Introduction

CNC machining aluminum is a vital process for many industries due to its precision and efficiency. In this article, we will break down the various factors that affect the cost of CNC machining aluminum. Understanding these factors can help you make informed decisions whether you’re sourcing aluminum parts or planning your next project. We’ll explore everything from material selection to design considerations, and how these influence the cost. So, let’s dive into the details and understand what goes into pricing CNC machining aluminum.

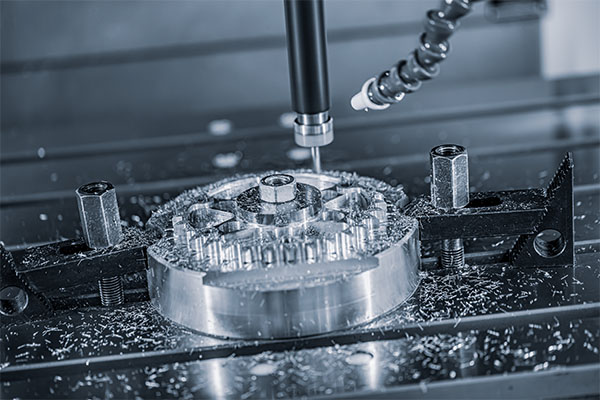

1. What is CNC Machining Aluminum?

CNC machining aluminum refers to the use of computer-controlled machines to shape and cut aluminum into precise parts or products. The process involves removing material from a solid aluminum block using tools like mills, lathes, or routers. The end product is a component with exact dimensions, making CNC machining ideal for industries that require high precision, such as aerospace, automotive, and electronics.

But here’s the kicker: aluminum is one of the most versatile metals used in CNC machining. It’s lightweight, durable, and resistant to corrosion, which is why it’s used in such a wide range of applications. The versatility of CNC machining aluminum makes it a go-to material for manufacturers worldwide.

This process starts by selecting the right type of aluminum, which can range from common grades like 6061 to specialized alloys. From there, the machining process involves using automated tools to cut, drill, and finish the aluminum parts to meet specific design requirements. The precision that CNC machining offers is why it’s often preferred over manual machining methods, ensuring consistent results for high-volume production runs.

Here’s a table summarizing the different aluminum alloys used in CNC machining and their key features:

Aluminum Alloys Used in CNC Machining

| Alloy | Key Features | Common Applications |

|---|---|---|

| 6061 | Good strength, lightweight, corrosion-resistant | Aerospace, automotive, marine |

| 7075 | High strength, resistant to stress corrosion cracking | Aircraft, military, sporting equipment |

| 2024 | High strength, excellent fatigue resistance | Aerospace, defense |

| 3003 | Good corrosion resistance, lightweight | Cooking utensils, chemical equipment |

2. Why is CNC Machining Aluminum Popular?

CNC machining aluminum is highly popular due to several key benefits that make it a preferred choice for manufacturers. One of the biggest advantages is aluminum’s lightweight nature. It provides strength while still being easy to handle, making it ideal for industries like aerospace and automotive, where weight reduction is crucial.

What’s the real story? The popularity of CNC machining aluminum isn’t just about its lightweight properties. Aluminum also offers excellent durability and resistance to corrosion, making it perfect for components exposed to harsh environments. Whether it’s exposed to high temperatures or aggressive chemicals, aluminum parts are durable and maintain their integrity.

The process also offers flexibility in design. With CNC machining, manufacturers can achieve intricate and complex designs with precision. This opens up a wide range of applications across various sectors, including medical devices, electronics, and industrial machinery. Aluminum’s ability to withstand harsh conditions, combined with its flexibility in design, makes it a go-to material for many industries.

