Introduction

Aluminum CNC machining is an essential process for many industries, providing high precision, efficiency, and versatility. In this article, we’ll explore the key benefits of aluminum CNC machining, discuss its various applications, and also look at some alternative materials. Whether you are a manufacturer or a buyer considering this process, understanding the advantages and challenges of aluminum CNC machining is crucial. So, let’s dive into the world of aluminum machining and explore why it’s such a popular choice.

1. What Are the Key Benefits of Aluminum CNC Machining?

Aluminum CNC machining offers several advantages that make it the go-to choice for many manufacturers. First, its lightweight properties ensure easy handling, which is crucial for industries like aerospace and automotive, where weight reduction can lead to better performance and fuel efficiency. But here’s the kicker: Aluminum is strong, yet lightweight, offering the perfect balance for high-stress applications.

The cost-effectiveness of aluminum also makes it an attractive material choice. Compared to steel and titanium, aluminum is more affordable, meaning manufacturers can achieve high-quality components without breaking the bank. This is especially important for industries that need large volumes of parts but need to keep costs under control. Ready for the good part? Aluminum is easily machinable, reducing the time and cost of manufacturing.

Lastly, aluminum is highly versatile, making it suitable for a wide range of industries. Whether it’s in electronics, automotive, or medical applications, aluminum’s adaptability means it can be used for everything from enclosures to precision mechanical components.

| Benefit | Explanation |

|---|---|

| Lightweight | Reduces handling costs and improves performance in specific industries. |

| Cost-effective | Lower material and manufacturing costs compared to other metals. |

| Versatile | Used in a wide variety of industries and applications. |

| Easily Machinable | Quick machining speeds and easy to work with. |

2. Why Is Aluminum Popular in CNC Machining?

There are several reasons why aluminum is one of the most popular materials used in CNC machining. You might be wondering what makes it such a preferred choice over others. First off, aluminum is incredibly corrosion-resistant, which means it can maintain its integrity even when exposed to the elements. This is particularly important in industries like aerospace and automotive, where parts are often exposed to harsh environmental conditions.

Another reason for aluminum’s popularity is its machinability. Compared to harder metals like steel or titanium, aluminum is much easier to machine, allowing for faster production times and reducing tool wear. This makes it ideal for both prototyping and high-volume manufacturing. Additionally, aluminum has excellent thermal conductivity, which is crucial in industries that require efficient heat dissipation, such as electronics.

Here’s the deal: aluminum’s properties, including its strength-to-weight ratio, resistance to corrosion, and ease of machining, make it an obvious choice for CNC machining.

| Property | Why It’s Beneficial for CNC Machining |

|---|---|

| Corrosion Resistance | Keeps parts functional and durable in challenging environments. |

| Machinability | Quick processing and low tool wear. |

| Thermal Conductivity | Ideal for components requiring effective heat dissipation. |

| Strength-to-Weight Ratio | Provides strength without the added weight, crucial for specific industries. |

3. What Are the Different Types of CNC Machining Methods for Aluminum?

When it comes to CNC machining aluminum, there are several methods used depending on the requirements of the project. So, what’s the real story behind these methods? Let’s break them down:

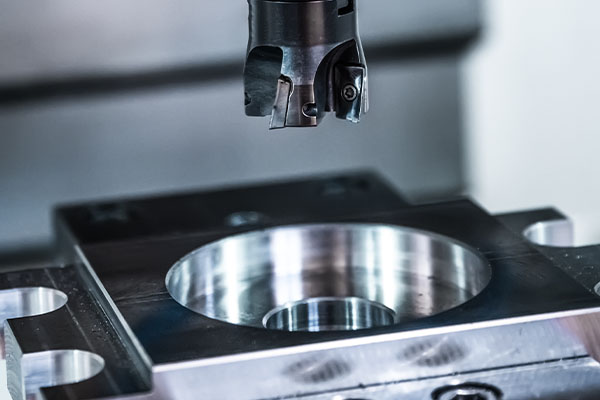

- Milling is one of the most commonly used methods for aluminum machining. CNC milling machines use rotary cutters to remove material from the workpiece, making it an excellent option for shaping complex geometries and intricate designs.

- Turning involves rotating the aluminum material against a cutting tool to create cylindrical parts. This method is great for producing high-precision components with a high degree of symmetry.

