospace and military applications. 2024 offers excellent fatigue resistance, making it ideal for parts subjected to high-stress environments.

Choosing the right grade for your CNC machining project depends on factors like strength requirements, weight restrictions, and environmental factors like corrosion resistance.

Table 4: Common Aluminum Grades for CNC Machining

| Aluminum Grade | Key Properties | Common Applications |

|---|---|---|

| 6061 | Versatile, easy to machine | General manufacturing, automotive |

| 7075 | High strength, aerospace-grade | Aerospace, military, structural |

| 2024 | Excellent fatigue resistance | Aircraft parts, heavy-duty equipment |

6. What Are the Common Challenges in CNC Machining Aluminum?

Despite its advantages, CNC machining aluminum comes with its challenges. But here’s the kicker – knowing these challenges can help you prepare and overcome them effectively.

One common issue is tool wear. Aluminum, although soft, can cause rapid wear on cutting tools, especially when machining at high speeds. Another challenge is chip removal. Aluminum chips tend to clog up the machine, which can lead to overheating and poor surface finishes. Lastly, heat generation is another concern. As the machine cuts through the aluminum, friction generates heat, which can warp or damage the part if not properly managed.

By understanding these challenges, manufacturers can take preventive measures like choosing the right cutting tools, using coolant, and optimizing the machining process to improve efficiency.

Table 5: Challenges in CNC Machining Aluminum

| Challenge | Description |

|---|---|

| Tool Wear | Cutting tools can wear out quickly, especially at high speeds |

| Chip Removal | Aluminum chips can clog machines and affect performance |

| Heat Generation | Excessive heat can cause material distortion or damage |

7. How to Optimize CNC Machining for Aluminum?

Optimizing CNC machining for aluminum involves selecting the right cutting speeds, tools, and techniques to maximize efficiency and minimize issues. Ready for the good part? Here are some strategies to get the best results:

- Cutting Speeds and Feeds – Aluminum requires higher cutting speeds compared to harder metals, but it’s important to balance speed with the feed rate to avoid overheating and poor finishes.

- Choosing the Right Tools – Use sharp, high-quality tools designed for aluminum machining. Carbide tools work well for aluminum and offer durability.

- Managing Heat – Keep the workpiece cool by using cutting fluids or coolants to prevent overheating, which can damage the part and the tool.

Optimizing these factors will ensure smoother machining, longer tool life, and better results overall.

8. What Are the Best CNC Machines for Aluminum?

Choosing the right CNC machine for aluminum is crucial for ensuring efficient and precise machining. This is where it gets interesting – the type of CNC machine you select will depend on the complexity of the parts you’re manufacturing and the specific aluminum grade you’re working with.

For lighter applications, CNC milling machines are often the best choice. These machines offer versatility and can handle various machining tasks, from drilling to complex milling operations. For higher precision and tighter tolerances, CNC lathes may be the better option, especially for parts that require cylindrical shaping. Vertical CNC machining centers are also popular for aluminum due to their precision and ease of use, particularly in industries like aerospace and automotive.

When selecting the best CNC machine for aluminum, consider factors like machine speed, tool compatibility, and the overall complexity of the parts you’re producing. Here’s the deal – choosing a machine with advanced cooling systems and quick tool changes can make a significant difference in efficiency and finish quality.

Table 6: CNC Machines for Aluminum Machining

| CNC Machine Type | Features | Best Applications |

|---|---|---|

| CNC Milling Machine | Versatile, handles drilling, milling, etc. | General machining, automotive parts |

| CNC Lathe | High precision for cylindrical parts | Aerospace, automotive, shafts |

| Vertical CNC Center | Precise, fast tool changes, high accuracy | Complex parts, high-tolerance designs |

9. How to Maintain CNC Machines for Aluminum Machining?

CNC machines require regular maintenance to ensure they continue performing at their best. What’s the real story? Proper machine maintenance can significantly extend the lifespan of your equipment and ensure consistent results.

The most critical aspects of maintenance include cleaning and lubrication. Machines should be regularly cleaned to remove metal shavings, dust, and coolant residues. Lubrication is key to reducing friction, preventing overheating, and ensuring smooth operation. Another important aspect is tool inspection and replacement. Cutting tools wear down over time and need to be replaced regularly to maintain the quality of the finished product.

To prevent mechanical failures, regularly check the machine’s calibration and make necessary adjustments to maintain accurate operations. Lastly, proper coolant management is vital. Using the correct cutting fluid and ensuring its flow helps maintain a cool temperature, which is essential for both tool longevity and quality machining.

