Introduction

When it comes to creating high-quality, custom parts, CNC aluminum machining offers some of the best solutions available today. Custom CNC aluminum parts are used in a wide variety of industries, ranging from aerospace to automotive, and offer superior precision, durability, and cost-effectiveness. This article will explore everything you need to know about custom CNC aluminum parts—from the manufacturing process to their applications and benefits. If you’re looking to understand how custom CNC aluminum parts can enhance your projects, you’re in the right place.

1. What Are Custom CNC Aluminum Parts?

Custom CNC aluminum parts are specifically manufactured components made from aluminum, designed to meet precise specifications using CNC (Computer Numerical Control) machining techniques. But here’s the kicker: CNC machining offers high precision, speed, and repeatability, making it ideal for industries requiring exact parts.

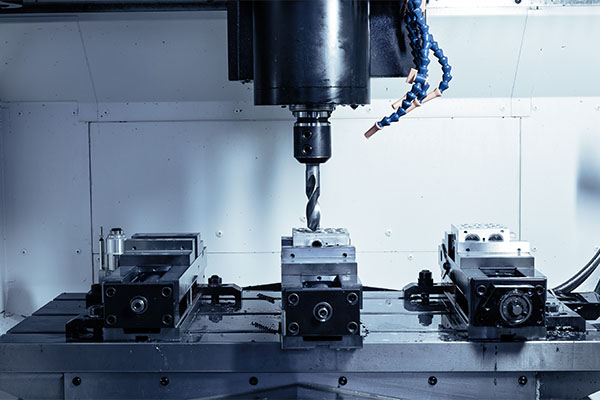

CNC machining is a subtractive process, where material is gradually removed from a solid block of aluminum to create a desired shape. Unlike traditional machining, CNC machining uses computer programs to control the movement of tools, enabling manufacturers to create intricate designs with minimal human intervention. CNC aluminum parts are widely used in industries where precision is key, including aerospace, automotive, and electronics.

Some of the main benefits of using CNC for aluminum parts include:

- Precision: CNC machining allows for tight tolerances and accuracy, often as low as 0.001 inches.

- Flexibility: Aluminum is a versatile material that can be used in various applications and designs.

- Strength: Aluminum parts are durable and lightweight, making them perfect for industries like aerospace.

Table 1: Benefits of CNC Aluminum Parts

| Benefit | Description |

|---|---|

| Precision | Allows for tight tolerances and accuracy |

| Flexibility | Can be used in various designs and applications |

| Strength | Durable and lightweight for demanding industries |

2. Why Choose CNC Aluminum Parts for Your Project?

You might be wondering, why choose CNC aluminum parts over other manufacturing processes or materials? CNC aluminum parts offer an array of advantages that make them the go-to choice for many industries.

Aluminum itself is a lightweight, strong, and durable material, making it ideal for custom parts. It’s also highly resistant to corrosion, especially when treated with anodization. These properties make aluminum a great choice for parts used in harsh environments, such as automotive and aerospace industries.

Additionally, CNC machining is incredibly efficient and precise. By using a computer-controlled machine, manufacturers can produce complex parts with minimal waste, reducing costs in the long run. The process is also highly repeatable, ensuring consistent quality across large production runs.

Here are a few reasons why CNC aluminum parts are the preferred choice:

- Lightweight and Strong: Aluminum is stronger than many other lightweight materials, making it perfect for aerospace and automotive parts.

- Customization: CNC machining allows for intricate designs, which would be difficult to achieve with other manufacturing methods.

- Cost-Effective: CNC machining minimizes material waste and offers high precision, reducing errors and the need for rework.

Table 2: Advantages of CNC Aluminum Parts

| Advantage | Description |

|---|---|

| Lightweight | Perfect for industries that require strength without the added weight |

| Customization | Allows for complex and detailed designs |

| Cost-Effective | Reduces waste and minimizes rework |

3. What Are the Key Applications of Custom CNC Aluminum Parts?

CNC aluminum parts are used across a variety of industries, thanks to their unique properties like lightweight, durability, and strength. The versatility of aluminum makes it suitable for a wide range of applications. But what’s the real story? CNC aluminum parts are especially popular in fields that demand high precision and reliability.