- Drilling is used for creating holes in aluminum components, which is a common requirement in many manufacturing processes.

- Laser cutting is another technique that can be used to cut aluminum parts with extreme precision, especially for thin sheets.

These methods allow manufacturers to tailor the machining process to the specific needs of the part being produced, providing maximum flexibility.

| Machining Method | Best For |

|---|---|

| Milling | Complex shapes and geometries |

| Turning | Cylindrical parts and high-precision components |

| Drilling | Creating holes in aluminum components |

| Laser Cutting | High-precision cutting for thin aluminum sheets |

4. How Does Aluminum CNC Machining Compare to Other Materials?

Aluminum is often compared to other metals like steel, titanium, and brass in CNC machining. What’s the real story? Let’s break it down:

- Compared to steel, aluminum is lighter and easier to machine. Steel may offer more strength, but it comes at a higher cost and requires more energy to process.

- Titanium is stronger and more heat-resistant than aluminum but is much more expensive and harder to machine, making it less practical for many applications.

- Brass offers better machinability than aluminum but lacks its strength-to-weight ratio and is not as cost-effective for large-scale operations.

While each material has its advantages, aluminum stands out for its combination of affordability, machinability, and versatility.

| Material | Pros | Cons |

|---|---|---|

| Aluminum | Lightweight, cost-effective, easy to machine | Less strong than steel or titanium |

| Steel | High strength and durability | Heavier, more difficult to machine |

| Titanium | Strong, heat-resistant | Expensive, difficult to machine |

| Brass | Excellent machinability | Not as strong, less cost-effective |

5. What Are the Environmental Benefits of Using Aluminum in CNC Machining?

Aluminum is widely known for being a sustainable material. This is where it gets interesting: aluminum is one of the most recyclable metals available. It can be recycled infinitely without losing its properties, making it a great choice for companies looking to reduce their environmental footprint.

Additionally, aluminum is lighter than many other metals, which means that products made from aluminum require less energy to transport, reducing carbon emissions. In manufacturing, using recycled aluminum can significantly lower the energy consumption required for processing, which makes it even more environmentally friendly.

By choosing aluminum for CNC machining, companies can contribute to sustainability while still achieving high-quality results.

| Environmental Benefit | Explanation |

|---|---|

| Recyclability | Aluminum can be recycled indefinitely without losing its properties. |

| Energy Efficiency | Using recycled aluminum reduces energy consumption in manufacturing. |

| Lightweight | Lighter weight results in lower transportation costs and carbon emissions. |

6. How Does the Cost of Aluminum CNC Machining Compare to Other Materials?

Aluminum is often the preferred choice when it comes to balancing cost and quality. But here’s the kicker: aluminum typically costs less than steel and titanium, making it an attractive option for manufacturers who need to keep costs down while maintaining quality.

When compared to steel, the material cost for aluminum is generally lower, and the ease of machining aluminum can also reduce labor and tooling costs. However, high-end aluminum alloys can sometimes be more expensive than basic steel grades, depending on the alloy’s specific properties.

| Material | Material Cost | Machining Cost | Total Cost |

|---|---|---|---|

| Aluminum | Lower | Lower | Generally lower |

| Steel | Higher | Higher | Generally higher |

| Titanium | Much higher | Much higher | Much higher |

7. What Are the Challenges of CNC Machining with Aluminum?

Despite its advantages, CNC machining with aluminum does come with its own set of challenges. So, what are the common issues manufacturers face?

- Tool wear: Aluminum is a relatively soft material, but it can be abrasive on tools, especially at high speeds. Regular maintenance or using more durable tooling materials can help mitigate this issue.

- Material distortion: When cutting aluminum, heat buildup can cause distortion or warping of the material. Using effective cooling methods during machining can minimize this risk.

- Surface finish: Achieving a smooth surface finish on aluminum parts can sometimes be tricky. The right combination of tooling, cutting parameters, and post-machining processes can ensure high-quality results.

| Challenge | Cause | Solution |

|---|---|---|

| Tool Wear | Aluminum is soft, causing wear | Use durable tooling materials |

| Material Distortion | Heat buildup during machining | Employ proper cooling methods |

| Surface Finish | Difficult to achieve smooth finish | Optimize tooling and machining parameters |

8. What Are the Common Applications of Aluminum CNC Machining?

Aluminum CNC machining is used in a wide range of industries due to the material’s strength, versatility, and ease of machining. Ready for the good part? Here are some of the most common applications:

- Aerospace: Aluminum is essential in the aerospace industry for manufacturing lightweight yet durable components like aircraft frames, wings, and engine parts.

