Introduction

CNC aluminum machining is a critical process in modern manufacturing, but it often comes with the challenge of material deformation. When machining aluminum, undesirable deformation can occur due to various factors, including heat, cutting forces, and improper tool paths. This article explores effective ways to avoid deformation in CNC aluminum machining, offering practical solutions to ensure high-quality, precise results. We’ll cover everything from process parameters to material behavior, and we’ll provide actionable insights to help you prevent deformation in your machining operations.

1. What Causes Undesirable Deformation in CNC Aluminum Machining?

Aluminum is a versatile material, but it can be prone to deformation during CNC machining due to several factors. But here’s the kicker: understanding the core causes of deformation is the first step in preventing it. Let’s break down the key contributors.

The first factor is heat generation during the machining process. Cutting aluminum generates friction, which leads to heat buildup. If the temperature becomes too high, the material can expand and deform. This heat is often a result of high cutting speeds or insufficient cooling.

Another major factor is tool wear and geometry. Over time, tools can become dull or improperly shaped, which increases the cutting forces acting on the aluminum. This imbalance can lead to unwanted deflection, causing deformation.

Finally, material properties also play a critical role. Aluminum alloys vary in terms of their hardness and tensile strength, and softer alloys are more prone to deformation under machining forces. Each alloy behaves differently, so it’s essential to understand the material you’re working with to adjust machining parameters accordingly.

Table 1: Common Causes of Deformation in CNC Aluminum Machining

| Cause of Deformation | Description | Impact on Machining |

|---|---|---|

| Heat Generation | Excessive heat from cutting leads to material expansion. | Causes warping and bending |

| Tool Wear and Geometry | Dull or incorrect tools increase cutting forces. | Results in part distortion |

| Material Properties | Different alloys have varying levels of resistance to stress. | Soft alloys deform easier |

2. How Can CNC Machining Process Parameters Lead to Deformation?

The parameters you set for your CNC machine can significantly affect whether deformation occurs. What’s the real story? The wrong settings can lead to excessive cutting forces, heat, or vibrations, all of which contribute to deformation.

One of the most important parameters is the cutting speed. Cutting too fast generates heat, which we’ve already established as a major cause of deformation. On the other hand, cutting too slowly can result in excessive cutting forces that strain the material.

Feed rate is another critical parameter. If the feed rate is too high, the tool will exert excessive force on the aluminum, causing it to deflect. Conversely, a low feed rate may increase heat buildup without effectively removing material, contributing to thermal expansion.

Additionally, tool pressure during the machining process must be carefully controlled. Excessive clamping pressure or poorly set fixturing can cause the aluminum to bend or deform under pressure.

Table 2: CNC Machining Parameters Affecting Deformation

| Parameter | Impact on Deformation | Best Practices |

|---|---|---|

| Cutting Speed | Too fast generates heat, too slow increases cutting forces. | Optimize for the material and tooling. |

| Feed Rate | High feed rate increases cutting forces. | Adjust based on tool and material. |

| Tool Pressure | Excessive pressure can bend the material. | Use proper fixturing and clamping. |

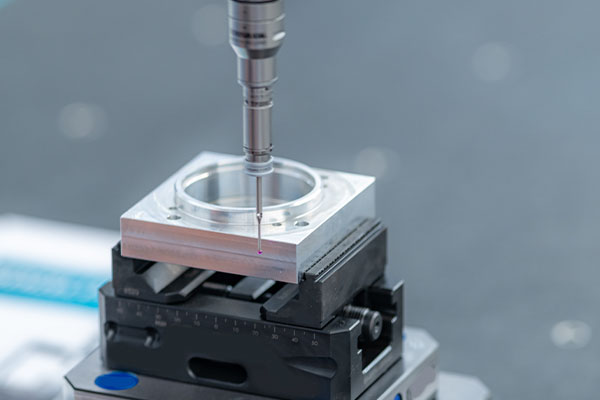

3. What is the Role of Tool Selection in Minimizing Deformation?

Tool selection is a critical factor in preventing deformation in CNC aluminum machining. This is where it gets interesting: the right tool can reduce cutting forces, minimize heat buildup, and improve overall machining precision.

