مقدمة

Low volume CNC machining is an excellent solution for custom part production. It allows businesses to produce high-quality parts in smaller quantities, which is often more cost-effective and efficient than traditional manufacturing methods. In this article, we will explore why low volume CNC machining is the perfect choice for custom parts and how it can benefit your business. Ready for the good part? Let’s dive into the specifics of low volume CNC machining and understand why it is becoming the go-to solution for many industries.

1. Why is Low Volume CNC Machining Perfect for Custom Parts?

When it comes to custom part production, businesses often face challenges such as high costs and long lead times. But here’s the kicker: low volume CNC machining solves both problems. Unlike traditional manufacturing processes that require large-scale production runs, low volume CNC machining allows for the creation of custom parts in smaller quantities. This flexibility is a game-changer for businesses that need high-quality, custom components without the large financial investment typically associated with mass production.

Low volume CNC machining is particularly beneficial for industries like aerospace, medical devices, and automotive manufacturing. In these fields, precision and customization are crucial, and low volume CNC provides the perfect solution. Custom parts for prototypes, limited-run production, and small batch orders can be produced with exceptional accuracy and minimal waste. Additionally, this approach reduces inventory costs since parts are produced only when needed, preventing overproduction and stockpiling.

Another reason low volume CNC machining is ideal for custom parts is its ability to handle a wide range of materials. From metals like aluminum and steel to plastics and composites, CNC machines can work with various materials, providing the flexibility needed for different industries. Plus, this process allows for intricate designs and complex geometries that are challenging to achieve with other manufacturing methods.

2. How Does Low Volume CNC Machining Work?

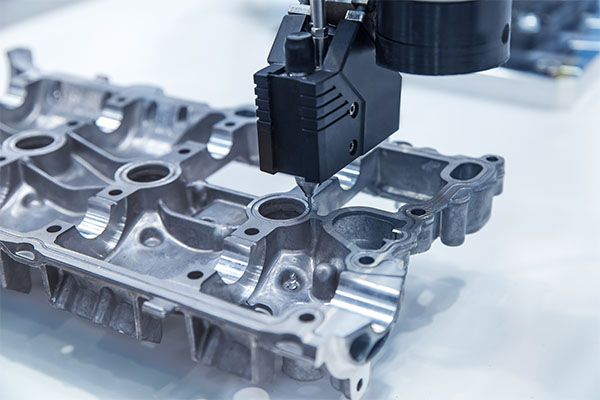

What’s the real story behind how low volume CNC machining works? CNC (Computer Numerical Control) machining involves using a computer to control machine tools that cut, mill, or shape materials. It’s a highly precise method that offers exceptional accuracy, making it perfect for producing custom parts in small quantities. Here’s the good news: the process is automated, which means it minimizes human error and ensures consistent quality.

First, a digital model of the part is created using CAD (Computer-Aided Design) software. This model is then converted into a set of instructions, called G-code, which the CNC machine follows to produce the part. The CNC machine uses various tools, such as drills, lathes, and mills, to remove material from the workpiece, shaping it into the desired form.

Low volume CNC machining typically involves shorter production runs, making it ideal for prototypes and small batches. In contrast to mass production, where large quantities of parts are made in one go, low volume CNC machining focuses on smaller orders, ensuring that each part is crafted to meet the required specifications.

The best part? Low volume CNC machining is not limited to just one material or type of part. The versatility of CNC machines means they can produce custom parts from a variety of materials like metals, plastics, and even exotic alloys. This adaptability makes it a top choice for industries needing high-quality, tailored parts in smaller quantities.

3. What Are the Key Benefits of Low Volume CNC Machining?

So, what are the key benefits of low volume CNC machining for custom parts? For starters, it offers a unique combination of cost-efficiency and precision. When compared to traditional methods, low volume CNC machining eliminates the need for expensive molds and tooling, which significantly reduces startup costs. Since the production process is automated, businesses also save on labor costs, as fewer workers are needed to operate the machines.

One of the most important advantages of low volume CNC machining is its ability to produce parts with a high degree of accuracy and consistency. Whether you need a single prototype or a small batch of custom parts, CNC machines can ensure that every piece meets strict tolerances. This level of precision is especially crucial in industries like aerospace and medical devices, where even the slightest deviation can result in failure or safety concerns.

