مقدمة

Finding the right CNC precision machining supplier can be challenging, especially with the vast number of suppliers available today. Whether you’re working on a complex part for aerospace, automotive, or medical applications, selecting a trusted supplier is critical. In this article, we’ll dive into the top CNC precision machining suppliers, breaking down what makes each one stand out. By the end of this guide, you’ll have the insights needed to make an informed decision based on quality, reliability, and your specific business needs.

What is CNC Precision Machining?

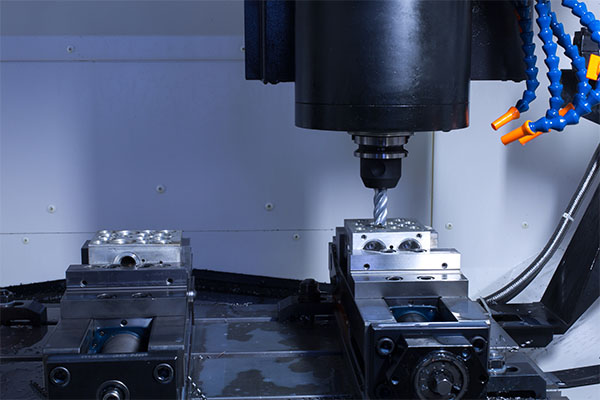

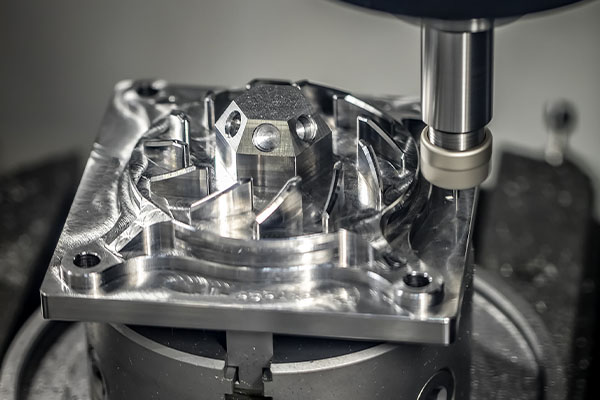

CNC precision machining refers to the process of using computer-controlled machines to produce precise parts and components from various materials. These machines, guided by computer software, can cut, shape, and mold materials with exceptional accuracy. Unlike traditional methods, CNC machining relies on pre-programmed commands, ensuring that parts are made to exact specifications.

The process can involve a range of techniques, including milling, turning, drilling, and grinding. CNC machines are capable of working with metals, plastics, and composites, offering unparalleled flexibility in material selection. Precision is crucial, especially in industries like aerospace, automotive, and medical, where tight tolerances and consistency are vital.

By utilizing CNC technology, manufacturers can produce high-quality components with minimal human intervention, reducing errors and boosting production speed. بعبارة أخرى, CNC precision machining is a game-changer for businesses that require precision and reliability in their components.

Key Factors to Consider When Choosing CNC Machining Suppliers

When selecting a CNC machining supplier, it’s important to weigh several key factors that can make or break your decision. First, quality and precision should be at the top of your list. The accuracy of the parts produced is paramount, as any small deviation could lead to costly errors down the line. Suppliers with high standards for quality control often use advanced equipment and techniques to guarantee their parts meet strict specifications.

Lead time is another crucial consideration. CNC machining is known for its efficiency, but depending on the complexity of the part and the supplier’s capabilities, lead times can vary. Make sure the supplier can meet your production deadlines without compromising quality.

فعالية التكلفة also plays a significant role. While it’s tempting to go with the cheapest option, it’s important to consider the long-term value. You may need to pay a little more for better quality and more reliable service. Ultimately, balancing cost with quality is essential.

Another factor to consider is a supplier’s ability to provide custom solutions. Your project might require specific materials, finishes, or unique design features. A supplier who specializes in custom work can help bring your ideas to life without compromising precision.

Lastly, don’t forget to check for relevant certifications and industry standards. Suppliers with certifications like ISO 9001 are often more reliable, as they adhere to internationally recognized quality management standards. These certifications help ensure that the supplier has a proven track record of delivering consistent, high-quality products.

How We Rank the Top CNC Precision Machining Suppliers

To compile our list of top CNC precision machining suppliers, we’ve used a variety of evaluation criteria. These include reputation, years in business, customer reviews, and their specialized capabilities. We also took into account their ability to handle large orders and meet tight deadlines, which are common in industries that rely on CNC machining.

