Introduction

The explosive growth of artificial intelligence has driven unprecedented demand for high-performance computing infrastructure, with GPUs serving as the cornerstone of modern AI systems. As these powerful processors generate increasingly significant amounts of heat, cooling solutions have evolved from a secondary consideration to a mission-critical component of data center design. This article explores the complex economics of GPU cooling in AI data centers, providing a comprehensive cost-benefit analysis and strategies for maximizing return on investment.

The Economic Challenge of AI Cooling

The economics of GPU cooling for AI workloads presents a complex challenge that extends far beyond simple cost calculations.

Problem: Advanced cooling solutions for AI hardware require significant upfront investment, creating financial barriers to adoption.

The capital costs for state-of-the-art cooling technologies can be substantial—often representing 15-25% of total data center infrastructure costs. This creates significant financial hurdles, particularly for organizations with constrained capital budgets.

Aggravation: Traditional ROI models often fail to capture the full value of advanced cooling investments.

Further complicating matters, conventional financial analysis approaches frequently undervalue or entirely overlook critical benefits of superior cooling, such as extended hardware lifespan, improved computational throughput, and reduced failure rates.

Solution: A comprehensive economic framework that captures all value dimensions can properly justify appropriate cooling investments:

The Evolving Economics of AI Infrastructure

Understanding the historical context of AI cooling economics provides important perspective:

- Historical Perspective:

- Early data centers (pre-2010): Cooling as overhead cost (15-20% of OpEx)

- Traditional GPU computing (2010-2018): Cooling as efficiency focus (PUE optimization)

- Early AI era (2018-2022): Cooling as performance enabler

- Current AI era (2023+): Cooling as strategic infrastructure

- Economic Shift Factors:

- GPU costs increasing dramatically (H100: $25,000-40,000 per unit)

- Power densities rising (300W → 700W+ per GPU)

- AI workloads running at sustained high utilization

- Model training times extending to weeks or months

- Hardware refresh cycles accelerating

- Mission-critical AI applications emerging

- Value Perception Evolution:

- Traditional view: Cooling as necessary expense

- Efficiency view: Cooling as energy cost reduction

- Current view: Cooling as performance enabler

- Emerging view: Cooling as strategic infrastructure

Here’s a critical insight: We are currently experiencing a fundamental paradigm shift in how organizations value cooling infrastructure. As AI becomes increasingly central to business operations and competitive advantage, cooling is transitioning from a cost center to a strategic investment that directly enables computational capability. This shift is similar to how network infrastructure evolved from a basic utility to a strategic asset during the internet revolution.

The Total Economic Impact Framework

A comprehensive approach to cooling economics must consider multiple value dimensions:

- Direct Cost Factors:

- Capital expenditures (CapEx)

- Operational expenditures (OpEx)

- Maintenance and support costs

- Upgrade and replacement cycles

- End-of-life and disposal costs

- Performance Value Dimensions:

- Computational throughput improvements

- Training and inference time reduction

- Higher sustained utilization rates

- Consistent performance delivery

- Enhanced model quality potential

- Risk Mitigation Elements:

- Hardware failure reduction

- Downtime prevention

- Performance variability minimization

- Disaster recovery enhancement

- Business continuity protection

Economic Impact Categories for AI Cooling

| Category | Traditional Valuation | Comprehensive Valuation | Value Gap |

|---|---|---|---|

| Energy Efficiency | Fully valued | Fully valued | None |

| Hardware Lifespan | Partially valued | Fully valued | 40-60% |

| Performance Improvement | Minimally valued | Fully valued | 70-90% |

| Reliability Enhancement | Partially valued | Fully valued | 30-50% |

| Density Enablement | Minimally valued | Fully valued | 60-80% |

| Risk Reduction | Rarely valued | Fully valued | 80-95% |

But here’s an interesting phenomenon: The most significant economic benefits of advanced cooling are often the hardest to quantify in traditional financial models. For example, the value of consistent performance for mission-critical AI applications or the competitive advantage of faster model development cycles doesn’t fit neatly into conventional ROI calculations. This “quantification gap” frequently leads to underinvestment in cooling infrastructure, creating hidden costs and missed opportunities that only become apparent over time.

Industry-Specific Economic Considerations

The economics of GPU cooling vary significantly across different sectors:

- Financial Services:

- Ultra-low latency requirements for trading algorithms

- Extreme reliability needs for financial systems

- Regulatory compliance considerations

- Competitive advantage from millisecond improvements

- High cost of downtime ($100,000+ per minute)

- Healthcare and Life Sciences:

- Long-running research computations

- Validation and reproducibility requirements

- Patient safety implications

- Regulatory and compliance factors

- Life-critical application reliability

- Technology and Cloud Providers:

- Massive scale deployment economics

- Multi-tenant infrastructure considerations

- Service level agreement requirements

- Competitive differentiation needs

- Continuous innovation pressures

Ready for the fascinating part? The economic value of advanced cooling varies by as much as 5-10x across different industries and use cases. For high-frequency trading applications where milliseconds translate directly to millions in profit, the value of performance consistency enabled by superior cooling can justify premium solutions with payback periods measured in weeks rather than years. Conversely, for non-time-sensitive batch processing, the economic equation may favor more modest cooling investments. This variability means that industry benchmarks and “standard” ROI calculations are often misleading—the true value must be calculated based on specific organizational contexts and use cases.

