Introduction

The rapid advancement of artificial intelligence has catalyzed unprecedented demand for computational power, driving the development of increasingly powerful and energy-intensive hardware. As AI models grow in size and complexity, the thermal management challenges associated with cooling these systems have become a critical bottleneck. This article explores the cutting-edge innovations and strategies emerging to address these challenges, with a particular focus on sustainable approaches that balance performance requirements with environmental responsibility.

The Thermal Challenge of Modern AI Hardware

The thermal challenges posed by modern AI accelerators represent one of the most significant engineering hurdles in computing today, pushing cooling technologies to their fundamental limits.

Problem: AI hardware thermal density is increasing at a pace that outstrips traditional cooling capabilities.

The numbers are staggering. Current generation AI accelerators like NVIDIA’s H100 generate up to 700 watts of heat from a single chip, while next-generation hardware is expected to approach or exceed 1000 watts. This creates thermal densities that conventional cooling approaches simply cannot handle effectively.

Aggravation: AI workloads create sustained high thermal loads with minimal variation.

Further complicating matters, AI workloads typically run at 90-100% utilization for extended periods—sometimes weeks or months for large training runs. This creates a relentless thermal load that gives cooling systems no opportunity to “recover” during periods of lower utilization, unlike traditional computing workloads with variable utilization patterns.

Solution: A new generation of cooling technologies and holistic thermal management strategies is emerging to address these unprecedented challenges.

The Evolution of AI Hardware Thermal Demands

Understanding the historical trajectory of AI hardware thermal demands provides important context:

- Historical Perspective:

- Early GPUs for AI (2015-2017): 150-250W TDP

- First-gen AI Accelerators (2018-2020): 250-350W TDP

- Current-gen AI GPUs (2021-2023): 400-700W TDP

- Next-gen AI Systems (2024-2025): 600-1000W+ TDP

- Future Projections (2026+): Potentially exceeding 1500W

- Thermal Density Progression:

- Early GPUs: 0.1-0.2 W/mm²

- First-gen AI Accelerators: 0.3-0.5 W/mm²

- Current-gen AI GPUs: 0.5-0.9 W/mm²

- Next-gen AI Systems: 0.8-1.5 W/mm²

- Future Projections: Potentially exceeding 2.0 W/mm²

- Cooling Technology Inflection Points:

- Below 250W: Advanced air cooling sufficient

- 250-400W: Air cooling reaches practical limits

- 400-700W: Liquid cooling becomes necessary

- 700W+: Advanced liquid cooling or immersion required

- 1000W+: Next-generation cooling technologies needed

Here’s a critical insight: We are currently at a fundamental inflection point in AI hardware cooling. The latest generation of AI accelerators has essentially reached the practical limits of what traditional cooling approaches can handle, even with significant modifications. This physical reality is driving a comprehensive rethinking of thermal management, with cooling considerations now taking center stage in the design process for AI systems.

Performance and Reliability Implications

The relationship between temperature and AI hardware performance is complex and multifaceted:

- Thermal Throttling Effects:

- Modern AI accelerators automatically reduce clock speeds when temperature thresholds are reached

- Throttling typically begins at 83-87°C

- Can reduce performance by 15-30%

- Creates inconsistent training performance

- May extend training time by days or weeks

- Temperature Stability Importance:

- AI training benefits from consistent performance

- Temperature fluctuations cause clock speed variations

- Can impact training convergence and reproducibility

- Stable temperatures enable maximum sustained performance

- Critical for large-scale distributed training

- Hardware Reliability Considerations:

- Every 10°C increase typically reduces component lifespan by 50%

- Thermal cycling creates physical stress on components

- Affects solder joints, interconnects, and packaging

- Increases failure rates and maintenance requirements

- Particularly important for 24/7 AI operations

Temperature Effects on AI Hardware Performance and Reliability

| Temperature Range | Performance Impact | Reliability Impact | Cooling Requirement |

|---|---|---|---|

| Below 55°C | Optimal performance, maximum boost clocks | Excellent reliability, extended lifespan | Advanced cooling required |

| 55-75°C | Good performance, sustained boost possible | Good reliability, normal lifespan | Standard high-performance cooling |

| 75-85°C | Moderate performance, intermittent throttling | Reduced lifespan (up to 30%) | Minimum acceptable cooling |

| Above 85°C | Poor performance, significant throttling | Substantially reduced lifespan (50%+) | Inadequate cooling |

But here’s an interesting phenomenon: Temperature affects not just hardware performance but can impact AI model quality itself. Research has shown that training with hardware experiencing thermal throttling can lead to subtle inconsistencies in the optimization process. In extreme cases, this can result in models with slightly lower accuracy (0.5-1.5% degradation) or require additional training epochs to reach the same quality level. For state-of-the-art models where every fraction of a percentage point matters, thermal management becomes an integral part of the AI development process itself.