The reputation of a supplier is one of the most significant factors in our rankings. A good reputation often indicates reliability, excellent customer service, and a proven track record of high-quality products. We’ve included suppliers known for their outstanding customer service, quick responses, and problem-solving skills.

Another factor we considered is industry specialization. Some CNC suppliers focus on specific industries, such as aerospace, medical, or automotive. Suppliers that have extensive experience in your industry can better understand your unique needs and provide tailored solutions.

Finally, customer feedback was a critical part of our assessment. By analyzing online reviews, case studies, and client testimonials, we gained insights into how well each supplier performs in real-world scenarios. This feedback helps us ensure that our rankings are based on actual experiences, not just marketing claims.

Comparing CNC Precision Machining Suppliers: What Sets Them Apart?

While all CNC machining suppliers can provide high-quality parts, there are key factors that differentiate the best from the rest. One of the most significant distinctions is the level of quality control employed by the supplier. Top-tier suppliers often implement rigorous testing and inspection processes to ensure their parts meet precise specifications. This could include dimensional checks, material testing, and finishing inspections.

The technology used by a CNC supplier also plays a vital role in their ability to deliver precise parts. Suppliers that invest in the latest CNC machines, such as multi-axis mills and automated systems, can handle more complex parts and provide faster turnaround times.

Customer service is another area where leading suppliers excel. A good CNC supplier offers more than just machining services—they also provide design assistance, technical support, and clear communication throughout the process. This customer-centric approach ensures that clients receive the best possible experience and results.

What Are the Different Types of CNC Machining?

CNC machining encompasses various techniques, each suited to specific applications. Here are the most common types:

الطحن باستخدام الحاسب الآلي: CNC mills are versatile machines used for a variety of tasks, including drilling, cutting, and shaping. Milling is ideal for creating complex parts with intricate features, such as holes and slots.

تحويل CNC: Turning is used to shape materials into cylindrical or conical forms. CNC lathes are ideal for producing parts such as shafts, spindles, and bushings.

CNC Grinding: Grinding is a high-precision technique used to achieve tight tolerances and fine finishes. It’s typically used for producing small, intricate parts with a smooth surface finish.

CNC EDM: Electrical Discharge Machining (EDM) is ideal for creating parts with complex shapes or fine details, such as cavities and holes. This process uses electrical sparks to erode material, making it highly effective for hard metals.

Each type of CNC machining offers unique benefits and is suited for different manufacturing needs. Choosing the right method depends on factors such as the complexity of the part, material requirements, and the desired finish.

How Can You Save on CNC Precision Machining Costs?

Saving on CNC precision machining costs doesn’t mean sacrificing quality. By implementing a few strategies, you can reduce costs while maintaining high standards:

Bulk Orders: Ordering parts in large quantities can significantly lower the cost per unit. Suppliers are often willing to offer discounts for high-volume orders, which can be especially beneficial for large-scale production runs.

اختيار المواد: The material you choose plays a big role in the cost of CNC machining. Certain materials are more expensive than others, so opting for less costly materials when possible can reduce your overall expenses.

Efficient Design: The more complex the design, the more time and effort it takes to machine. By simplifying your designs and eliminating unnecessary features, you can reduce machining time and lower costs.

Establishing long-term relationships with CNC suppliers can also lead to cost savings. Suppliers value repeat customers and may offer better pricing or terms for ongoing orders.

Custom CNC Machining: What Does it Mean for Your Business?

Custom CNC machining refers to the ability to design and produce unique parts tailored to your specific requirements. Whether it’s for a prototype or a production run, custom machining allows for greater flexibility and precision. Suppliers offering custom CNC machining services can work with you to create parts that meet your exact specifications.

The benefit of custom CNC machining is its ability to produce parts that can’t be easily made with off-the-shelf components. It’s particularly beneficial for industries that require highly specialized or complex parts, such as aerospace or medical devices. Custom machining services can accommodate unique materials, finishes, and designs, ensuring that your parts perform exactly as needed.

Additionally, custom CNC machining can help optimize your production process. Whether you’re creating a prototype or preparing for mass production, a custom supplier can ensure that your parts are designed for manufacturability, reducing waste and improving efficiency.

Customer Service and Support: How It Impacts Your CNC Machining Experience

The quality of customer service and support you receive from a CNC machining supplier can significantly affect your experience. Effective communication throughout the process is crucial, as any miscommunication can lead to costly mistakes or delays. Suppliers that offer clear, responsive communication ensure that all project requirements are understood and met on time.

