Introduction

CNC Machining has become a go-to solution for industries that need fast, reliable, and precise prototypes. Fast CNC Machining Service for Rapid Prototypes delivers parts in record time while ensuring high precision, quality, and flexibility. In this article, we will explore how CNC machining works, the benefits it brings to rapid prototyping, how to choose the right service provider, and answer some frequently asked questions.

1. What is CNC Machining Service?

CNC machining service is a manufacturing process that uses computer-controlled machines to create parts from various materials. Whether it’s metal, plastic, or composite, CNC machines are programmed to follow specific designs, ensuring that the final product meets exact specifications.

What’s the real story? CNC machining is essential for creating everything from small parts to large, complex components. By using precise measurements and automated systems, CNC machining ensures consistent quality in every product produced. This method is used across various industries, such as automotive, aerospace, and medical device manufacturing.

CNC machining services can be categorized into several types, including CNC milling, CNC turning, and CNC grinding. Each type of CNC machining service is suited to different manufacturing needs. In addition, CNC machining can handle both prototypes and end-use parts, making it versatile for different stages of product development.

But here’s the kicker: The real value of CNC machining comes in its precision and repeatability, making it indispensable for industries requiring tight tolerances and intricate details.

Table 1: Types of CNC Machining Services

| CNC Service Type | Description | Common Applications |

|---|---|---|

| CNC Milling | Uses rotating cutters to remove material | Automotive, Aerospace |

| CNC Turning | Uses a rotating workpiece to shape material | Medical, Electronics |

| CNC Grinding | Uses an abrasive wheel to finish parts | High-precision machining |

2. Why Choose a CNC Machining Service for Rapid Prototypes?

The need for rapid prototypes in product development cannot be overstated. CNC machining service offers a fast turnaround without sacrificing quality, making it the ideal choice for companies that need to test and iterate on designs quickly.

Ready for the good part? CNC machining for rapid prototypes allows designers and engineers to evaluate functionality and fit before committing to mass production. This is especially important for complex designs where traditional manufacturing methods may fall short. Moreover, CNC machining provides cost-effective prototyping without the high upfront costs typically associated with injection molding or other traditional methods.

This is where it gets interesting: CNC machining offers a combination of speed, precision, and flexibility that allows companies to test different materials and configurations easily. Prototypes can be made from the exact materials that will be used in production, ensuring that the end product functions just as expected.

Table 2: Advantages of CNC Machining for Rapid Prototypes

| Benefit | Description |

|---|---|

| Speed | Fast turnaround time for prototypes |

| Precision | High accuracy, ideal for tight tolerances |

| Material Flexibility | Works with a variety of materials |

| Cost-Effectiveness | Lower cost compared to other prototyping methods |

3. How Does CNC Machining Work for Prototyping?

Understanding how CNC machining works is key to appreciating its value in rapid prototyping. The process begins with a CAD (Computer-Aided Design) file, which is then converted into machine code. This code tells the CNC machine how to move, cut, and shape the material into the desired form.

You might be wondering, “How does the machine actually create the prototype?” The CNC machine uses precise tools like drills, lathes, and mills to carve away at the material. These machines are controlled by G-code, which dictates the speed, feed, and path of the cutting tools. Here’s the kicker: Unlike manual machining, CNC machining ensures that every part is exactly the same, offering unmatched consistency.

But the real magic happens when the machine operates without human intervention. Once set up, the machine can run autonomously, producing parts around the clock, which means rapid prototypes can be delivered in a fraction of the time.

Table 3: CNC Machining Process Overview

| Step | Description |

|---|---|

| Design | CAD file is created for the prototype |

| Programming | G-code is generated from the CAD file |

| Setup | Machine is set up with the correct tools |

| Machining | The machine cuts the material as per instructions |

| Finishing | Prototype is inspected and finished |

4. What Types of CNC Machining Services Are Available?

There are several types of CNC machining services available, each with its own set of applications and benefits. CNC milling, for instance, is used for cutting and shaping materials into precise parts using rotary cutters. This service is ideal for creating complex shapes and fine details.

