Introduction

CNC operators play an essential role in modern manufacturing, overseeing the operation of sophisticated machines that produce high-precision parts. These operators are the backbone of industries such as automotive, aerospace, and electronics, where precise machining is critical. However, becoming a skilled CNC operator requires more than just operating a machine. It involves a mix of technical expertise, hands-on experience, and a deep understanding of the tools and materials being used. In this comprehensive guide, we will explore the key skills you need to succeed as a CNC operator, how to acquire them, and the steps to take to start a rewarding career in CNC machining.

What is CNC and What Does a CNC Operator Do?

Understanding CNC Technology

CNC, or Computer Numerical Control, is the technology behind modern machining tools that allows machines to be operated through computer programs. This advancement has revolutionized manufacturing by replacing traditional manual controls with automated processes. CNC machines are equipped with motors, sensors, and controllers that read and follow instructions provided by computer software to create precise parts, tools, and components.

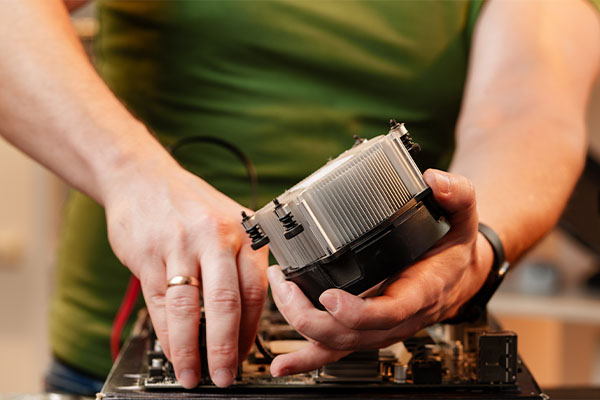

CNC Operator’s Role

A CNC operator is responsible for setting up, operating, and maintaining CNC machines. These professionals ensure that machines run efficiently, produce high-quality parts, and meet all specified tolerances. Their tasks may include loading materials, adjusting machine settings, inspecting parts, and troubleshooting machine issues. Operators must be proficient in using a variety of equipment like mills, lathes, grinders, and drills, all of which can be operated using CNC technology.

Why CNC Operators Are Essential

CNC operators are crucial to the manufacturing process because they help ensure production runs smoothly, efficiently, and with minimal waste. Their role directly impacts product quality and the overall productivity of the manufacturing plant. Without skilled CNC operators, many industries would struggle to meet the demand for precise, high-quality parts that modern machinery requires.

Key Skills Every CNC Operator Should Have

Technical Skills

Being a CNC operator requires a strong understanding of the machines and software involved in the production process. Operators must be familiar with the various types of CNC machinery, including mills, lathes, and grinders, as well as the software used to program and control these machines. They must also understand how to adjust the machine’s settings to ensure the parts are manufactured to precise specifications.

Attention to Detail

In CNC machining, even the slightest mistake can result in a defective part, which can lead to costly errors or delays. CNC operators must have excellent attention to detail to ensure every part meets strict tolerance standards. They must be able to spot inconsistencies in the machine’s operation and address them before they become significant problems.

Problem-Solving Skills

CNC machines are highly complex, and issues may arise unexpectedly. A skilled operator must be able to troubleshoot and resolve mechanical problems quickly and efficiently. This might involve diagnosing issues with the machine’s software, hardware, or the material being used. Operators need to stay calm under pressure and use their problem-solving skills to keep the production line running smoothly.

How to Become a CNC Operator: Step-by-Step Guide

Educational Requirements

While a high school diploma is typically required to begin a career as a CNC operator, additional education and training are highly recommended. Many aspiring operators attend technical schools or community colleges that offer specialized courses in CNC machining. These programs provide foundational knowledge in machine operations, blueprint reading, and safety protocols.

Hands-On Training

In addition to classroom education, CNC operators must undergo extensive hands-on training. This training can be obtained through apprenticeships, internships, or on-the-job training. These practical experiences are crucial for mastering the operation of CNC machines, interpreting blueprints, and developing the problem-solving skills needed in real-world manufacturing environments.

Certification Programs

Although certification is not always required, obtaining certification from recognized industry bodies such as the National Institute for Metalworking Skills (NIMS) can enhance a CNC operator’s qualifications and improve their job prospects. Certification demonstrates proficiency in operating CNC machines, understanding blueprints, and meeting safety standards.

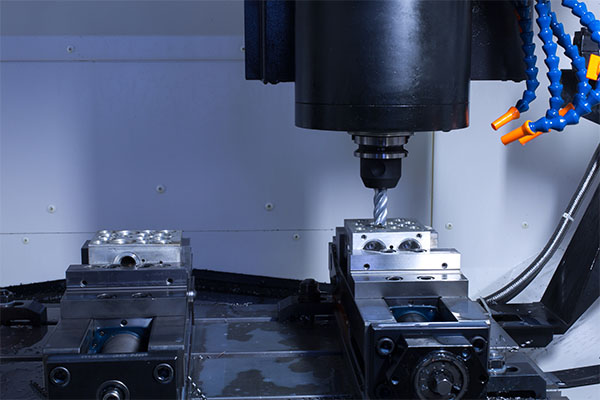

Understanding CNC Machine Components and Functions

Basic Components of CNC Machines

To succeed as a CNC operator, you need a thorough understanding of the various components of CNC machines. These include the spindle, tool holder, feed system, and the controller, which interprets the program instructions. Understanding the function of each part will help operators troubleshoot issues and maintain machines properly.

How CNC Machines Function

CNC machines operate based on a set of instructions, known as a program, which is fed into the machine’s controller. The program dictates the machine’s movements, speed, and other functions. Operators must be able to read and interpret these programs, make adjustments when necessary, and monitor the machine’s performance to ensure that the desired part is produced accurately.