Table 7: Key Aspects of CNC Machine Maintenance

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Cleaning & Lubrication | Weekly | Reduces wear and tear, improves performance |

| Tool Inspection | Monthly | Ensures precision and quality |

| Calibration Checks | Bi-monthly | Prevents errors, maintains accuracy |

| Coolant Management | Regular use | Prevents overheating, prolongs tool life |

10. What Are the Costs Involved in CNC Machining Aluminum?

The costs associated with CNC machining aluminum can vary depending on several factors, including the complexity of the part, the aluminum grade used, and the machining time required. So, what are the key cost drivers? Here’s a breakdown:

- Material Costs – The price of aluminum fluctuates based on the grade and market conditions. Common grades like 6061 are relatively affordable, but specialized grades like 7075 may cost more.

- Labor Costs – CNC machining is typically a labor-intensive process that requires skilled operators. Labor costs will depend on the complexity of the work and the expertise required.

- Machine Time – The time it takes to machine the aluminum part directly affects the cost. More complex parts with tighter tolerances take longer to machine, increasing the overall cost.

- Post-Processing – After machining, some parts may require additional processes such as anodizing, coating, or polishing. These post-processing steps can add to the total cost.

Table 8: Breakdown of CNC Machining Aluminum Costs

| Cost Factor | Description |

|---|---|

| Material | Based on aluminum grade and market conditions |

| Labor | Skilled operators required for machining |

| Machine Time | Dependent on part complexity and tolerances |

| Post-Processing | Coating, anodizing, polishing, etc. |

11. How Do Tolerances Impact CNC Machining Aluminum?

In CNC machining, tolerances refer to the permissible limits of variation in the dimensions of a part. What’s the real story? Tighter tolerances often require more precise and slower machining processes, which can increase both time and cost.

For example, parts that require tight tolerances (e.g., aerospace components) will need to be machined with higher precision, resulting in higher costs due to increased machine time, tooling, and inspection. On the other hand, parts with looser tolerances (e.g., automotive brackets) can be machined more quickly and at a lower cost.

Managing tolerances is an essential skill in CNC machining. If not properly maintained, incorrect tolerances can lead to defective parts, costly rework, and wasted material. So, whether you’re working with a highly precise part or a simple component, it’s crucial to know the tolerances required and choose the appropriate machine settings.

Table 9: Tolerances in CNC Machining

| Tolerance Type | Description | Impact on Production |

|---|---|---|

| Tight Tolerances | Low variation, typically below 0.001″ | Increases machining time, cost |

| Looser Tolerances | Higher variation, greater than 0.01″ | Faster machining, lower cost |

12. What Are the Applications of CNC Machining Aluminum?

CNC machining aluminum is used in a wide range of industries, from aerospace to automotive, due to the material’s lightweight and durable properties. What’s the real benefit here? Aluminum’s versatility makes it ideal for producing everything from structural components to intricate, high-precision parts.

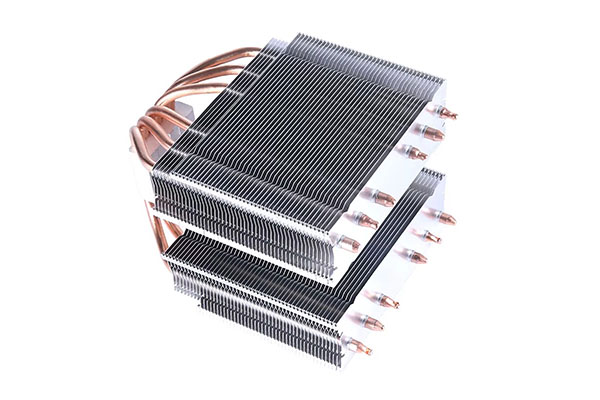

In the aerospace industry, aluminum is used for manufacturing lightweight but strong components that need to withstand extreme stress. Automotive manufacturers use aluminum for engine parts, brackets, and frames to reduce weight and improve fuel efficiency. Electronics manufacturers rely on CNC-machined aluminum for heat sinks, casings, and connectors because of its excellent thermal conductivity.

From medical devices to consumer products, the applications of CNC-machined aluminum are virtually limitless. The ability to produce both high-strength and lightweight parts makes aluminum a go-to material for a variety of industries.