You might be wondering, “What about turning and grinding?” CNC turning is used to machine parts by rotating the material against a stationary tool, ideal for cylindrical parts like shafts or bushings. CNC grinding, on the other hand, is used to finish parts to an even finer tolerance, often used for high-precision components.

Ready for the good part? Knowing which type of CNC machining to use can help you streamline your prototype process and ensure the highest quality product. These services can be used together in a multi-stage production process to achieve the desired results.

Table 4: Comparison of CNC Machining Services

| Service Type | Key Features | Best Used For |

|---|---|---|

| CNC Milling | Rotating cutters to shape material | Complex shapes, large parts |

| CNC Turning | Material is rotated while cutting with a stationary tool | Cylindrical parts |

| CNC Grinding | Abrasive tools are used to finish parts | High-precision finishing |

5. What Are the Key Benefits of CNC Machining for Prototypes?

CNC machining provides several key benefits when it comes to prototyping. High precision and accuracy are paramount for testing prototypes. CNC machines can create parts to tight tolerances, ensuring that prototypes are a true representation of the final product.

But here’s the kicker: Flexibility is another major benefit. CNC machines can work with a variety of materials, from plastics to metals, offering flexibility in design and functionality. This means prototypes can be made from materials that reflect the final product’s qualities, helping companies make more informed decisions before proceeding to mass production.

This is where it gets interesting: The ability to create prototypes in rapid succession means companies can quickly test multiple iterations. This allows for faster design improvements, accelerating the overall product development process.

Table 5: Key Benefits of CNC Machining for Prototypes

| Benefit | Description |

|---|---|

| Precision | Tight tolerances and high accuracy |

| Flexibility | Works with a wide range of materials |

| Speed | Faster turnaround times compared to traditional methods |

| Cost-Efficiency | Less expensive for small batches of prototypes |

Conclusion

CNC machining services for rapid prototypes are a game-changer for businesses looking to streamline product development. From fast turnaround times to high precision and material flexibility, CNC machining offers several advantages that make it the ideal choice for prototyping. Choosing the right CNC machining service ensures that you can produce high-quality prototypes quickly and efficiently, allowing you to test your designs and bring your product to market faster.

6. How to Choose the Right CNC Machining Service Provider?

Choosing the right CNC machining service provider is a critical step in ensuring the success of your prototyping project. You might be wondering, “What should I look for in a service provider?” The first thing to consider is experience and expertise. A provider with years of experience is more likely to understand your specific needs and handle complex designs.

But here’s the kicker: Technology matters. CNC machining has evolved, and modern machines are faster, more precise, and able to work with a wider range of materials. Look for providers with up-to-date equipment to ensure they can handle your project efficiently.

Another key factor is customer service. Good communication is essential throughout the process, from the initial consultation to the delivery of the prototype. Ensure that the service provider offers clear, responsive communication and can address your concerns promptly.

This is where it gets interesting: Lead time and pricing are also important factors. Request quotes and compare delivery times to ensure the provider aligns with your schedule and budget. A provider that offers transparent pricing and clear timelines will save you time and money in the long run.

Table 6: Key Factors When Choosing a CNC Machining Service Provider

| Factor | Description |

|---|---|

| Experience | Look for providers with proven industry experience |

| Technology | Modern machines and up-to-date capabilities |

| Customer Service | Responsive communication and support |

| Lead Time | Shorter lead times can accelerate your project |

| Pricing | Transparent and competitive pricing |

7. What Are the Common Applications of CNC Machining Services?

CNC machining services are used across a variety of industries due to their ability to produce parts with high precision and flexibility. But what are the most common applications for CNC machining services?

Let’s start with the automotive industry. CNC machining is used to create a range of parts, including engine components, body parts, and custom tooling. These parts need to meet stringent quality and durability standards, which is why CNC machining is ideal.

