مقدمة

CNC machining has revolutionized the manufacturing industry, offering precise and automated ways to produce complex parts with high efficiency. One of the critical decisions for manufacturers is choosing between 3 and 5 axis CNC machines. The difference between these two types of machines can significantly affect production costs, precision, and the overall efficiency of operations. In this article, we’ll dive into the world of CNC machining, exploring the differences, benefits, and applications of both 3 and 5 axis CNC machines.

By the end, you’ll have a clear understanding of which machine might be the best fit for your manufacturing needs. Let’s get started!

1. What Are 3 and 5 Axis CNC Machines?

Before we get into the details, let’s first establish what exactly a CNC machine is. A CNC (Computer Numerical Control) machine is a device used for automating control of tools such as drills, lathes, mills, and grinders. It is programmed to execute specific tasks with high accuracy, often in the manufacturing of parts for industries such as automotive, aerospace, and medical.

So, what’s the difference between 3 and 5 axis CNC machines?

A 3 axis CNC machine moves the tool or workpiece along three primary axes: X (left to right), Y (front to back), and Z (up and down). This configuration is perfect for relatively simple cuts and milling tasks. But here’s the kicker—when you need to machine more complex parts with intricate details, that’s where 5 axis CNC machines come into play. A 5 axis CNC machine adds two more axes: A (rotational movement along the X axis) and B (rotational movement along the Y axis), allowing for more precise cuts and the ability to work on more complex geometries.

You might be wondering: why does this matter? Well, the added rotational axes in a 5 axis machine give it the ability to perform more intricate operations in a single setup, reducing the need for reorienting the workpiece. This leads to faster turnaround times and higher precision, especially when working with materials that are difficult to machine.

Here’s a table to quickly compare the two types of CNC machines:

CNC Machine Comparison

| ميزة | 3 Axis CNC Machine | 5 Axis CNC Machine |

|---|---|---|

| Axes of Movement | X, Y, Z | X, Y, Z, A, B |

| Movement Flexibility | Limited to basic cuts | Greater flexibility for complex parts |

| دقة | Suitable for simple designs | High precision for intricate designs |

| يكلف | Lower | Higher |

| Setup Time | Generally faster | Can be slower due to complexity |

2. How Does a 3 Axis CNC Machine Work?

A 3 axis CNC machine, as the name suggests, operates along three linear axes: X, Y, and Z. The X axis controls horizontal movement (left to right), the Y axis controls front to back movement, and the Z axis controls vertical movement (up and down). These machines are ideal for machining parts that don’t require a lot of rotation, such as flat pieces or simple geometries.

Here’s the real story: when it comes to 3 axis machines, simplicity is both their strength and their limitation. They are much easier to operate and less expensive than their 5 axis counterparts. However, their inability to rotate the workpiece means you may need multiple setups to create parts with more complex features. For example, a 3 axis machine would require repositioning the part to mill the other sides, which can slow down production.

The most common industries that benefit from 3 axis CNC machining include automotive, woodworking, and plastic molding. Let’s take a quick look at some specific examples of parts that are made using 3 axis CNC machines. You’ll often see them used for creating flat plates, brackets, or housings with relatively simple geometric shapes.

But wait, there’s more! Even with their limitations, 3 axis CNC machines still offer excellent precision and speed for straightforward manufacturing tasks. Their low setup costs make them the go-to choice for businesses looking to create simple parts in high volumes.