Here are some of the key applications of custom CNC aluminum parts:

- Aerospace: Aluminum is often used in the production of airplane parts due to its strength-to-weight ratio and resistance to corrosion.

- Automotive: CNC aluminum parts are used in car engines, wheels, and suspension components for lightweight and high-performance characteristics.

- Electronics: Aluminum is also commonly used for custom housings in electronic devices due to its heat conductivity and strength.

Table 3: Key Industries Using CNC Aluminum Parts

| Industry | Application |

|---|---|

| Aerospace | Aircraft parts, structural components |

| Automotive | Engine components, wheels, suspension parts |

| Electronics | Housings for devices, heat sinks |

4. How Does CNC Machining Work for Aluminum Parts?

Now, you might be curious: how does the actual CNC machining process work when making custom aluminum parts? In short, CNC machining is a computer-controlled process that can execute precise cuts and modifications to a block of aluminum. This process allows manufacturers to create parts with complex geometries and tight tolerances.

The steps typically include:

- Designing the Part: The first step is to design the part using CAD (Computer-Aided Design) software.

- Programming the CNC Machine: Once the design is ready, the part’s specifications are programmed into the CNC machine.

- Machining: The CNC machine uses rotary cutters, drills, and other tools to remove material from the aluminum block, creating the part.

- Finishing: After machining, the part may undergo finishing processes such as polishing or anodizing for added durability and aesthetics.

Table 4: CNC Machining Process for Aluminum Parts

| Step | Description |

|---|---|

| Design | CAD software is used to design the part |

| Programming | CNC machine is programmed with the part specs |

| Machining | Tools remove material from the aluminum block |

| Finishing | Parts are polished or anodized for durability |

5. What Are the Advantages of Custom CNC Aluminum Parts Over Standard Parts?

Here’s the deal: custom CNC aluminum parts provide significant advantages over standard parts, particularly when it comes to design flexibility, quality, and precision. Standard parts might suffice for basic applications, but when it comes to intricate, high-performance projects, custom CNC parts stand out.

Custom CNC parts are designed specifically for a particular project, meaning they can be optimized for specific requirements like weight, strength, or functionality. This level of customization ensures a perfect fit and improved performance in any application.

Additionally, CNC machining allows for:

- Precise Tolerances: Parts are made to exact specifications, ensuring consistent performance.

- High Durability: CNC aluminum parts are resistant to wear and tear, making them long-lasting.

- Better Fit: Custom CNC parts fit precisely into the designed space, improving overall performance.

Table 5: Advantages of Custom CNC Aluminum Parts

| Advantage | Description |

|---|---|

| Precise Tolerances | Made to exact specifications for a perfect fit |

| Durability | Resistant to wear, tear, and environmental factors |

| Custom Fit | Tailored to specific requirements for better performance |

6. How Can You Ensure High-Quality Custom CNC Aluminum Parts?

What’s the real story behind ensuring high-quality CNC aluminum parts? The key lies in choosing a reliable, experienced machining provider that can meet your specific requirements. To ensure top-notch quality, it’s crucial to evaluate the machining process, the material sourcing, and the provider’s overall capabilities.

Here are a few tips for ensuring high-quality custom CNC aluminum parts:

- Choose Experienced Providers: Work with a provider who has extensive experience with CNC aluminum machining.

- Use Quality Materials: Ensure that the aluminum used is of the highest grade and has been sourced responsibly.

- Quality Control: The provider should have stringent quality control processes in place to check parts at every stage.

Table 6: Quality Control Checklist for CNC Aluminum Parts

| Step | Description |

|---|---|

| Choose a Provider | Select an experienced CNC machining provider |

| Material Sourcing | Ensure high-grade aluminum material is used |

| Quality Control | Implement quality checks at every stage of production |

7. How Is CNC Aluminum Machining Different From Other Manufacturing Processes?

When it comes to choosing a manufacturing process for custom parts, there are many options available. CNC aluminum machining offers specific advantages over other methods, such as injection molding or additive manufacturing.