The material of the cutting tool is an important consideration. Tools made from high-performance materials like carbide or coated materials tend to last longer and maintain their sharpness. They can withstand higher cutting speeds and temperatures without becoming dull, reducing the risk of deformation.

Tool geometry also plays a pivotal role. The shape of the cutting edge, the rake angle, and the tool’s surface finish all affect how the tool interacts with the aluminum. A sharp, well-maintained tool with the proper geometry will cut more efficiently, applying less force to the material and reducing deformation risks.

Finally, tool wear is inevitable, but it needs to be monitored closely. As tools wear down, they exert more force on the material, leading to deformation. Regular inspection and replacement of tools help maintain machining quality.

Table 3: Tool Selection Criteria for CNC Aluminum Machining

| Tool Feature | Description | Effect on Deformation |

|---|---|---|

| Tool Material | High-performance materials like carbide reduce wear. | Reduces cutting forces and heat. |

| Tool Geometry | Proper rake angles and sharp edges minimize material stress. | Lowers deformation potential. |

| Tool Wear | Dull tools increase cutting forces and heat. | Increases deformation risk. |

4. How Does Cutting Temperature Affect Aluminum Machining?

Cutting temperature is another crucial factor when machining aluminum. Here’s the deal: if the temperature rises too much, the aluminum may soften and deform under the pressure of the tool. Let’s dive into why this happens and how you can manage it.

When cutting aluminum, friction between the tool and material generates heat. Aluminum has a relatively low melting point compared to other metals, which means it can easily become soft if exposed to excessive heat. This softening can cause the aluminum to lose its shape, especially if the cutting speed and feed rate aren’t optimized.

Cooling systems are essential for managing cutting temperatures. Using the right cutting fluid or coolant can help dissipate heat, reduce friction, and prevent the material from softening. The flow rate and type of coolant are important to ensure that the cutting area remains at an optimal temperature.

Table 4: Impact of Cutting Temperature on Deformation

| Temperature Effect | Description | Resulting Impact on Machining |

|---|---|---|

| Excessive Heat | Increases material expansion and softens aluminum. | Causes warping and bending. |

| Proper Cooling | Reduces friction and keeps temperatures stable. | Prevents softening and deformation. |

| Cooling Fluid Choice | High-performance fluids help maintain cutting temperatures. | Ensures better tool life and finish. |

5. What Are the Best Practices for Fixturing in CNC Aluminum Machining?

Fixturing refers to the process of securing the material during machining to prevent movement or distortion. You might be wondering: how does this relate to deformation? Proper fixturing is essential for keeping the aluminum part stable during cutting, ensuring that it doesn’t shift or warp under pressure.

Fixturing plays a major role in clamping pressure. If the pressure is too high, the material may be deformed by the clamps. Conversely, insufficient pressure can allow the part to move, leading to inaccuracies and deformation. The goal is to apply even, consistent pressure that holds the material securely without stressing it.

Fixture design is equally important. Fixtures should be designed to support the material in the right areas, minimizing unsupported zones where deformation could occur. For complex parts, it may be necessary to use specialized fixtures to ensure stability during machining.

Table 5: Best Fixturing Practices for CNC Aluminum Machining

| Fixturing Technique | Description | Effect on Deformation |

|---|---|---|

| Proper Clamping Pressure | Apply consistent, even pressure to avoid part movement. | Prevents material distortion. |

| Fixture Design | Use specialized fixtures to support the part correctly. | Reduces unsupported deformation areas. |

| Adjustable Fixtures | Ensure the fixture can adapt to various part shapes. | Accommodates complex geometries. |

6. How Do Material Properties Influence Deformation in CNC Machining?

Material properties such as tensile strength, hardness, and ductility determine how aluminum will behave during machining. What’s the real story? Softer aluminum alloys are more prone to deformation under cutting forces, while harder alloys can withstand higher stresses but may be more challenging to machine.

Each aluminum alloy has its own unique characteristics that influence its machinability. For example, 6061 aluminum is relatively easy to machine but can deform more easily under high cutting forces. In contrast, 7075 aluminum is much stronger and resistant to deformation, but it can be more difficult to machine due to its hardness.