Here’s a table highlighting some of the key advantages of CNC machining aluminum:

Key Advantages of CNC Machining Aluminum

| Benefit | Description |

|---|---|

| Lightweight | Aluminum is much lighter than many other metals like steel and titanium, reducing overall weight. |

| Corrosion Resistance | The material naturally resists corrosion, making it ideal for use in harsh environments. |

| Versatility | Suitable for a wide range of applications, from aerospace to consumer electronics. |

| Cost-Effective | Aluminum is relatively inexpensive compared to other metals like titanium or steel. |

3. What Factors Affect the Cost of CNC Machining Aluminum?

Several factors influence the cost of CNC machining aluminum, making it crucial for businesses to consider all aspects before starting a project. Material costs are one of the first considerations. The grade of aluminum selected will play a major role in determining the price. For instance, higher-grade aluminum alloys like 7075 are more expensive than 6061, but they offer better strength and durability, making them ideal for demanding applications.

Ready for the good part? Another major factor is the complexity of the design. The more intricate the design, the more time it will take to machine, which will increase the cost. For instance, machining parts with complex features like deep holes, tight tolerances, or advanced surface finishes will require specialized equipment and tools, which can drive up prices.

Additionally, the number of parts being produced also plays a role in determining costs. Lower production volumes often result in higher per-part costs because of setup and tool changes. Conversely, higher production runs benefit from economies of scale, making the per-part cost much lower.

Here’s a table summarizing the main factors that affect CNC machining aluminum costs:

Key Cost Factors in CNC Machining Aluminum

| Factor | Description |

|---|---|

| Material Selection | The grade of aluminum chosen (e.g., 6061 vs. 7075) affects the base cost. |

| Design Complexity | Complex designs with intricate features or tight tolerances are more costly to machine. |

| Quantity | Small batch production increases the cost per part due to setup and tooling changes. |

| Machine Time | Longer machining times lead to higher costs, especially for detailed parts. |

4. How Do CNC Machining Services Calculate Costs?

CNC machining services calculate costs based on several key elements. One of the primary components is the machine time, which is the amount of time the CNC machine spends on each part. The longer the machining process, the higher the cost. CNC services typically charge on an hourly basis, with rates varying depending on the machine type and complexity of the task.

So, what’s involved in calculating the price? Apart from machine time, there are other factors like setup time, tooling costs, and post-processing. For instance, specialized tooling for certain parts can significantly add to the cost, as can post-machining processes such as finishing, coating, or heat treatment. These additional services are necessary for achieving the desired quality but come with added costs.

Another important consideration is the cost of labor. While CNC machining is automated, skilled technicians are still required to set up and monitor machines. The labor costs associated with these tasks will also factor into the overall pricing.

Here’s a breakdown of how CNC machining costs are calculated:

Breakdown of CNC Machining Cost Calculation

| Cost Component | Description |

|---|---|

| Machine Time | Cost based on the hours the CNC machine operates. |

| Setup Time | Time spent setting up the machine and preparing for production. |

| Tooling Costs | The cost of specialized tools needed for machining specific parts. |

| Labor Costs | Skilled labor needed for machine operation, setup, and oversight. |

5. What is the Average CNC Machining Aluminum Cost?

The average cost of CNC machining aluminum can vary greatly depending on the factors mentioned above. Generally, the cost ranges from $50 to $150 per hour, depending on the complexity and materials used. For simple aluminum parts with minimal design, the costs may be on the lower end, while more complex, highly detailed parts can push the cost higher.

But here’s the kicker: While the cost per part can vary, bulk orders typically reduce the cost significantly due to economies of scale. For example, ordering 100 parts may cost significantly less per unit compared to ordering 10 parts. Companies that need large production runs often find CNC machining to be more affordable in the long term, despite the higher initial cost.

Here’s a table comparing typical machining rates for different part complexities:

Typical CNC Machining Rates for Aluminum Parts

| Part Complexity | Cost per Hour |

|---|---|

| Simple Parts | $50 – $75 |

| Medium Complexity | $75 – $100 |

| High Complexity | $100 – $150 |

6. How Do Design and Tolerances Impact CNC Machining Costs?

The design of the part and the tolerances required play a significant role in determining the cost of CNC machining aluminum. More intricate designs or those with tighter tolerances require more advanced machines and longer machine times, thus increasing costs. When a design calls for high precision, such as in aerospace or medical device manufacturing, the price of CNC machining can increase significantly.