- Automotive: Aluminum is used extensively in the automotive industry for making lightweight parts that improve fuel efficiency and performance, such as wheels, engine components, and body panels.

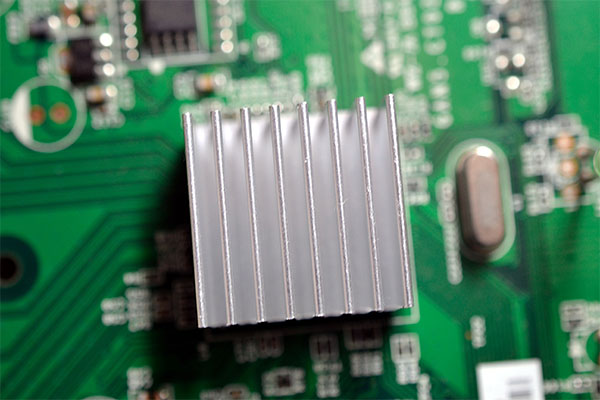

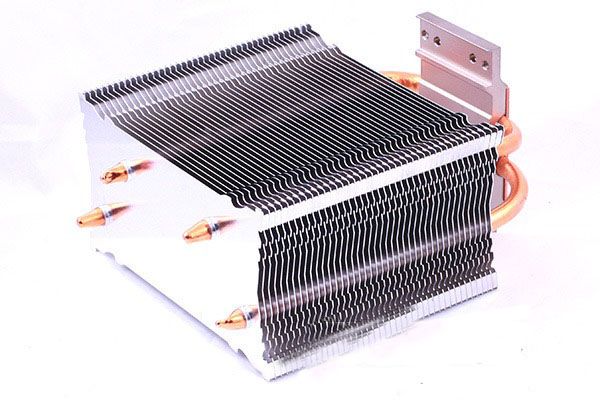

- Electronics: From heat sinks to enclosures, aluminum is often used in electronics to provide both structural support and heat dissipation.

| Industry | Application | Advantages of Aluminum |

|---|---|---|

| Aerospace | Aircraft frames, wings, engine components | Lightweight, durable, high strength |

| Automotive | Engine parts, wheels, body panels | Fuel efficiency, performance |

| Electronics | Heat sinks, enclosures | Effective heat dissipation |

9. How Do Tolerances and Surface Finishes Impact Aluminum CNC Machining?

When machining aluminum, tight tolerances and high-quality surface finishes are critical. In industries like aerospace and medical devices, even the smallest deviation from the required specifications can lead to performance issues. But here’s the kicker: achieving these tight tolerances and smooth finishes requires advanced machining techniques and the right equipment.

The surface finish can also affect the performance of aluminum parts. For example, in components used for heat dissipation, a smooth finish is essential to ensure optimal heat transfer. Achieving the required surface finish often involves additional processes like polishing or coating.

| Process | Impact on Machining | Importance |

|---|---|---|

| Tolerances | Tight tolerances required for high-performance components | Ensures precision and reliability |

| Surface Finish | Smooth finishes improve function and appearance | Crucial for heat dissipation and aesthetics |

10. What Are the Alternatives to Aluminum CNC Machining?

While aluminum is an excellent choice for many CNC machining projects, there are several alternatives to consider depending on the application. What’s the real story? Let’s compare some common materials:

- Steel offers more strength but is heavier and more difficult to machine.

- Brass is highly machinable but lacks the strength and corrosion resistance of aluminum.

- Titanium offers superior strength and heat resistance but at a much higher cost.

Each material has its place depending on the specific needs of the application, so it’s important to consider all the factors before choosing an alternative.

| Material | Strength | Machinability | Cost |

|---|---|---|---|

| Aluminum | Moderate | High | Low |

| Steel | High | Moderate | Moderate |

| Brass | Moderate | Very High | Low to Moderate |

| Titanium | Very High | Low | Very High |

11. How Do Different Aluminum Grades Affect CNC Machining?

Aluminum alloys come in a variety of grades, each offering different characteristics suited to specific applications. What’s the real story behind these different grades?