Capital Expenditure Considerations

The upfront investment in cooling infrastructure represents a significant portion of AI data center costs, requiring careful analysis and planning.

Problem: Advanced cooling technologies often require substantial capital investment, creating financial barriers to adoption.

High-performance cooling solutions for AI hardware typically involve significant upfront costs, with premium technologies like direct liquid cooling or immersion systems requiring 2-3x the capital investment of traditional approaches.

Aggravation: The rapid evolution of AI hardware creates uncertainty about the longevity of cooling investments.

Further complicating matters, the accelerating pace of AI hardware development creates uncertainty about how long any cooling infrastructure will remain adequate, making long-term ROI calculations particularly challenging.

Solution: A comprehensive capital expenditure analysis that considers all direct and indirect costs, along with future flexibility, can guide appropriate investment decisions:

Direct Equipment Costs

Understanding the complete equipment cost picture for different cooling approaches:

- Air Cooling Systems:

- Precision air handling units: $1,500-3,000 per kW

- In-row cooling units: $2,000-4,000 per kW

- Rear door heat exchangers: $3,000-5,000 per kW

- Specialized high-density air cooling: $4,000-7,000 per kW

- Total system cost: $150,000-700,000 per rack (depending on density)

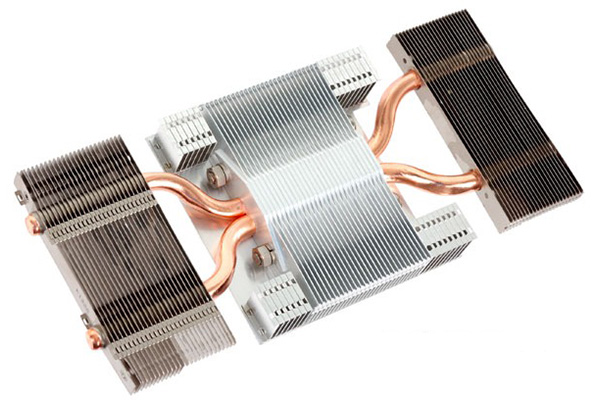

- Direct Liquid Cooling:

- Cold plates and manifolds: $500-1,500 per GPU

- CDUs (Cooling Distribution Units): $30,000-100,000 each

- Piping and distribution: $10,000-50,000 per rack

- Monitoring and control systems: $5,000-20,000 per rack

- Total system cost: $200,000-800,000 per rack (depending on configuration)

- Immersion Cooling:

- Immersion tanks: $30,000-100,000 each

- Dielectric fluid: $15-40 per liter ($3,000-15,000 per system)

- Heat rejection systems: $30,000-80,000 per system

- Filtration and maintenance equipment: $10,000-30,000 per system

- Total system cost: $250,000-900,000 per equivalent rack

Here’s what makes this fascinating: The capital cost differential between cooling technologies narrows significantly at the highest power densities. While basic air cooling might cost 50-60% less than liquid cooling for low-density deployments, this gap shrinks to just 10-20% for ultra-high-density AI clusters. This convergence occurs because air cooling requires increasingly complex and expensive supplemental systems to handle extreme heat loads, while liquid cooling scales more efficiently. This “density inflection point” typically occurs around 30-40kW per rack, beyond which the capital cost advantage of traditional cooling approaches diminishes rapidly.

Infrastructure Requirements

Cooling technologies have varying impacts on broader infrastructure costs:

- Facility Modifications:

- Raised floor requirements

- Ceiling height considerations

- Structural reinforcement needs

- Containment systems

- Space allocation efficiency

- Power Infrastructure:

- UPS sizing for cooling systems

- Power distribution requirements

- Generator capacity implications

- Redundancy considerations

- Peak vs. average demand management

- Mechanical Systems:

- Heat rejection equipment

- Water treatment systems

- Pumping infrastructure

- Piping and distribution networks

- Redundancy and backup provisions

But here’s an interesting phenomenon: The most significant capital cost impacts of cooling technology choices often appear in seemingly unrelated infrastructure elements. For example, liquid cooling can reduce overall data center electrical infrastructure costs by 15-25% by eliminating fan power and enabling higher operating temperatures. Similarly, immersion cooling can reduce required floor space by 30-50% through higher density and elimination of spacing requirements. These secondary effects can sometimes create greater total capital savings than the direct cost differential between cooling technologies, fundamentally changing the economic equation.

