Einführung

Starting a CNC machining business offers lucrative opportunities, with the potential to serve various industries such as automotive, aerospace, and medical devices. Whether you’re a seasoned professional or an aspiring entrepreneur, understanding how to build a CNC business from the ground up is crucial for success. In this article, we will walk through the essential steps you need to take to launch a profitable CNC machining operation. From choosing the right equipment to navigating market demands, we will cover every detail to help you enter this competitive field with confidence.

1. Understanding CNC Machining: The Basics

Was ist CNC-Bearbeitung?

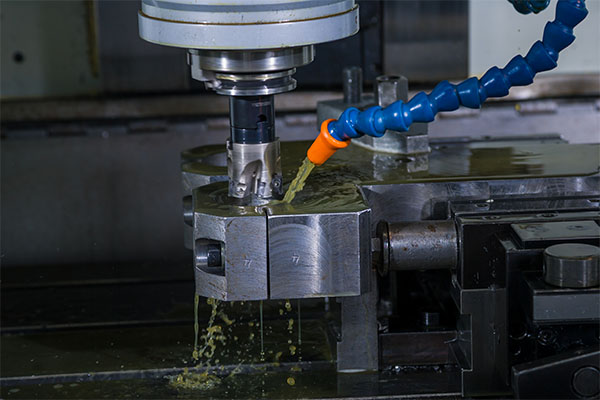

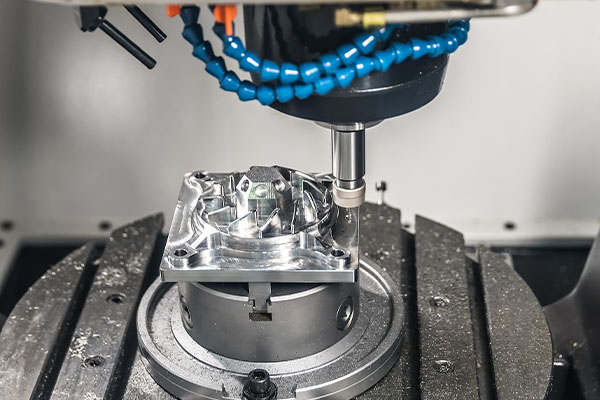

CNC machining refers to the use of computer-controlled machinery to automate the production of parts. This involves programming a machine to cut, shape, or finish a material based on precise measurements and designs. CNC machines are capable of operating with high precision, making them ideal for producing parts that require consistent quality. The process is applicable to a variety of materials, including metals, plastics, and composites, and can create everything from small parts to large components used in critical industries like aerospace and automotive.

Why is CNC Machining Important for Modern Manufacturing?

The role of CNC machining in modern manufacturing cannot be overstated. As industries increasingly demand high-quality, precise parts, CNC machining is becoming a key technology for meeting these needs. CNC machines streamline the production process by offering rapid turnaround times, reducing human error, and enhancing production efficiency. For businesses, this results in fewer defects and higher profits. By automating tasks that once required manual labor, CNC machining can also help reduce labor costs while maintaining a high level of craftsmanship. The technology’s adaptability makes it indispensable across various sectors, ensuring a growing market for CNC machining services.

2. Market Research: Analyzing Demand and Competitors

How Do You Analyze Market Demand for CNC Machining Services?

Before launching your CNC machining business, conducting thorough market research is crucial. The demand for CNC machining services is driven by industries that require precision-engineered parts. By focusing on specific sectors, such as automotive, aerospace, or medical devices, you can identify where your services will be most in demand. Investigating the local market will help you understand the scope of competition and whether the demand is sufficient to support a new business. Additionally, global demand for precision parts may create opportunities for remote operations or international clients, making it essential to understand where your expertise fits within the larger manufacturing ecosystem.

How to Assess Your Competitors?

Understanding your competition is essential for differentiating your services. Start by identifying key players in your area and analyzing their service offerings. Do they specialize in a particular type of part? Are they known for quick turnaround times or cost efficiency? Assess their strengths and weaknesses to determine how you can compete. It’s also crucial to monitor their pricing strategies and customer satisfaction levels. Bucket Brigades such as “So, what can you do differently?” or “Here’s what sets you apart” can help refine your positioning. Differentiation might come from offering specialized services, faster delivery, or exceptional customer support.

