Introduction

CNC machining aluminum is a widely used manufacturing process that involves computer-controlled machines to create parts and components from aluminum material. As one of the most versatile metals, aluminum is used in various industries, including aerospace, automotive, and medical sectors. This article will provide a comprehensive guide to CNC machining aluminum, including its benefits, challenges, applications, and the best practices to optimize the machining process. Whether you’re a manufacturer, engineer, or just curious about CNC machining, this article will help you understand the process in depth.

1. What Is CNC Machining Aluminum?

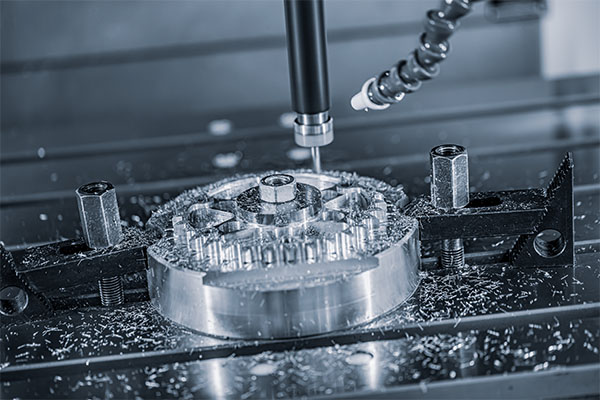

CNC machining aluminum refers to using computer numerical control (CNC) machines to cut, shape, and form aluminum parts with high precision. Aluminum is a lightweight, durable material often used in manufacturing for its strength-to-weight ratio and corrosion resistance. The CNC machining process for aluminum is ideal for creating parts with intricate designs, complex geometries, and tight tolerances.

But here’s the kicker: While aluminum is easier to machine than other metals like steel, it still requires careful planning and understanding of the material properties. The process typically involves removing material through milling, turning, or drilling to achieve the desired shape. Specialized tools and machines like CNC mills, lathes, and routers are often used for aluminum machining.

The versatility of CNC machining aluminum makes it an excellent choice for industries like aerospace, automotive, and electronics. With advancements in technology, CNC machines now offer higher precision and efficiency, making aluminum machining more cost-effective and reliable.

| Process Type | Description | Common Machines |

|---|---|---|

| Milling | Removing material using rotating cutters | CNC Mills |

| Turning | Rotating material while cutting it | CNC Lathes |

| Drilling | Creating holes in the material | CNC Drills |

2. Why Is CNC Machining Aluminum Popular?

CNC machining aluminum is popular for several reasons. First, aluminum is a lightweight material, which makes it ideal for industries where weight is a concern, such as aerospace and automotive. Second, aluminum has excellent corrosion resistance, making it suitable for outdoor and marine applications.

Ready for the good part? The high precision and efficiency offered by CNC machining make it a top choice for manufacturers needing complex parts with tight tolerances. Additionally, CNC machines can operate continuously with minimal human intervention, reducing labor costs and increasing productivity. These machines also have the ability to create repeatable, consistent parts, which is essential for large production runs.

Finally, the cost-effectiveness of CNC machining aluminum cannot be ignored. While aluminum may be more expensive than other materials like plastic, it offers a higher return on investment in the long run due to its durability and ability to withstand harsh environments.

| Benefit | Description |

|---|---|

| Lightweight | Reduces weight, ideal for aerospace and automotive |

| Corrosion Resistance | Suitable for outdoor, marine, and industrial applications |

| Precision and Efficiency | Offers high precision and consistent results |

3. How Does CNC Machining Work for Aluminum?

The CNC machining process for aluminum involves several stages, starting with design and programming. The first step is to create a 3D model of the part using CAD software. Once the design is finalized, the part is programmed into the CNC machine using G-code, a language that tells the machine how to move and cut.

This is where it gets interesting: The CNC machine uses various tools like mills, lathes, and drills to shape the aluminum into the final part. The cutting tools are controlled by the computer to ensure that the part is made to the precise specifications. The material is typically clamped securely to the machine table to prevent movement during the cutting process.

