Einführung

When it comes to manufacturing custom parts, precision is key. Custom Nylon CNC machining is a go-to solution for industries that require durable, reliable, and high-quality parts. In this article, we’ll dive into what Nylon CNC machining is, why it’s preferred, and how to choose the best services for your needs. Let’s get started.

1. What is Nylon CNC Machining?

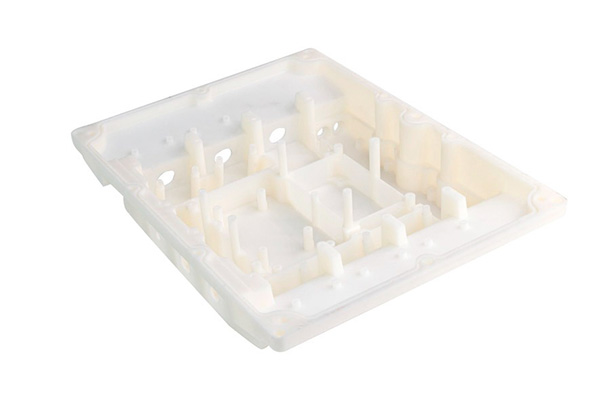

Nylon CNC machining is the process of using computer-controlled machinery to cut, shape, and carve Nylon material into precise, custom parts. It’s a method used by manufacturers across industries to create parts that meet specific designs and tolerances. But here’s the kicker—Nylon is a popular material because it has outstanding durability, chemical resistance, and the ability to withstand high wear and tear. It’s perfect for creating parts used in automotive, aerospace, medical devices, and more.

What’s the real story? Well, the beauty of Nylon CNC machining is that it’s a highly customizable process, offering flexibility in terms of part complexity. Whether you need simple washers or complex gears, CNC machines can do it all. With the added bonus of precision, the process ensures that the parts meet your exact specifications.

What makes Nylon ideal for CNC machining?

The primary reason Nylon is used in CNC machining is its excellent mechanical properties. Nylon is strong, abrasion-resistant, and flexible, making it ideal for parts that need to endure stress, heat, and friction. Its high fatigue resistance makes it a good choice for producing parts that undergo repeated motion, such as gears and bearings.

Ready for the good part? The CNC machining process itself can handle high tolerances, ensuring that the parts are consistent and precise every time. The combination of material and precision machining makes Nylon a go-to for custom parts in various industries.

| Besonderheit | Nylon CNC Machining | Other Materials |

|---|---|---|

| Haltbarkeit | Hoch | Varies |

| Chemical Resistance | Exzellent | Mäßig |

| Wear Resistance | Exzellent | Niedrig |

2. Why is Nylon Popular for CNC Machining?

You might be wondering why Nylon has become such a popular material for CNC machining. Well, Nylon’s properties make it the perfect fit for a wide range of applications. One of the key reasons Nylon is preferred is its strength-to-weight ratio. It’s stronger than many other materials but still lightweight, which is essential in industries like aerospace and automotive, where every ounce counts.

So, why does this matter? Nylon’s versatility in CNC machining is unmatched. It can be used in both low-stress and high-stress environments, making it suitable for everything from structural components to intricate parts. It also has great wear resistance, meaning parts made from Nylon can last much longer than those made from other materials.

Let’s take a closer look at some applications. For instance, in the automotive industry, Nylon is used for components like intake manifolds and fuel tanks. These parts need to be lightweight but also resistant to heat and wear, which is exactly what Nylon offers. In the medical industry, it’s used for surgical tools and implants because it’s biocompatible and resistant to chemicals.

So, ready to understand more? The durability, flexibility, and ease of machining make Nylon a highly favored material in CNC machining.

| Anwendung | Industrie | Material Benefits |

|---|---|---|

| Fuel Tanks | Automobilindustrie | Lightweight, Durable |

| Surgical Tools | Medizinisch | Biocompatible |

| Bearings | Industriell | Wear-resistant |

3. What Types of Nylon Are Used in CNC Machining?

Nylon comes in various grades and formulations, each suited for different applications. Here’s where it gets interesting—each type of Nylon offers unique benefits, and choosing the right one depends on the specific demands of your project.