3. Setting Your CNC Machining Business Goals

What Are Your Short-term and Long-term Business Goals?

Once you understand the demand and competitive landscape, it’s time to set clear, actionable goals for your CNC machining business. Short-term goals might include securing your first set of clients or achieving a specific revenue target in the first year. Long-term goals, on the other hand, might focus on expanding your fleet of machines, increasing your capacity, or entering new markets. Bucket Brigades like “You’re probably wondering how to get started” or “Here’s how you can set yourself up for growth” can provide direction as you develop your strategy. Be sure to make your goals measurable, so you can track your progress and adjust your approach as needed.

How Will You Measure Success?

Measuring success in CNC machining isn’t just about revenue. It’s about operational efficiency, client retention, and quality control. Some important Key Performance Indicators (KPIs) to track include lead times, customer satisfaction, defect rates, and the efficiency of your machine usage. Bucket Brigades such as “Wondering how to track your progress?” can guide readers through determining which metrics matter most to their business. Regular reviews of these metrics will ensure you stay on track and identify areas that need improvement.

4. Legal and Regulatory Requirements

What Are the Legal Steps to Starting a CNC Machining Business?

Setting up a CNC machining business involves several legal steps. First, you’ll need to register your business and choose the right legal structure, whether it’s a sole proprietorship, LLC, or corporation. Each structure comes with different tax implications and liability protections, so it’s important to consult with a business attorney or accountant. You’ll also need to obtain any necessary business licenses and permits. These might vary depending on your location and the type of products you plan to manufacture. Bucket Brigades such as “Let’s break this down” or “Here’s the legal checklist” can help clarify the process.

What Regulations Must You Adhere to?

CNC machining is highly regulated due to the nature of the products being manufactured. Depending on your industry focus, you’ll need to comply with specific standards, such as ISO certification or industry-specific regulations like the FDA for medical devices. Compliance with safety regulations, such as OSHA standards, is also critical to ensure a safe working environment for employees. Bucket Brigades like “This might sound complex, but” or “Here’s how to stay compliant” can guide readers through these regulations.

5. Choosing the Right CNC Machines for Your Business

What Types of CNC Machines Do You Need?

Selecting the right machines for your CNC business is one of the most significant decisions you’ll make. The type of CNC machine you need depends on the kind of products you plan to manufacture. CNC mills, lathes, routers, and grinders are common choices. If you’re planning to handle larger, more complex parts, you might need a CNC mill or lathe with a high degree of precision. Bucket Brigades like “So, which machines do you really need?” can help you navigate through this decision-making process. Remember, it’s important to balance the machine’s capabilities with your business goals.

Should You Buy New or Used CNC Machines?

When starting, you might be tempted to buy used CNC equipment to save on upfront costs. While this can be a smart financial decision, it’s crucial to inspect used machines for potential wear and tear. You might also want to consider new machines for their warranties and advanced features. Bucket Brigades such as “It’s a tough choice, but here’s what you need to know” can help readers weigh the pros and cons of buying new versus used equipment.

6. Setting Up Your CNC Workshop or Facility

How Much Space Do You Need for Your CNC Operation?

Choosing the right facility for your CNC machining business is essential for smooth operations. Depending on the size of your machinery, your shop may need to accommodate multiple machines, storage for raw materials, and space for employees. Ideally, you want to ensure that the workflow is efficient, with easy access to all parts of the shop. Bucket Brigades like “Wondering how much space you’ll need?” or “Let’s look at some facility options” can guide your readers through the considerations for selecting a space.

What Equipment and Tools Will You Need?

In addition to CNC machines, your shop will need various tools and equipment, such as measuring instruments, cutting tools, and maintenance equipment. You’ll also need a computer system with the proper software to control your machines. Maintenance equipment is crucial for ensuring that your machines are running smoothly and efficiently. Bucket Brigades like “Now that you have the machines, here’s what else you need” can help emphasize the additional equipment requirements.

7. Hiring Skilled CNC Operators and Technicians

What Skills and Experience Do You Need in Your Team?