Environmental and Sustainability Challenges

The thermal management of AI hardware creates significant environmental challenges:

- Energy Consumption:

- Cooling typically consumes 30-40% of total AI system energy

- Contributes significantly to operational carbon footprint

- Creates substantial operational costs

- Impacts grid infrastructure requirements

- Limits deployment in energy-constrained regions

- Water Usage:

- Many cooling technologies require significant water

- Typical data center uses 3-5 liters of water per kWh

- Creates pressure on local water resources

- Particularly problematic in water-stressed regions

- Regulatory and community concerns

- Material and Resource Considerations:

- Cooling infrastructure requires substantial materials

- Some cooling technologies use specialized chemicals

- Manufacturing embodied carbon impacts

- End-of-life disposal considerations

- Supply chain sustainability challenges

Ready for the fascinating part? The environmental impact of AI hardware cooling isn’t just about operational resource consumption—it’s increasingly about the embodied impact in the hardware itself. As operational efficiency improves through advanced cooling, the relative importance of manufacturing and materials impacts grows. Some organizations are finding that extending hardware lifespan through superior cooling actually creates greater environmental benefits than incremental operational efficiency improvements. A high-performance cooling system that extends AI accelerator lifespan by 2-3 years can reduce lifetime environmental impact by 30-50% through avoided manufacturing impacts, fundamentally changing the sustainability equation.

Next-Generation Cooling Technologies

The extreme thermal demands of AI hardware are driving rapid innovation in cooling technologies, with several promising approaches emerging to address these challenges.

Problem: Traditional cooling technologies cannot efficiently handle the thermal output of modern AI accelerators.

Even advanced air cooling and conventional liquid cooling approaches that were sufficient for previous generations are proving inadequate for the latest AI hardware, leading to performance limitations and reliability concerns.

Aggravation: The rapid pace of AI hardware advancement creates a moving target for cooling solutions.

Further complicating matters, the accelerating pace of AI hardware development means cooling technologies must evolve quickly to keep pace with changing thermal requirements and form factors.

Solution: Several next-generation cooling technologies show particular promise for addressing the unique challenges of AI hardware:

Advanced Liquid Cooling Innovations

Liquid cooling continues to evolve with significant innovations for AI hardware:

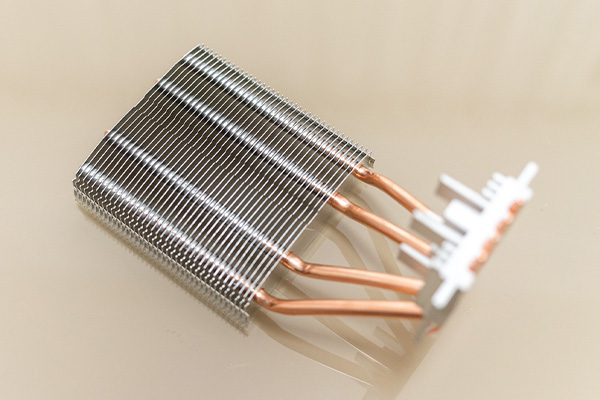

- Direct-to-Chip Liquid Cooling Advancements:

- Microchannel cold plates with channel widths of 100-500 microns

- 3D printed optimized geometries

- Multi-zone designs for non-uniform heat sources

- Reduced thermal resistance by 30-50%

- Support for 600-1000W per chip

- Two-Phase Liquid Cooling:

- Utilizes phase change from liquid to vapor

- 5-10x higher heat transfer coefficients

- Reduced pumping power requirements

- More uniform temperature distribution

- Supports extreme power densities

- Dielectric Fluid Innovations:

- New synthetic fluids with improved properties

- Higher thermal conductivity (0.13-0.15 W/m·K)

- Reduced viscosity for better natural convection

- Extended fluid lifespan (10+ years)

- Improved environmental profiles

Here’s what makes this fascinating: The latest generation of liquid cooling technologies doesn’t just incrementally improve upon previous designs—it fundamentally rethinks the relationship between coolant and hardware. For example, some advanced systems are implementing “thermal-aware cooling” where the cold plate design is customized based on detailed thermal mapping of specific AI chip architectures. By analyzing the heat distribution across different functional units of the chip, engineers can create cooling solutions with variable channel densities and geometries that provide more cooling capacity precisely where it’s needed most. This “thermal-aware” approach can improve cooling efficiency by 20-30% compared to uniform designs.

Immersion Cooling Breakthroughs

Immersion cooling—submerging hardware directly in thermally conductive but electrically insulating fluids—offers compelling advantages for AI systems:

- Single-Phase Immersion Advancements:

- Full hardware immersion in non-boiling dielectric fluid

- Elimination of thermal interfaces

- Uniform cooling across all components

- Simplified system design

- Support for 50-100kW per rack

- Two-Phase Immersion Innovations:

- Utilizes fluid boiling for extremely efficient heat transfer

- Passive phase-change cooling (no pumps required)

- Isothermal operation at fluid boiling point

- Highest cooling efficiency (PUE approaching 1.01-1.03)

- Support for 100-200kW per rack

- Hybrid Immersion Approaches:

- Targeted immersion of highest-power components

- Simplified implementation compared to full immersion

- Reduced fluid volume requirements

- Easier serviceability

- Transitional approach for existing infrastructure

But here’s an interesting phenomenon: Immersion cooling doesn’t just improve thermal performance—it fundamentally changes the reliability profile of AI hardware. By eliminating air exposure, immersion cooling prevents oxidation, reduces thermal cycling, eliminates fan failures, and prevents dust accumulation—all common causes of hardware failures. Data from large-scale deployments indicates that immersion-cooled AI systems can have 30-50% lower failure rates compared to air-cooled equivalents, significantly reducing maintenance costs and improving overall system availability. For mission-critical AI infrastructure, this reliability improvement may be as valuable as the thermal benefits.