The most common types of Nylon used in CNC machining are Nylon 6 Und Nylon 66. Nylon 6 is known for its excellent wear resistance and low friction, making it ideal for applications like gears and bearings. On the other hand, Nylon 66 offers better strength and thermal stability, which makes it perfect for high-performance applications.

What’s the real story? Nylon 12 is another variant that’s often used for applications that require low moisture absorption, such as in electrical components. Each type of Nylon has unique properties that make it suited for specific uses.

Now, how do you choose the right type for your project? It’s all about understanding the demands of your parts. Are they going to be exposed to high temperatures? Do they need to withstand repeated stress? Your CNC machining service provider can guide you through the selection process to ensure you get the best material for your needs.

| Nylon Type | Stärke | Best Use |

|---|---|---|

| Nylon 6 | High Wear | Gears, Bearings |

| Nylon 66 | High Strength | High-performance Parts |

| Nylon 12 | Low Moisture Absorption | Electrical Components |

4. What Are the Advantages of Custom Nylon Parts?

Custom Nylon parts have numerous advantages. First, they can be tailored to meet specific needs. Whether you’re looking for a custom shape, size, or performance characteristic, Nylon CNC machining allows you to create parts that are unique to your business.

But here’s the kicker—custom parts can offer a significant cost advantage, especially in small to medium production runs. Rather than paying for large-scale injection molding or other expensive manufacturing methods, you can use CNC machining to create high-quality parts at a fraction of the cost. Plus, there’s no need for tooling or molds, which can be expensive and time-consuming.

What’s the real story? The ability to customize parts allows for a higher degree of flexibility and precision. For instance, in the automotive industry, custom Nylon parts can be designed to perfectly fit specific machinery or vehicles. This not only improves the performance but also ensures that the parts integrate seamlessly with the rest of the system.

Another benefit? Custom Nylon parts can be manufactured quickly, which is crucial in industries that demand fast turnaround times. Whether you need a few parts for prototypes or a full batch for production, CNC machining can deliver the results you need on time and within budget.

| Vorteil | Nutzen |

|---|---|

| Customization | Tailored parts for specific needs |

| Cost Efficiency | No need for expensive molds |

| Schnelle Bearbeitung | Fast production and delivery |

5. How Does the CNC Machining Process Work for Nylon?

CNC machining is a precise, automated process that involves the use of computer-controlled machines to shape and carve material into a specific design. So, what’s the deal? The process begins with a 3D model of the part, which is fed into the CNC machine. From there, the machine follows the design and cuts the Nylon into the desired shape.

Now, here’s the thing—CNC machines can perform various operations like milling, turning, and drilling. For Nylon CNC machining, the most common methods are milling and turning, which can be used to create detailed and complex shapes. These processes ensure that parts are both functional and precise, meeting the design specifications exactly.

But it gets better! Because CNC machines are automated, they reduce human error and improve consistency. The result is a higher-quality part produced in less time compared to traditional methods. This makes CNC machining the ideal solution for custom Nylon parts that require a high degree of precision and quality.

| Verfahren | Beschreibung | Best Use |

|---|---|---|

| Mahlen | Removing material using rotating tools | Complex shapes |

| Drehen | Rotating the material while cutting it | Cylindrical parts |

| Bohren | Creating holes in the material | Hole drilling |

6. What Are the Key Benefits of Using Nylon CNC Machining Services?

The advantages of using Nylon CNC machining services are immense, and the benefits go beyond just producing high-quality parts. Ready for the good part? One of the most significant advantages is Präzision. CNC machining allows for very tight tolerances and exact specifications, ensuring that every part produced meets the exact design required. This level of accuracy is crucial for industries where parts must fit perfectly in highly technical systems.

What’s the real story? Beyond precision, CNC machining services can also offer consistency. Each part produced is identical to the last, which is especially important in mass production or when working on prototypes. CNC machining services are able to provide this reliability without the need for constant oversight or manual intervention, reducing human error and ensuring that your production runs smoothly.

Another key benefit of using Nylon CNC machining services is flexibility. With a wide range of machinery and tools available, CNC machining can be adapted to produce parts of almost any size, shape, or complexity. Whether it’s a simple, functional part or a highly intricate, detailed design, CNC machining can handle it all.