Unlike injection molding, which uses molten material injected into a mold, CNC machining uses a solid block of material, providing superior precision and control. Additive manufacturing, or 3D printing, is ideal for prototyping but often lacks the strength and material options available with CNC machining.

Table 7: CNC Aluminum Machining vs. Other Processes

| Process | Description | Advantages |

|---|---|---|

| CNC Machining | Subtractive manufacturing from solid material | High precision, variety of materials, cost-effective |

| Injection Molding | Material is injected into molds | Ideal for high-volume production |

| Additive Manufacturing | Builds parts layer by layer | Great for prototyping, less material waste |

8. What Are the Common Challenges in CNC Aluminum Machining?

CNC aluminum machining offers exceptional precision, but there are some challenges that manufacturers may face along the way. These challenges often arise from the specific properties of aluminum, such as its softness and tendency to accumulate heat during machining.

One of the main challenges is tool wear, which occurs due to the abrasive nature of aluminum. To address this, manufacturers may need to use specialized coatings or lubricants to reduce wear on the cutting tools. Another issue is heat buildup, which can affect the machining quality and lead to inaccuracies. Proper cooling techniques must be used to prevent this.

Table 8: Common Challenges in CNC Aluminum Machining

| Challenge | Solution |

|---|---|

| Tool Wear | Use of coated tools or lubrication |

| Heat Buildup | Implement cooling techniques during machining |

8. What Are the Common Challenges in CNC Aluminum Machining?

Despite its advantages, CNC aluminum machining does come with a few challenges that manufacturers must navigate. One of the primary issues is tool wear. Aluminum, though lightweight and strong, can be abrasive to cutting tools, causing them to wear out more quickly compared to other materials. This can lead to higher operational costs, as tools need to be replaced more frequently. The solution here lies in using specialized coatings on the tools or employing lubricants during the machining process to reduce friction and prolong tool life.

Another challenge that manufacturers face is heat buildup. Aluminum is a great conductor of heat, and when it is machined, the cutting process generates significant heat. Without proper cooling methods, this heat can cause thermal expansion, resulting in inaccuracies and potentially affecting the material properties of the finished part. To manage this, cooling systems like flood coolant or mist cooling are employed during the machining process to prevent overheating and maintain part quality.

Lastly, tolerance and finish can also be challenging. Achieving extremely tight tolerances is difficult when dealing with materials like aluminum, especially during mass production runs. This often requires highly precise CNC machinery and careful monitoring throughout the production process.

Table 8: Common Challenges in CNC Aluminum Machining

| Challenge | Solution |

|---|---|

| Tool Wear | Use of coated tools or lubrication |

| Heat Buildup | Implement cooling techniques during machining |

| Tolerance & Finish | Use high-precision machinery and continuous monitoring |

9. What Industries Benefit Most from CNC Aluminum Parts?

CNC aluminum parts are utilized in a wide range of industries, particularly those where precision and performance are crucial. One of the most prominent industries is aerospace. The aerospace sector requires components that are lightweight yet incredibly strong, making aluminum an ideal material. CNC aluminum machining enables the production of parts such as aircraft engine components, structural elements, and interior fittings, all while maintaining strict tolerance and quality standards.

In the automotive industry, CNC aluminum parts are essential for creating components like engine blocks, transmission parts, and suspension systems. The lightweight nature of aluminum improves fuel efficiency and vehicle performance, making it a popular choice in the automotive sector. CNC machining allows manufacturers to create these parts with the precision required for optimal performance.

Medical device manufacturing also relies heavily on CNC aluminum parts. From surgical instruments to implants, aluminum’s biocompatibility, strength, and corrosion resistance make it a top choice for high-precision components. CNC machining ensures that these parts are manufactured to exact specifications, improving the safety and efficacy of medical devices.