Implementation and Deployment Costs

The process of implementing cooling systems involves significant costs beyond the equipment itself:

- Design and Engineering:

- Thermal modeling and simulation

- Computational fluid dynamics analysis

- Mechanical and electrical engineering

- Control system design

- Integration planning

- Installation and Commissioning:

- Physical installation labor

- System testing and validation

- Performance verification

- Documentation development

- Staff training and knowledge transfer

- Operational Readiness:

- Procedure development

- Monitoring system implementation

- Spare parts inventory

- Maintenance tool procurement

- Emergency response planning

Capital Cost Comparison by Cooling Technology

| Cost Category | Traditional Air | Advanced Air | Direct Liquid | Immersion |

|---|---|---|---|---|

| Equipment Cost | $$ | $$$ | $$$$ | $$$$$ |

| Installation Complexity | Low | Medium | High | Very High |

| Space Requirements | Very High | High | Medium | Low |

| Power Infrastructure | $$$ | $$$ | $$ | $ |

| Facility Modifications | $$ | $$$ | $$$$ | $$$ |

| Deployment Timeline | 1-2 months | 2-3 months | 3-6 months | 4-8 months |

| Future Flexibility | Low | Medium | High | Medium |

Future-Proofing and Flexibility Considerations

The ability to adapt to evolving requirements significantly impacts the long-term value of capital investments:

- Scalability Characteristics:

- Incremental expansion capability

- Minimum deployment size

- Scaling economics (linear vs. non-linear)

- Performance consistency during scaling

- Operational complexity with scale

- Technology Adaptability:

- Compatibility with future hardware

- Upgrade paths without replacement

- Vendor lock-in considerations

- Standard vs. proprietary interfaces

- Backward compatibility

- Hybrid Approach Benefits:

- Mixed cooling technology deployments

- Targeted application of premium cooling

- Phased implementation strategies

- Technology transition management

- Risk mitigation through diversity

Ready for the fascinating part? The most cost-effective capital investment strategies often involve “cooling zones” with different technologies optimized for specific workloads rather than uniform cooling approaches across the entire data center. For example, implementing immersion or direct liquid cooling only for high-density AI clusters while using advanced air cooling for lower-density support systems can reduce total capital costs by 20-30% compared to uniform cooling deployments. This “cooling ecosystem” approach allows organizations to apply the most appropriate technology to each specific need, optimizing capital efficiency while maintaining necessary performance.

Operational Cost Analysis

The ongoing costs of cooling infrastructure significantly impact total cost of ownership and long-term economic viability.

Problem: Operational costs for cooling AI hardware can be substantial, often exceeding the initial capital investment over the system lifetime.

The energy consumption, maintenance requirements, and support costs for cooling systems represent a significant ongoing expense that must be carefully managed to ensure economic sustainability.

Aggravation: Different cooling technologies have vastly different operational cost profiles that are not always obvious from initial analysis.

Further complicating matters, the operational cost advantages of different cooling approaches vary significantly based on facility characteristics, local utility rates, climate conditions, and maintenance capabilities.

Solution: A comprehensive operational cost analysis that considers all direct and indirect expenses can identify the most economically sustainable cooling approach:

Energy Consumption Economics

Energy represents the largest operational cost for most cooling systems:

- Direct Cooling Energy:

- Fan power for air movement

- Pump energy for liquid circulation

- Compressor power for refrigeration

- Control system and monitoring power

- Heat rejection energy requirements

- Efficiency Metrics and Comparisons:

- PUE (Power Usage Effectiveness): 1.8-2.2 for traditional air cooling

- PUE: 1.3-1.6 for advanced air with economization

- PUE: 1.1-1.3 for direct liquid cooling

- PUE: 1.03-1.15 for immersion cooling

- Annual energy cost differential: $50,000-500,000 per MW of IT load

- Efficiency Variability Factors:

- Climate and weather patterns

- Seasonal temperature variations

- Workload density and utilization

- Facility design and implementation quality

- Operational practices and setpoints

Here’s what makes this fascinating: The energy cost advantage of advanced cooling technologies increases non-linearly with AI hardware density. For example, at 10kW per rack, liquid cooling might offer a 20-30% energy advantage over air cooling. At 40kW per rack, this advantage typically grows to 40-60%, and at 100kW per rack, the advantage can exceed 70-80%. This exponential efficiency relationship occurs because air cooling requires dramatically increasing fan power as density rises, while liquid cooling energy scales much more linearly with heat load. This creates an economic inflection point where the operational savings of advanced cooling accelerate rapidly beyond certain density thresholds.