Low volume CNC machining also offers faster turnaround times compared to traditional manufacturing methods. With the ability to quickly create and modify digital models, businesses can go from design to production in a fraction of the time it would take with other processes. This speed allows for more rapid prototyping and faster product iterations, which is essential for industries that need to respond quickly to market demands or customer needs.

Additionally, low volume CNC machining provides the flexibility to work with a variety of materials, making it ideal for industries that require customized components. Whether it’s for creating parts with complex geometries or testing out new materials, CNC machining can deliver the flexibility and innovation required for today’s rapidly changing industries.

4. When is Low Volume CNC Machining a Good Choice?

At what point does low volume CNC machining become the go-to solution? The answer lies in your production needs. If you require high-precision, custom parts but don’t have the volume needed for mass production, low volume CNC machining is your best bet. For instance, businesses that need prototypes or small batches of parts benefit greatly from this method, as it eliminates the costly tooling and setup required for traditional manufacturing.

Low volume CNC machining is perfect for industries such as medical devices, aerospace, automotive, and electronics, where custom parts are often needed in small quantities. These industries demand high accuracy and quality, and low volume CNC machining can provide that without the high costs associated with mass production. Additionally, the ability to make quick revisions and adjustments makes CNC machining ideal for testing out new designs or materials before committing to large-scale production.

But wait, there’s more: low volume CNC machining is also a great option for companies that are experimenting with new products or need to test the market with a limited run of custom parts. Instead of investing in expensive molds or tooling for mass production, businesses can use low volume CNC machining to create prototypes or small batches, evaluate their designs, and gather feedback before moving forward.

5. What Makes Low Volume CNC Machining Cost-Effective?

What’s the secret behind the cost-effectiveness of low volume CNC machining? The cost savings come from eliminating the need for expensive molds and tooling, which are typically required in traditional manufacturing processes. This is especially important for businesses that only need small quantities of custom parts, as the upfront investment for mass production runs can be prohibitively high.

Low volume CNC machining also minimizes material waste, which can lead to additional savings. Since the process is highly precise, it ensures that each part is produced with minimal waste, allowing businesses to get the most out of their materials. Additionally, the automated nature of CNC machines means fewer human workers are required, reducing labor costs and making the process more cost-efficient overall.

Another way low volume CNC machining is cost-effective is through its speed. Unlike traditional methods, where production runs can take weeks or even months, low volume CNC machining allows for faster turnaround times. This means businesses can get their products to market quicker, generating revenue faster and reducing the time spent on manufacturing.

The flexibility to work with a wide range of materials also contributes to cost savings. Whether you’re using metal, plastic, or composite materials, CNC machining offers the ability to work with a variety of options that may be more affordable than other manufacturing methods.

6. How Can Low Volume CNC Machining Save Time?

Ready for the good part? Low volume CNC machining is a time-saving powerhouse. The automated nature of CNC machines means they can work around the clock, producing parts faster than traditional manufacturing methods. This rapid production process significantly reduces lead times, allowing businesses to get their products to market much quicker.

Another factor contributing to the time savings is the ability to quickly adjust designs. With CNC machining, changes to the digital model can be made easily, and the machine can immediately start producing the updated parts. This flexibility is especially useful for businesses that need to iterate on their designs quickly or respond to changes in customer demands.

Low volume CNC machining also eliminates the need for costly setup times associated with traditional manufacturing methods. With CNC machines, once the design is set, production can begin immediately. This eliminates delays caused by setting up molds, fixtures, and tools, making it easier to produce small batches of custom parts with a fast turnaround.

Furthermore, the speed and accuracy of low volume CNC machining lead to fewer errors and rework. Since the process is computer-controlled, it’s much less prone to human error, ensuring that parts are produced correctly the first time. This reduces the need for rework and further production time, making the entire process more efficient.

7. Why is Precision Critical in Low Volume CNC Machining?

What makes precision so crucial in low volume CNC machining? In industries like aerospace, automotive, and medical devices, precision is not just important—it’s a matter of safety and functionality. Low volume CNC machining delivers high accuracy, ensuring that each custom part meets the required specifications without compromise.