Here’s a table summarizing the key aspects of a 3 axis CNC machine:

3 Axis CNC Machine Features

| ميزة | Details |

|---|---|

| Movement | X, Y, Z |

| Complexity | Simple to moderate |

| Setup Cost | Lower |

| Ideal For | Simple shapes, flat surfaces |

| سرعة | High in simple applications |

3. How Does a 5 Axis CNC Machine Work?

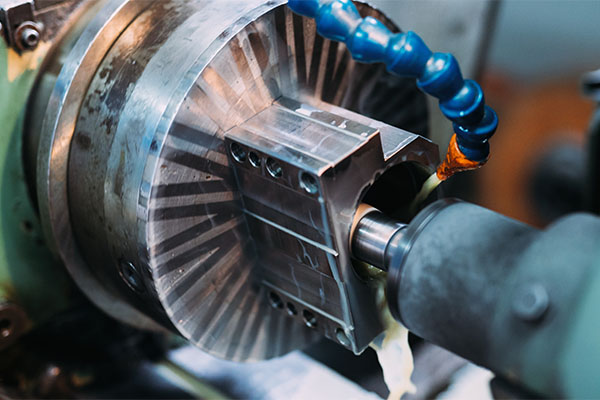

Now, let’s take a deep dive into 5 axis CNC machines, which are a step above in terms of capability. Unlike 3 axis CNC machines, 5 axis machines can rotate the workpiece on two additional axes, giving them the ability to cut more intricate parts with fewer setups. In other words, it’s like having a multi-dimensional workspace that lets the machine reach all angles of the part without needing to reposition it.

What’s the real story? The ability to move along five axes makes these machines ideal for complex parts that require high precision, such as turbine blades, aerospace components, and medical devices. The added rotational axes (A and B) allow for simultaneous 5-axis movement, reducing the need for multiple setups, which can be a time-consuming and costly process.

This makes the 5 axis CNC machine perfect for industries where precision and complexity are paramount. Think of aerospace parts, where every curve and angle must be exact, or medical devices where minute details matter.

Here’s the kicker—while 5 axis machines offer increased capabilities, they come at a higher cost. The added complexity and need for more advanced software make them an investment worth considering for businesses that need to handle intricate machining jobs. But if you’re producing complex parts, the return on investment is usually worth it.

Let’s take a look at the benefits of a 5 axis CNC machine:

5 Axis CNC Machine Features

| ميزة | Details |

|---|---|

| Movement | X, Y, Z, A, B |

| Complexity | High, suitable for complex geometries |

| Setup Cost | Higher cost |

| Ideal For | Aerospace, medical, automotive |

| دقة | High, able to create intricate parts |

4. What Are the Key Differences Between 3 and 5 Axis CNC Machines?

Here’s where it gets interesting—the primary difference between 3 and 5 axis CNC machines lies in their flexibility and precision. As we discussed earlier, a 3 axis machine is limited to simple tasks, while a 5 axis machine excels at handling complex, multi-dimensional cuts.

Why does this matter? It’s not just about the extra axes. The difference in capabilities has a direct impact on production speed, accuracy, and cost. A 5 axis CNC machine can reduce the number of setups required to produce a part, leading to shorter lead times and more efficient production processes. This translates to savings in time and labor costs, making it an ideal choice for manufacturers who need high-volume production of complex parts.

On the flip side, 3 axis CNC machines are more affordable and are excellent for mass-producing simple parts at a faster pace. However, they can’t match the precision and versatility of 5 axis machines.

Here’s a table comparing the differences between 3 and 5 axis CNC machines:

Comparison: 3 vs. 5 Axis CNC Machines

| ميزة | 3 Axis CNC Machine | 5 Axis CNC Machine |

|---|---|---|

| Setup Time | Shorter, simpler setups | Longer due to complexity |

| المرونة | Limited to simpler parts | High flexibility for complex tasks |

| دقة | Suitable for basic tasks | Ideal for precision parts |

| يكلف | More affordable | Higher cost due to complexity |

| طلب | High-volume, simple parts | Low-volume, complex parts |

5. When Should You Use a 3 Axis CNC Machine?

So, when is a 3 axis CNC machine the right choice? As we’ve seen, it works best for simpler parts that don’t require a lot of rotation. If you’re producing parts that have basic geometries or need to mill flat surfaces, a 3 axis CNC machine is likely the right fit. It’s also perfect for high-volume manufacturing, as it’s faster and more cost-effective than a 5 axis machine.

