Introduction

CNC machining is a key manufacturing process that enables high precision and efficiency when working with materials like aluminum. This article provides a comprehensive guide to CNC machining of aluminum parts, explaining why it’s a popular choice, how the process works, and the best practices for optimizing machining operations. Whether you’re new to CNC machining or looking to improve your aluminum machining processes, this guide will help you understand the essentials, tackle common challenges, and achieve the best results.

1. What is CNC Machining and How Does it Work?

CNC machining is a process that uses computer-controlled machines to create parts with high precision. These machines follow a specific set of instructions, known as G-code, that tell the machine exactly how to move, what tools to use, and how fast to operate. The process begins with a CAD (Computer-Aided Design) file that contains the design of the part to be machined.

But here’s the kicker: CNC machining allows for highly complex designs and precise tolerances that would be difficult or impossible to achieve with manual machining. In CNC machining, the material—typically a block of metal, plastic, or composite—is placed on the machine, and tools are used to cut or shape the material into the desired part.

CNC machines can perform various functions, such as drilling, milling, turning, and tapping. The versatility of these machines makes them ideal for producing aluminum parts in industries like aerospace, automotive, and electronics. The machine’s ability to execute repetitive tasks with pinpoint accuracy also reduces human error and ensures consistent quality.

The main advantage of CNC machining is its ability to work with complex shapes and designs, delivering parts that are virtually identical each time they are produced. This makes CNC machining the go-to process for mass production and high-quality machining of aluminum parts.

2. Why Choose CNC Machining for Aluminum?

Aluminum is an excellent material for CNC machining due to its combination of strength, light weight, and resistance to corrosion. But what makes it even more appealing is its machinability—aluminum is easier to machine than many other metals, making it ideal for precision operations.

What’s the real story here? CNC machining of aluminum offers a few notable advantages. First, it provides precise control over dimensions and tolerances, ensuring that parts meet stringent specifications. Additionally, aluminum’s low density allows for the creation of lightweight components without compromising strength. This makes CNC-machined aluminum parts a popular choice in industries like aerospace and automotive, where weight is a critical factor.

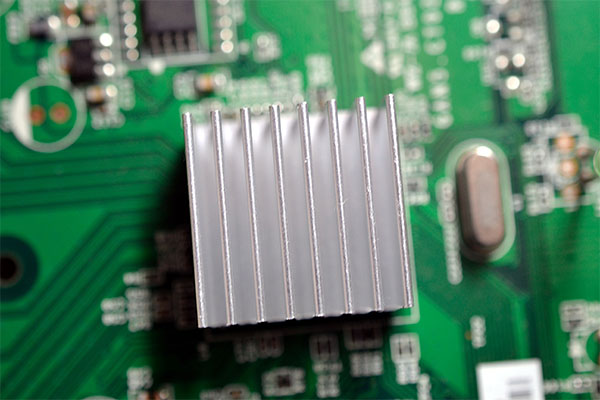

Here’s a fun fact: Aluminum has a high thermal conductivity, which helps dissipate heat from machined parts. This is why it’s commonly used for heat exchangers, radiators, and other components where heat management is essential. It’s also highly durable, which means parts last longer, reducing the need for frequent replacements or repairs.

By choosing CNC machining, manufacturers can ensure that aluminum parts are produced with minimal waste, efficient cycle times, and consistent quality.

3. What Are the Key Steps in CNC Machining of Aluminum?

The process of CNC machining aluminum is systematic, involving multiple stages to ensure precision and quality. First, the CAD design is converted into a machine-readable file. The G-code, which contains all the necessary instructions, is then uploaded to the CNC machine.

Here’s where it gets interesting: The first step in the actual machining process is often to secure the aluminum workpiece to the CNC machine bed. Once secured, the machine starts removing material to create the desired shape, which may involve drilling, milling, or turning operations. During each stage, careful monitoring ensures that the process stays on track, and any potential issues are addressed before they can affect the quality of the final part.

To ensure the part meets the design requirements, each stage of the process involves detailed inspection. For instance, after milling, the part may be checked for dimensional accuracy using coordinate measuring machines (CMM). If needed, additional fine-tuning is done until the part is perfect.

Finally, finishing touches like deburring, polishing, or anodizing may be applied to enhance the part’s appearance or performance. This comprehensive process guarantees that the final aluminum part is both functional and aesthetically pleasing.

4. How to Choose the Right CNC Machine for Aluminum?

Choosing the right CNC machine is crucial for effective machining of aluminum. But why does it matter so much? The CNC machine you select will directly impact the quality of your final product, as well as the efficiency of your operations.

The first thing to consider is the type of machining operation you require—milling, turning, or drilling. For example, if you’re making complex shapes, a 5-axis CNC machine might be the best choice, as it allows for machining on multiple sides of a part simultaneously. Alternatively, for simpler operations, a 3-axis machine could suffice.