Emerging Cooling Technologies

Several emerging technologies show promise for addressing future AI cooling challenges:

- Microfluidic Cooling:

- Cooling channels integrated directly into chips or packages

- Channel dimensions from 10-100 microns

- Brings cooling fluid extremely close to heat source

- Dramatically reduced thermal resistance

- Potential to handle heat fluxes >1000 W/cm²

- Vapor Chamber Advancements:

- Ultra-thin vapor chambers (<1mm)

- Integration directly into chip packages

- 3D vapor chamber structures

- Variable thickness designs

- Multi-stage vapor chambers

- Novel Materials Applications:

- Graphene and carbon nanotube heat spreaders

- Diamond-copper composite interfaces

- Phase change materials for transient loads

- Nanofluids with enhanced thermal properties

- Metamaterials with directional thermal conductivity

Next-Generation Cooling Technology Comparison

| Technology | Cooling Capacity | Implementation Readiness | Sustainability Profile | Best Applications |

|---|---|---|---|---|

| Advanced Direct Liquid | 600-1000W per chip | Commercial | Good (water-based) | Enterprise AI systems |

| Two-Phase Liquid | 800-1200W per chip | Early commercial | Good (closed-loop) | High-density AI clusters |

| Single-Phase Immersion | 50-100kW per rack | Commercial | Medium (chemical fluids) | AI data centers |

| Two-Phase Immersion | 100-200kW per rack | Commercial | Medium (chemical fluids) | Extreme density AI |

| Microfluidic Cooling | >1000W per chip | Research/Prototype | Excellent (minimal resources) | Future AI accelerators |

| Advanced Vapor Chambers | 500-800W per chip | Early commercial | Excellent (passive) | Next-gen AI hardware |

Integration and Implementation Considerations

Practical factors significantly impact cooling technology selection and implementation:

- Facility Integration Requirements:

- Infrastructure modifications needed

- Space and weight considerations

- Redundancy and reliability requirements

- Monitoring and control systems

- Maintenance access and serviceability

- Operational Considerations:

- Staff expertise requirements

- Maintenance procedures and frequency

- Reliability and failure modes

- Serviceability and component access

- Monitoring and management complexity

- Transition Strategies:

- Phased implementation approaches

- Hybrid cooling during transition

- Testing and validation methodologies

- Risk mitigation strategies

- Operational continuity planning

Ready for the fascinating part? The most successful cooling technology implementations don’t just focus on the technology itself—they carefully consider the human factors and operational integration. Organizations that invest in comprehensive staff training, detailed operational procedures, and thorough monitoring systems typically achieve 15-25% better real-world performance from the same cooling technology compared to those focusing solely on the technical implementation. This “operational excellence dividend” often represents the difference between theoretical cooling performance and actual results in production environments.

Sustainable Cooling Strategies

Balancing the performance requirements of AI hardware with environmental responsibility requires thoughtful sustainable cooling strategies.

Problem: Traditional approaches to AI hardware cooling create significant environmental impacts through energy consumption, water usage, and resource utilization.

The massive energy consumption of AI systems, combined with the substantial resources required for cooling, creates a significant environmental footprint that is increasingly concerning to organizations, regulators, and the public.

Aggravation: The rapidly growing scale of AI deployment is amplifying these environmental impacts to potentially unsustainable levels.

Further complicating matters, the exponential growth in AI deployment is multiplying these environmental impacts, creating urgency around developing more sustainable approaches to thermal management.

Solution: A comprehensive approach to sustainable cooling can significantly reduce environmental impact while maintaining the performance needed for AI workloads:

Energy Efficiency Optimization

Minimizing energy consumption is the foundation of sustainable cooling:

- Cooling System Efficiency:

- High-efficiency pumps and heat exchangers

- Variable speed drives for all motors

- Optimized fluid dynamics

- Reduced pressure drops

- Minimized parasitic losses

- Temperature Management Strategies:

- Higher operating temperature setpoints

- Wider temperature ranges where appropriate

- Reduced overcooling

- Temperature-based workload placement

- Dynamic temperature optimization

- Control System Optimization:

- AI-driven predictive cooling control

- Workload-based cooling adjustment

- Dynamic resource allocation

- Machine learning optimization

- Digital twin simulation for efficiency

Here’s what makes this fascinating: The most effective energy efficiency approaches don’t just optimize individual components—they create holistic systems where cooling is dynamically matched to actual thermal requirements. Advanced implementations use machine learning to predict workload patterns and proactively adjust cooling parameters, potentially reducing energy consumption by 15-30% compared to reactive approaches. These intelligent systems continuously learn and improve, creating compounding efficiency gains over time that significantly outperform static optimization approaches.