Once the machining is complete, the part is checked for quality using advanced measurement tools, ensuring that it meets the required tolerances. Post-processing may include polishing, anodizing, or painting to enhance the appearance and performance of the aluminum part.

| Step | Description |

|---|---|

| Design and CAD | Creating a 3D model of the part |

| CNC Programming | Inputting the design into the CNC machine using G-code |

| Cutting and Shaping | Using mills, lathes, and drills to shape the material |

| Quality Check | Inspecting the part for accuracy and tolerances |

4. What Are the Different Types of CNC Machining for Aluminum?

CNC machining for aluminum includes several methods, each suited for different applications and part designs. The most common types include milling, turning, and drilling.

You might be wondering: What’s the difference between these methods? Milling involves using rotating cutters to remove material and create complex shapes. Turning, on the other hand, rotates the material while a stationary tool removes material to create cylindrical shapes. Drilling is used to make holes in the material, and it’s one of the most common operations in CNC machining.

Other specialized techniques include EDM (electrical discharge machining) and laser cutting, both of which are used for specific applications where high precision is required. Each method has its own strengths and weaknesses, and the choice of method depends on factors like part geometry, material thickness, and production volume.

| Method | Description | Common Uses |

|---|---|---|

| Milling | Rotating cutters remove material to create shapes | Complex shapes, parts with multiple features |

| Turning | Material rotates while cutting tools shape it | Cylindrical shapes, shafts, and tubes |

| Drilling | Creates holes in the material | Hole-making in a variety of part types |

5. What Are the Challenges of CNC Machining Aluminum?

While CNC machining aluminum offers numerous benefits, it comes with its own set of challenges. One of the main issues is the wear and tear on tools. Aluminum is a soft material, but when it is machined at high speeds, it can cause excessive tool wear. Here’s the deal: Proper tool selection and maintenance are essential to avoid breakdowns and prolong tool life.

Another challenge is managing the heat generated during the machining process. Aluminum has high thermal conductivity, which means it tends to heat up quickly during cutting. Without proper cooling, this can lead to material warping or tool failure. CNC machines use coolant systems to keep temperatures in check and ensure smooth machining.

Finally, while aluminum is easy to machine, its softness can make it prone to scratching or denting, especially when handling large quantities of parts. To mitigate this, manufacturers must use careful handling and storage techniques.

| Challenge | Description | Solution |

|---|---|---|

| Tool Wear | Aluminum can cause rapid tool wear | Use high-quality tools and maintain them regularly |

| Heat Management | High temperatures can cause warping or failure | Use coolant systems to control temperature |

| Material Damage | Aluminum is prone to scratches and dents | Implement careful handling and storage practices |

6. How Do You Choose the Right CNC Machining Method for Aluminum?

Selecting the right CNC machining method for aluminum depends on several factors, including the part geometry, material properties, and the production volume. What’s the real story? The right machining method ensures that parts are produced efficiently, accurately, and at a reasonable cost.

For parts with complex geometries or multiple features, milling is often the best option. For cylindrical parts or shafts, turning is the preferred method. Drilling is commonly used for parts that require holes, and EDM or laser cutting is used when high precision is required for small or intricate features.

The size and volume of production also play a significant role in the decision-making process. For large volumes, automated CNC machines are often used to ensure consistency and speed, whereas low-volume production may use manual setups or smaller machines to reduce costs.

| Factor | Description | Recommended Method |

|---|---|---|

| Part Geometry | Complexity of the part shape | Milling |

| Shape and Size | Cylindrical parts, tubes, and shafts | Turning |

| Hole Requirements | Need for holes in parts | Drilling |

7. How Does the CNC Machining Process Differ for Different Aluminum Alloys?

Different aluminum alloys require different machining processes. Alloys such as 6061 and 7075 are commonly used in CNC machining. This is where it gets interesting: Some alloys are easier to machine than others due to differences in hardness, thermal conductivity, and strength.

For example, 6061 aluminum is relatively soft and easy to machine, while 7075 aluminum is stronger but more difficult to work with due to its hardness. Choosing the right alloy for the application is critical for both machining efficiency and the desired part properties.

Additionally, the machining parameters, such as feed rates and tool selection, will differ depending on the alloy being used. Some alloys may require slower cutting speeds, while others can be machined at faster speeds.

| Alloy | Properties | Machining Considerations |

|---|---|---|

| 6061 Aluminum | Soft, versatile, corrosion-resistant | Easier to machine, faster cutting speeds |

| 7075 Aluminum | Stronger, higher strength-to-weight ratio | Slower cutting speeds, special tools needed |

8. What Are the Common CNC Machining Techniques for Aluminum?

CNC machining aluminum uses several techniques to create parts with high precision. The most common techniques include milling, turning, and drilling, each of which has its own strengths and applications. You might be wondering: Why do we need different techniques?