Maintenance and Support Costs

Ongoing maintenance requirements vary significantly between cooling approaches:

- Preventative Maintenance Requirements:

- Air cooling: Filter replacements, fan bearing service, coil cleaning

- Direct liquid: Fluid testing, leak checks, pump maintenance

- Immersion: Fluid analysis, filtration service, heat exchanger cleaning

- Typical annual maintenance cost: 3-8% of initial capital cost

- Staffing and Expertise Needs:

- Skill level requirements

- Training and certification costs

- Staffing levels for different technologies

- Vendor support contract expenses

- Specialized tool and equipment needs

- Consumables and Replacement Parts:

- Fluid replacement schedules

- Filter replacement frequency

- Pump and fan replacement intervals

- Sensor calibration and replacement

- Chemical treatment requirements

But here’s an interesting phenomenon: The maintenance cost differential between cooling technologies often follows a counterintuitive pattern. While advanced technologies like liquid and immersion cooling are generally perceived as more maintenance-intensive, data from large-scale deployments indicates they can actually reduce total maintenance costs by 15-30% compared to traditional approaches. This occurs because they eliminate numerous failure-prone components (particularly fans) and reduce the total component count requiring service. However, they do require more specialized expertise, creating a tradeoff between maintenance frequency and complexity that varies based on organizational capabilities.

Reliability and Downtime Costs

The economic impact of cooling-related failures can be substantial:

- Failure Rate Comparisons:

- Air cooling: 0.5-1.0 failures per rack per year

- Direct liquid: 0.2-0.5 failures per rack per year

- Immersion: 0.1-0.3 failures per rack per year

- Mean time to repair: 2-8 hours (varies by technology)

- Downtime cost: $500-50,000+ per hour (application dependent)

- Failure Mode Differences:

- Air cooling: Fan failures, clogged filters, control issues

- Direct liquid: Leaks, pump failures, blockages

- Immersion: Fluid degradation, heat exchanger issues

- Detection and remediation time variations

- Failure impact scope differences

- Business Impact Considerations:

- Production impact of cooling failures

- Service level agreement violations

- Customer experience degradation

- Reputation and trust implications

- Regulatory and compliance consequences

Operational Cost Comparison by Cooling Technology

| Cost Category | Traditional Air | Advanced Air | Direct Liquid | Immersion |

|---|---|---|---|---|

| Energy Efficiency (PUE) | 1.8-2.2 | 1.3-1.6 | 1.1-1.3 | 1.03-1.15 |

| Annual Energy Cost | $$$$$ | $$$ | $$ | $ |

| Maintenance Frequency | High | Medium-High | Medium | Low |

| Expertise Required | Low | Medium | High | Very High |

| Water Consumption | Medium-High | Medium | Low-Medium | Very Low |

| Failure Rate | High | Medium | Low | Very Low |

| Operational Complexity | Low | Medium | High | Medium-High |

Resource Utilization Factors

Cooling technologies have varying impacts on other resource consumption:

- Water Usage Considerations:

- Traditional cooling towers: 3-5 liters per kWh

- Adiabatic cooling: 1-2 liters per kWh

- Closed-loop systems: 0.1-0.3 liters per kWh

- Water cost: $2-10 per 1,000 gallons (highly location dependent)

- Water availability constraints in some regions

- Space Utilization Economics:

- Air cooling spatial requirements: 25-35 ft² per rack

- Direct liquid cooling: 15-25 ft² per rack

- Immersion cooling: 10-20 ft² per rack

- Facility cost impact: $200-2,000 per square foot

- Land and building cost considerations

- Operational Staffing Efficiency:

- Staff-to-rack ratios for different technologies

- Automation and remote management capabilities

- Monitoring and management tool differences

- Incident response requirements

- Specialized vs. general expertise needs

Ready for the fascinating part? The operational cost advantages of advanced cooling technologies compound over time through multiple reinforcing mechanisms. For example, the superior temperature stability of liquid cooling extends component lifespan, which reduces replacement frequency, which decreases maintenance interventions, which lowers the risk of human error, which further improves reliability. These compounding effects can create a 2-3x difference in total operational costs over a 5-year period, even when initial analysis suggests a much smaller differential. This “operational advantage compounding” represents one of the most significant but frequently overlooked economic benefits of advanced cooling technologies.

Performance and Productivity Benefits

The performance impact of cooling has significant economic implications that extend far beyond direct operational costs.

Problem: Traditional economic analyses often fail to capture the substantial performance and productivity benefits of advanced cooling.

The impact of cooling on computational throughput, hardware utilization, and AI development velocity represents significant economic value that is frequently overlooked in conventional ROI calculations.

Aggravation: The performance benefits of superior cooling are often difficult to quantify in standard financial terms.

Further complicating matters, the economic value of performance improvements varies dramatically based on specific AI applications and business contexts, making standardized valuation challenging.