When machining aluminum, it’s essential to understand the material’s properties to adjust the machining process accordingly. This includes adjusting the feed rates, cutting speeds, and tool selection based on the alloy being used.

7. Why is Tool Path Optimization Important for Preventing Deformation?

Tool path optimization is one of the most effective ways to minimize deformation in CNC aluminum machining. Ready for the good part? Optimizing the path that the tool follows can significantly reduce the stresses applied to the material, ensuring a smoother and more accurate finish.

One of the primary reasons tool path optimization is so effective is that it helps to distribute cutting forces more evenly. When the tool follows a poor or inefficient path, it can concentrate forces on specific areas of the material, leading to deformation. By optimizing the tool path, these forces are spread out, reducing the likelihood of material distortion.

There are several strategies that can be employed to optimize the tool path. For example, adaptive tool paths allow the tool to adjust its movement based on the material being cut, resulting in more efficient material removal and reduced cutting forces. Additionally, zigzag cutting patterns and climb milling techniques can further minimize deflection and deformation by ensuring a more consistent cutting process.

Lastly, software advancements have enabled the creation of automated tool path generation that can identify the best possible route for the tool, optimizing for both speed and material preservation. These programs can analyze the material, machine capabilities, and cutting conditions to deliver a precise and efficient tool path.

Table 6: Benefits of Tool Path Optimization in CNC Aluminum Machining

| Benefit | Description | Impact on Deformation |

|---|---|---|

| Even Distribution of Cutting Forces | Reduces localized stress on the material. | Minimizes material distortion. |

| Adaptive Tool Paths | Adjusts tool movement based on material characteristics. | Prevents excessive cutting force. |

| Automated Tool Path Generation | Software optimizes tool paths for efficiency and precision. | Ensures accurate part geometry. |

8. How Does CNC Machine Calibration Help Avoid Deformation?

Machine calibration is another essential factor in preventing deformation during CNC aluminum machining. But here’s the kicker: without proper calibration, even the best tools and processes won’t deliver consistent results.

CNC machine calibration ensures that every axis of the machine is properly aligned and functioning correctly. If the machine’s spindle, tool holder, or other components are misaligned, it can cause inaccurate cutting, leading to deformation in the final part.

For instance, if the spindle isn’t aligned properly, the cutting tool may not stay perpendicular to the material surface, causing uneven cuts and surface inconsistencies. Additionally, incorrect tool offsets or misaligned tool holders can result in part misplacement, which can introduce stresses that lead to deformation.

Regular calibration checks and alignment procedures are necessary to ensure that the machine operates within its specified tolerances. By keeping the machine in peak condition, you reduce the risk of inaccurate machining and material distortion.

Table 7: CNC Machine Calibration Checks

| Calibration Task | Description | Effect on Deformation |

|---|---|---|

| Spindle Alignment | Ensures spindle is perpendicular to the material surface. | Prevents uneven cuts and warping. |

| Tool Holder Alignment | Verifies that the tool is correctly positioned. | Reduces the risk of misalignment. |

| Tool Offset Verification | Checks that tool offsets are accurately set. | Ensures precision and reduces stress. |

9. How Can Machinists Control Vibration During CNC Aluminum Machining?

Vibration is a common issue in CNC machining, especially when working with softer materials like aluminum. This is where it gets interesting: controlling vibration can drastically reduce the chances of deformation.

Vibration occurs when the cutting forces exceed the rigidity of the machine or the material. It can result in chatter marks, surface imperfections, and, ultimately, part deformation. To combat this, machinists need to ensure that the CNC machine is as rigid as possible, and that cutting forces are minimized.

One way to control vibration is by choosing the right machine setup. Machines with high rigidity will be less susceptible to vibration, which means less deformation. Additionally, selecting the right tool with appropriate geometry can help absorb vibrations and reduce their effects on the material.

The use of damping devices is another effective method. These devices, when added to the machine or tooling, help absorb the excess energy from vibrations, keeping the cutting process smooth and consistent.