Let’s break it down further—industries like automotive, consumer electronics, and furniture often rely on 3 axis CNC machines for mass production of parts with fewer intricacies. For example, think of a manufacturer producing hundreds of metal brackets for an assembly line. The simple, straightforward design of the part doesn’t require the added complexity of a 5 axis machine.

By the same token, the lower investment required for a 3 axis machine makes it accessible for smaller businesses or startups looking to keep costs low while ramping up production.

Check out the table below to see where 3 axis machines shine the most:

Ideal Applications for 3 Axis CNC Machines

| صناعة | طلب |

|---|---|

| السيارات | Manufacturing simple parts |

| Furniture | Mass production of wood components |

| Electronics | Basic enclosures and panels |

6. When Should You Use a 5 Axis CNC Machine?

You might be wondering, what about when precision is key? That’s where the 5 axis CNC machine truly excels. For industries like aerospace, medical, and high-end automotive, where precision and complexity are required, 5 axis machines are a game-changer. These machines allow manufacturers to create parts with intricate geometries in a single setup, reducing errors and improving the overall quality of the finished product.

In aerospace, for example, parts like turbine blades require high precision and the ability to work with curved surfaces. The added axes of a 5 axis machine make it possible to achieve these cuts without needing to reposition the workpiece multiple times, which would add time and increase the risk of mistakes.

Here’s the thing: despite their higher initial cost, 5 axis machines are an investment that pays off over time, especially for industries requiring precision. The return on investment comes in the form of faster turnaround times, better quality control, and a more streamlined production process.

Here’s a quick summary of industries where 5 axis CNC machines thrive:

Ideal Applications for 5 Axis CNC Machines

| صناعة | طلب |

|---|---|

| الفضاء الجوي | Manufacturing turbine blades |

| طبي | Surgical equipment and implants |

| السيارات | High-end engine components |

7. What Are the Benefits of Using 3 Axis CNC Machines?

3 axis CNC machines are known for their simplicity and speed. They’re highly efficient for creating parts that have basic designs and require little rotation. But here’s the kicker: while they might not offer the complexity of 5 axis machines, their benefits are substantial for the right applications.

Here are some benefits of using 3 axis CNC machines:

- سرعة: Due to their simpler setup, 3 axis machines can produce parts faster than 5 axis machines.

- Cost-effective: With lower initial and operational costs, they are ideal for high-volume production.

- Ease of use: 3 axis machines are simpler to operate, making them a great choice for companies with smaller teams or less experience in CNC machining.

To give you an example, a 3 axis CNC machine could be used in the production of hundreds or thousands of identical parts, like brackets, casings, or panels. The high-speed operation and cost efficiency make them the go-to option for mass manufacturing of simple parts.

Here’s a table that highlights the benefits of using a 3 axis CNC machine:

Benefits of 3 Axis CNC Machines

| فائدة | وصف |

|---|---|

| سرعة | Faster production due to simple setup |

| يكلف | Lower initial and operational costs |

| Ease of Use | Less complex to operate |

8. What Are the Benefits of Using 5 Axis CNC Machines?

On the other hand, 5 axis CNC machines bring a host of benefits, especially when dealing with intricate parts. Ready for the good part? Here are some of the advantages that make 5 axis machines a worthy investment:

- Higher Precision: The ability to move along five axes allows for highly precise cuts, even on complex parts.

- More Complex Parts: If your parts require multiple angles or rotations, 5 axis machines can handle it in one setup, reducing errors and improving efficiency.

- Time Savings: Fewer setups mean less time spent repositioning the workpiece, allowing for faster production.

This is where the 5 axis CNC machine truly shines—it can produce complex parts with ease. For example, aerospace parts such as engine components and turbine blades require the kind of precision that only a 5 axis CNC machine can provide.