Solution: A structured approach to quantifying performance and productivity benefits can provide a more complete picture of cooling investment value:

Computational Throughput Impact

Cooling directly affects the computational performance of AI systems:

- Thermal Throttling Prevention:

- Modern GPUs reduce clock speeds at high temperatures

- Throttling typically begins at 83-87°C

- Can reduce performance by 15-30%

- Affects both training and inference workloads

- Particularly impactful for sustained high-utilization AI tasks

- Clock Speed Stability:

- Superior cooling enables sustained boost clocks

- Temperature fluctuations cause clock speed variations

- Stable temperatures provide consistent performance

- Performance predictability improves resource planning

- Critical for large-scale distributed training

- Quantifiable Performance Improvements:

- Training time reduction: 10-25% typical

- Inference throughput increase: 5-20% typical

- Batch size optimization potential

- Memory bandwidth improvements

- Overall computational efficiency enhancement

Here’s what makes this fascinating: The performance impact of cooling is non-linear across different types of AI workloads. Memory-bound operations typically see modest improvements (5-10%) with better cooling, while compute-bound operations can experience dramatic gains (20-30%). This variability means that the economic value of cooling investments depends significantly on the specific AI workload profile of the organization. For compute-intensive applications like large language model training, the performance benefits of premium cooling can create economic value that exceeds the entire cooling system cost within months.

Hardware Utilization Optimization

Cooling quality significantly impacts how effectively AI hardware can be utilized:

- Utilization Rate Improvements:

- Poor cooling limits sustainable utilization

- Advanced cooling enables 90%+ sustained utilization

- Utilization improvement potential: 10-30%

- Hardware investment efficiency increase

- Reduced idle capacity requirements

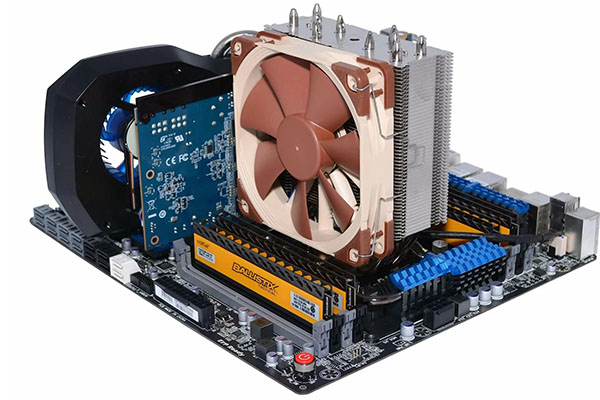

- Density Enablement Value:

- Traditional cooling: 15-25kW per rack practical limit

- Advanced air cooling: 25-40kW per rack

- Direct liquid cooling: 40-100kW per rack

- Immersion cooling: 100-200kW per rack

- Space efficiency economic impact: $100,000-1,000,000+ per rack

- Hardware Lifespan Extension:

- Every 10°C reduction approximately doubles component lifespan

- Advanced cooling can reduce temperatures by 20-30°C

- Potential lifespan extension: 2-4x

- Deferred replacement capital expenditure

- Reduced electronic waste and embodied carbon

But here’s an interesting phenomenon: The economic value of hardware lifespan extension increases non-linearly with component cost. For standard servers, extending lifespan might create modest value. For high-end AI accelerators costing $25,000-40,000 each, the same percentage lifespan extension creates 5-10x more economic value. As AI hardware costs continue to rise with each generation, the financial benefit of extending hardware life through superior cooling grows proportionally, fundamentally changing the ROI equation for cooling investments.

AI Development Velocity

Cooling quality can significantly impact AI development speed and effectiveness:

- Training Cycle Acceleration:

- Faster training completion

- More experimental iterations possible

- Accelerated hyperparameter optimization

- Quicker model refinement cycles

- Faster time-to-market for AI applications

- Resource Availability Improvements:

- Reduced queuing time for training jobs

- More consistent resource access

- Better planning and scheduling capabilities

- Improved developer productivity

- Enhanced research and development efficiency

- Model Quality Considerations:

- More training iterations within time constraints

- Larger batch sizes possible

- More extensive hyperparameter exploration

- Potential for higher accuracy models

- Competitive advantage through superior AI capabilities

Performance Value Comparison by Cooling Technology

| Value Category | Traditional Air | Advanced Air | Direct Liquid | Immersion |

|---|---|---|---|---|

| Thermal Throttling Prevention | Poor | Moderate | Excellent | Outstanding |

| Clock Speed Stability | Poor | Moderate | Good | Excellent |

| Sustainable Utilization | 70-80% | 80-90% | 90-95% | 95-100% |

| Density Enablement | 15-25kW/rack | 25-40kW/rack | 40-100kW/rack | 100-200kW/rack |

| Hardware Lifespan | Baseline | 1.3-1.5x | 1.5-2.5x | 2.0-3.0x |

| Development Velocity Impact | Baseline | 5-15% improvement | 15-25% improvement | 20-30% improvement |

Competitive Advantage Factors

Superior cooling can create strategic competitive advantages:

- Time-to-Market Acceleration:

- Faster model development cycles

- Earlier deployment of AI capabilities

- Competitive timing advantages

- Market share capture opportunities

- First-mover benefits in AI applications

- Capability Enhancement:

- Ability to train larger models

- More extensive experimentation

- Advanced AI capabilities development

- Performance differentiation

- Superior customer experiences

- Operational Excellence:

- More reliable AI services

- Consistent performance delivery

- Predictable resource availability

- Enhanced customer satisfaction

- Reputation for quality and reliability

Ready for the fascinating part? The competitive advantage created by superior cooling infrastructure compounds over time through accelerated learning effects. Organizations with faster training cycles can complete more iterations, learn more quickly from results, and improve their AI capabilities at a faster rate than competitors. This creates an expanding capability gap that becomes increasingly difficult for competitors to close. In rapidly evolving AI fields, this “learning velocity advantage” can be worth far more than the direct cost savings or performance improvements, potentially representing the most valuable economic benefit of advanced cooling investments.

Risk Mitigation Value

The risk reduction provided by advanced cooling has quantifiable economic value that is frequently underestimated in traditional analyses.

Problem: Conventional ROI calculations often fail to properly account for the risk mitigation value of superior cooling.

The economic benefit of preventing failures, avoiding downtime, and ensuring consistent performance is substantial but frequently overlooked or undervalued in traditional financial analyses.

Aggravation: As AI becomes increasingly mission-critical, the cost of failures and performance issues grows dramatically.

Further complicating matters, as organizations become more dependent on AI for core business functions, the financial, operational, and reputational impact of cooling-related problems increases substantially.

Solution: A structured approach to quantifying risk mitigation value can provide a more complete picture of cooling investment benefits:

Hardware Failure Risk Reduction

Advanced cooling significantly reduces hardware failure rates:

- Failure Rate Comparisons:

- Every 10°C increase typically doubles failure rates

- Advanced cooling can reduce temperatures by 20-30°C

- Potential failure rate reduction: 75-90%

- Mean time between failures improvement: 2-5x

- Annual failure avoidance: 0.3-0.8 incidents per rack

- Failure Cost Components:

- Hardware replacement expenses

- Technical staff time and expertise

- Diagnostic and repair labor

- Expedited shipping and emergency service

- Warranty claim processing

- Secondary Failure Prevention:

- Reduced thermal cycling stress

- Lower humidity variation

- Elimination of hotspots

- More consistent operating conditions

- Prevention of cascading failures

Here’s what makes this fascinating: The relationship between temperature and hardware reliability is exponential rather than linear. Research indicates that for every 10°C increase in operating temperature, failure rates approximately double. This means that cooling solutions that reduce temperatures by 20-30°C can potentially decrease failure rates by 75-90%. For high-value AI accelerators, this dramatic reliability improvement can create economic value that exceeds the entire cost of the cooling system over its lifetime, particularly when considering the full cost of failures beyond just the hardware replacement.

Downtime Prevention Value

The economic impact of avoiding cooling-related downtime can be substantial:

- Downtime Cost Factors:

- Lost computational capacity

- Delayed AI model development

- Service level agreement violations

- Revenue impact from service disruption

- Reputation and customer confidence damage

- Downtime Cost Variability:

- Financial services: $100,000-1,000,000+ per hour

- E-commerce: $50,000-500,000 per hour

- Healthcare: $25,000-250,000 per hour

- Manufacturing: $10,000-100,000 per hour

- Research: $5,000-50,000 per hour

- Recovery Time Considerations:

- Problem identification time

- Repair or replacement duration

- System restart and validation

- Workload rescheduling

- Return to normal operations

But here’s an interesting phenomenon: The cost of AI infrastructure downtime is increasing dramatically as organizations become more dependent on these systems for core business functions. Five years ago, AI system failures typically created inconvenience; today, they can halt entire business operations. This escalating impact means that the economic value of downtime prevention is growing much faster than general inflation or even the increasing cost of the hardware itself. For mission-critical AI applications, this growing “downtime premium” is fundamentally changing the risk-adjusted ROI calculation for cooling investments.

Performance Consistency Value

The economic benefit of reliable, consistent performance is significant:

- Performance Variability Costs:

- Unpredictable training completion times

- Resource planning challenges

- Inconsistent service delivery

- User experience degradation

- Business planning uncertainty

- Service Level Agreement Considerations:

- Performance guarantee requirements

- Penalty clauses for non-compliance

- Customer compensation costs

- Contract risk exposure

- Competitive disadvantage from missed targets

- Operational Planning Benefits:

- Reliable resource scheduling

- Accurate capacity planning

- Predictable project timelines

- Consistent budget forecasting

- Improved stakeholder confidence

Risk Mitigation Value by Cooling Technology

| Risk Category | Traditional Air | Advanced Air | Direct Liquid | Immersion |

|---|---|---|---|---|

| Hardware Failure Reduction | Baseline | 20-40% | 50-70% | 70-90% |

| Downtime Prevention | Baseline | Moderate | Significant | Substantial |

| Performance Consistency | Poor | Moderate | Good | Excellent |

| Disaster Recovery | Limited | Moderate | Enhanced | Superior |

| Business Continuity | Basic | Improved | Advanced | Comprehensive |

| Regulatory Compliance | Minimal | Partial | Substantial | Complete |

Disaster Recovery Enhancement

Advanced cooling can significantly improve resilience to environmental and infrastructure challenges:

- Environmental Resilience:

- Heat wave tolerance

- Humidity fluctuation resistance

- Air quality issue mitigation

- Weather event impact reduction

- Climate change adaptation

- Infrastructure Failure Handling:

- Cooling redundancy effectiveness

- Graceful degradation capabilities

- Thermal buffering capacity

- Recovery time improvement

- Restart and resumption efficiency

- Operational Recovery Advantages:

- Simplified disaster recovery procedures

- Reduced recovery time objectives (RTOs)

- Improved recovery point objectives (RPOs)

- Enhanced business continuity

- Reduced insurance costs and requirements

Ready for the fascinating part? The most advanced cooling technologies don’t just reduce risk—they fundamentally change the disaster recovery profile of AI infrastructure. For example, immersion cooling creates substantial thermal mass that provides 10-30 minutes of “thermal runway” during complete cooling failures, compared to 30-90 seconds for air cooling. This extended grace period transforms the disaster recovery approach from emergency shutdown to orderly transition, potentially saving millions in avoided data loss and recovery costs during critical incidents. This “resilience dividend” represents one of the most valuable but frequently overlooked benefits of advanced cooling investments.

ROI Calculation Methodologies

Accurately calculating return on investment for cooling infrastructure requires sophisticated methodologies that capture all value dimensions.

Problem: Traditional ROI calculations often fail to capture the full value of cooling investments, leading to suboptimal decisions.

Conventional financial analysis approaches frequently focus narrowly on energy savings while overlooking critical value factors like performance improvements, hardware lifespan extension, and risk reduction.

Aggravation: The value components of cooling investments vary dramatically across different organizations and use cases.

Further complicating matters, the relative importance of different value factors depends heavily on specific organizational contexts, AI applications, and business priorities, making standardized ROI calculations potentially misleading.

Solution: Comprehensive, context-specific ROI methodologies that incorporate all value dimensions can guide optimal investment decisions:

Comprehensive TCO Analysis

Total Cost of Ownership analysis provides a foundation for cooling investment decisions:

- TCO Component Identification:

- Initial capital expenditure

- Installation and commissioning costs

- Energy expenses over system lifetime

- Maintenance and support costs

- Upgrade and replacement expenses

- End-of-life and disposal costs

- Lifetime Consideration Factors:

- Expected infrastructure lifespan

- Hardware refresh cycles

- Technology obsolescence timelines

- Facility lifetime and amortization

- Changing business requirements

- Comparative TCO Methodologies:

- Baseline vs. advanced cooling comparison

- Multiple technology option analysis

- Hybrid approach evaluation

- Phased implementation consideration

- Sensitivity analysis for key variables

Here’s what makes this fascinating: The most accurate TCO analyses don’t just compare cooling technologies in isolation—they model the impact of cooling choices on the entire data center ecosystem. For example, advanced cooling might enable higher rack densities, which reduces white space requirements, which decreases building size, which lowers construction costs, property taxes, and facility maintenance expenses. These cascading effects can create 2-3x more economic value than the direct cooling system benefits, fundamentally changing the TCO equation. The most sophisticated organizations are now using “ecosystem TCO” approaches that capture these complex interdependencies, leading to significantly different investment decisions than traditional isolated analyses.

Performance Value Quantification

Translating performance benefits into financial terms requires structured methodologies:

- Computational Throughput Valuation:

- Training time reduction value

- Inference capacity increase worth

- Job completion acceleration benefits

- Resource utilization improvement value

- Overall computational efficiency gains

- Hardware Utilization Economics:

- Capital efficiency improvement value

- Density enablement benefits

- Space utilization optimization worth

- Power capacity utilization value

- Overall infrastructure efficiency gains

- Development Velocity Valuation:

- Time-to-market acceleration worth

- Additional iteration value

- Improved model quality benefits

- Competitive advantage quantification

- Overall innovation acceleration value

But here’s an interesting phenomenon: The economic value of performance improvements follows a non-linear relationship with business impact. For non-critical applications, a 20% performance improvement might create only modest value. For time-sensitive applications like financial trading algorithms or critical healthcare diagnostics, the same percentage improvement could create 10-100x more value. This “criticality multiplier” means that performance benefits must be valued in the specific business context rather than using standardized metrics. Organizations that apply context-specific valuation typically identify 3-5x higher ROI for cooling investments compared to those using generic performance value estimates.

