Introduction

Aluminum CNC machining is a precision manufacturing process used to create highly accurate parts from aluminum materials. Whether you’re a business owner, engineer, or designer, understanding the basics of aluminum CNC machining can help you make informed decisions about material selection and the best machining practices for your projects. This guide will provide a detailed look at aluminum CNC machining, from the types of aluminum used to the machining process itself, and how to optimize your operations for better efficiency and cost savings.

1. What is Aluminum CNC Machining?

Aluminum CNC machining refers to the use of computer numerical control (CNC) machines to manufacture parts from aluminum. CNC machines use pre-programmed software to control the movement of tools that cut and shape aluminum materials with high precision. The process is commonly used to produce components for industries such as aerospace, automotive, and electronics, where precision and durability are crucial. But here’s the kicker—aluminum is the material of choice for many CNC applications due to its versatility and advantageous properties.

CNC machining involves a variety of techniques like milling, turning, and drilling, with the choice of method depending on the part’s design. Aluminum’s low density, coupled with its excellent strength-to-weight ratio, makes it perfect for parts that need to be both strong and lightweight. These qualities are vital for industries that require both functionality and efficiency in their products.

Table: Common Applications of Aluminum CNC Machining

| Application Area | Examples of Parts | Key Benefits |

|---|---|---|

| Aerospace | Aircraft components, wings, engine parts | Lightweight, high strength |

| Automotive | Engine blocks, wheels, chassis | Durability, corrosion resistance |

| Electronics | Heat sinks, housings, connectors | Thermal conductivity, precision |

2. Why Should You Choose Aluminum for CNC Machining?

Choosing aluminum for CNC machining is often driven by its unique combination of properties. Aluminum is lightweight, which makes it ideal for applications where weight reduction is important without sacrificing strength. This is why aluminum is used extensively in aerospace and automotive industries. But wait, there’s more—aluminum also boasts excellent resistance to corrosion, which makes it highly durable in harsh environments.

Another key benefit of aluminum in CNC machining is its cost-effectiveness. Compared to other metals like titanium or stainless steel, aluminum is generally more affordable and easier to work with. Its machinability ensures faster production times, which ultimately translates into lower manufacturing costs. The combination of affordability and performance makes aluminum a go-to choice for many manufacturers looking to optimize their production process.

Table: Comparison of Aluminum with Other Materials for CNC Machining

| Material | Weight (g/cm³) | Corrosion Resistance | Cost | Machinability |

|---|---|---|---|---|

| Aluminum | 2.70 | High | Low | Excellent |

| Steel | 7.85 | Moderate | Medium | Good |

| Titanium | 4.43 | Excellent | High | Moderate |

3. What Are the Different Types of Aluminum Used in CNC Machining?

Aluminum comes in various grades, each with distinct properties suited to different machining applications. The most commonly used grades include 6061, 7075, and 2024, each offering unique advantages depending on the specific needs of the project.

The 6061 grade is highly versatile and is frequently used for general machining tasks. It is well-suited for both structural and aesthetic components due to its excellent weldability and strength. Meanwhile, 7075 aluminum is known for its exceptional strength and is typically used in more demanding applications, such as aerospace and military components. For projects requiring high fatigue strength, 2024 aluminum is a top choice.

Here’s the real story—selecting the right aluminum grade depends on the specific requirements of your project, such as strength, weight, and resistance to corrosion.

Table: Comparison of Common Aluminum Grades for CNC Machining

| Grade | Strength | Workability | Applications |

|---|---|---|---|

| 6061 | Good | Excellent | Automotive, marine, general-purpose |

| 7075 | Very High | Moderate | Aerospace, military, high-strength |

| 2024 | High | Good | Aircraft, structural components |

4. How Does Aluminum CNC Machining Work?

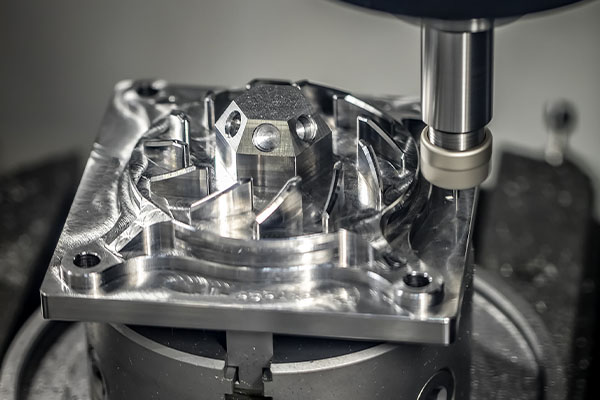

The aluminum CNC machining process involves several key steps that ensure the final product meets precise specifications. Initially, a digital design is created using CAD (computer-aided design) software, which is then converted into machine code using CAM (computer-aided manufacturing) software. This code guides the CNC machine in performing tasks such as cutting, drilling, and milling. The machine uses various tools to remove material from an aluminum block, gradually shaping it into the desired part.