What’s the real story? Tight tolerances, such as those requiring dimensions within thousandths of an inch, demand more time for machining and careful calibration, which means higher costs. It’s crucial for companies to understand that choosing tight tolerances must be balanced against the cost to ensure the final product is within budget.

Here’s a table showing how different tolerance levels affect machining time and cost:

Impact of Tolerance on CNC Machining Costs

| Tolerance Level | Machining Time | Cost Impact |

|---|---|---|

| Loose Tolerances | Shorter | Lower cost |

| Standard Tolerances | Moderate | Moderate cost |

| Tight Tolerances | Longer | Higher cost |

7. Can You Reduce CNC Machining Aluminum Costs?

Yes, there are several strategies you can use to reduce the cost of CNC machining aluminum. One of the most effective ways is by optimizing the design to minimize material waste. For instance, creating a design that uses the most efficient cutting patterns and reducing unnecessary excess material can lead to cost savings. This is especially important because raw material costs can make up a significant portion of the overall machining cost.

What’s the real story? Another key factor in reducing costs is selecting the right machining process. While CNC machining is highly versatile, other processes like die-casting or injection molding might offer a more cost-effective solution depending on the complexity and volume of the part. For smaller, less complex parts, it might be worth considering alternative methods to reduce costs further.

Another approach is to work with the right CNC service provider. Choosing a provider that offers competitive rates and has access to the latest, most efficient machines can help lower the overall cost. Additionally, negotiating with suppliers for bulk material discounts and optimizing the production schedule to reduce downtime can contribute to overall cost savings.

Here’s a table showing a few methods to reduce CNC machining costs:

Methods to Reduce CNC Machining Aluminum Costs

| Method | Description |

|---|---|

| Optimize Design | Reduce material waste by designing parts with efficient cutting patterns. |

| Choose the Right Process | Evaluate alternative manufacturing methods that might be more cost-effective. |

| Use Standard Tools | Standardize tooling to reduce setup times and lower costs. |

| Bulk Orders | Larger orders reduce cost per unit due to economies of scale. |

8. How Does Batch Size Influence CNC Machining Costs?

Batch size plays a critical role in determining the cost of CNC machining aluminum parts. For small production runs, the per-part cost tends to be higher due to setup time, machine calibration, and tooling changes. This is because each part requires a new setup, and each setup takes time and labor.

Ready for the good part? When you increase the batch size, the per-part cost typically decreases. This is because the setup time and tooling costs are spread out over a larger number of parts, making each part less expensive to manufacture. Larger batch sizes allow manufacturers to achieve economies of scale, which is a crucial factor in reducing overall costs.

The decision on batch size should always be made based on the project’s requirements. If you only need a small number of parts, it might be worth paying the higher per-part cost. However, if you’re planning for mass production, larger batch sizes are the way to go.

Here’s a table showing how batch size impacts the cost:

Impact of Batch Size on CNC Machining Costs

| Batch Size | Cost per Part | Description |

|---|---|---|

| Small Batch | Higher | Costs increase due to setup and tooling for each part. |

| Medium Batch | Moderate | Setup costs are spread across more parts, reducing cost per unit. |

| Large Batch | Lower | Significant cost savings due to economies of scale and fewer setups. |

9. What Are the Benefits of Outsourcing CNC Machining Aluminum?

Outsourcing CNC machining aluminum can bring a number of benefits, especially for businesses that do not have the equipment, resources, or expertise to handle machining in-house. By outsourcing, companies can tap into specialized knowledge and cutting-edge technology that may be expensive or impractical to maintain internally.

But here’s the kicker: outsourcing also provides flexibility. You can scale production up or down without the need for long-term investment in machinery or skilled labor. Additionally, outsourcing to experienced CNC machining companies can result in faster turnaround times, reducing lead times and improving time-to-market for your products.