Milling is ideal for creating complex shapes with multiple features. Turning is used for cylindrical parts and shafts, while drilling is used for making holes. Each of these techniques can be customized based on the requirements of the part being produced, allowing manufacturers to choose the best method for the job.

For parts that require intricate or highly precise features, techniques like EDM or laser cutting may be used to achieve the necessary level of accuracy.

| Technique | Description | Common Uses |

|---|---|---|

| Milling | Removing material with rotating cutters | Complex, multi-feature parts |

| Turning | Rotating material while cutting it | Cylindrical parts and shafts |

| Drilling | Creating holes in materials | Hole-making in various parts |

9. How Can You Improve CNC Machining Efficiency for Aluminum?

Improving CNC machining efficiency for aluminum involves optimizing several factors, such as machine settings, tool selection, and feed rates. But here’s the kicker: The right combination of these elements can significantly reduce machining time and costs.

One way to improve efficiency is by using the correct cutting speeds and feed rates. For aluminum, using high feed rates can speed up the machining process without sacrificing quality. Additionally, using the right cutting tools, such as carbide or coated tools, can reduce tool wear and increase productivity.

Another way to boost efficiency is by minimizing downtime. Proper machine maintenance and timely tool changes can ensure that the CNC machine runs smoothly, reducing the chances of unexpected failures or stoppages.

| Improvement Area | Action | Result |

|---|---|---|

| Cutting Speed | Use high feed rates for faster material removal | Faster machining times |

| Tool Selection | Use carbide or coated tools | Reduced tool wear, higher productivity |

| Machine Maintenance | Regular maintenance and tool changes | Less downtime, smoother operations |

10. How Does CNC Machining Aluminum Compare to Other Materials?

CNC machining aluminum has distinct advantages compared to other materials like steel and plastic. What’s the real story? Aluminum is lightweight, making it ideal for applications where weight is a critical factor, such as in aerospace and automotive manufacturing.

Additionally, aluminum is more corrosion-resistant than many other metals, which makes it suitable for outdoor and marine applications. The material is also easier to machine compared to harder metals like steel, which can require specialized tools and higher cutting speeds.

However, while aluminum is cost-effective for many applications, it may not be as strong as steel, which is better suited for high-strength applications.

| Material | Advantages | Disadvantages |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, easy to machine | Less strength compared to steel |

| Steel | Stronger, more durable | Harder to machine, heavier |

11. What Are the Most Common Applications of CNC Machining Aluminum?

CNC machining aluminum is used in a wide range of industries, from aerospace to automotive to medical devices. Here’s the kicker: The versatility of aluminum allows it to be used in many different applications, including structural components, consumer electronics, and custom parts.

In aerospace, aluminum is used for aircraft frames, wings, and fuselages due to its lightweight properties. In automotive manufacturing, aluminum is used for engine parts, transmission components, and body panels. Medical devices, such as surgical instruments and implants, also often utilize CNC-machined aluminum for its biocompatibility and durability.

| Industry | Application | Common Parts Made |

|---|---|---|

| Aerospace | Lightweight components for aircraft | Aircraft frames, wings |

| Automotive | Parts for vehicles, from engines to bodywork | Engine parts, body panels |

| Medical Devices | Biocompatible components | Surgical instruments, implants |

12. How Do Tolerances and Precision Impact CNC Machining Aluminum?

Tolerances and precision are critical in CNC machining aluminum. What’s the real story? In many applications, especially in aerospace and medical industries, parts must be made to strict tolerances to ensure they function correctly.

For aluminum, tight tolerances are typically required for parts that must fit together precisely or operate under demanding conditions. CNC machines are capable of achieving incredibly tight tolerances, sometimes as small as a few microns.

However, achieving these high tolerances often requires specialized equipment and techniques, which can increase costs. Therefore, manufacturers must balance precision with cost-effectiveness when deciding on the level of tolerance required for each part.

| Tolerance Level | Impact | Example Application |

|---|---|---|

| Tight Tolerances | High precision required, can increase cost | Aerospace, medical parts |

| Looser Tolerances | Less precision, more cost-effective | General manufacturing |

13. What Are the Safety Considerations When CNC Machining Aluminum?

CNC machining aluminum involves various safety considerations to ensure the safety of operators and equipment. This is where it gets interesting: Aluminum chips and dust can pose fire hazards, especially when working at high speeds.