Here’s a summary of the key benefits of 5 axis CNC machines:

Benefits of 5 Axis CNC Machines

| فائدة | وصف |

|---|---|

| دقة | High precision for intricate parts |

| كفاءة | Reduces setup time and handling errors |

| المرونة | Able to machine complex parts in one setup |

9. What Are the Costs Involved in Using 3 Axis vs. 5 Axis CNC Machines?

When it comes to cost, there’s a big difference between 3 and 5 axis CNC machines. A 3 axis CNC machine is generally much more affordable in terms of both initial investment and operating costs. Ready for the good part? Let’s break it down.

3 Axis CNC Machines:

- Initial Cost: Relatively lower due to simpler technology and less moving parts.

- Operational Cost: Lower because of fewer maintenance requirements and faster production times.

- Return on Investment: Quick ROI, especially for high-volume, low-complexity jobs.

5 Axis CNC Machines:

- Initial Cost: Higher, due to the added complexity and rotational axes.

- Operational Cost: More expensive to maintain, as they require skilled operators and regular servicing.

- Return on Investment: Longer ROI period but higher profit margins for high-precision, low-volume work.

Here’s a cost comparison table to show the differences:

CNC Machine Cost Comparison

| ميزة | 3 Axis CNC Machine | 5 Axis CNC Machine |

|---|---|---|

| Initial Cost | Lower | Higher |

| Operational Cost | Lower | Higher |

| ROI | Quick for high-volume tasks | Longer for high-precision tasks |

10. How Do You Choose Between a 3 Axis and 5 Axis CNC Machine?

So, you’re considering which CNC machine is best for your needs. Well, here’s what you need to know:

- Choose a 3 Axis CNC Machine if your parts have simple geometries and you’re producing high volumes of basic items. Think about mass production and cost efficiency.

- Choose a 5 Axis CNC Machine if you need to produce parts with intricate details or work in industries requiring high precision. The upfront investment may be higher, but the return on investment is substantial for complex projects.

Here’s a simple guide to choosing the right CNC machine:

Choosing the Right CNC Machine

| Task Complexity | 3 Axis CNC Machine | 5 Axis CNC Machine |

|---|---|---|

| Simple Parts | Excellent for high-volume jobs | Less efficient for simple jobs |

| Complex Parts | Limited flexibility | Excellent for precision parts |

11. What Materials Can Be Machined Using 3 Axis and 5 Axis CNC Machines?

Both 3 and 5 axis CNC machines can machine a wide range of materials. However, the type of material and its complexity will often determine which machine is best suited.

3 Axis CNC Machines:

- المعادن: Aluminum, mild steel, stainless steel

- البلاستيك: ABS, polycarbonate, PVC

- Wood: Commonly used for simple woodworking tasks

5 Axis CNC Machines:

- المعادن: Titanium, Inconel, high-performance alloys

- البلاستيك: High-end plastics used in aerospace and medical devices

- Complex Materials: Composite materials, hard-to-machine metals

Here’s a table summarizing the materials used for each machine:

Materials for 3 Axis and 5 Axis CNC Machines

| مادة | 3 Axis CNC Machine | 5 Axis CNC Machine |

|---|---|---|

| المعادن | Aluminum, Steel, Stainless | Titanium, Inconel, Alloys |

| البلاستيك | ABS, PVC, Polycarbonate | High-end plastics |

| Complex Materials | Limited | Composites, hard metals |

12. How Does a 5 Axis CNC Machine Improve Precision and Efficiency?

You’re probably wondering how 5 axis CNC machines improve precision and efficiency. Well, the added axes provide a higher level of movement control, which leads to more accurate and intricate cuts. This results in a tighter tolerance, which is crucial for industries like aerospace, medical, and automotive.

The efficiency comes from the reduced need to reposition the workpiece. With 5 axis machines, everything can be done in a single setup, saving time, and reducing human error. But here’s the kicker—the added precision makes these machines ideal for the most complex designs.