Finally, speed is a major advantage. The CNC machining process is significantly faster than traditional methods, such as manual labor or injection molding. This is especially important when dealing with tight deadlines or urgent orders. Whether you’re producing small runs or large batches, CNC machining can deliver fast results while maintaining high quality.

| Nutzen | Vorteil |

|---|---|

| Präzision | Tight tolerances, exact specifications |

| Consistency | Identical parts every time |

| Flexibility | Can handle parts of all sizes and complexities |

| Speed | Quick turnaround times |

7. How Does Nylon CNC Machining Compare to Injection Molding?

When considering manufacturing options for custom parts, one common question that arises is: What’s the difference between Nylon CNC machining and injection molding? This is where it gets interesting—both are widely used methods, but they each have unique advantages.

So, what’s the real story? Nylon CNC machining is best for creating parts that require high precision and tight tolerances. It’s also ideal when you need to create small quantities or prototypes. Since CNC machining uses digital designs, there’s no need for expensive molds, and changes to the design can be made quickly, saving time and money.

On the other hand, Spritzguss is more suited for large-scale production. In injection molding, the material is melted and injected into a mold, where it cools and hardens into the desired shape. This process is more cost-effective for mass production but requires expensive molds that can be costly and time-consuming to create. What’s more, design changes after mold production can be quite expensive.

Ready for the good part? The key advantage of CNC-Bearbeitung over injection molding is that it is more versatile. CNC machining allows for rapid prototyping, which means that you can quickly test and refine designs. Injection molding is better for mass production but isn’t as adaptable once the molds are created.

| Besonderheit | Nylon CNC Machining | Spritzguss |

|---|---|---|

| Präzision | Hoch | Mäßig |

| Production Volume | Low to medium | Hoch |

| Flexibility | Hoch | Niedrig |

| Cost (Initial Setup) | Lower | Higher |

8. What Are the Challenges in Nylon CNC Machining?

Nylon CNC machining is a powerful tool, but like any manufacturing process, it comes with its own set of challenges. But here’s the kicker—the material itself presents some difficulties that machinists must overcome to ensure optimal results.

What’s the real story? One of the primary challenges is the abrasiveness of Nylon. While it’s a tough and durable material, it can wear down machining tools more quickly than softer materials. This means that more frequent tool maintenance or replacement is required, which can increase costs and downtime.

Another challenge is material deformation. Nylon has a tendency to absorb moisture from the air, which can cause the material to expand or contract. This can affect the machining process, especially when tight tolerances are needed. To counteract this, machinists must ensure that the Nylon is properly stored and prepped before machining, and sometimes, the material must be baked to remove excess moisture.

Bereit für den guten Teil? Despite these challenges, Nylon CNC machining remains a top choice for many industries due to its versatility. By understanding these challenges and taking the proper precautions, manufacturers can overcome these obstacles and deliver high-quality, reliable parts.

| Herausforderung | Auswirkungen | Lösung |

|---|---|---|

| Tool Abrasiveness | Tools wear down quickly | Use hard coatings or more frequent tool replacements |

| Material Deformation | Changes in size due to moisture absorption | Pre-bake material and control storage conditions |

9. What Industries Can Benefit from Nylon CNC Machining?

Nylon CNC machining is versatile and adaptable, which makes it a valuable tool across multiple industries. So, why does this matter? The wide range of industries that benefit from Nylon CNC machining underscores its importance in modern manufacturing.

What’s the real story? The automotive industry is one of the primary beneficiaries of Nylon CNC machining. Nylon is commonly used for gears, bearings, and other internal components in vehicles. These parts need to be lightweight yet durable enough to withstand high pressures and temperatures, making Nylon the perfect material.

Im aerospace industry, precision parts are essential, and Nylon CNC machining provides the exacting standards needed. Components like bushings, brackets, and seals made from Nylon are used in aircraft because of their strength, lightness, and ability to resist wear in extreme conditions.

The Medizinindustrie also benefits from Nylon CNC machining. Parts like surgical tools, prosthetics, and diagnostic equipment need to be made from materials that are both durable and biocompatible. Nylon fits the bill, making it a popular choice for medical applications.