Understanding Tolerances and Measurements

The Basics of CNC Programming

Precision is crucial in CNC machining. Operators must be adept at measuring and interpreting tolerances, which are the allowable deviations from a part’s intended dimensions. These measurements are specified in blueprints and drawings, and it is the operator’s responsibility to ensure that each part falls within these specifications.

CNC Programming: What You Need to Know

Programmation CNC is the process of creating the code that tells CNC machines how to operate. Operators must understand the language used in CNC programming, typically G-code, which is a series of instructions that tell the machine what movements to make. While some CNC operators may have to write their own programs, others rely on pre-programmed instructions.

Importance of CAD and CAM Systems

CNC operators should also have familiarity with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems. CAD software is used to create the design of the part, while CAM software generates the instructions that control the machine. Operators need to be able to read CAD drawings and convert them into machine instructions using CAM systems.

How to Read Blueprints and Schematics

A CNC operator must also be able to read and interpret technical drawings, blueprints, and schematics. These documents provide the information needed to set up the machine and create the desired part. Operators should understand the various symbols and measurements used in blueprints to ensure that they can set up and operate the machine correctly.

Safety Protocols in CNC Operations

Why Safety Is Critical

CNC machines are powerful and can be dangerous if not operated properly. Operators must always follow strict safety guidelines to prevent accidents and injuries. This includes wearing proper protective equipment, ensuring that the machine is in good working condition, and following lockout/tagout procedures during maintenance.

Common Safety Hazards

Operators should be aware of the various safety hazards that may arise when working with CNC machines. These hazards include exposure to high-speed rotating parts, sharp edges, and hot surfaces. Operators should also be mindful of the risks associated with the machine’s electrical systems and the potential for fumes or dust.

Preventing Workplace Injuries

To prevent injuries, CNC operators must adhere to safety protocols, such as performing regular maintenance checks, ensuring that the work area is clean and organized, and avoiding distractions while operating machines. Training on safe machine operation and emergency procedures is essential to keeping the workplace safe.

Advancing Your CNC Career: Opportunities and Growth

Gaining Experience and Expanding Skills

As CNC operators gain experience, they have the opportunity to take on more complex tasks and responsibilities. This may include working with different types of CNC machines, taking on supervisory roles, or learning advanced programming techniques. Operators should continually seek opportunities to expand their skills to stay competitive in the field.

Pursuing Certifications and Specializations

Operators who wish to advance their careers may choose to pursue additional certifications or specializations. For example, they may become certified in specific types of CNC machines, such as multi-axis machines, or learn advanced techniques like 3D printing. Specialized knowledge can open the door to higher-paying positions and more advanced roles.

Becoming a CNC Machine Programmer

For CNC operators interested in further career advancement, becoming a CNC programmer is a natural progression. CNC programmers write and modify machine codes, and they play a key role in optimizing the production process. This role requires more in-depth knowledge of programming languages, CAD/CAM software, and machine optimization.

CNC Operator Salary Expectations

Factors That Affect CNC Operator Pay

CNC operators can expect to earn competitive salaries, though pay varies depending on factors such as experience, location, and the complexity of the work being performed. Operators with specialized skills and certifications tend to earn more than those with general qualifications. Additionally, CNC operators in industries such as aerospace or medical device manufacturing may earn higher wages due to the increased precision required.

Average Salary Ranges for CNC Operators

According to industry reports, the average salary for CNC operators ranges from $30,000 to $60,000 per year, with the potential for higher earnings as experience and skills increase. CNC operators who move into supervisory or management positions may see their salaries increase significantly.

Job Outlook for CNC Operators

The demand for skilled CNC operators is expected to remain strong in the coming years as industries continue to rely on automation and high-precision manufacturing. With the increasing complexity of manufacturing processes and the growing use of advanced CNC technologies, the need for well-trained CNC operators is anticipated to grow.

Challenges Faced by CNC Operators

Dealing with Machine Malfunctions

Despite the advanced nature of CNC technology, machine malfunctions can still occur. Operators must be prepared to deal with breakdowns, software glitches, and mechanical failures. This requires a strong understanding of the machine’s components and the ability to troubleshoot and resolve issues quickly.

Managing Tight Deadlines

CNC operators often work under tight deadlines, particularly in high-demand industries. This can create pressure to maintain high levels of accuracy while also meeting production goals. Operators must be able to manage their time effectively, prioritize tasks, and stay focused under pressure.

FAQ

What are the basic qualifications needed to become a CNC operator?

Typically, a high school diploma is required, but many CNC operators also attend technical schools or obtain certifications in CNC operation and programming.

How long does it take to become a skilled CNC operator?

Becoming proficient as a CNC operator can take anywhere from a few months to a few years, depending on the level of formal education, hands-on training, and experience.

Can a CNC operator advance to higher positions?

Yes, many CNC operators advance to higher roles, such as CNC programmer or supervisor, by gaining experience and additional certifications.

How important are problem-solving skills in CNC operation?

Problem-solving is crucial for CNC operators, as they often need to troubleshoot machine malfunctions, adjust settings, and ensure that production runs smoothly.

What kind of industries employ CNC operators?

CNC operators are employed in a variety of industries, including automotive, aerospace, electronics, and medical device manufacturing, all of which require high-precision parts.

Conclusion

In conclusion, becoming a successful CNC operator requires a combination of technical skills, attention to detail, and practical experience. Whether you’re just starting out or looking to advance your career, there are plenty of opportunities for growth in this field. By gaining the right education, pursuing certifications, and continuing to develop your skills, you can carve out a rewarding and long-lasting career in CNC machining. If you’re ready to start, there’s no better time than now to dive in and begin your journey toward becoming a skilled CNC operator.