Water Conservation Approaches

Reducing or eliminating water consumption is increasingly critical:

- Waterless Cooling Technologies:

- Dry coolers instead of cooling towers

- Closed-loop refrigerant systems

- Air-cooled heat rejection

- Immersion cooling with dry heat exchangers

- Radiative cooling approaches

- Water Efficiency Improvements:

- Advanced cooling tower technologies

- Higher cycles of concentration

- Drift eliminators and water recovery

- Smart controls for blowdown optimization

- Water treatment innovations

- Alternative Water Sources:

- Rainwater harvesting

- Municipal reclaimed water

- Process water recycling

- Condensate recovery

- On-site water treatment and reuse

But here’s an interesting phenomenon: The water-energy nexus creates complex sustainability tradeoffs. Waterless cooling typically increases energy consumption by 10-30% compared to water-based approaches, particularly in warmer climates. The most sustainable solutions often involve sophisticated hybrid approaches that dynamically balance water and energy use based on local conditions, time of year, and even time of day. These adaptive systems can reduce total environmental impact by 20-40% compared to static approaches that optimize for either water or energy alone.

Heat Recovery and Reuse

Capturing and utilizing waste heat transforms a problem into a resource:

- Low-Grade Heat Applications:

- Office and support space heating

- Domestic hot water production

- Snow melting and deicing

- Greenhouse heating

- Aquaculture and agriculture

- Medium-Grade Heat Utilization:

- District heating integration

- Industrial process heat

- Absorption cooling

- Drying applications

- Food processing

- Heat Transformation Technologies:

- Heat pumps for temperature boosting

- Organic Rankine Cycle for electricity generation

- Thermal energy storage

- Cascading heat use systems

- Heat-to-cooling conversion

Sustainable Cooling Strategy Comparison

| Strategy | Environmental Benefit | Performance Impact | Implementation Complexity | Best Applications |

|---|---|---|---|---|

| Energy Efficiency | Reduced carbon emissions | Neutral to positive | Low to medium | All AI systems |

| Waterless Cooling | Water conservation | Slight energy penalty | Medium | Water-stressed regions |

| Heat Recovery | Energy offset, reduced emissions | Neutral | Medium to high | Facilities with heating needs |

| Renewable Integration | Carbon reduction | Neutral | Low to medium | All AI deployments |

| Circular Design | Reduced embodied impact | Neutral | Medium | New construction |

Circular Economy Principles

Applying circular thinking to cooling infrastructure reduces lifetime impact:

- Design for Longevity:

- Durable materials and components

- Modular, repairable designs

- Future-compatible interfaces

- Simplified maintenance

- Extended service life

- Resource Efficiency:

- Minimized material use

- Recycled and sustainable materials

- Reduced chemical use

- Optimized manufacturing processes

- Reduced transportation impacts

- End-of-Life Considerations:

- Designed for disassembly

- Recyclable components

- Reusable modules

- Reduced landfill impact

- Manufacturer take-back programs

Ready for the fascinating part? The embodied environmental impact of cooling infrastructure is becoming an increasingly significant portion of lifetime emissions as operational efficiency improves. For some advanced systems, embodied carbon can represent 30-50% of lifetime emissions. This is driving a fundamental shift in sustainability strategy from an almost exclusive focus on operational efficiency to a more balanced approach that considers manufacturing impacts and infrastructure longevity as equally important. Leading organizations are now making infrastructure decisions based on total lifetime carbon (embodied + operational) rather than just operational efficiency, fundamentally changing design priorities and vendor selection criteria.

System-Level Thermal Management

The most effective approach to AI hardware cooling takes a holistic, system-level perspective that considers the entire thermal path and all interactions between components.

Problem: Component-level cooling solutions often fail to address system-level thermal challenges.

Many cooling approaches focus exclusively on the AI accelerators themselves, neglecting the complex thermal interactions within the entire system. This narrow approach often leads to suboptimal performance and unexpected hotspots.

Aggravation: As AI systems become more complex, thermal interactions become increasingly significant.

Further complicating matters, modern AI systems include multiple interacting components—accelerators, CPUs, memory, power delivery, networking—all generating heat in close proximity. These thermal interactions create complex patterns that can’t be addressed with isolated cooling solutions.

Solution: A system-level approach to thermal design considers the entire heat flow path and all thermal interactions:

Holistic Thermal Design

Considering the complete thermal system rather than individual components:

- Complete Thermal Path Analysis:

- Heat generation at component level

- Heat transfer through thermal interfaces

- Heat spreaders and heat sinks

- Heat transfer to cooling medium

- Heat removal from the immediate environment

- Heat rejection to the outside environment

- Thermal Interface Optimization:

- Advanced thermal interface materials

- Liquid metal interfaces

- Graphene and carbon nanotube enhanced compounds

- Direct liquid contact where possible

- Minimized interface resistance

- System Architecture Considerations:

- Component placement and orientation

- Airflow or liquid flow patterns

- Thermal isolation and zoning

- Shared cooling resource allocation

- System-level thermal gradients

Here’s what makes this fascinating: In high-performance AI systems, the thermal interface between heat-generating components and cooling solutions often represents 30-50% of the total thermal resistance, despite being only a fraction of a millimeter thick. Advanced thermal interface materials like liquid metal can reduce this resistance by 60-80%, potentially lowering component temperatures by 10-15°C even with no other changes to the cooling system. This demonstrates why focusing on the complete thermal path, rather than just the cooling technology itself, is critical for optimal performance.