Outsourcing also allows companies to focus on their core competencies. Rather than investing time and resources into learning CNC machining, businesses can concentrate on other aspects of their operations, such as marketing, design, or product development. This is a strategic way to allocate resources more efficiently.

Here’s a table comparing the benefits of in-house vs. outsourced CNC machining:

In-House vs. Outsourced CNC Machining

| Factor | In-House | Outsourced |

|---|---|---|

| Cost | High initial investment in equipment and labor | Lower costs due to economies of scale |

| Flexibility | Limited scalability | Highly flexible with scalability options |

| Expertise | Requires internal training | Access to specialized expertise |

| Speed | Depends on available equipment | Faster turnaround with experienced providers |

10. How Do Different CNC Machines Affect Cost?

The type of CNC machine used can have a significant impact on the cost of machining aluminum parts. CNC milling machines, CNC lathes, and CNC routers each come with their own set of advantages and limitations. Milling machines, for example, are versatile and can create a wide range of shapes, but they tend to be more expensive to operate.

What’s the real story? Advanced machines with higher precision capabilities can also drive up costs. Machines that can handle multiple axes or complex tool paths require more sophisticated programming and setup, which increases the overall cost of machining. On the other hand, simpler machines that operate on fewer axes are cheaper to use but may not be as versatile.

Additionally, machines that are highly automated may have higher upfront costs but can reduce labor and operational costs in the long run. These machines can work around the clock, increasing production efficiency and lowering per-part costs for larger runs.

Here’s a table summarizing the cost comparison between different CNC machines:

CNC Machine Cost Comparison

| Machine Type | Features | Cost Impact |

|---|---|---|

| CNC Milling | Versatile, can handle complex parts | High initial cost, but versatile and efficient |

| CNC Lathe | Used for cylindrical parts, precise | Moderate cost, efficient for specific tasks |

| CNC Router | Good for large sheets of material | Lower cost, but limited in capabilities |

| Multi-Axis CNC | Can perform complex cuts in multiple directions | High cost, but suitable for high-precision tasks |

11. Are There Additional Costs Associated with CNC Machining Aluminum?

While CNC machining aluminum is often cost-effective, there are several additional costs to consider. One such cost is tooling. Specialized tools for cutting or finishing aluminum parts can be expensive, especially when custom tooling is required. This cost is typically factored into the overall pricing of the part.

Here’s where it gets interesting: finishing processes, such as anodizing, polishing, or coating, can add to the cost. These post-machining processes are often necessary to achieve the desired final product quality and appearance. For example, anodizing aluminum can enhance its corrosion resistance and aesthetic appeal, but it comes at an additional cost.

Shipping and handling costs can also add to the overall price, particularly when machining requires parts to be transported between different locations for additional processes. It’s important to account for these additional costs when budgeting for CNC machining projects.

Here’s a table showing the additional costs associated with CNC machining aluminum:

Additional CNC Machining Costs

| Cost Component | Description |

|---|---|

| Tooling | Specialized cutting and finishing tools can increase costs. |

| Finishing | Post-machining processes like anodizing or polishing. |

| Shipping | Costs for transporting parts to other facilities or customers. |

12. How Does CNC Machining Aluminum Compare to 3D Printing?

CNC machining aluminum and 3D printing are both popular manufacturing techniques, but they differ in cost, application, and quality. CNC machining is often preferred for producing high-precision parts, especially when strength and durability are required. The material cost and labor involved in CNC machining are typically higher, but the results are often more reliable.

What’s the real story? On the other hand, 3D printing is more cost-effective for low-volume production runs. However, it may not always provide the same level of precision or strength as CNC machining. 3D printing is better suited for prototyping and parts that require more complex geometries that are difficult or impossible to achieve with traditional machining.