The reason precision is so critical in low volume CNC machining is that even small variations in dimensions can lead to significant issues down the line. A part that doesn’t meet the exact tolerances can affect the performance of an entire assembly, leading to costly repairs or replacements. That’s why CNC machining’s ability to consistently produce parts within tight tolerances is a major selling point.

But here’s the kicker: the precision of low volume CNC machining doesn’t only apply to large, complex parts. Even smaller, intricate components benefit from the high degree of accuracy that CNC machines offer. Whether you need a part with complex geometries or a simple, functional component, CNC machining ensures that the part will be made with the highest level of detail and precision.

This level of accuracy is especially important in industries where parts must fit perfectly together, such as in the assembly of medical devices or aircraft components. Low volume CNC machining is capable of producing parts that meet these exacting standards, ensuring reliability and safety across a wide range of applications.

8. What Materials Are Best for Low Volume CNC Machining?

What materials can be used in low volume CNC machining? The beauty of this process lies in its flexibility, as it can handle a wide range of materials with different properties. From metals to plastics and composites, low volume CNC machining can accommodate various materials based on the needs of the project. Let’s break it down further.

Metals such as aluminum, steel, and titanium are commonly used for التصنيع باستخدام الحاسب الآلي, especially in industries like aerospace, automotive, and medical. These metals provide strength and durability, making them ideal for parts that need to withstand harsh conditions or high-stress environments. Aluminum, for example, is lightweight yet strong, making it perfect for custom parts that need to be both strong and lightweight. Steel is used for its toughness and corrosion resistance, while titanium is favored for its excellent strength-to-weight ratio and ability to perform in extreme temperatures.

In addition to metals, plastics such as ABS, polycarbonate, and PEEK are also commonly machined. These materials are used for parts that require flexibility, impact resistance, and lower weight. For example, ABS is widely used for prototypes and functional parts in various industries due to its strength and ease of machining. Polycarbonate, on the other hand, is known for its transparency and high impact resistance, making it ideal for parts like lenses and covers.

But here’s the kicker: low volume CNC machining isn’t just limited to metals and plastics. Composites, such as carbon fiber and fiberglass, are increasingly being used in CNC machining for parts that require high strength and lightweight properties. These materials are commonly used in industries like aerospace and automotive, where performance and efficiency are paramount.

In short, the material selection depends on the specific needs of the custom part. Whether you need a strong, durable part or one that is lightweight and flexible, low volume CNC machining can handle it all.

9. How Does Low Volume CNC Machining Benefit Small Businesses?

How does low volume CNC machining benefit small businesses? Small businesses often struggle with the high costs and long lead times associated with mass production. But with low volume CNC machining, they can produce high-quality custom parts without the large upfront investment that typically comes with large-scale manufacturing. Here’s how it works in practice.

For one, low volume CNC machining allows small businesses to produce parts in smaller batches. This eliminates the need for expensive tooling and molds, which are required for traditional manufacturing processes. Without the need for these expensive investments, small businesses can start production quickly and at a much lower cost. This makes low volume CNC machining an affordable solution for startups, small manufacturers, and those who need custom parts in limited quantities.

Low volume CNC machining also offers flexibility in terms of design. Since CNC machines are computer-controlled, modifications to the design can be made quickly and easily. This flexibility is particularly useful for businesses that are constantly innovating or testing new product designs. Instead of having to invest in expensive molds for every new design iteration, small businesses can modify their digital files and start production immediately.

What’s the real story here? Low volume CNC machining also speeds up time-to-market. In industries like tech, automotive, and medical devices, time is often a critical factor. The ability to quickly produce prototypes or small batches of parts means businesses can test their designs faster and bring products to market more quickly. This gives small businesses a competitive edge, allowing them to stay ahead of larger companies and react quickly to customer demands.