Multi-Accelerator Thermal Management

Multi-accelerator systems create unique thermal management challenges:

- Thermal Interaction Management:

- Heat transfer between adjacent accelerators

- Shared cooling resources

- Airflow or liquid flow patterns

- Temperature gradients across the system

- Balanced cooling for all accelerators

- Flow Distribution Optimization:

- Balanced cooling for all accelerators

- Parallel vs. serial cooling configurations

- Manifold designs for even distribution

- Pressure drop management

- Temperature uniformity optimization

- Thermal Synchronization Considerations:

- Temperature matching between accelerators

- Clock speed synchronization

- Performance consistency

- Thermal throttling prevention

- System-wide thermal management

But here’s an interesting phenomenon: In multi-accelerator systems, thermal uniformity between chips can be as important as absolute temperature. Research has shown that temperature differences between accelerators in parallel computing tasks can cause clock speed variations that reduce overall system efficiency. Some advanced cooling systems now prioritize temperature matching between accelerators, even if it means slightly higher absolute temperatures, because the performance benefits of thermal synchronization outweigh the minor impact of slightly elevated but uniform temperatures.

Intelligent Thermal Management

Advanced control systems are essential for optimizing AI system cooling:

- AI-Driven Cooling Optimization:

- Machine learning for predictive cooling control

- Pattern recognition in thermal behavior

- Workload-based cooling adjustment

- Continuous system learning and improvement

- 15-30% efficiency improvement potential

- Workload-Aware Thermal Management:

- Dynamic cooling based on specific AI workloads

- Predictive cooling for known job patterns

- Thermal-aware job scheduling

- Performance-thermal optimization

- Coordinated system-wide management

- Digital Twin Technology:

- Real-time simulation models of cooling systems

- Predictive analysis of changes

- Virtual testing of control strategies

- Anomaly detection through model comparison

- Optimization scenario evaluation

Intelligent Thermal Management Comparison

| Approach | Performance Benefit | Efficiency Improvement | Implementation Complexity | Best Applications |

|---|---|---|---|---|

| Rule-Based Control | Baseline | Baseline | Low | Simple systems |

| Model Predictive Control | 5-10% | 10-20% | Medium | Production AI systems |

| Machine Learning Control | 10-20% | 20-30% | High | Large AI clusters |

| Digital Twin Simulation | 15-25% | 25-35% | Very High | Critical AI infrastructure |

| Federated Learning Systems | 20-30% | 30-40% | Extremely High | Next-generation AI infrastructure |

Facility Integration

Effective integration with facility infrastructure is critical for optimal performance:

- Cooling Distribution Architecture:

- Centralized vs. distributed approaches

- Redundancy and reliability considerations

- Scalability and modularity

- Maintenance access planning

- Future expansion capability

- Monitoring and Instrumentation:

- Comprehensive temperature sensing

- Flow and pressure monitoring

- Power consumption correlation

- Environmental condition monitoring

- Predictive maintenance capabilities

- Emergency and Backup Systems:

- Graceful degradation capabilities

- Backup cooling provisions

- Thermal buffering approaches

- Emergency shutdown procedures

- Disaster recovery planning

Ready for the fascinating part? The most advanced AI cooling implementations are beginning to implement “digital twin” technology that maintains a complete virtual model of the entire cooling system running in parallel with the physical system. This approach enables operators to predict the impact of changes before implementation, identify subtle performance degradation, and optimize complex systems with hundreds of variables that would be impossible to manage manually. Some implementations have demonstrated 15-25% improvements in cooling efficiency through these advanced control approaches, creating substantial operational savings while improving thermal performance.

Economic Considerations and ROI

The economics of AI hardware cooling involve complex tradeoffs between capital costs, operational expenses, performance benefits, and risk mitigation.

Problem: Advanced cooling technologies often require significant upfront investment, creating financial barriers to adoption.

The most effective cooling solutions for AI hardware typically involve substantial capital expenditure, making it challenging to justify the investment based on traditional ROI calculations.

Aggravation: The rapid evolution of AI hardware creates uncertainty about the longevity of cooling investments.

Further complicating matters, the accelerating pace of AI hardware development creates uncertainty about how long any cooling infrastructure will remain adequate, making long-term ROI calculations particularly challenging.

Solution: A comprehensive economic analysis that considers all value factors can justify appropriate cooling investments:

Capital Cost Considerations

Understanding the full capital cost picture for cooling technologies:

- Direct Equipment Costs:

- Cooling hardware and components

- Installation and commissioning

- Control systems and monitoring

- Backup and redundancy provisions

- Testing and validation

- Infrastructure Requirements:

- Facility modifications

- Power distribution upgrades

- Structural reinforcements

- Space allocation

- Safety and containment systems

- Implementation Factors:

- Project management

- Staff training

- Operational procedure development

- Documentation and knowledge transfer

- Certification and compliance

Here’s what makes this fascinating: The most effective capital cost analyses don’t just consider the cooling technology in isolation—they evaluate the system-level impacts across the entire infrastructure. For example, while liquid cooling may have higher direct equipment costs than air cooling, it often reduces overall facility costs by eliminating raised floors, reducing ceiling heights, and decreasing electrical infrastructure requirements. These secondary effects can reduce total capital costs by 10-20% compared to analyzing the cooling system in isolation, fundamentally changing the economic equation for advanced cooling technologies.

