Introduction

CNC aluminum machining is a precise and efficient manufacturing process used across industries to produce high-quality parts from aluminum. This process involves using computer-controlled machines to cut, shape, and finish aluminum workpieces. If you’re in the business of manufacturing or sourcing aluminum components, understanding CNC aluminum machining is essential for ensuring quality, efficiency, and cost-effectiveness in your production processes. In this article, we will explore everything you need to know about CNC aluminum machining—from its workings and benefits to the machines used and the key considerations for optimal results.

1. What is CNC Aluminum Machining?

CNC aluminum machining refers to the process of using computer numerical control (CNC) machines to shape and cut aluminum materials into specific parts or products. CNC machining is widely favored for its precision and ability to create complex designs with high repeatability. The process typically involves three main steps: designing the part using CAD software, programming the CNC machine using CAM software, and machining the aluminum part. The precision and versatility of CNC machining make it a preferred method in industries such as aerospace, automotive, and medical device manufacturing.

CNC aluminum machining stands out because aluminum is a lightweight, corrosion-resistant metal that’s ideal for creating components with complex geometries. But here’s the kicker: Not all aluminum alloys are created equal. Each alloy has different properties, which makes it crucial to select the right type of aluminum based on the intended application.

2. How Does CNC Aluminum Machining Work?

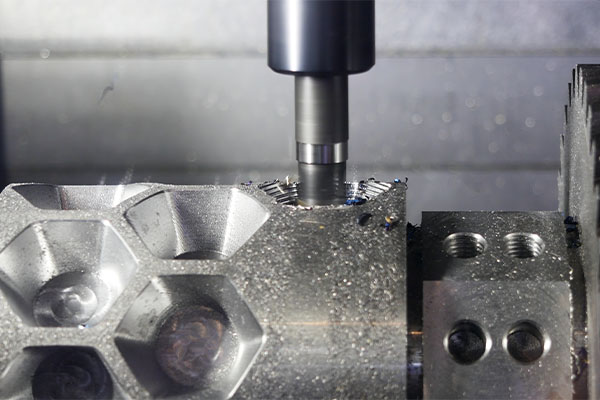

The CNC aluminum machining process starts with the creation of a digital model using computer-aided design (CAD) software. Once the model is finalized, the design is converted into a set of instructions that a CNC machine can understand through computer-aided manufacturing (CAM) software. This software generates tool paths and coordinates, which direct the CNC machine to perform the necessary cuts, drills, and finishes on the aluminum.

CNC machines used for aluminum machining are typically equipped with rotary cutting tools like mills and lathes. The machine’s movements are highly precise, allowing for accurate dimensions and finishes. What’s the real story? Unlike manual machining, CNC aluminum machining is automated, meaning the process is not only faster but also more accurate, with reduced human error.

The CNC machine uses various cutting tools, including drills, lathes, and end mills, to remove material from the aluminum workpiece. Depending on the complexity of the part, the machining process may involve multiple steps, including turning, milling, drilling, and tapping. The final part is then inspected to ensure it meets the required specifications.

3. What Are the Benefits of CNC Aluminum Machining?

One of the main advantages of CNC aluminum machining is its precision. CNC machines can work with very tight tolerances, which is crucial for industries requiring exact specifications, such as aerospace and automotive. The repeatability of CNC machining ensures that identical parts can be produced with the same accuracy, even in high-volume production runs.

CNC aluminum machining is also highly efficient. Automated machines can run continuously, reducing the need for manual labor and increasing production speed. This, in turn, leads to cost savings for manufacturers, as fewer resources are required to produce high volumes of parts.

Another benefit is flexibility. CNC aluminum machining can accommodate a wide range of designs, from simple to highly complex geometries. Whether you need a small batch of custom components or a large production run, CNC machining is adaptable to your needs.

But here’s the kicker: CNC aluminum machining isn’t just fast—it’s versatile too. It can handle a wide variety of aluminum alloys, each suited to different types of applications, whether in lightweight structures, corrosion-resistant environments, or heat-sensitive components.