Beyond communication, technical support is another key element of customer service. Whether you need help troubleshooting an issue or assistance with the design process, having access to knowledgeable support staff can make a huge difference. Suppliers that provide design assistance can help optimize your designs for CNC machining, saving you time and money.

Post-production services also play a critical role. Many top CNC suppliers offer value-added services such as packaging, assembly, and logistics, making it easier for you to receive the final product without having to manage these tasks yourself.

Understanding Lead Times and Delivery Schedules

Lead time is a crucial factor to consider when choosing a CNC machining supplier. The complexity of the project and the supplier’s production capacity can impact how long it takes to receive your parts. For straightforward projects, lead times may be relatively short, while more complex designs can take longer to produce.

It’s important to discuss your timeline upfront with the supplier. If you have tight deadlines or need expedited services, make sure they can accommodate your needs. Some suppliers offer rush services, but be prepared to pay a premium for faster turnaround times.

To avoid delays, it’s helpful to provide clear and complete specifications for your parts. Any revisions or changes to the design after production has started can cause significant delays.

Common Mistakes When Choosing a CNC Precision Machining Supplier

When selecting a CNC machining supplier, there are a few common mistakes that businesses often make. One of the most frequent is focusing too much on price. While it’s tempting to choose the cheapest option, it’s important to remember that quality should always come first. Low-cost suppliers may cut corners, resulting in poor-quality parts and costly rework.

Another mistake is not verifying certifications. It’s essential to ensure that your supplier adheres to quality standards, such as ISO 9001, which can give you peace of mind that they follow best practices.

Lastly, many businesses fail to check a supplier’s capabilities before making a commitment. If your project requires specialized machining techniques or materials, make sure the supplier can handle your specific needs.

Trends in CNC Precision Machining: What You Need to Know

The CNC machining industry is constantly evolving, driven by technological advancements and market demands. الأتمتة و artificial intelligence (AI) are playing an increasingly important role in the field, helping to optimize production processes and reduce human error. AI-powered systems can assist in predictive maintenance, ensuring that machines are operating at peak efficiency.

Another significant trend is sustainability. As the global focus on environmental responsibility grows, CNC machining suppliers are adopting more eco-friendly practices. This includes using sustainable materials and reducing waste in the production process.

بالإضافة إلى ذلك، advanced materials are gaining traction in CNC machining. High-performance materials such as titanium and carbon fiber are becoming more accessible, allowing suppliers to produce parts with enhanced durability and functionality.

The Future of CNC Precision Machining

The future of CNC precision machining looks promising, with continuous innovations on the horizon. Automation and smart manufacturing are expected to revolutionize the industry, making CNC machining faster, more cost-effective, and even more precise. As technology advances, suppliers will be able to offer more customized solutions to meet the growing demands of various industries.

CNC machining will continue to play a central role in global manufacturing, particularly as companies look to produce high-precision parts for industries like aerospace, medical, and automotive. New technologies, such as 3D printing and hybrid manufacturing techniques, are also poised to change the landscape of CNC machining, opening up new possibilities for product development.

Conclusion: Finding the Right CNC Precision Machining Supplier for Your Needs

اختيار الصحيح CNC precision machining supplier requires careful consideration of several factors, including quality, lead times, and customer service. By understanding your specific needs and evaluating potential suppliers against these criteria, you can ensure that you select the best partner for your project.

Ultimately, selecting the right supplier will help you achieve high-quality results, meet your deadlines, and stay within budget. Whether you’re working on a one-time project or looking for a long-term partner, the right CNC machining supplier can make all the difference in your manufacturing success.

قسم الأسئلة الشائعة

What is the typical cost of CNC machining?

CNC machining costs can vary significantly based on factors such as the complexity of the part, the material used, and the quantity of parts ordered. In general, CNC machining is cost-effective for medium to large production runs, and the price per part decreases as the volume increases.

How long does it take to get a CNC machining quote?

The time it takes to receive a CNC machining quote depends on the complexity of the part and the supplier’s process. Typically, you can expect a quote within a few days to a week.

What materials can be used in CNC precision machining?

CNC machining is compatible with a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics and composites. The choice of material depends on the part’s intended use and performance requirements.

Can CNC machining handle large-scale production?

Yes, CNC machining can handle both small and large production runs. For high-volume production, many CNC suppliers offer automated systems to streamline the process and reduce costs.

What certifications should I look for in CNC suppliers?

Look for suppliers that are ISO 9001 certified, as this indicates they meet international standards for quality management systems. Other industry-specific certifications may be necessary depending on your project requirements.