Operational Cost Analysis

Ongoing costs significantly impact the total cost of ownership:

- Energy Consumption:

- Cooling system power requirements

- Potential efficiency improvements

- Peak vs. average consumption

- Time-of-use considerations

- Renewable energy integration potential

- Maintenance Requirements:

- Preventative maintenance procedures

- Consumable replacement

- Staff time and expertise

- Vendor support contracts

- Lifecycle replacement planning

- Reliability Impacts:

- Downtime risk reduction

- Mean time between failures

- Mean time to repair

- Spare parts inventory

- Business continuity considerations

But here’s an interesting phenomenon: The operational cost benefits of advanced cooling often extend far beyond direct energy savings. Improved cooling can significantly extend hardware lifespan, reduce failure rates, and minimize performance throttling—all of which have substantial economic value. Some organizations have found that these secondary benefits can be 2-3x more valuable than the direct energy savings, particularly for expensive AI accelerators where each percentage point of improved utilization or extended lifespan translates to significant financial returns.

Performance and Productivity Benefits

The performance impact of cooling has significant economic implications:

- Throughput Improvements:

- Reduced thermal throttling

- Higher sustained clock speeds

- More consistent performance

- Improved training and inference speeds

- Faster time-to-results

- Utilization Optimization:

- Higher average utilization rates

- Reduced idle time due to thermal issues

- More predictable performance

- Better resource allocation

- Improved scheduling efficiency

- Model Quality Considerations:

- More consistent training conditions

- Reduced convergence variability

- Potentially improved model accuracy

- Fewer training runs needed

- Higher quality AI outputs

Economic Value of Cooling Improvements

| Benefit Category | Typical Value Range | Measurement Approach | Most Significant For |

|---|---|---|---|

| Energy Cost Reduction | 20-40% cooling energy | Direct measurement | Large-scale deployments |

| Hardware Lifespan Extension | 30-50% longer life | Failure rate comparison | High-value accelerators |

| Performance Improvement | 10-25% throughput | Benchmark comparison | Production AI systems |

| Downtime Reduction | 20-40% less downtime | Historical comparison | Mission-critical AI |

| Density Improvement | 2-5x higher density | Space utilization analysis | Space-constrained facilities |

| Resale Value Preservation | 20-30% higher residual | Market comparison | Organizations with refresh cycles |

Risk Mitigation Value

The risk reduction provided by advanced cooling has quantifiable economic value:

- Hardware Failure Risk:

- Reduced component failures

- Lower warranty claim rates

- Decreased replacement costs

- Minimized emergency service needs

- Business continuity protection

- Performance Variability Risk:

- More consistent AI results

- Reduced training failures

- Predictable completion times

- Reliable service level agreements

- Improved customer satisfaction

- Operational Risk Factors:

- Simplified maintenance procedures

- Reduced human error potential

- Enhanced monitoring and alerting

- Proactive issue identification

- Improved disaster recovery capabilities

Ready for the fascinating part? The risk mitigation value of advanced cooling is often underestimated in traditional ROI calculations but can be substantial for mission-critical AI systems. For applications where AI downtime has significant business impact, the value of improved reliability can dwarf other economic factors. Some organizations in finance, healthcare, and critical infrastructure sectors have justified premium cooling solutions entirely on reliability improvements, with energy efficiency and performance benefits treated as secondary considerations. This “reliability premium” reflects the growing importance of AI as business-critical infrastructure rather than experimental technology.

Future Directions and Emerging Innovations

The field of AI hardware cooling continues to evolve rapidly, with several emerging trends poised to reshape thermal management approaches.

Problem: Even today’s advanced cooling technologies may be insufficient for next-generation AI hardware.

As AI accelerators continue to increase in power and density, with some projections suggesting chips exceeding 1500W in the near future, even current advanced cooling approaches may reach their practical limits.

Aggravation: The pace of AI hardware advancement is accelerating, creating a moving target for cooling solutions.

Further complicating matters, the rapid pace of AI hardware development means cooling solutions must evolve quickly to keep pace with changing thermal requirements and form factors.

Solution: Understanding emerging trends provides insights to make forward-looking cooling decisions:

Integration of Cooling and Computing

The boundary between computing hardware and cooling systems is increasingly blurring:

- Co-Designed Systems:

- Cooling designed simultaneously with computing hardware

- Optimized interfaces between chips and cooling

- Purpose-built cooling for specific AI architectures

- Thermal considerations influencing chip design

- Unified thermal-computational optimization

- Embedded Cooling Technologies:

- Microfluidic channels integrated into chip packages

- On-die cooling structures

- Advanced thermal interface materials

- 3D-stacked chips with interlayer cooling

- Cooling as an integral part of the chip

- Heterogeneous Integration Impacts:

- Chiplet architectures with distributed cooling

- Interposer-level cooling integration

- 3D stacking thermal management

- Advanced packaging with integrated cooling

- System-in-package thermal solutions

Here’s what makes this fascinating: The next generation of AI hardware is being designed with cooling as a primary consideration rather than an afterthought. This represents a fundamental shift in computing architecture philosophy. For example, several major hardware manufacturers are now including cooling engineers in the earliest stages of chip design, allowing thermal considerations to influence fundamental architecture decisions. This co-design approach could potentially double cooling efficiency compared to retrofitted solutions, enabling significant performance improvements while maintaining manageable thermal profiles.