Table 8: Vibration Control Methods in CNC Machining

| Vibration Control Method | Description | Effect on Deformation |

|---|---|---|

| Machine Rigidity | Using machines with a solid and rigid frame. | Minimizes movement and instability. |

| Tool Geometry Selection | Choosing tools that can absorb vibrations. | Reduces chatter and part distortion. |

| Damping Devices | Implementing devices to absorb vibrations during cutting. | Smoothens cutting, reducing deformation. |

10. What Role Does Cutting Fluid Play in Minimizing Deformation?

Cutting fluid is essential when machining aluminum to control temperature and friction. What’s the real story? If cutting fluid isn’t used correctly, it can lead to overheating, tool wear, and ultimately, deformation.

Cutting fluid helps reduce friction between the tool and the material, which minimizes heat generation during machining. The more heat that is generated, the higher the chances of material expansion and deformation. By using the correct cutting fluid, machinists can keep temperatures at an optimal level and prevent part distortion.

Additionally, coolant flow rate is a key factor. If too little coolant is used, it won’t be effective in cooling the cutting zone. On the other hand, too much coolant can lead to flooding or tool interference. It’s important to find the right balance for each specific machining operation.

Table 9: Cutting Fluid Effectiveness in CNC Machining

| Fluid Type | Description | Impact on Deformation |

|---|---|---|

| Coolant Fluids | Fluids that reduce friction and heat during cutting. | Keeps temperature under control. |

| Lubricating Oils | Reduces tool wear and minimizes heat build-up. | Prevents part warping and surface damage. |

| Fluid Flow Rate | Ensures proper cooling and lubrication during machining. | Reduces material expansion and stress. |

11. What Are the Key Indicators of Deformation During Machining?

Deformation often happens gradually during the machining process, so recognizing the signs early can help prevent further issues. This is where it gets interesting: identifying deformation indicators can save time and materials.

Some of the most common signs of deformation include visible part distortion. This could be in the form of bowed surfaces or edges that no longer align correctly. Another indicator is measurement deviations. If the part dimensions are off from the design specifications, it’s a clear sign that deformation has occurred.

Using precision measuring tools, such as calipers and CMMs (Coordinate Measuring Machines), can help detect these issues early. Machinists should regularly check the dimensions of parts during production to ensure that no deformation occurs.

Table 10: Key Indicators of Deformation

| Indicator | Description | Action Required |

|---|---|---|

| Visual Distortion | Bowed surfaces or misaligned edges. | Inspect and correct machine setup. |

| Measurement Deviations | Part dimensions are off from design specifications. | Stop machining and check parameters. |

| Surface Imperfections | Chatter marks or rough surfaces on the part. | Adjust cutting conditions or tooling. |

12. How Can Post-Machining Processes Help in Reducing Deformation?

Even after machining, additional steps can help reduce or correct deformation. Here’s the deal: post-machining processes like stress relief and heat treatment can help stabilize the material.

Stress relieving involves heating the part to a specific temperature and then cooling it at a controlled rate. This process helps reduce residual stresses that may have developed during machining, preventing further deformation after the part is completed.

Another post-machining technique is heat treatment, which can increase the strength of aluminum, making it less prone to deformation in future operations. In some cases, surface finishing processes like polishing or grinding can also improve part stability.

Table 11: Post-Machining Techniques for Deformation Reduction

| Technique | Description | Effect on Deformation |

|---|---|---|

| Stress Relieving | Controlled heating and cooling to relieve internal stresses. | Reduces further distortion. |

| Heat Treatment | Heating aluminum to increase strength and reduce deformation. | Strengthens material and resists bending. |

| Surface Finishing | Polishing or grinding to correct surface imperfections. | Improves dimensional accuracy. |

13. How Does CNC Aluminum Machining Differ from Other Materials in Terms of Deformation?

When machining aluminum, the risk of deformation differs from harder materials like steel or titanium. What’s the real story? Aluminum’s relatively low melting point and soft nature make it more susceptible to thermal expansion and plastic deformation.