Ready for the good part? Industries like electronics, consumer goods, Und industrial machinery also rely on Nylon CNC machining for the production of durable, high-performance parts.

| Industrie | Anwendung | Nylon Benefits |

|---|---|---|

| Automobilindustrie | Gears, Bearings | Lightweight, Durable |

| Luft- und Raumfahrt | Bushings, Brackets | Strength, Lightweight |

| Medizinisch | Surgical Tools, Implants | Biocompatible, Durable |

| Electronics | Connectors, Casings | Precision, Durability |

10. How to Choose the Right CNC Machining Service for Nylon Parts?

Choosing the right CNC machining service for your Nylon parts can make all the difference in the final product. What’s the real story? The first thing to consider is Erfahrung. You want a CNC machining service that has worked with Nylon before and understands its unique properties. This ensures that they’ll be able to handle the material properly and produce high-quality results.

Another factor to consider is the capabilities of the CNC machines. Not all CNC machines are created equal, and certain machines are better suited for working with materials like Nylon. Ensure that the service you choose has state-of-the-art equipment capable of providing the precision and quality you need.

But here’s the kicker—don’t forget to review customer feedback and testimonials. Past clients can offer valuable insights into the quality of service, the speed of delivery, and how well the machining service meets expectations.

What’s the real story? If possible, visit the machining facility or ask for sample work before making a final decision. This gives you a sense of the service’s quality and ensures they have the right tools to meet your requirements.

| Faktor | What to Look For | Why It Matters |

|---|---|---|

| Experience | Familiarity with Nylon | Ensures quality results |

| Machine Capability | Advanced CNC equipment | Ensures precision |

| Customer Feedback | Testimonials and case studies | Provides trust and insight |

11. What Are the Typical Applications of Custom Nylon Parts?

Nylon parts are incredibly versatile, and custom Nylon parts can be designed for a wide variety of applications. Let’s break it down further. Bereit für den guten Teil? Custom Nylon parts can be used in industries ranging from aerospace to consumer electronics. Their ability to resist wear and handle high stress makes them perfect for everything from gears to medical devices.

Im automotive industry, custom Nylon parts are often used for gears, bushings, and washers. These parts need to be durable, lightweight, and capable of handling friction. Nylon fits the bill perfectly. Custom parts can be designed to meet specific shapes, sizes, and tolerances, ensuring that the part fits perfectly in the final assembly.

In medical applications, custom Nylon parts can be used for items like surgical tools, prosthetics, and diagnostic equipment. These parts must be biocompatible, durable, and able to withstand harsh cleaning processes. Custom CNC machining allows for highly precise, high-quality parts.

What’s the real story? Custom Nylon parts are also widely used in the consumer electronics industry for connectors, housings, and screens. Nylon’s electrical insulating properties make it ideal for these applications, and CNC machining ensures that parts are made to exact specifications.

| Industrie | Anwendung | Custom Nylon Benefit |

|---|---|---|

| Automobilindustrie | Gears, Washers, Bushings | Durability, Lightweight |

| Medizinisch | Surgical Tools, Prosthetics | Biocompatibility, Durability |

| Unterhaltungselektronik | Connectors, Housings | Electrical Insulation, Precision |

12. What Are the Cost Considerations for Nylon CNC Machining?

When planning a project using Nylon CNC machining, understanding the cost factors involved is crucial. But here’s the kicker—CNC machining can be highly cost-effective, especially for small to medium production runs, but several factors influence the price.

What’s the real story? The first thing to consider is the complexity of the part. More intricate designs require more time and effort to machine, which can increase costs. Toleranzen also play a role; the more precise the part needs to be, the more time-consuming and expensive the process.

Another factor is Menge. While CNC machining is affordable for small quantities, mass production can become more cost-effective when using other methods like injection molding. However, CNC machining remains competitive because it eliminates the need for expensive tooling costs.

Ready for the good part? The material cost of Nylon also affects pricing. Different grades of Nylon have different costs, and additional treatments, like moisture removal or heat treatment, can further impact the price.

| Faktor | Impact on Cost | Why It Matters |

|---|---|---|

| Part Complexity | Higher cost for intricate designs | More machining time required |

| Quantity | Lower for small runs, higher for mass production | Larger orders may reduce cost per unit |

| Material Choice | Nylon grade affects pricing | Different properties and performance |

13. How to Maintain and Care for Custom Nylon Parts?

Proper maintenance is key to ensuring the longevity of your custom Nylon parts. Bereit für den guten Teil? Regular care can extend the lifespan of your parts and keep them performing at their best.