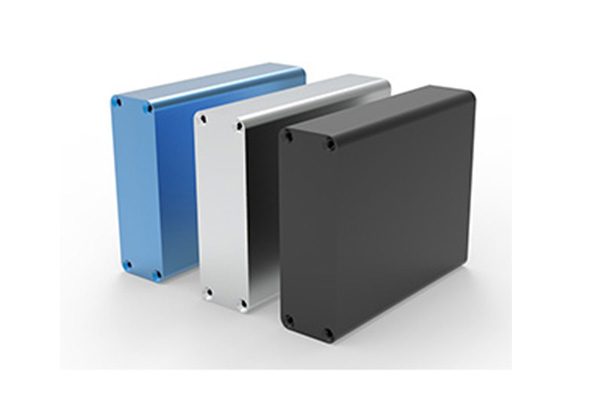

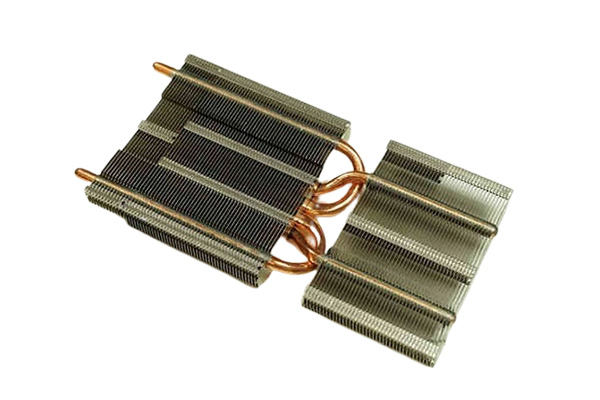

Next, aerospace manufacturers rely on CNC machining for critical components like turbine blades, brackets, and housings. Given the need for lightweight, high-strength materials and tight tolerances, CNC machining delivers the precision that aerospace components require.

In the medical device sector, CNC machining is used to manufacture everything from surgical instruments to orthopedic implants. Medical devices require both precision and biocompatibility, and CNC machining offers both in a cost-effective manner.

What’s the real story? CNC machining is essential in industries where parts must meet high-performance standards and be produced in relatively low volumes, making it versatile for prototype development and limited production runs.

Table 7: Common CNC Machining Applications

| Industry | Key Applications |

|---|---|

| Automotive | Engine parts, custom tooling, brackets |

| Aerospace | Turbine blades, housings, brackets |

| Medical Devices | Surgical instruments, implants, diagnostic tools |

| Electronics | Circuit boards, housings, connectors |

8. How Long Does It Take to Get a Rapid CNC Prototype?

Speed is one of the primary reasons companies turn to CNC machining for rapid prototypes. But how long does it actually take? It depends on the complexity of the part, the material, and the availability of machines.

Generally speaking, simple parts can be produced within 1-2 days, while more intricate designs may take several weeks. Factors like machine setup time, the need for special tooling, and the size of the prototype all contribute to the timeline.

Here’s the kicker: Lead time can also be impacted by your choice of CNC service provider. Some providers have more advanced equipment that allows them to deliver prototypes faster. It’s always a good idea to discuss lead times upfront with your provider to ensure that your project timeline aligns with their capabilities.

But what about more complex prototypes? In those cases, the timeline can stretch, but working with experienced professionals who are adept at solving potential issues can help ensure that the project stays on track.

Table 8: CNC Prototyping Lead Times

| Complexity Level | Typical Lead Time |

|---|---|

| Simple Parts | 1-2 Days |

| Moderate Complexity | 3-5 Days |

| High Complexity | 1-2 Weeks |

| Custom Material Parts | 2-3 Weeks |

9. How Much Does CNC Machining for Prototypes Cost?

When it comes to CNC machining, cost is always a major consideration. But how much should you expect to pay for a rapid prototype? The answer is a bit complex, as pricing depends on several factors, such as material choice, part complexity, and machine time.