Table 9: Key Industries Using CNC Aluminum Parts

| Industry | Application |

|---|---|

| Aerospace | Aircraft parts, structural components |

| Automotive | Engine components, transmission, suspension parts |

| Medical | Surgical instruments, implants, medical devices |

10. How Do You Choose the Right CNC Aluminum Machining Service?

Choosing the right CNC aluminum machining service is critical to ensuring the success of your project. Here’s the thing: not all CNC providers offer the same level of service, so you need to consider several factors when selecting a machining partner.

First, experience matters. A provider with years of experience in machining aluminum parts will be more capable of meeting your specific needs and understanding the intricacies of working with this material. Look for companies that have worked in your industry or on similar projects, as they will have a deeper understanding of the required tolerances, finishes, and other specifics.

Another key factor is certifications. Many industries, particularly aerospace and medical, require that manufacturers hold certain certifications, such as ISO 9001, to ensure consistent quality. Verifying that your provider has these certifications can give you confidence in their ability to meet your quality standards.

Technology and Equipment are also crucial. CNC aluminum machining is only as good as the equipment being used. Ensure that the provider uses modern, high-quality CNC machines that are capable of achieving the precision and speed required for your project.

Table 10: Factors to Consider When Choosing a CNC Aluminum Machining Service

| Factor | Considerations |

|---|---|

| Experience | Look for providers with experience in your industry |

| Certifications | Verify ISO or industry-specific certifications |

| Technology & Equipment | Ensure use of modern CNC machines for high precision |

11. What Are the Costs Involved in Custom CNC Aluminum Parts?

The cost of producing custom CNC aluminum parts can vary depending on a variety of factors. Understanding these costs is crucial for businesses planning to manufacture custom parts. So, what’s the real story? There are several factors that influence the final price of CNC aluminum parts, including design complexity, material cost, and production volume.

Design complexity is one of the most significant cost drivers. More intricate designs, such as those with complex geometries or tight tolerances, will require more time and specialized equipment, which increases costs. The material cost of aluminum itself also plays a role. While aluminum is generally affordable, higher-grade materials or specific alloys may increase the price.

Production volume is another key factor. Small runs typically incur higher per-unit costs due to the setup time required for CNC machining. In contrast, larger production volumes benefit from economies of scale, reducing the per-part price. Additionally, the finishing process—such as anodizing, polishing, or coating—can also add to the cost.

Table 11: Factors Affecting CNC Aluminum Part Costs

| Factor | Impact on Cost |

|---|---|

| Design Complexity | More intricate designs increase machining time |

| Material Cost | High-grade materials or alloys raise the price |

| Production Volume | Small runs cost more per unit; large runs are cheaper |

| Finishing Process | Anodizing, polishing, and coatings add additional costs |

12. How Long Does It Take to Manufacture Custom CNC Aluminum Parts?

Time is money, and when it comes to manufacturing custom CNC aluminum parts, understanding the lead times is crucial. The time it takes to produce a custom part depends on a variety of factors, including the complexity of the design, production volume, and the provider’s capabilities.

A simple, straightforward part with minimal features may take just a few hours to produce, whereas a complex design with tight tolerances and custom finishes may require several days or even weeks. Additionally, prototyping may add extra time if you’re testing and refining a new design before final production.

In general, production time for CNC aluminum parts can range from a few days for basic parts to several weeks for large, complex orders. Expedited services are often available for rush orders, but these come at a premium.

Table 12: Estimated Production Times for CNC Aluminum Parts

| Design Complexity | Estimated Time to Manufacture |

|---|---|

| Simple Parts | 1-3 days |

| Moderate Complexity | 3-7 days |

| High Complexity | 1-3 weeks |

13. How Do You Optimize Your Design for CNC Aluminum Machining?

Optimizing your design for CNC aluminum machining is essential for reducing costs, improving production efficiency, and ensuring part quality. Here’s the deal: understanding how CNC machines work and how to adjust your designs accordingly can significantly improve your outcomes.

First, simplifying your design can help reduce machining time and costs. For instance, minimizing sharp angles and intricate features can lower tool wear and increase machining speed. Standardizing dimensions where possible also allows for faster setup and less variation in parts.