Ready for the good part? The efficiency of CNC machining allows for high-volume production, making it ideal for industries that need both quality and speed. CNC machines can operate 24/7, ensuring a continuous flow of production, which is particularly valuable in mass production scenarios. In addition, the use of advanced tools and high-tech machines ensures that each part is manufactured with a high degree of accuracy.

Table: CNC Machining Process Breakdown

| Step | Description |

|---|---|

| Design | CAD model created and converted into CAM code |

| Cutting/Drilling | CNC machine removes material to achieve desired shape |

| Finishing | Surface treatment to enhance appearance and functionality |

5. What Are the Benefits of Aluminum CNC Machining Over Other Materials?

When compared to other materials, aluminum offers numerous advantages in CNC machining. Its low density ensures lightweight components without compromising strength, which is essential for industries that rely on the efficient performance of their products. Additionally, aluminum’s natural corrosion resistance means it can withstand harsh environmental conditions, making it ideal for applications in automotive and aerospace industries.

But here’s the kicker—aluminum is also one of the most cost-effective metals for CNC machining. It is easy to machine, which reduces tool wear and minimizes machine downtime. This results in faster production times and lower costs. When looking for a material that balances performance and affordability, aluminum is a clear winner.

Table: Aluminum vs. Steel in CNC Machining

| Property | Aluminum | Steel |

|---|---|---|

| Weight | Lightweight | Heavier |

| Corrosion Resistance | Excellent | Moderate |

| Cost | Low | Medium-High |

6. What Are the Challenges of Aluminum CNC Machining?

While aluminum offers numerous benefits, machining it does come with some challenges. One of the most common issues is that aluminum can easily overheat during the machining process, especially when cutting at high speeds. This can lead to tool wear and a decrease in the quality of the finished part. To mitigate this, cooling systems such as flood coolant or misting are often used to keep the material and the tools cool during operation.

Another challenge is that aluminum is prone to burr formation, especially when using high-speed cutting tools. These burrs can affect the quality of the finished part, requiring additional finishing processes like deburring. Furthermore, maintaining precision during aluminum CNC machining requires careful machine settings and a steady hand.

Table: Common Challenges in Aluminum CNC Machining

| Challenge | Solution |

|---|---|

| Overheating | Use cooling systems like misting or flood coolant |

| Burr Formation | Implement deburring techniques post-machining |

| Precision Control | Regular calibration and fine-tuning of machine settings |

7. How Do You Choose the Right CNC Machine for Aluminum?

Choosing the right CNC machine for aluminum machining depends on several factors, such as the type of aluminum, the complexity of the part, and the required precision. Generally, high-speed CNC machines with powerful spindles are recommended for aluminum, as they are better equipped to handle the material’s properties.

It’s also important to consider the machine’s versatility. A multi-axis CNC machine allows for more flexibility in machining aluminum parts, especially those with complex shapes. The right machine should be capable of handling both the volume and precision needed for your aluminum machining projects.

Table: Factors to Consider When Choosing a CNC Machine for Aluminum

| Factor | Consideration |

|---|---|

| Speed | High-speed spindles for efficient machining |

| Versatility | Multi-axis capabilities for complex designs |

| Precision | Machines capable of producing tight tolerances |

8. What Are the Key Tools and Equipment Used in Aluminum CNC Machining?

The tools and equipment used in aluminum CNC machining are critical to achieving the desired precision and efficiency in the machining process. A variety of cutting tools, such as end mills, drills, and inserts, are commonly used to cut and shape aluminum. These tools are designed to handle the specific properties of aluminum, including its softness compared to harder metals like steel.

Here’s the real story—choosing the right tool material is essential to extend tool life and maintain performance. Carbide tools, for example, are frequently used for aluminum machining because they are hard, durable, and maintain sharpness over time. These tools are especially useful when dealing with high-speed operations and can withstand the increased temperatures generated during the machining process.

In addition to cutting tools, the CNC machine itself plays a pivotal role in ensuring smooth and efficient machining. Machines equipped with high-speed spindles and precision tool holders are ideal for aluminum machining. These machines can work at higher speeds and provide the accuracy needed for detailed work. Moreover, appropriate machine settings, such as feed rates and cutting speeds, are necessary to optimize both tool life and the quality of the finished part.