Typically, CNC machining costs are calculated based on machine time, the type of material used, and the labor involved. Simple, smaller parts will cost less, while larger, more intricate parts will naturally be more expensive due to the additional time and expertise required.

Here’s the kicker: It’s crucial to get a detailed quote from your service provider that includes all potential costs, such as setup fees, machine time, and any post-processing (like finishing or assembly) that may be necessary.

Another important factor is whether or not you’re looking to mass-produce the prototype. While the cost per piece might be higher for rapid prototypes, CNC machining can be much more cost-effective than traditional manufacturing methods when it comes to low-volume production.

Table 9: CNC Machining Cost Factors

| Factor | Impact on Price |

|---|---|

| Material | Cost varies by material type (metal, plastic, etc.) |

| Complexity | More complex parts take longer and cost more |

| Machine Time | Longer machine time increases cost |

| Post-Processing | Finishing, coating, or assembly adds to the price |

| Volume | Larger orders reduce the cost per unit |

10. What Are the Common Challenges in CNC Machining Prototypes?

Although CNC machining offers numerous benefits, it’s not without its challenges. What are the most common obstacles companies face when using CNC machining for prototypes?

One of the main challenges is the material limitations. Some materials are more difficult to machine than others, and certain types of metals or plastics may not be suitable for CNC machining due to their hardness or thickness. This can limit the range of possible designs or require additional steps to prepare the material.

Machine calibration and setup time can also be a challenge, especially if the prototype requires custom tooling. Every machine needs to be properly calibrated to ensure the parts meet the required specifications, which can add to the timeline and cost.

What’s the real story? CNC machining also struggles with complex geometries and tight tolerances. While the machines are highly accurate, some designs may be too intricate for standard CNC capabilities, requiring additional work or specialized equipment.

Table 10: Common CNC Machining Challenges

| Challenge | Description |

|---|---|

| Material Limitations | Some materials are difficult to machine |

| Calibration & Setup | Machine setup time adds to overall cost and lead time |

| Complex Geometries | Intricate parts may require specialized equipment |

| Tolerances | Tight tolerances may require additional work |

11. How Do I Ensure Quality in My CNC Machined Prototypes?

Ensuring quality in your CNC machined prototypes is crucial for testing functionality and moving on to mass production. How do you make sure that your prototype meets all necessary quality standards?

The first step is to use a trusted CNC machining provider. Work with professionals who understand your industry’s specific needs and quality standards. They should offer clear documentation, including inspection reports and certifications that demonstrate their adherence to quality control standards.

Here’s the kicker: Quality control during machining is vital. Providers should have a well-established process for inspecting parts as they are machined, using tools like coordinate measuring machines (CMMs) to ensure dimensions are accurate.

Additionally, it’s important to verify prototype quality before moving forward. This involves thorough inspection and testing to ensure that the prototype performs as expected in real-world conditions.

Table 11: Quality Control Methods in CNC Machining

| Method | Description |

|---|---|

| Visual Inspection | Checking for surface defects or errors |

| CMM (Coordinate Measuring Machine) | Accurate measurement of dimensions |

| Functional Testing | Ensuring the prototype performs as intended |

12. What Are the Latest Trends in CNC Machining for Prototyping?

CNC machining is constantly evolving, and staying up to date with the latest trends can help businesses stay ahead. So, what are some of the trends in CNC machining for prototyping?

One of the key trends is the integration of automation. Advanced CNC machines now have automated tool changers and part loaders, improving efficiency and reducing human error. Automation speeds up the prototyping process, making it even faster to get prototypes into the hands of engineers.

Another major trend is the use of AI and machine learning. These technologies can analyze machining data to optimize processes, predict potential failures, and improve the overall quality of the parts produced.

What’s the real story? Additive manufacturing (3D printing) is also starting to intersect with CNC machining. Hybrid machines that combine CNC and additive technologies are now available, allowing for more complex designs and faster prototyping.