You should also consider material usage. Reducing the amount of material removed during the machining process not only lowers costs but also helps minimize waste. Using CAD software that is compatible with CNC machines allows for more efficient designs that minimize tool movements, which can cut down production time.

Table 13: Tips for Optimizing CNC Aluminum Part Design

| Tip | Benefit |

|---|---|

| Simplify Design | Reduces machining time and tool wear |

| Standardize Dimensions | Speeds up setup and reduces variation |

| Reduce Material Waste | Cuts material costs and minimizes waste |

14. How Do You Maintain CNC Aluminum Parts for Longevity?

Maintaining the longevity of your CNC aluminum parts is crucial for ensuring that they continue to perform at a high level over time. Proper maintenance helps to prevent wear, corrosion, and damage, ultimately extending the lifespan of your parts.

One of the most effective methods for maintaining aluminum parts is regular cleaning. Dust, debris, and oil buildup can cause parts to malfunction or degrade over time, so keeping them clean is essential. Surface treatments such as anodizing or coating can also help protect aluminum parts from corrosion, especially in harsh environments.

Proper storage is another critical factor. Parts should be stored in a cool, dry place to prevent exposure to moisture, which can lead to corrosion. Regular inspections are necessary to detect any signs of wear or damage early on, allowing for timely repairs or replacements.

Table 14: Maintenance Tips for CNC Aluminum Parts

| Maintenance Tip | Description |

|---|---|

| Regular Cleaning | Prevents buildup of dust, oil, and debris |

| Surface Treatments | Anodizing or coating protects against corrosion |

| Proper Storage | Keeps parts in optimal condition by avoiding moisture |

15. What Are the Future Trends in CNC Aluminum Machining?

As industries continue to evolve, so too does CNC aluminum machining. The future holds exciting developments in technology, material science, and production efficiency. Here’s where it gets interesting: CNC machining is expected to become even more efficient, accurate, and accessible.

Automation is one trend that is already making waves. The integration of AI and robotics into CNC machining processes allows for faster production times, reduced human error, and more cost-effective operations. Additive manufacturing (3D printing) is also expected to play a larger role, enabling the creation of complex aluminum parts with even less waste and at lower costs.

New materials and alloys are constantly being developed, offering better performance and greater resistance to wear and corrosion. Additionally, improvements in software will make designing and prototyping CNC aluminum parts easier and more intuitive.

Table 15: Future Trends in CNC Aluminum Machining

| Trend | Description |

|---|---|

| Automation | AI and robotics integration for faster production |

| Additive Manufacturing | 3D printing to create more complex parts with less waste |

| New Materials | Development of stronger, more corrosion-resistant alloys |

Conclusion

In conclusion, custom CNC aluminum parts offer a range of advantages for businesses in need of high-precision components. From aerospace to automotive and electronics, CNC aluminum machining is a critical process for producing strong, lightweight, and durable parts. By choosing the right provider, optimizing your design, and ensuring quality control, you can create custom aluminum parts that meet your exact needs and specifications. Whether you’re looking for a single part or large-scale production, CNC machining delivers unmatched accuracy and versatility.

FAQ Section

Q1: What is CNC machining? CNC machining is a computer-controlled manufacturing process that uses pre-programmed software to control the movement of tools, allowing for precise and complex part creation from various materials, including aluminum.

Q2: How does CNC machining work for aluminum parts? CNC machining works by feeding a digital design into a computer system that controls cutting tools to shape aluminum parts with high precision. The process involves cutting, drilling, and milling to achieve the final design.

Q3: Why should I use custom CNC aluminum parts? Custom CNC aluminum parts offer superior precision, flexibility in design, and the ability to tailor parts to specific requirements, making them ideal for industries that demand high-performance components.

Q4: What are the main industries that use CNC aluminum parts? Industries such as aerospace, automotive, medical, electronics, and manufacturing benefit from CNC aluminum parts due to their strength, lightweight properties, and precision.

Q5: How can I reduce costs when ordering custom CNC aluminum parts? To reduce costs, optimize your part design for simpler shapes, consider ordering in larger quantities, and work with an experienced CNC provider who can advise on cost-effective manufacturing methods.