What’s the real story? The most important aspect of maintaining Nylon parts is cleaning. Nylon parts should be regularly cleaned to remove dirt, debris, and oils that can affect performance. It’s also important to avoid using harsh chemicals that can degrade the material.

Another factor to consider is storage. Nylon is sensitive to moisture, and excess exposure to water or humid conditions can cause it to swell or warp. Store Nylon parts in a dry, cool place to ensure they retain their shape and strength over time.

But here’s the kicker—lubrication is important for parts that undergo repeated motion, such as gears or bearings. Proper lubrication reduces wear and tear, helping to extend the life of the part.

| Maintenance Tip | Nutzen | Why It’s Important |

|---|---|---|

| Regelmäßige Reinigung | Prevents dirt and debris build-up | Keeps parts functioning properly |

| Richtige Lagerung | Avoids moisture absorption | Prevents warping or swelling |

| Lubrication | Reduces wear and friction | Extends lifespan of moving parts |

14. What Are Some Common Mistakes to Avoid in Nylon CNC Machining?

Avoiding common mistakes is crucial for ensuring the success of your Nylon CNC machining project. But here’s the kicker—even small errors can lead to costly delays and unsatisfactory results. Let’s explore some of the most common mistakes.

What’s the real story? One common mistake is incorrect machine settings. If the machine settings aren’t adjusted to suit Nylon’s unique properties, it can result in poor-quality parts, tool damage, and increased costs.

Another mistake is failing to account for moisture absorption. Nylon has the ability to absorb moisture from the air, which can lead to size changes. To avoid this, parts must be properly dried before machining and stored in controlled conditions.

Bereit für den guten Teil? Not using the right type of Nylon can also be a mistake. Choosing the wrong grade for your application can result in parts that are too weak or not durable enough for the intended use. Always work with a CNC machining service that understands the different types of Nylon and can recommend the right material for your needs.

| Fehler | Consequence | Lösung |

|---|---|---|

| Incorrect Machine Settings | Poor quality parts, tool damage | Adjust settings for Nylon |

| Moisture Absorption | Material deformation | Pre-dry material, store properly |

| Wrong Nylon Grade | Weakened parts | Choose the appropriate grade |

15. How Can Nylon CNC Machining Support Sustainable Manufacturing?

Sustainability is becoming increasingly important in manufacturing, and Nylon CNC machining offers several ways to support environmentally friendly practices. What’s the real story? One of the primary advantages is waste reduction. Since CNC machining is a precise process, it minimizes material waste by using only the exact amount of material needed for the part.

But here’s the kicker—Nylon is recyclable. This means that parts can be recycled at the end of their lifecycle, reducing the overall environmental impact. Additionally, the ability to create custom parts on demand means that manufacturers aren’t overproducing or creating excess inventory, which contributes to a more sustainable approach.

Finally, energy efficiency is another advantage. CNC machines use energy efficiently by performing tasks with minimal waste. Combined with the sustainability of Nylon, CNC machining becomes a great choice for companies looking to reduce their environmental footprint.

| Nachhaltigkeitsfaktor | Auswirkungen | Nutzen |

|---|---|---|

| Waste Reduction | Reduces material waste | Less scrap material |

| Recycling | Nylon can be recycled | Reduces environmental impact |

| Energieeffizienz | CNC machines use energy efficiently | Lower energy consumption |

FAQ-Bereich

Frage 1: What is Nylon CNC machining?

Nylon CNC machining is a manufacturing process that uses computer-controlled machinery to cut, shape, and carve Nylon into custom parts with high precision and durability.

Frage 2: How does the CNC machining process work for Nylon?

The CNC machining process for Nylon starts with a 3D model that is fed into the machine, which then follows the design to cut, drill, or mill the material to create the part.

Frage 3: Why is Nylon a good material for CNC machining?

Nylon is strong, durable, and resistant to wear and chemicals, making it an ideal choice for parts that need to withstand stress, friction, and harsh environments.

Frage 4: What industries use Nylon CNC machining?

Industries such as automotive, aerospace, medical devices, and consumer electronics commonly use Nylon CNC machining to create custom, high-quality parts.

Frage 5: How do I choose the right type of Nylon for CNC machining?

The choice of Nylon depends on the specific needs of your parts. Nylon 6, Nylon 66, and Nylon 12 are common options, each offering unique strengths and benefits for different applications.