Table: Common Tools Used in Aluminum CNC Machining

| Tool Type | Use | Recommended Material |

|---|---|---|

| End Mills | Milling operations, surface finishing | Carbide |

| Drills | Drilling holes in aluminum components | High-Speed Steel |

| Inserts | Cutting, shaping, and trimming edges | Carbide |

9. How Do You Optimize CNC Machining for Aluminum?

Optimizing CNC machining for aluminum involves adjusting several key parameters to ensure efficiency, high precision, and minimal waste. The first factor to consider is the cutting speed. Aluminum requires high cutting speeds compared to other metals, but the challenge lies in ensuring that the speed does not cause excessive heat buildup, which can damage the tool and part.

Ready for the good part? You can optimize machining by carefully selecting the right feed rate and depth of cut. A higher feed rate and shallow depth of cut may reduce tool wear but may also increase machining time. The ideal balance will depend on the part’s design and complexity. Additionally, using appropriate coolant or lubrication can help maintain cutting efficiency and prevent overheating, further ensuring that both tool life and part quality are optimized.

Tool path strategies also play a critical role in optimizing CNC machining. A well-designed tool path minimizes unnecessary tool movements and reduces machining time, making it crucial for improving production efficiency. Using advanced CAD and CAM software allows manufacturers to design more efficient tool paths, which can lead to faster cycle times and more accurate parts.

Table: Factors Affecting Aluminum CNC Machining Optimization

| Factor | Ideal Setting | Impact |

|---|---|---|

| Cutting Speed | High but controlled | Prevents heat buildup and wear |

| Feed Rate | Adjusted to part complexity | Affects cycle time and precision |

| Coolant Usage | Appropriate cooling/lubrication | Reduces tool wear and heat |

10. How Does CNC Machining of Aluminum Affect Product Quality?

CNC machining of aluminum significantly influences the quality of the final product. Due to the high precision involved, the machining process ensures that parts meet stringent tolerances, especially when working with tight designs in industries like aerospace and automotive. Achieving high-quality parts requires careful attention to the machining parameters, including cutting speed, tool choice, and cooling methods.

This is where it gets interesting—aluminum is highly responsive to machining processes that focus on precision. With the right machine settings and cutting tools, the machining process can yield parts with smooth surface finishes, tight tolerances, and minimal defects. The use of CNC machines also helps minimize human error, ensuring consistent quality across production runs. However, poor machining practices, such as improper tool choice or inadequate cooling, can lead to defects like surface roughness, burrs, or dimensional inaccuracies.

Additionally, surface finishing processes such as anodizing or powder coating are often used in aluminum machining to improve product aesthetics and enhance performance. These finishing treatments add another layer of protection and durability to the parts, further improving their functionality.

Table: Surface Finishing Options for Aluminum Parts

| Surface Finish Type | Benefits | Common Applications |

|---|---|---|

| Anodizing | Increases corrosion resistance, aesthetics | Aerospace, automotive components |

| Powder Coating | Adds color, improves durability | Consumer products, machinery |

| Polishing | Provides smooth, shiny surface | Electronics, decorative items |

11. How Much Does Aluminum CNC Machining Cost?

The cost of aluminum CNC machining depends on several factors, including material choice, complexity of the design, and the machining processes used. In general, aluminum is an affordable material for CNC machining, especially compared to harder metals like titanium or steel. However, the complexity of the part and the number of machining operations required can increase the cost.

What’s the real story? While the material cost for aluminum may be relatively low, the labor, machine time, and tooling costs can add up. For example, a complex part with intricate designs or multiple machining operations will require more machine time and potentially more expensive tools, which can increase the overall cost. On the other hand, simple parts with straightforward designs can be machined at a lower cost.

Another factor that impacts cost is the volume of parts being produced. The cost per part typically decreases as production volume increases, thanks to economies of scale. Larger runs of aluminum parts allow manufacturers to amortize the cost of tooling and setup across multiple units, lowering the cost per part.

Table: Factors Influencing Aluminum CNC Machining Costs

| Factor | Impact on Cost |

|---|---|

| Material Choice | Aluminum is relatively inexpensive |

| Part Complexity | Complex designs require more machine time |

| Production Volume | Larger volumes lower per-part cost |

12. How Long Does Aluminum CNC Machining Take?

The time required for aluminum CNC machining can vary based on the complexity of the part, the size of the part, and the number of machining operations required. For simple parts with minimal machining, the process can take just a few hours. However, more intricate designs with multiple operations may take longer, potentially days or even weeks depending on the production volume.