Compared to harder materials, steel and titanium require more force to machine but are less likely to deform under the same cutting conditions. Aluminum, however, is much more sensitive to heat buildup, which is why it requires precise control of cutting speeds, feed rates, and cooling systems.

In addition, aluminum alloys have different mechanical properties, and softer alloys are generally more prone to deformation. Understanding these differences allows machinists to adapt their processes to the specific material being worked with.

Table 12: Comparison of Deformation Risks for Different Materials

| Material | Deformation Risk | Key Factors |

|---|---|---|

| Aluminum | High due to low melting point and softness. | Requires optimal temperature control. |

| Steel | Lower due to higher hardness. | Needs more cutting force. |

| Titanium | Low but harder to machine. | Requires higher cutting speeds. |

14. What Are Common Mistakes That Lead to Deformation in CNC Aluminum Machining?

There are several mistakes that can increase the likelihood of deformation in CNC aluminum machining. Ready for the good part? Let’s take a look at the top mistakes to avoid.

One common mistake is using incorrect cutting parameters. Machinists who don’t adjust the cutting speed or feed rate for the specific aluminum alloy may end up overheating the material, causing it to deform.

Another mistake is poor tool maintenance. Using worn-out tools increases the cutting forces on the aluminum, which can lead to deformation. Regular tool checks and replacements are essential for maintaining machining precision.

Lastly, some machinists overlook fixturing. If the part isn’t held securely during machining, it can shift or bend under the cutting forces, resulting in part distortion.

Table 13: Common Mistakes Leading to Deformation

| Mistake | Description | Preventive Action |

|---|---|---|

| Incorrect Cutting Parameters | Using the wrong feed rate or cutting speed. | Adjust settings based on material. |

| Poor Tool Maintenance | Worn-out tools increase cutting forces. | Regularly check and replace tools. |

| Overlooking Fixturing | Insufficient fixturing allows the part to shift. | Use proper clamping and fixtures. |

15. How Can You Prevent Deformation in High-Volume CNC Aluminum Machining?

In high-volume CNC aluminum machining, maintaining precision and preventing deformation becomes even more critical. This is where it gets interesting: scaling up operations without compromising quality is a challenge that requires careful planning and consistent quality control.

The key to high-volume machining is automation. By incorporating automated tool changers, robotic arms, and precision measurement systems, manufacturers can maintain consistent part quality across large batches. These systems reduce human error and ensure that parts are machined to exact specifications every time.

Continuous monitoring is also crucial. By using advanced sensors and data analytics, manufacturers can monitor machine conditions in real-time, making adjustments to the machining parameters as necessary to prevent deformation.

Table 14: Key Practices for Preventing Deformation in High-Volume Machining

| Practice | Description | Impact on Deformation |

|---|---|---|

| Automation | Use of automated systems to ensure consistency. | Reduces human error and maintains quality. |

| Continuous Monitoring | Real-time data analysis to adjust parameters. | Ensures consistent precision and reduces deformation. |

| Regular Maintenance | Routine machine checks and tool replacements. | Keeps machines in peak condition, preventing errors. |

This comprehensive approach helps maintain precision in high-volume CNC aluminum machining, ensuring that deformation is kept to a minimum throughout the process.

FAQ Section

Q1: What is CNC aluminum machining?

CNC aluminum machining is a process where a CNC machine is used to cut, shape, and finish aluminum parts with high precision.

Q2: How does tool selection impact deformation in CNC machining?

Using the correct tool material and geometry reduces cutting forces and heat, minimizing the chances of deformation.

Q3: Why is cutting temperature important in CNC aluminum machining?

Excessive heat can soften aluminum, leading to deformation, which is why temperature management is critical for precision machining.

Q4: What are the best practices for preventing deformation during CNC machining?

Optimizing feed rates, using the right tooling, ensuring proper fixturing, and managing temperature are key to preventing deformation.

Q5: How can post-machining processes help prevent deformation?

Post-machining processes like stress-relieving and surface finishing can help correct minor deformations and improve part integrity.

This comprehensive article has covered the key strategies for preventing undesirable deformation in CNC aluminum machining, ensuring that you can achieve precise, high-quality results in your operations.