Novel Materials and Approaches

Innovative materials and physical approaches are expanding cooling capabilities:

- Advanced Material Applications:

- Diamond heat spreaders (2000+ W/m·K conductivity)

- Graphene thermal interfaces (5000+ W/m·K in-plane)

- Carbon nanotube arrays for thermal interfaces

- Phase change materials for transient loads

- Metamaterials with engineered thermal properties

- Nanoscale Thermal Management:

- Phononic crystal structures

- Surface acoustic wave cooling

- Near-field radiation heat transfer

- Quantum thermal transport

- Molecular-engineered thermal interfaces

- Biological Inspiration:

- Biomimetic vascular cooling networks

- Self-organizing flow patterns

- Adaptive surface structures

- Hierarchical branching systems

- Self-healing thermal interfaces

But here’s an interesting phenomenon: The most promising cooling innovations don’t just apply new materials—they fundamentally rethink the physics of heat transfer at different scales. For example, some research teams are developing thermal metamaterials that can effectively create “heat superconductors” along specific paths while simultaneously acting as insulators in other directions. These directional thermal conductors could potentially channel heat away from sensitive components with unprecedented efficiency, enabling much higher power densities than currently possible with isotropic materials.

AI-Optimized Thermal Management

Artificial intelligence itself is being applied to thermal management challenges:

- Machine Learning Control Systems:

- Neural networks for thermal prediction

- Reinforcement learning for cooling optimization

- Anomaly detection for early problem identification

- Workload characterization and thermal profiling

- Continuous system improvement through learning

- Digital Twin Technology:

- Real-time thermal simulation models

- Predictive thermal behavior modeling

- What-if scenario analysis

- Optimization testing in virtual environments

- Calibrated models reflecting actual system behavior

- Autonomous Thermal Management:

- Self-optimizing cooling systems

- Automated response to changing conditions

- Predictive maintenance scheduling

- Self-healing capabilities

- Minimal human intervention requirements

Future Cooling Innovation Comparison

| Innovation Area | Potential Impact | Timeline to Mainstream | Development Stage | Key Challenges |

|---|---|---|---|---|

| Chip-Integrated Cooling | Revolutionary | 3-5 years | Advanced R&D | Manufacturing integration |

| Advanced Materials | Transformative | 2-4 years | Early commercial | Cost and scale |

| AI-Driven Control | Significant | 1-3 years | Early adoption | System complexity |

| Quantum Thermal Management | Revolutionary | 5-10+ years | Fundamental research | Theoretical understanding |

| Biological Inspiration | Transformative | 3-7 years | Applied research | Biological-mechanical interfaces |

| Nanoscale Engineering | Revolutionary | 4-8 years | Advanced R&D | Manufacturing precision |

Sustainability and Circular Economy

Environmental considerations are increasingly shaping cooling innovation:

- Zero-Impact Cooling Goals:

- Carbon-neutral cooling systems

- Zero water consumption approaches

- Biodegradable and sustainable materials

- Closed-loop resource cycles

- Positive environmental impact designs

- Energy Transformation:

- Waste heat to energy conversion

- Thermal energy harvesting

- Heat-driven cooling cycles

- Energy recovery and reuse

- Net-positive energy systems

- Circular Design Principles:

- Design for disassembly and recycling

- Modular components for easy upgrade

- Remanufacturing and refurbishment

- Material passport tracking

- Closed-loop material flows

Ready for the fascinating part? The organizations most successfully navigating the rapidly evolving AI cooling landscape are adopting an “infrastructure as code” mindset—treating cooling systems as flexible, programmable resources rather than fixed installations. This approach emphasizes software-defined control systems, modular physical components, standardized interfaces, and data-driven optimization. By building adaptability into their fundamental infrastructure approach, these organizations can more easily incorporate new cooling technologies as they emerge, without requiring complete system replacements.

Frequently Asked Questions

Q1: How do I determine the most appropriate cooling technology for my specific AI hardware deployment?

Determining the most appropriate cooling technology for AI hardware requires a systematic assessment approach: First, evaluate your thermal requirements—calculate the total heat load, power density, and temperature sensitivity of your specific AI accelerators and supporting components. For systems below 300W per accelerator, advanced air cooling may be sufficient; 300-600W typically requires direct liquid cooling; above 600W generally necessitates advanced liquid or immersion approaches. Second, consider your facility constraints—available space, structural capacity, existing infrastructure, and expansion plans may limit your options or require significant modifications for certain technologies. Third, analyze your operational capabilities—different cooling technologies require varying levels of expertise, maintenance procedures, and support systems. Ensure your team can effectively operate and maintain the chosen solution. Fourth, evaluate your economic parameters—consider not just the initial capital cost but the total cost of ownership including energy, maintenance, reliability impacts, and performance benefits. Fifth, assess your risk tolerance—more established technologies offer lower implementation risk but potentially lower performance, while cutting-edge approaches may provide superior cooling but with higher implementation uncertainty. The most appropriate solution is rarely universal—it depends on your specific context, priorities, and constraints. Many organizations find that hybrid approaches combining multiple cooling technologies optimized for different parts of the system provide the best overall results.

Q2: What are the most cost-effective approaches to upgrading cooling for existing AI infrastructure?