Take a look at the following table to see how 5 axis CNC machines offer superior precision:

Precision with 5 Axis CNC Machines

| ميزة | وصف |

|---|---|

| دقة | Achieves tighter tolerance |

| كفاءة | Reduced setup time, fewer repositioning |

| Ideal For | Aerospace, medical, automotive |

13. What Are the Challenges in Operating 3 Axis and 5 Axis CNC Machines?

While CNC machining offers numerous benefits, it comes with its own set of challenges. Here’s what you need to know:

3 Axis CNC Machines:

- Limited Flexibility: These machines can’t handle complex geometries without multiple setups.

- Skill Requirement: Operators need to know how to manually reorient the workpiece for each cut.

5 Axis CNC Machines:

- Complexity: They require more advanced programming and skilled operators.

- Maintenance: The added components and axes require more frequent maintenance and servicing.

Here’s a table to summarize the challenges of each machine:

CNC Machine Challenges

| ميزة | 3 Axis CNC Machine | 5 Axis CNC Machine |

|---|---|---|

| المرونة | Limited for complex parts | High, but complex programming |

| Skill Requirement | Basic operator skills | Advanced programming skills |

| Maintenance | Simple maintenance | Frequent servicing required |

14. How Can You Maintain and Service 3 Axis and 5 Axis CNC Machines?

Proper maintenance is crucial to keeping CNC machines running smoothly. Here’s how you should approach it:

3 Axis CNC Machines:

- التنظيف المنتظم: Dust and debris can cause wear and tear on the machine, so keep it clean.

- Lubrication: Ensure the moving parts are lubricated regularly to prevent friction and damage.

5 Axis CNC Machines:

- Advanced Servicing: Given their complexity, 5 axis machines need regular calibration and more detailed servicing.

- Software Updates: Keep the software up-to-date for smooth operation and precision.

Here’s a maintenance table comparing the two machines:

CNC Machine Maintenance

| Maintenance Task | 3 Axis CNC Machine | 5 Axis CNC Machine |

|---|---|---|

| Cleaning | Regular cleaning | Requires more detailed cleaning |

| Lubrication | Basic lubrication | Frequent lubrication needed |

| معايرة | Simple checks | Regular calibration required |

15. What Are the Future Trends in CNC Machining?

As technology evolves, so does the world of CNC machining. Ready for the good part? Here are some of the trends that will shape the future of CNC:

- الأتمتة: More and more CNC machines will integrate with robotics for enhanced efficiency.

- AI and Machine Learning: These technologies will help optimize machining processes and improve accuracy.

- Hybrid Machining: Combining CNC machining with additive manufacturing to produce even more complex parts.

This is where the future of التصنيع باستخدام الحاسب الآلي is heading. The introduction of these advanced technologies will make CNC machines even more versatile, faster, and more precise.

الاتجاهات المستقبلية في تصنيع الآلات ذات التحكم الرقمي

| اتجاه | وصف |

|---|---|

| الأتمتة | Integration with robotics for efficiency |

| AI & Machine Learning | Optimized processes and enhanced precision |

| Hybrid Machining | Combining CNC and additive manufacturing |

قسم الأسئلة الشائعة

س1: What is a 3 axis CNC machine?

A 3 axis CNC machine uses three linear axes (X, Y, and Z) to move the tool or workpiece and is ideal for simpler tasks.

س2: How does a 5 axis CNC machine work?

A 5 axis CNC machine adds two rotational axes (A and B) to allow for more precise cuts and greater flexibility when machining complex parts.

س3: What are the advantages of using a 3 axis CNC machine?

3 axis CNC machines are cost-effective, fast, and ideal for mass production of simple parts with less complexity.

س4: When should I use a 5 axis CNC machine over a 3 axis machine?

Choose a 5 axis CNC machine when precision and complexity are critical, such as in aerospace, medical, or automotive industries.

س5: How do I decide between a 3 axis and 5 axis CNC machine for my business?

Consider factors such as the complexity of your parts, production volume, and budget. 3 axis machines are best for simple, high-volume production, while 5 axis machines are ideal for precision and complex designs.