10. What Are Some Common Applications of Low Volume CNC Machining?

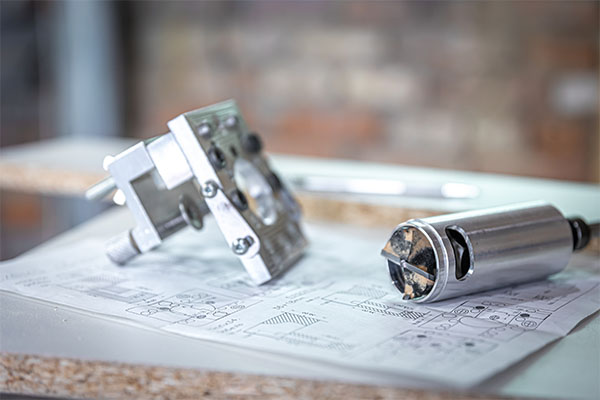

Ready for the good part? Low volume CNC machining has a wide range of applications across different industries. Whether it’s producing prototypes, creating custom parts, or supporting small batch production, CNC machining is used to make parts for everything from consumer products to industrial machinery. Let’s take a look at some of the most common applications.

One of the most common applications is the production of prototypes. Low volume CNC machining is perfect for creating accurate, functional prototypes that can be used for testing and evaluation. This is particularly important in industries like automotive and aerospace, where prototypes are essential for testing designs before committing to large-scale production. With low volume CNC machining, businesses can create these prototypes quickly and efficiently, reducing time-to-market.

Another application is the creation of custom parts. Low volume CNC machining allows businesses to create custom parts for various industries, such as medical devices, robotics, and electronics. Whether it’s custom brackets for a piece of equipment or specialized components for a machine, CNC machining offers high precision and flexibility in creating parts that are tailored to specific requirements.

But here’s the kicker: low volume CNC machining is also used in small batch production. Instead of producing thousands of parts, businesses can use CNC machining to create smaller quantities of parts with the same level of precision and quality. This is particularly beneficial for industries like medical devices, where smaller production runs are often required. It allows businesses to meet specific customer demands without the need for large-scale manufacturing.

11. How Can You Ensure Quality in Low Volume CNC Machining?

What’s the secret to ensuring quality in low volume CNC machining? The key lies in choosing the right CNC machining provider and implementing effective quality control measures throughout the production process. Here’s how businesses can ensure high-quality parts every time.

First, it’s essential to work with a reputable CNC machining provider that has experience in producing custom parts for your industry. A skilled provider will be familiar with the specific requirements of your project and will be able to produce parts that meet your quality standards. When selecting a provider, it’s crucial to review their certifications, past work, and customer reviews to ensure they have a proven track record of delivering high-quality parts.

Next, it’s important to establish quality control processes throughout the production cycle. This includes conducting regular inspections at various stages of production, from the initial setup to the final inspection of finished parts. Quality control checks can help identify issues early in the process, preventing defects and ensuring that each part meets the required tolerances.

But here’s the kicker: investing in quality testing equipment can further ensure that parts are produced to the highest standards. Tools like coordinate measuring machines (CMM) and other precision measurement devices allow manufacturers to check the accuracy of parts in real time. This enables quick adjustments and ensures that parts are produced with the utmost precision.

12. What Challenges Are There in Low Volume CNC Machining?

Let’s face it: no manufacturing process is without its challenges. So, what challenges should businesses be aware of when considering low volume CNC machining? While this method offers numerous benefits, there are some obstacles that may arise during the production process.

One of the main challenges is the material cost. While low volume CNC machining eliminates the need for expensive molds, the cost of raw materials can still be significant, especially for high-performance metals or exotic materials. Depending on the complexity and material requirements of the part, businesses may find themselves paying a premium for materials, which could increase the overall cost of production.

Another challenge is the need for skilled labor. Although CNC machines are automated, they still require skilled operators who are familiar with the machines and the production process. Finding qualified operators can sometimes be difficult, especially for businesses that are new to CNC machining. This means that businesses may need to invest in training or hire experienced personnel to ensure the success of the project.

But here’s the kicker: low volume CNC machining can also pose challenges in terms of time management. While the process is generally faster than traditional manufacturing methods, it’s still important to account for setup times, programming, and adjustments that may be required. Tight deadlines or rushed schedules can lead to mistakes or quality issues, so it’s essential to plan ahead and ensure ample time for production.