4. What Materials Can Be Machined with CNC Aluminum?

Aluminum is a versatile material with numerous alloys, each with specific characteristics that affect how it can be machined. Some common aluminum alloys used in CNC machining include 6061, 7075, and 2024. These alloys are prized for their strength, corrosion resistance, and ability to be easily machined, making them ideal for a range of industries, from aerospace to automotive.

6061 aluminum, for example, is commonly used in manufacturing due to its excellent corrosion resistance and strength-to-weight ratio. It’s a go-to material for parts like aircraft frames, marine components, and automotive structures. 7075 aluminum, on the other hand, is stronger and harder, making it suitable for parts that require superior mechanical properties.

Ready for the good part? The machinability of aluminum alloys depends on their composition. For example, alloys with higher silicon content tend to be easier to machine, while those with high copper or magnesium content may require more advanced cutting techniques.

5. What Are the Common Applications of CNC Aluminum Machining?

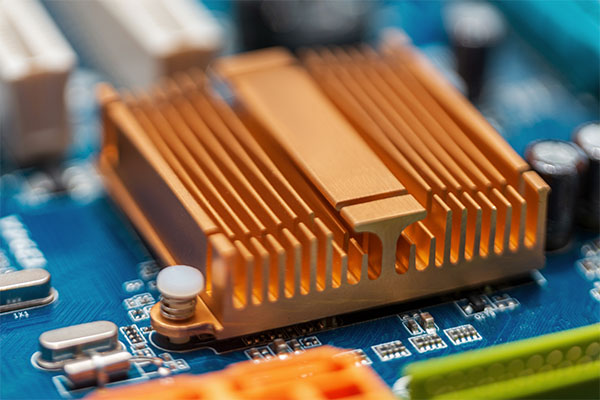

CNC aluminum machining is employed across a wide array of industries, with applications ranging from aerospace to medical devices. In the aerospace industry, aluminum parts are critical due to their lightweight yet durable nature. CNC aluminum machining is used to manufacture aircraft components such as fuselages, wings, and landing gears.

In automotive manufacturing, aluminum parts are increasingly used to reduce weight and improve fuel efficiency. CNC aluminum machining plays a key role in producing engine blocks, transmission parts, and chassis components.

You might be wondering: How does CNC machining play a role in medical device production? Well, the precision and reliability of CNC aluminum machining make it ideal for manufacturing parts for medical devices, such as surgical instruments, implants, and diagnostic equipment.

6. What Are the Key Considerations for CNC Aluminum Machining?

When working with CNC aluminum machining, there are several key factors to consider to ensure the best results. First, choosing the right aluminum alloy is critical. As discussed, different alloys have different properties, and selecting the right one for your application can significantly affect the performance of the final product.

Another important consideration is the machining speed. Since aluminum is a soft material, the machining process typically involves high cutting speeds to maximize efficiency. However, it’s essential to find a balance to avoid overheating and to ensure high-quality finishes.

What’s the real story? The choice of tooling also plays a significant role in the quality of the final product. Using the correct cutting tools for the specific aluminum alloy can help reduce tool wear and improve machining accuracy.

7. What CNC Machines Are Best for Aluminum Machining?

Several types of CNC machines are used for aluminum machining, including CNC mills, CNC lathes, and CNC routers. Each type of machine offers unique advantages, depending on the complexity and size of the part being machined.

CNC milling machines are often used for creating detailed, complex parts that require high precision. They can be equipped with multiple cutting tools to handle various types of cuts, including face milling, end milling, and drilling.

But here’s the kicker: While CNC lathes are best for cylindrical parts, CNC mills are often the go-to choice for aluminum machining due to their versatility and ability to handle complex shapes.

8. What Are the Challenges in CNC Aluminum Machining?

Despite its many advantages, CNC aluminum machining does come with challenges. One of the primary issues is the heat generation during the machining process. Since aluminum is a relatively soft material, it can cause rapid tool wear and the buildup of heat. This can lead to poor surface finishes and reduced tool life.