Table 10: Applications of CNC Machining Aluminum

| Industry | Common Applications |

|---|---|

| Aerospace | Structural components, aircraft parts |

| Automotive | Engine parts, brackets, frames |

| Electronics | Heat sinks, casings, connectors |

| Medical Devices | Surgical tools, implants, casings |

13. How Do You Choose a CNC Machining Service for Aluminum?

When selecting a CNC machining service for aluminum, there are several factors to consider. What’s the real deal? You want to ensure the provider has experience working with aluminum and can meet your specific quality and timeline requirements.

- Experience – Choose a provider that specializes in machining aluminum and has a proven track record in the industry.

- Capabilities – Ensure the company has the right machinery and equipment for your specific needs, whether you require high-precision milling or rapid prototyping.

- Quality Control – Look for a company that offers stringent quality control processes to ensure the final parts meet your specifications.

- Customer Support – A good CNC machining service should offer excellent customer support, providing assistance throughout the design, production, and delivery phases.

Table 11: Factors to Consider When Choosing a CNC Machining Service

| Factor | Description |

|---|---|

| Experience | Proven track record in CNC machining aluminum |

| Capabilities | Available equipment and tooling |

| Quality Control | Consistent quality assurance processes |

| Customer Support | Accessible and responsive support team |

14. How to Troubleshoot Common CNC Machining Aluminum Problems?

When machining aluminum, you may encounter a variety of issues, including poor surface finish, tool wear, and dimensional inaccuracies. What’s the best way to troubleshoot these problems?

- Poor Surface Finish – This can be caused by dull tools, incorrect cutting speeds, or inadequate cooling. To resolve this, replace worn-out tools, adjust machining parameters, and ensure sufficient coolant flow.

- Tool Wear – High-speed machining can cause rapid tool wear. Use high-quality carbide tools and ensure proper lubrication to extend tool life.

- Dimensional Inaccuracies – If parts are out of spec, check machine calibration, tool offsets, and cutting parameters. You may also want to check for material inconsistencies or distortion due to heat.

Table 12: Troubleshooting Common CNC Machining Issues

| Problem | Cause | Solution |

|---|---|---|

| Poor Surface Finish | Dull tools, improper cutting speeds | Replace tools, adjust speeds, increase coolant |

| Tool Wear | High-speed machining, poor lubrication | Use carbide tools, apply proper lubrication |

| Dimensional Inaccuracy | Miscalibrated machines, improper tool offsets | Check calibration, adjust cutting parameters |

15. How is the Future of CNC Machining Aluminum Evolving?

The future of CNC machining aluminum is bright, with numerous advancements on the horizon. Here’s the kicker – technologies like automation, AI, and machine learning are poised to revolutionize the way CNC machining is performed.

In the near future, robotic automation will play an increasingly important role in reducing labor costs and improving machining precision. AI-powered machines will also help optimize cutting parameters, reducing errors and increasing production speed. Additionally, additive manufacturing (3D printing) is expected to complement traditional CNC machining, offering new ways to manufacture aluminum parts with complex geometries.

As these technologies continue to develop, manufacturers will benefit from even greater efficiency, precision, and cost savings in CNC machining.

Table 13: Future Trends in CNC Machining Aluminum

| Trend | Description |

|---|---|

| Robotic Automation | Reduces labor costs, improves precision |

| AI and Machine Learning | Optimizes cutting parameters, reduces errors |

| Additive Manufacturing | Complements CNC machining, enables complex geometries |

Conclusion

In conclusion, CNC machining aluminum remains a fundamental part of modern manufacturing. With its precision, versatility, and cost-effectiveness, CNC-machined aluminum is used in a wide range of industries, from aerospace to automotive and electronics. By understanding the complexities of the machining process, selecting the right tools and machines, and addressing common challenges, manufacturers can ensure that their CNC machining projects run smoothly and efficiently.

FAQ Section

Q1: What is CNC machining aluminum?

CNC machining aluminum refers to the process of using computer-controlled machines to cut and shape aluminum into custom parts for various industries.

Q2: How does CNC machining aluminum work?

CNC machining aluminum involves designing a part in CAD software, setting up a CNC machine with appropriate tools, and then machining the aluminum according to the design specifications.

Q3: What are the benefits of using aluminum in CNC machining?

Aluminum offers benefits such as lightweight, strength, corrosion resistance, and ease of machining, making it ideal for numerous industrial applications.

Q4: What types of aluminum are used in CNC machining?

Common aluminum grades used in CNC machining include 6061, 7075, and 2024, each chosen based on factors like strength, weight, and environmental conditions.

Q5: How can I reduce costs when CNC machining aluminum?

To reduce costs, focus on optimizing material usage, choosing the right machine and tooling, and fine-tuning machining parameters like feed rates and cutting speeds.