13. How Does Low Volume CNC Compare to Other Custom Manufacturing Methods?

What’s the real story behind low volume CNC machining compared to other custom manufacturing methods? In today’s world, businesses have a variety of options for producing custom parts, including 3D printing, injection molding, and more. However, low volume CNC machining offers several advantages over these methods, making it a top choice for many industries.

One of the biggest differences between low volume CNC machining and other methods is the precision and consistency it offers. Unlike 3D printing, which can sometimes produce parts with less accuracy, CNC machining ensures high tolerances and exact specifications for each part. Additionally, CNC machining can handle a wider range of materials compared to 3D printing, making it more versatile for industries that require durable or complex parts.

When compared to injection molding, low volume CNC machining offers a significant cost advantage for small batch production. Injection molding requires expensive molds to be created before production can begin, which can be prohibitively expensive for small businesses. On the other hand, CNC machining doesn’t require expensive tooling and can produce custom parts with a relatively low upfront investment.

What makes low volume CNC machining truly stand out, though, is its speed and flexibility. Unlike other methods that may require lengthy setup times or specific conditions, CNC machines can start producing parts almost immediately once the design is ready. This allows for quicker iterations and faster time-to-market, which is a huge advantage for businesses looking to stay ahead of the competition.

14. What Are the Future Trends in Low Volume CNC Machining?

Ready for the next wave of innovation? Low volume CNC machining is continuously evolving, and the future holds exciting possibilities for businesses. Let’s explore some of the trends that are shaping the future of this manufacturing process.

One trend is the increasing use of automation in CNC machining. Automation technologies, such as robotic arms and AI-driven systems, are making it possible to further streamline production, reduce labor costs, and improve efficiency. With automation, businesses can produce parts faster and with even greater accuracy, leading to improved quality and reduced turnaround times.

Another trend is the integration of advanced materials into low volume CNC machining. With industries increasingly demanding lightweight, high-performance parts, there is a growing interest in materials such as carbon fiber, composites, and advanced alloys. CNC machines are becoming more capable of handling these materials, opening up new possibilities for industries like aerospace, automotive, and medical devices.

But here’s the kicker: 3D printing and CNC machining are starting to be used together in hybrid manufacturing processes. By combining the strengths of both methods, businesses can produce custom parts with even more complexity and precision. 3D printing can be used to create intricate geometries, while CNC machining ensures that parts are finished to the highest standards of quality.

15. How Can You Get Started with Low Volume CNC Machining?

How can you get started with low volume CNC machining? The process begins by identifying your specific production needs. Start by determining the materials, quantities, and level of precision required for your custom parts. Once you have a clear understanding of your needs, you can begin searching for a reputable CNC machining provider that specializes in low volume production.

The next step is to work with your chosen provider to create digital models of the parts you want to produce. These models will then be converted into instructions for the CNC machine, which will begin the manufacturing process. It’s important to maintain clear communication with your provider throughout the process to ensure that the final parts meet your exact specifications.

But here’s the kicker: getting started with low volume CNC machining is easier than you might think. With the right provider, you can start producing high-quality, custom parts with a fast turnaround and low upfront investment. The flexibility and precision of CNC machining make it the perfect solution for businesses looking to produce custom parts in small quantities.

قسم الأسئلة الشائعة

س1: What is low volume CNC machining?

Low volume CNC machining refers to the production of small quantities of custom parts using CNC machines. This process offers high precision and customization, making it ideal for industries that require limited-run parts.

س2: How does low volume CNC machining work?

Low volume CNC machining works by using computer-controlled machines to remove material from a workpiece based on a digital model. The machine follows precise instructions to create custom parts in smaller batches.

س3: What materials are commonly used in low volume CNC machining?

Common materials used in low volume CNC machining include metals like aluminum, steel, and titanium, as well as plastics and composites. The material selection depends on the specific requirements of the custom parts.

س4: How can low volume CNC machining benefit small businesses?

Small businesses can benefit from low volume CNC machining by gaining access to affordable, custom parts without the need for large production runs. It offers flexibility, faster turnaround times, and cost savings compared to traditional manufacturing.

س5: How can I ensure quality in low volume CNC machining?

Ensuring quality in low volume CNC machining involves selecting an experienced provider, conducting regular quality control checks, and testing prototypes to ensure parts meet required specifications.