Here’s a table comparing CNC machining aluminum and 3D printing:

CNC Machining vs 3D Printing for Aluminum Parts

| Aspect | CNC Machining | 3D Printing |

|---|---|---|

| Precision | High, with tight tolerances | Moderate, depends on the printer and material |

| Material Strength | Stronger, ideal for functional parts | Lower strength, more suited for prototypes |

| Cost | Higher, especially for small runs | Lower, especially for low-volume production |

| Speed | Faster for larger runs | Slower, but faster for prototyping |

13. What Is the Impact of Material Thickness on CNC Machining Costs?

The thickness of the aluminum material can have a significant impact on the cost of CNC machining. Thicker materials require more machining time and more powerful equipment, both of which add to the overall cost. Parts that require deep cuts or heavy material removal will naturally be more expensive to produce.

But here’s the kicker: thinner materials, while easier and quicker to machine, may not always be suitable for applications that require strength and durability. It’s important to balance material thickness with the desired strength and functionality of the final product.

Here’s a table showing how material thickness can affect machining time and cost:

Material Thickness vs. CNC Machining Cost

| Material Thickness | Machining Time | Cost Impact |

|---|---|---|

| Thin Material | Shorter machining time | Lower cost |

| Standard Thickness | Moderate machining time | Moderate cost |

| Thick Material | Longer machining time | Higher cost |

14. How Can You Find the Best CNC Machining Aluminum Services?

Finding the best CNC machining aluminum service requires considering several factors. The first is experience. Look for a service provider with a proven track record in machining aluminum, particularly for the types of parts you need. Also, consider the technology they use. The latest CNC machines and technology can offer better precision, faster turnaround times, and lower costs.

What’s the real story? A good CNC machining service should also offer excellent customer support and clear communication. You’ll want a provider that can work closely with you to ensure your needs are met and to help troubleshoot any potential issues that arise during the machining process.

Here’s a table showing key factors to consider when selecting a CNC machining service:

Key Factors When Choosing a CNC Machining Service

| Factor | Importance |

|---|---|

| Experience | A proven track record in CNC machining aluminum. |

| Technology | Advanced machinery and precision capabilities. |

| Communication | Clear and responsive communication throughout the process. |

| Pricing | Competitive pricing without compromising quality. |

15. What Are the Key Considerations Before Starting a CNC Machining Aluminum Project?

Before beginning a CNC machining aluminum project, it’s essential to have a clear understanding of your budget, timeline, and the final part requirements. Proper planning can help prevent costly mistakes and ensure that the project stays within budget. Understanding the materials, design requirements, and finishing processes needed will allow you to select the best CNC machining service.

Ready for the good part? It’s also important to evaluate the long-term needs of the project. Will you need to scale production, or is this a one-time order? Considering these factors upfront can save you money and time down the road.

Here’s a table showing the key considerations before starting a CNC machining aluminum project:

Key Considerations Before Starting CNC Machining

| Consideration | Description |

|---|---|

| Budget | Make sure your project aligns with your budget. |

| Timeline | Factor in lead times for prototyping, production, and shipping. |

| Material & Design | Ensure the right materials and design are chosen to meet your specifications. |

| Long-Term Needs | Determine if you’ll need a high-volume run or if this is a one-time project. |

FAQ Section

Q1: What is CNC machining aluminum?

CNC machining aluminum refers to the process of using computer-controlled machines to cut and shape aluminum into precise parts or products. This process is used across a variety of industries due to aluminum’s versatility and strength.

Q2: How does CNC machining work?

CNC machining works by using automated tools to cut, drill, and shape aluminum parts from a solid block based on a computer-aided design (CAD). The machine moves along multiple axes to perform various tasks.

Q3: What factors influence the cost of CNC machining aluminum?

The cost is influenced by material selection, design complexity, machine time, labor costs, and the quantity of parts being produced. Higher complexity and tight tolerances increase the overall cost.

Q4: Can I reduce the cost of CNC machining aluminum?

Yes, optimizing designs to reduce material waste, choosing more cost-effective materials, and selecting the right machining process can help lower the cost of CNC machining aluminum.

Q5: How do batch sizes affect CNC machining aluminum costs?

Larger batch sizes benefit from economies of scale, reducing the cost per part. Smaller production runs typically cost more due to setup and tool changes.