Your CNC machining business will only be as successful as the people you hire. CNC operators, programmers, and maintenance technicians all require specialized skills to ensure the smooth running of your machines. Look for candidates with experience in CNC programming and machine operation. Offering training and certification programs can also help you build a skilled team that is aligned with your company’s standards. Bucket Brigades such as “Don’t worry, here’s how to find top talent” can help you refine your hiring strategy.

How to Manage Labor Costs While Ensuring Efficiency?

Balancing labor costs with the need for highly skilled workers can be challenging. Offering competitive wages and providing opportunities for growth can attract the best talent. Consider cross-training employees to handle multiple tasks to ensure flexibility and reduce downtime. Bucket Brigades like “Here’s a trick to keep labor costs under control” can help you create strategies to manage labor without compromising on productivity.

8. Software and Technology for CNC Machining

Which CNC Software Do You Need to Operate Your Machines?

CNC machining requires advanced software for both designing and programming your parts. Programs such as SolidWorks, AutoCAD, and Fusion 360 are commonly used for designing parts, while CAM software helps create the machining instructions that guide the CNC machines. Choosing the right software can make a significant difference in both the efficiency and quality of your work. Bucket Brigades like “Wondering which software is right for your business?” can help you navigate through the best choices available.

What Role Does CAM (Computer-Aided Manufacturing) Play in Your Business?

CAM software plays a pivotal role in bridging the gap between design and production. It converts digital designs into machine-readable instructions, optimizing the manufacturing process by reducing errors and increasing production speed. Implementing CAM software in your CNC operation can drastically improve your machine efficiency and output quality. Bucket Brigades like “Here’s why CAM software is a game-changer” can provide insights into its benefits.

9. Building Supplier Relationships and Sourcing Materials

How Do You Find Reliable Material Suppliers?

A reliable supplier is essential for any CNC machining business. You’ll need raw materials such as metals, plastics, and composites to create the parts your clients require. Building relationships with trusted suppliers will help ensure that you have consistent access to high-quality materials at competitive prices. Look for suppliers that offer flexibility and reliability in their delivery schedules. Bucket Brigades like “Here’s how to find the right suppliers” can guide you through the process of selecting the best ones.

How Can You Negotiate Better Prices with Suppliers?

Negotiating prices with suppliers is an important part of controlling costs. Consider ordering in bulk, establishing long-term contracts, or finding exclusive deals. Negotiating better payment terms can also help improve cash flow. Bucket Brigades like “Ready to save money?” can help readers understand how to strike the best deals with suppliers.

10. Setting Pricing Strategies for CNC Machining Services

How Do You Price CNC Machining Services?

Setting a competitive price for your CNC machining services requires understanding your cost structure, including material, labor, machine time, and overhead. Pricing can be done on an hourly basis, per part, or through a flat-rate model depending on the complexity of the part. Researching your competitors’ pricing can help you determine where you fit within the market. Bucket Brigades like “Here’s how to figure out your pricing” or “Wondering how to stay competitive?” can help guide your pricing strategy.

How to Stay Competitive While Maintaining Profit Margins?

Balancing profitability with competitive pricing is key to long-term success. Offering high-quality work with fast turnaround times can help justify slightly higher prices. Additionally, offering volume discounts or custom pricing for larger clients can help you retain loyal customers. Bucket Brigades like “Let’s talk about how to stay ahead of the competition” can help you explore strategies for maintaining a competitive edge.

11. Marketing Your CNC Machining Business

What Are Effective Marketing Strategies for CNC Machining Services?

Marketing a CNC machining business involves a combination of traditional and digital strategies. Building an online presence through a website, SEO, and social media can help attract clients. Attending trade shows and networking events can also help generate leads. Bucket Brigades like “Wondering how to market your CNC business?” or “Here’s where to focus your efforts” can guide readers in selecting the best marketing techniques.

How Can You Build a Strong Brand and Reputation?

Branding is key to standing out in a competitive industry. Showcasing your work through case studies, testimonials, and high-quality photos of your projects can help build trust with potential clients. Delivering consistently high-quality work will help establish a strong reputation over time. Bucket Brigades like “Let’s break down your branding strategy” can help readers build their CNC brand.