Next, you need to consider the machine’s size and capabilities. Aluminum parts come in all shapes and sizes, so it’s important to choose a CNC machine that can handle the size of your workpieces. Additionally, some machines are equipped with more advanced features, like automatic tool changers or high-speed spindles, which can significantly improve machining efficiency and accuracy.

Lastly, the software compatibility of the machine is an important consideration. If the machine isn’t compatible with the CAM (Computer-Aided Manufacturing) software you use, it could lead to delays or costly mistakes.

5. What Are the Best CNC Cutting Tools for Aluminum?

The choice of cutting tools plays a significant role in the success of CNC machining operations. Aluminum is a relatively soft material compared to others like steel, which means it can be machined with specialized tools. However, the right tool choice is essential for achieving clean cuts, preventing tool wear, and ensuring a high-quality surface finish.

Ready for the good part? When machining aluminum, carbide tools are often the best choice due to their durability and heat resistance. Carbide inserts and end mills are particularly effective in cutting through aluminum quickly without dulling prematurely.

In addition to material choice, tool coatings are also important. Coated tools, such as those with titanium nitride (TiN) or aluminum oxide (Al2O3) coatings, offer enhanced wear resistance and better performance when machining aluminum. These coatings help to reduce friction, improve chip removal, and extend tool life.

For smaller precision components, high-speed steel (HSS) tools can also be effective. While HSS tools don’t last as long as carbide tools, they are more affordable and can still produce quality parts for less demanding applications.

6. What Are the Challenges in CNC Machining of Aluminum?

While CNC machining of aluminum offers numerous benefits, it’s not without its challenges. For one, aluminum is prone to excessive heat generation during machining, especially at high speeds. This can lead to tool wear, dimensional inaccuracies, or even material deformation.

What’s the solution here? Effective heat management is key. By adjusting feed rates and spindle speeds, it’s possible to minimize heat buildup and ensure better cutting conditions. Additionally, using cutting fluids or coolants during the process can help to reduce temperatures and improve the quality of the finished part.

Another challenge in aluminum machining is maintaining the correct tolerances and avoiding material distortion. Aluminum can expand or contract slightly as it’s machined, so it’s crucial to account for these changes in the process. This is where high-precision CNC machines and skilled operators come into play.

Lastly, tool wear can be accelerated when machining aluminum, especially if the cutting conditions are not optimal. Regular maintenance of tools and machines is vital for reducing wear and extending tool life.

7. How to Improve CNC Machining Efficiency for Aluminum?

Improving machining efficiency not only reduces costs but also enhances production capacity. The most effective way to increase efficiency is by optimizing feed rates, spindle speeds, and depth of cuts. By finding the ideal combination of these variables, you can reduce cycle times and improve surface finishes, all while keeping tool wear to a minimum.

But here’s the kicker: Automation is another excellent way to boost efficiency. Implementing automatic tool changers, robotic part handling, or even automated in-process measurement systems can significantly speed up production times while maintaining high levels of precision.

Additionally, using CAM software to optimize toolpaths can also improve machining efficiency. CAM systems can simulate the entire machining process, allowing for adjustments that minimize material waste and maximize tool life.

8. What Role Does CAM Software Play in CNC Machining of Aluminum?

CAM software (Computer-Aided Manufacturing) plays a crucial role in the CNC machining process by translating CAD designs into machine-readable code. This software essentially provides the “instructions” that guide the CNC machine through the entire machining process.

What’s the real story here? CAM software helps to streamline production by optimizing toolpaths, selecting the right cutting tools, and calculating the most efficient machining strategies. This not only improves machining speed but also reduces errors and increases part accuracy.

Moreover, CAM software allows for advanced features like simulation and virtual machining. This enables manufacturers to test and adjust their machining processes before actually cutting any material, preventing costly mistakes and rework. Popular CAM software options like Mastercam and Fusion 360 are widely used in CNC machining of aluminum due to their powerful features and ease of use.

9. How Does Aluminum Machining Impact Sustainability?

Aluminum machining is often considered environmentally friendly due to the material’s recyclability. Aluminum can be recycled infinitely without losing its properties, making it a sustainable choice for many industries. However, the machining process itself can have environmental impacts, primarily through energy consumption and the use of cutting fluids.

What’s the kicker here? By using advanced machining techniques and more efficient CNC machines, manufacturers can reduce energy consumption and waste generation. Additionally, environmentally friendly cutting fluids are available, which reduce the impact on the environment and improve the sustainability of the process.

Another key factor in sustainability is the management of waste materials. Aluminum chips generated during machining can be recycled, and manufacturers can implement systems to collect and reuse these chips, reducing waste and maximizing material usage.