Here’s where it gets interesting—the use of high-speed CNC machines can significantly reduce machining time, especially when combined with optimized cutting speeds and efficient tool paths. CNC machines can also operate continuously, allowing for round-the-clock production, which is especially valuable in mass production scenarios.

The time required for aluminum CNC machining is also influenced by the need for secondary operations such as deburring, polishing, or surface finishing. These additional steps can add extra time but are necessary for ensuring the final part meets the required quality standards.

Table: Average Machining Times for Aluminum Parts

| Part Complexity | Estimated Machining Time | Notes |

|---|---|---|

| Simple Design | 1-4 hours | Basic shapes, few operations |

| Complex Design | 4-20 hours | Multiple operations required |

| Mass Production Run | 1-2 hours per part | Higher volume, less time |

13. How to Maintain Aluminum CNC Machines for Long-Term Performance?

Maintaining CNC machines is crucial for ensuring long-term performance and minimizing downtime. For aluminum CNC machining, regular maintenance is essential to prevent wear and tear on both the machine and the tools. One key maintenance task is keeping the machine clean and free from debris. Dust and aluminum chips can accumulate and affect the precision of the machine if not cleaned regularly.

Additionally, it’s important to check the machine’s lubrication system and ensure that all moving parts are well-lubricated to reduce friction and prevent damage. Tool wear is another critical area of maintenance—frequent checks should be made to ensure that cutting tools remain sharp and in good condition. Replacing worn tools before they become ineffective helps maintain the quality of the finished parts.

A well-maintained CNC machine not only performs better but also lasts longer, reducing the need for costly repairs or replacements down the line.

Table: Key Maintenance Tasks for Aluminum CNC Machines

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Cleaning | Daily | Prevents buildup and maintains precision |

| Lubrication | Weekly/Monthly | Reduces friction and wear |

| Tool Replacement | As Needed | Ensures cutting accuracy |

14. What Are the Environmental Considerations for Aluminum CNC Machining?

Aluminum CNC machining has several environmental considerations that manufacturers must address to reduce the environmental impact of their operations. Aluminum itself is a highly recyclable material, which reduces the need for new raw materials and lowers environmental impact. However, the machining process does generate waste, such as aluminum chips, which need to be disposed of or recycled properly.

Another important factor is energy consumption. CNC machines, particularly those running continuously, can consume a significant amount of energy. To mitigate this, many manufacturers are adopting energy-efficient machines and processes that help reduce electricity consumption and minimize their carbon footprint. Additionally, using environmentally friendly coolants and lubricants helps minimize the use of harmful chemicals in the machining process.

Table: Environmental Impact of Aluminum CNC Machining

| Environmental Factor | Mitigation Strategy |

|---|---|

| Material Waste | Recycling aluminum chips and scrap |

| Energy Consumption | Use energy-efficient CNC machines |

| Chemical Usage | Implement environmentally friendly coolants |

15. How to Find a Reliable CNC Machining Service for Aluminum Parts?

Finding a reliable CNC machining service for aluminum parts requires careful research and consideration. Start by looking for companies with a proven track record in aluminum machining and ask for case studies or examples of previous work. Additionally, it’s important to evaluate the company’s equipment and capabilities—make sure they use high-quality machines that can handle the precision required for aluminum parts.

Another key consideration is communication. A reliable CNC machining service should be responsive and willing to work closely with you to understand your project requirements. Ask about their lead times, quality assurance processes, and pricing structure to ensure you’re getting a service that aligns with your needs.

Table: Criteria for Choosing a CNC Machining Service

| Criteria | What to Look For |

|---|---|

| Equipment | High-quality, well-maintained CNC machines |

| Experience | Proven expertise in aluminum machining |

| Customer Service | Responsive communication and flexibility |

FAQ Section

Q1: What is aluminum CNC machining?

Aluminum CNC machining is a manufacturing process where computer-controlled machines are used to cut and shape aluminum materials with high precision.

Q2: How does aluminum CNC machining work?

The process uses a CAD model that is translated into machine code, guiding the CNC machine to cut, mill, or drill aluminum into precise shapes.

Q3: What types of aluminum are used in CNC machining?

Common types of aluminum used in CNC machining include 6061, 7075, and 2024, each with specific characteristics suited for various applications.

Q4: What are the benefits of using aluminum for CNC machining?

Aluminum offers lightweight properties, corrosion resistance, and cost-effectiveness, making it ideal for industries like aerospace and automotive.

Q5: How do I choose the right CNC machine for aluminum machining?

The choice of machine depends on the type of aluminum, complexity of the part, and the required precision, with high-speed and multi-axis machines being ideal for aluminum.