The most cost-effective approaches to upgrading cooling for existing AI infrastructure, ranked by typical ROI: First, optimization of existing systems—implementing advanced controls, optimizing setpoints, improving airflow management, and enhancing monitoring can improve cooling efficiency by 10-30% with minimal investment. Second, targeted liquid cooling—implementing direct liquid cooling only for the highest-power components (typically AI accelerators) while maintaining existing cooling for other components can provide substantial thermal improvement with moderate investment. Third, rear door heat exchangers—adding water-cooled doors to existing racks can increase cooling capacity by 2-3x with relatively simple installation and minimal disruption. Fourth, hybrid immersion solutions—immersing only the highest-density components while maintaining conventional cooling for the rest of the system can provide many immersion benefits with lower implementation complexity. Fifth, enhanced thermal interfaces—upgrading to advanced thermal interface materials like liquid metal can reduce component temperatures by 5-15°C for minimal cost. The highest ROI typically comes from addressing the most restrictive thermal bottlenecks first, which often aren’t the most obvious components. For most systems, a combination of optimization, targeted liquid cooling, and enhanced thermal interfaces provides the best initial return on investment. More substantial upgrades should be considered after these optimization opportunities are exhausted, or when hardware reaches end of life.

Q3: How does cooling technology selection impact the total cost of ownership for AI systems?

Cooling technology selection impacts total cost of ownership (TCO) for AI systems through multiple mechanisms: First, capital expenditure—advanced cooling technologies typically require higher initial investment but may reduce other infrastructure costs like raised floors or oversized power systems. Second, energy costs—more efficient cooling can reduce operational expenses by 20-40%, creating substantial savings over system lifetime. Third, hardware lifespan—superior cooling can extend AI accelerator life by 30-50% by reducing thermal stress, significantly amortizing expensive hardware costs. Fourth, performance optimization—better cooling prevents thermal throttling, potentially improving computational throughput by 10-25% and increasing effective value per dollar spent. Fifth, density improvements—advanced cooling enables higher compute density, reducing facility costs per unit of computation. Sixth, reliability impacts—improved cooling typically reduces failure rates by 20-40%, decreasing maintenance costs and downtime losses. When all factors are considered, the cooling technology with the lowest initial cost rarely delivers the lowest TCO. For high-value AI infrastructure, premium cooling solutions often reduce lifetime costs by 15-30% compared to minimum viable cooling, despite higher upfront investment. This TCO advantage becomes increasingly significant as AI accelerator costs rise and as applications become more mission-critical, fundamentally changing the economic equation for cooling investment decisions.

Q4: What are the key considerations for implementing liquid cooling for AI hardware?

When implementing liquid cooling for AI hardware, several key factors should guide your approach: First, system compatibility—ensure your AI accelerators have compatible liquid cooling blocks available or select hardware specifically designed for liquid cooling. Retrofitting can be challenging and may void warranties. Second, facility readiness—assess your existing infrastructure for water availability, distribution pathways, floor loading capacity, and leak containment. These factors may require significant facility modifications before liquid cooling can be implemented. Third, implementation strategy—determine whether to implement liquid cooling comprehensively or take a targeted approach focusing only on AI accelerators initially. For most organizations, a phased approach starting with accelerator-only cooling provides the best balance of performance improvement and implementation complexity. Fourth, redundancy and reliability—design appropriate redundancy into pumps, heat exchangers, and distribution systems based on your availability requirements. Fifth, monitoring and management—implement comprehensive temperature, flow, and pressure monitoring to ensure proper operation and enable proactive maintenance. Sixth, operational readiness—liquid cooling requires different maintenance procedures, monitoring approaches, and emergency protocols. Invest in staff training and updated operational documentation before implementation. A successful implementation typically begins with a pilot deployment that allows your organization to develop expertise and refine procedures before scaling to production environments. This approach significantly reduces risk and improves outcomes compared to attempting large-scale transitions without prior experience.

Q5: How should organizations prepare for future AI cooling requirements as hardware continues to evolve?

Organizations should prepare for future AI cooling requirements through several strategic approaches: First, adopt modular and flexible infrastructure—implement cooling distribution systems with standardized interfaces, excess capacity, and the ability to support multiple cooling technologies simultaneously. This creates the foundation for adaptability as requirements change. Second, design for density headroom—when building new infrastructure, design core systems for 2-3x the current maximum power density to accommodate future growth without fundamental rebuilding. Third, implement comprehensive monitoring—deploy detailed thermal and performance monitoring across all systems to understand current limitations and identify emerging bottlenecks before they become critical. Fourth, develop internal expertise—invest in staff training and knowledge development around advanced cooling technologies, even before full implementation. This builds the capability to evaluate and adopt new approaches as they emerge. Fifth, engage in scenario planning—regularly develop and update multiple future scenarios for AI hardware evolution and corresponding cooling requirements, identifying key decision triggers and technology milestones. Sixth, establish strategic vendor partnerships—work closely with both hardware and cooling technology vendors to gain early insight into roadmaps and emerging solutions. The most future-proof approach combines physical infrastructure flexibility with sophisticated management systems that can optimize across multiple cooling technologies. This hybrid, software-defined approach to cooling infrastructure provides the greatest adaptability to the rapidly evolving AI hardware landscape, allowing organizations to incorporate new cooling technologies as they emerge without requiring complete system replacements.