10. What Are the Key Aluminum Grades Used in CNC Machining?

Aluminum comes in a variety of grades, each with its own properties suited for different applications. Some of the most commonly used grades in CNC machining include 6061, 7075, and 2024.

Here’s the deal: Grade 6061 is one of the most versatile and widely used aluminum alloys. It offers a good balance of strength, corrosion resistance, and machinability, making it ideal for applications in aerospace, automotive, and construction. Grade 7075, on the other hand, is known for its high strength and is often used in aerospace and military applications where high performance is required.

Grade 2024 is another high-strength alloy, but it is more prone to corrosion, which means it’s often used in applications where strength is more important than corrosion resistance. Understanding the differences between these alloys is crucial when choosing the right material for CNC machining of aluminum.

11. How Does Surface Finish Affect CNC Machined Aluminum Parts?

The surface finish of CNC machined aluminum parts plays a significant role in both aesthetics and performance. A smooth, polished surface can improve the part’s appearance and reduce friction in applications like bearings and gears. But achieving the right surface finish requires careful control of machining conditions and post-processing steps.

What’s the secret? The choice of cutting tools, feed rates, and speeds can all impact the surface finish. For example, slower feed rates often produce finer finishes, but they can also increase machining time. Additionally, post-machining processes like polishing, anodizing, or coating can enhance the finish and provide added protection against corrosion and wear.

12. What is the Cost of CNC Machining Aluminum?

The cost of CNC machining aluminum depends on several factors, including the complexity of the part, the material grade, the machine used, and the quantity produced. For example, intricate designs or small production runs may result in higher per-unit costs due to longer machining times and additional setup requirements.

But here’s the kicker: While the initial cost may seem high, CNC machining offers long-term savings through its precision, repeatability, and low material waste. Additionally, aluminum’s cost-effectiveness and recyclability make it a competitive option in the long run.

13. How to Ensure High-Quality CNC Machined Aluminum Parts?

Achieving high-quality CNC machined aluminum parts requires precision in both the design and machining stages. Starting with a well-defined CAD model and ensuring that the right CNC machine and tools are selected is essential.

Here’s where it gets interesting: Quality control should be integrated throughout the entire process. After each machining step, it’s crucial to inspect the part using tools like coordinate measuring machines (CMM). Any deviations from the design specifications should be corrected immediately to prevent costly errors in the final product.

Regular maintenance of machines and tools is also essential to ensure continued accuracy and performance. By keeping machines in optimal condition, manufacturers can avoid quality issues caused by tool wear or machine malfunctions.

14. What Are Common Applications of CNC Machined Aluminum Parts?

CNC machined aluminum parts are used in a wide range of industries, from aerospace to consumer goods. In aerospace, aluminum is used for lightweight structural components, such as brackets and housings, that must meet strict strength and weight requirements.

What’s the real story here? In the automotive industry, CNC machined aluminum is used for everything from engine parts to trim pieces, where durability and lightweight properties are crucial. Aluminum’s ability to withstand corrosion makes it a popular choice for outdoor equipment, such as boats and bicycles, as well.

15. How Can You Avoid Common Mistakes in CNC Machining of Aluminum?

The most common mistakes in CNC machining of aluminum include improper machine settings, incorrect tool selection, and lack of proper maintenance. One mistake manufacturers often make is not optimizing feed rates and speeds for aluminum, which can result in excessive tool wear or poor surface finishes.

What’s the key here? Regularly inspecting parts during production can catch issues before they become problems. Additionally, investing in training for CNC operators can ensure that they fully understand the machining process and the nuances of working with aluminum.

Conclusion

CNC machining of aluminum is an essential manufacturing process for producing high-quality, precise parts in a wide range of industries. By understanding the key principles of CNC machining, selecting the right tools and machines, and optimizing processes for efficiency, manufacturers can produce top-tier aluminum parts with consistent quality and performance. The right approach to machining aluminum can lead to better results, fewer errors, and reduced costs, making it a go-to method for manufacturers worldwide.

FAQ Section

Q1: What is CNC machining?

CNC machining is a manufacturing process that uses computer-controlled machines to cut, shape, and form materials with high precision.

Q2: How does CNC machining work?

CNC machining involves converting a CAD design into a machine-readable file, which directs the CNC machine to perform specific tasks on a material.

Q3: Why is aluminum a popular material for CNC machining?

Aluminum is lightweight, durable, and corrosion-resistant, making it ideal for CNC machining. Its machinability allows for precise parts to be produced quickly and efficiently.

Q4: What are the benefits of using CNC over manual machining?

CNC machining offers higher precision, repeatability, and faster production times compared to manual machining, reducing errors and increasing efficiency.

Q5: How do I choose the right CNC machine for aluminum machining?\

Consider the complexity of the part, the size of the material, and the required machining operations to select the appropriate CNC machine for aluminum.