CNC machines should always have proper cooling systems in place to prevent overheating. Operators must also wear protective gear, such as goggles and gloves, to avoid injury from flying chips and tools. Additionally, regular maintenance and safety checks on machines are crucial to prevent malfunctions that could lead to accidents.

| Safety Measure | Action | Importance |

|---|---|---|

| Coolant Systems | Use cooling fluids to prevent overheating | Prevent tool failure and warping |

| Protective Gear | Operators must wear safety goggles and gloves | Prevent injury from flying debris |

| Regular Maintenance | Conduct routine checks on machines | Avoid malfunction and accidents |

14. What Are the Costs Involved in CNC Machining Aluminum?

The costs of CNC machining aluminum depend on several factors, including material cost, machine time, and labor expenses. What’s the real story? Aluminum is typically more expensive than plastic, but its advantages often outweigh the higher cost, especially in industries where durability and performance are critical.

Costs can also vary depending on the complexity of the part. More intricate parts require more machining time and higher precision, which can increase labor and machine costs. For large production runs, automated CNC machines are more cost-effective, while small batch production may require more manual labor.

| Cost Factor | Description | Impact on Pricing |

|---|---|---|

| Material | Aluminum cost can vary based on grade and quantity | Affects overall cost of production |

| Machine Time | More complex parts take longer to machine | Increases labor and equipment usage |

| Labor | Manual labor is more expensive for small runs | Affects overall production cost |

15. How Do You Maintain CNC Machines for Aluminum Machining?

Proper maintenance of CNC machines is essential to ensure they run efficiently and produce high-quality aluminum parts. You might be wondering: How often should machines be maintained?

Routine maintenance tasks include cleaning the machines regularly, checking for wear and tear, and ensuring that the coolant system is functioning correctly. Machine calibration should also be performed regularly to ensure precise cutting and high accuracy. Proper storage of tools and spare parts is also crucial to prevent damage and minimize downtime.

| Maintenance Task | Description | Frequency |

|---|---|---|

| Machine Cleaning | Regular cleaning of machines to remove debris | Weekly |

| Calibration | Ensuring machines are calibrated for accuracy | Monthly |

| Tool Storage | Properly storing tools to prevent damage | After each production run |

Conclusion

CNC machining aluminum is a highly effective and efficient process that is widely used in many industries. By understanding the various methods, challenges, and applications of CNC machining, manufacturers can optimize their processes and create high-quality aluminum parts. Proper maintenance, selecting the right machining techniques, and understanding the cost factors involved are essential for ensuring the success of aluminum machining projects. Whether you’re new to CNC machining or looking to improve your existing processes, this guide provides the key insights you need to make informed decisions.

FAQ Section

Q1: What is CNC machining aluminum?

CNC machining aluminum refers to the use of computer-controlled machines to cut, shape, and form aluminum into precise parts and components. It is widely used for manufacturing complex shapes with high precision in industries like aerospace, automotive, and medical.

Q2: How does CNC machining work for aluminum?

CNC machining for aluminum involves creating a 3D design of the part, programming the CNC machine with the design’s specifications, and then using various cutting tools to remove material from the aluminum until the desired shape is achieved. This process is precise and efficient.

Q3: What are the advantages of CNC machining aluminum?

CNC machining aluminum offers high precision, repeatability, and the ability to work with intricate designs. Aluminum itself is lightweight, corrosion-resistant, and easy to machine, making it a popular choice in many industries. Additionally, CNC machines can operate continuously with minimal labor input.

Q4: What are the common applications of CNC machining aluminum?

Common applications of CNC machining aluminum include aerospace components like wings and fuselages, automotive parts such as engine blocks and body panels, medical devices like surgical tools, and consumer electronics like phone housings and custom parts for prototyping.

Q5: What factors affect the cost of CNC machining aluminum?

The cost of CNC machining aluminum depends on factors such as material quality, the complexity of the design, machine time, labor, and production volume. The more intricate the part, the higher the machining cost, as it requires more time and precision to manufacture.