Table 12: Latest CNC Machining Trends

| Trend | Description |

|---|---|

| Automation | Reduced setup time and human error |

| AI & Machine Learning | Optimizing processes and predicting failures |

| Hybrid Manufacturing | Combining CNC and 3D printing technologies |

13. Can CNC Machining Services Help with Mass Production After Prototyping?

One of the key advantages of CNC machining is its ability to scale from prototype production to mass manufacturing. But how do CNC machining services transition from prototyping to mass production?

The transition involves scaling up production while maintaining the same level of precision and quality that was achieved during prototyping. In many cases, the same machines and processes used for prototypes are used for mass production, which ensures consistency across the entire production run.

Here’s the kicker: CNC machining allows for high-volume production without the need for complex mold-making, making it ideal for both small batch production and larger quantities. This flexibility is crucial for industries that require high-quality parts in both small and large quantities.

Table 13: Transitioning from Prototype to Mass Production

| Stage | Description |

|---|---|

| Prototyping | Initial small runs, testing for design and function |

| Scaling | Increasing production while maintaining quality |

| Mass Production | High-volume production using the same process |

14. What Are the Environmental Considerations in CNC Machining?

CNC machining is not just about precision and speed—it also comes with environmental considerations. What are the key environmental concerns associated with CNC machining?

One concern is the energy consumption of CNC machines. While modern machines are more energy-efficient, machining still requires a significant amount of power, especially during long runs.

Waste generation is another issue. Cutting and grinding materials can produce waste chips and fluids, which must be properly managed. The good news is that CNC providers are increasingly adopting eco-friendly practices such as recycling materials and using biodegradable oils for machining.

What’s the real story? Reducing waste and energy consumption will become an increasingly important focus for CNC machining companies as they look for more sustainable ways to meet demand.

Table 14: Environmental Impact of CNC Machining

| Environmental Concern | Solution |

|---|---|

| Energy Consumption | Use of energy-efficient machines and processes |

| Waste Generation | Recycling materials and using biodegradable fluids |

15. How Do CNC Machining Services Support Product Innovation?

CNC machining services play a vital role in fostering product innovation. How do CNC machining services help bring innovative products to market faster?

By enabling rapid prototyping, CNC machining allows engineers and designers to test new concepts and designs quickly. This speed enables faster iterations, helping companies refine their ideas before committing to full-scale production.

Here’s the kicker: CNC machining helps reduce time-to-market, giving companies a competitive edge in fast-moving industries. By using CNC machining, companies can quickly adapt their designs based on testing results and customer feedback.

Table 15: Role of CNC Machining in Product Innovation

| Factor | Impact on Product Development |

|---|---|

| Rapid Prototyping | Speeds up testing and iteration |

| Design Flexibility | Allows for quick adjustments and design changes |

| Reduced Time-to-Market | Accelerates the product launch process |

Conclusion

CNC machining services provide businesses with the ability to create high-quality, rapid prototypes that support innovation and product development. From precision and flexibility to cost-effectiveness, CNC machining offers numerous advantages that make it an essential part of the prototyping process. By choosing the right CNC machining service provider, businesses can ensure fast, accurate prototypes that allow for successful product development.

FAQ Section

Q1: What is CNC Machining?

CNC Machining is a manufacturing process that uses computer-controlled machines to create precise parts from various materials.

Q2: How does CNC Machining for rapid prototypes work?

CNC Machining works by using CAD files converted into machine code that guides the machine to cut and shape materials precisely.

Q3: How long does it take to complete a CNC prototype?

The time it takes to complete a CNC prototype varies but typically ranges from a few days to a few weeks, depending on complexity and material choice.

Q4: How much does CNC Machining for prototypes cost?

The cost varies based on material, complexity, and machine time. It’s generally more cost-effective than other traditional prototyping methods.

Q5: What industries benefit from CNC Machining services?

Industries like automotive, aerospace, and medical device manufacturing benefit from CNC Machining due to its precision, flexibility, and efficiency.