- 6061 aluminum is one of the most commonly used alloys due to its balance of strength, machinability, and corrosion resistance.

- 7075 aluminum is stronger and more durable, making it ideal for high-stress applications, but it is also harder to machine.

Choosing the right grade of aluminum is crucial for ensuring that the final product meets the required performance and cost parameters.

| Grade | Strength | Machinability | Common Applications |

|---|---|---|---|

| 6061 | Moderate | High | General manufacturing, structural parts |

| 7075 | Very High | Moderate | Aerospace, military, high-performance applications |

12. What Are the Best Practices for CNC Machining Aluminum Parts?

To get the best results from aluminum CNC machining, it’s essential to follow best practices. Ready for the good part? These practices can help you achieve high precision, reduce costs, and improve overall efficiency.

Some key practices include optimizing cutting speeds and feeds to avoid tool wear, using lubrication or cooling systems to prevent overheating, and selecting the right tooling materials to enhance the quality of the parts.

| Best Practice | Benefit |

|---|---|

| Optimizing cutting speeds | Reduces tool wear and improves efficiency |

| Using lubrication | Minimizes heat and improves machining performance |

| Selecting proper tooling | Enhances finish quality and tool life |

13. How Can You Improve Efficiency in Aluminum CNC Machining?

Improving efficiency in aluminum CNC machining can lead to significant cost savings and faster production times. But here’s the kicker: using the right equipment and strategies can make all the difference.

For instance, upgrading to advanced CNC machines with automated features can reduce setup times and improve accuracy. Additionally, using high-performance cutting tools designed for aluminum can speed up the machining process and reduce wear.

| Efficiency Improvement | Impact |

|---|---|

| Automated CNC machines | Reduces setup time and improves consistency |

| High-performance tools | Speeds up machining and reduces tool wear |

| Process optimization | Improves overall workflow and reduces waste |

14. What Are the Future Trends in Aluminum CNC Machining?

The world of aluminum CNC machining is constantly evolving, with new technologies and methods emerging regularly. What’s the real story? The future is all about automation, AI, and Industry 4.0.

AI-driven CNC machines can analyze data and adjust machining parameters in real-time to optimize performance. Additionally, additive manufacturing (3D printing) is being integrated with CNC machining to create even more complex and precise parts.

| Trend | Impact |

|---|---|

| Automation | Increases efficiency and reduces human error |

| AI Integration | Optimizes machine performance in real-time |

| Additive Manufacturing | Enables the creation of complex geometries |

15. Why Should You Consider Aluminum CNC Machining for Your Next Project?

Aluminum CNC machining offers a combination of cost-effectiveness, versatility, and high performance that makes it a top choice for manufacturers. Whether you need lightweight parts, complex geometries, or durable components, aluminum is an excellent choice. Here’s the deal: by understanding the benefits and challenges of aluminum CNC machining, you can make an informed decision that best suits your project needs.

| Reason | Explanation |

|---|---|

| Cost-effective | Low material costs and easy machinability |

| Versatile | Can be used across multiple industries |

| High-performance | Durable and efficient for demanding applications |

FAQ Section

Q1: What is Aluminum CNC Machining?

Aluminum CNC machining is the process of using CNC technology to cut, shape, and finish aluminum parts with high precision. It’s widely used in industries such as aerospace, automotive, and electronics.

Q2: How does CNC machining with aluminum work?

CNC machines follow digital instructions to perform operations like milling, turning, drilling, and cutting on aluminum parts. The process ensures accuracy, repeatability, and high-quality results.

Q3: What is the difference between aluminum and other metals in CNC machining?

Aluminum is lighter, easier to machine, and more cost-effective than materials like steel or titanium, making it ideal for high-volume production with tight tolerances.

Q4: What are some common issues when CNC machining aluminum?

Issues like tool wear, material distortion, and heat buildup are common. These can be managed by optimizing machine settings and using the appropriate cooling and tooling methods.

Q5: What are some alternatives to aluminum CNC machining?

Alternatives include steel, titanium, brass, and various composite materials. The choice depends on factors like strength, machinability, and cost for the intended application.