12. Managing Finances: Budgeting and Cost Control

How Do You Budget for Your CNC Business?

Effective financial management is crucial for the success of your CNC machining business. A solid budget should cover both fixed and variable costs, including machinery, labor, materials, and utilities. Careful tracking of expenses and revenue will help you maintain profitability. Bucket Brigades like “Wondering where to start with budgeting?” can provide guidance on establishing a clear financial plan.

How Can You Minimize Operational Costs and Maximize Profits?

Streamlining your operations is essential for minimizing costs. Implementing lean manufacturing principles can help reduce waste and improve efficiency. Regular maintenance of your machines will also ensure they operate at peak performance, reducing costly breakdowns. Bucket Brigades like “Here’s how to optimize your operations” can help readers understand how to increase profitability.

13. Scaling Your CNC Machining Business

When Should You Consider Expanding Your CNC Business?

As your CNC machining business grows, you may need to expand. Signs that it’s time to scale include increased demand for your services, a full production schedule, or the need to meet new market opportunities. Expanding your business requires careful planning and investment in additional equipment, staff, and space. Bucket Brigades like “Wondering when it’s time to scale?” or “Here’s when you should expand” can guide readers in making the right move.

How Do You Expand Without Sacrificing Quality?

As you scale, maintaining quality is crucial. Implementing standardized processes and training programs for new staff will help ensure consistent production quality. Expanding gradually while maintaining tight control over processes can help you grow without compromising your standards. Bucket Brigades like “Here’s how to scale while keeping your standards high” will help your readers manage the scaling process effectively.

14. Common Challenges in CNC Machining and How to Overcome Them

What Are Some of the Most Common CNC Machining Challenges?

Starting and running a CNC machining business comes with its own set of challenges. Some of the most common issues include machine breakdowns, high maintenance costs, and staffing shortages. Meeting tight deadlines and managing customer expectations can also be challenging. Bucket Brigades like “Let’s look at the top hurdles” can help you tackle these common challenges head-on.

How Can You Mitigate These Challenges?

By planning for common issues, you can reduce their impact on your business. For example, implementing regular machine maintenance schedules, offering training programs for staff, and setting realistic timelines with clients can help reduce the risk of delays and errors. Bucket Brigades like “Here’s how to minimize these challenges” can guide your readers through problem-solving strategies.

15. Conclusion and Final Thoughts

What’s the Key to Starting a Successful CNC Machining Business?

The key to success in the CNC machining business is a balance of quality, cost management, and customer service. By understanding the industry’s needs and providing precision machining services, you can establish a competitive edge in the market. Bucket Brigades such as “Ready to take the next step?” or “Let’s summarize what you need to do” can motivate your readers to take action.

How Can You Get Started Today?

The best way to get started is to take action. Begin with thorough research, build a solid plan, and invest in the right equipment and talent. The CNC machining industry is competitive, but with the right approach, you can build a profitable business. Bucket Brigades like “Don’t wait—get started today” can inspire your readers to begin their journey toward success.

FAQ-Bereich

What’s the Initial Investment Required to Start a CNC Machining Business?

The initial investment varies depending on the scale of your business, but it typically includes costs for machinery, software, facility setup, and legal expenses. A small operation may require an initial investment of $50,000 to $100,000, while larger operations might need upwards of $250,000.

How Long Does It Take to Get a CNC Machining Business Up and Running?

It can take anywhere from a few months to a year to set up a CNC machining business, depending on the complexity of your operation and market conditions. The process includes securing funding, purchasing equipment, and building relationships with suppliers and clients.

Do I Need to Learn CNC Programming to Run My Business?

While it is not mandatory to learn CNC programming if you’re running the business, understanding the basics of CNC programming will help you manage your operations more effectively and communicate with technicians and clients.

What Are the Most Profitable CNC Machining Services?

High-precision industries like aerospace and medical device manufacturing offer some of the most profitable CNC machining services. Specializing in niche areas or offering quick turnaround services can also increase profitability.

How Do I Find Clients for My CNC Machining Business?

Networking, attending trade shows, and online marketing can help attract clients. Building relationships with suppliers and leveraging word-of-mouth recommendations are also powerful tools for growing your client base.