Another challenge is achieving the right surface finish. Aluminum tends to develop a rough surface when machined, which can be problematic for parts that require a smooth, polished finish. Various post-processing techniques, such as anodizing or polishing, can help improve the finish, but these add extra steps to the manufacturing process.

9. How Can You Improve CNC Aluminum Machining Efficiency?

Improving the efficiency of CNC aluminum machining involves several strategies. The most effective approach is optimizing feed rates and cutting speeds. By adjusting these parameters, manufacturers can minimize tool wear, reduce material waste, and improve cycle times.

Another way to enhance efficiency is through the use of automated CNC systems. These systems allow for continuous, unmanned operation, further reducing labor costs and increasing productivity.

This is where it gets interesting: Many CNC machines now come equipped with advanced features such as adaptive controls and sensors, which can automatically adjust cutting conditions to maintain optimal performance during the machining process.

10. What Safety Measures Should Be Taken in CNC Aluminum Machining?

Safety is a critical consideration in CNC aluminum machining. As with any machining process, operators should wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and ear protection. Ensuring that the workplace is clean and free from hazards is also essential for reducing the risk of accidents.

CNC machines should be operated according to strict safety protocols. Machine guards and sensors should be in place to prevent accidental contact with moving parts. Additionally, operators should be trained in safe operating procedures and know how to handle any emergency situations.

11. How Do You Maintain CNC Machines for Aluminum Machining?

Regular maintenance is essential to keep CNC machines in optimal condition. This includes cleaning the machines to remove any debris, checking for wear on components, and ensuring that all moving parts are lubricated.

Calibration is another crucial aspect of machine maintenance. CNC machines should be regularly calibrated to ensure they maintain the accuracy and precision required for aluminum machining.

12. How Much Does CNC Aluminum Machining Cost?

The cost of CNC aluminum machining depends on several factors, including the complexity of the part, the type of machine used, and the quantity of parts being produced. Generally, more complex parts with tighter tolerances will cost more to produce.

13. What Are the Future Trends in CNC Aluminum Machining?

Looking ahead, the future of CNC aluminum machining is likely to be shaped by advancements in machine technology and automation. New machines with greater speed and precision are being developed, allowing manufacturers to produce parts more efficiently.

14. How to Choose a CNC Aluminum Machining Service?

When selecting a CNC aluminum machining service, it’s important to consider several factors, such as the company’s experience, the quality of their machines, and their ability to meet your specific needs. Evaluating their turnaround times and cost-efficiency is also crucial for making an informed decision.

15. What Are Some FAQs About CNC Aluminum Machining?

The FAQ section will answer common questions and provide additional insights into CNC aluminum machining. Topics covered will include common misconceptions, tips for optimizing the machining process, and advice on choosing the right machining service.

Conclusion

CNC aluminum machining is an incredibly versatile and efficient method for producing high-quality aluminum components. It offers significant advantages in terms of precision, repeatability, and cost-effectiveness. By understanding the various aspects of CNC aluminum machining—from materials and machines to processes and challenges—businesses can make informed decisions that improve both the quality and cost-efficiency of their manufacturing processes.

FAQ Section

Q1: What is CNC Aluminum Machining?

CNC aluminum machining is a manufacturing process that uses computer-controlled machines to cut, shape, and finish aluminum parts with high precision.

Q2: How does CNC Aluminum Machining work?

CNC aluminum machining involves using CAD and CAM software to design and program the machining process, which is then carried out by CNC machines to create precise aluminum parts.

Q3: What are the main advantages of CNC Aluminum Machining?

CNC aluminum machining offers high precision, repeatability, and efficiency, allowing manufacturers to produce complex parts quickly and accurately.

Q4: How can I choose the best CNC Aluminum Machining service for my needs?

Consider factors like the company’s experience, the quality of their machines, their ability to meet your specifications, and their cost-efficiency when choosing a service provider.

Q5: What safety measures should be followed in CNC Aluminum Machining?

Safety measures include wearing PPE, following machine safety protocols, and ensuring that operators are well-trained to handle the machinery and materials safely.