Risk-Adjusted Return Calculation

Incorporating risk mitigation value into ROI analysis provides a more complete picture:

- Expected Loss Reduction:

- Failure probability decrease

- Average incident cost

- Annual loss expectancy reduction

- Cumulative risk mitigation value

- Risk-adjusted return calculation

- Business Impact Analysis Integration:

- Critical function identification

- Downtime cost quantification

- Recovery time improvement value

- Business continuity enhancement worth

- Overall operational resilience value

- Compliance and Governance Considerations:

- Regulatory requirement fulfillment

- Audit and certification support

- Legal liability reduction

- Insurance cost implications

- Overall governance risk reduction

ROI Calculation Approaches Comparison

| Methodology | Complexity | Accuracy | Value Capture | Best Applications |

|---|---|---|---|---|

| Simple Payback | Very Low | Very Low | Energy savings only | Initial screening |

| Basic TCO | Low | Low-Medium | Direct costs only | Budget planning |

| Enhanced TCO | Medium | Medium | Direct + some indirect | Standard projects |

| Performance-Adjusted TCO | Medium-High | Medium-High | Includes performance value | AI infrastructure |

| Risk-Adjusted TCO | High | High | Includes risk mitigation | Mission-critical AI |

| Comprehensive Value | Very High | Very High | All value dimensions | Strategic investments |

Scenario Analysis and Sensitivity Testing

Addressing uncertainty through multiple scenarios improves decision quality:

- Variable Identification:

- Energy cost projections

- Hardware cost trends

- Technology evolution pace

- Workload growth patterns

- Business requirement changes

- Scenario Development:

- Base case definition

- Optimistic and pessimistic variants

- Technology disruption scenarios

- Business change considerations

- Regulatory environment evolution

- Decision Support Approaches:

- Monte Carlo simulation

- Decision tree analysis

- Real options valuation

- Portfolio optimization

- Robust decision methodologies

Ready for the fascinating part? The most sophisticated cooling investment analyses don’t just calculate a single ROI figure—they develop “value landscapes” that map how ROI varies across different scenarios and assumptions. This approach reveals that some cooling investments create option value by enabling future flexibility, while others may offer higher returns under current conditions but create technology lock-in. Organizations using these advanced decision methodologies typically make significantly different investment choices than those relying on simple ROI calculations, prioritizing solutions that perform well across multiple possible futures rather than optimizing for a single scenario.

Strategic Investment Approaches

Beyond tactical ROI calculations, strategic approaches to cooling investment can create long-term competitive advantage and value.

Problem: Treating cooling as a purely tactical infrastructure decision misses opportunities for strategic advantage.

Many organizations view cooling investments through a narrow operational lens, missing opportunities to use thermal management as a strategic enabler for AI capabilities and competitive differentiation.

Aggravation: The strategic value of cooling infrastructure increases as AI becomes more central to business success.

Further complicating matters, as AI transitions from experimental to mission-critical status, the strategic implications of cooling infrastructure decisions grow substantially, requiring executive-level attention rather than purely technical evaluation.

Solution: Approaching cooling as a strategic investment that enables AI capabilities can create significant long-term value:

Strategic Timing Considerations

When to invest in cooling infrastructure has significant strategic implications:

- Technology Adoption Timing:

- Early adopter advantages

- Fast follower benefits

- Technology maturity considerations

- Implementation risk factors

- Competitive positioning impact

- Business Alignment Factors:

- AI roadmap synchronization

- Hardware refresh cycle coordination

- Facility lifecycle integration

- Budget cycle optimization

- Strategic initiative alignment

- Market Timing Elements:

- Vendor negotiation opportunities

- Industry capacity constraints

- Supply chain considerations

- Economic cycle positioning

- Regulatory change anticipation

Here’s what makes this fascinating: The optimal timing for cooling investments often follows a counter-cyclical pattern relative to general IT spending. During economic downturns when many organizations reduce capital expenditures, cooling infrastructure investments can create exceptional value through lower implementation costs, better vendor terms, and positioning for competitive advantage during the subsequent recovery. Organizations that strategically time their cooling investments can achieve 15-30% better economics than those following standard budget cycles, while simultaneously creating technological advantages that persist for years.

Phased Implementation Strategies

Staged approaches to cooling deployment can optimize both economics and risk:

- Pilot-to-Production Pathways:

- Small-scale pilot implementations

- Operational experience development

- Technology validation in real environments

- Risk-managed expansion

- Knowledge-based scaling

- Targeted Deployment Approaches:

- High-value application prioritization

- Critical infrastructure focus

- Performance bottleneck targeting

- Risk-based implementation sequencing

- Value-maximizing deployment order

- Hybrid Cooling Ecosystems:

- Multiple technology integration

- Workload-optimized cooling zones

- Technology transition management

- Legacy and advanced system coexistence

- Operational complexity balancing

But here’s an interesting phenomenon: The most successful cooling implementation strategies don’t just focus on the technology—they equally emphasize the organizational learning process. Organizations that implement advanced cooling technologies through carefully structured phases typically achieve 20-30% better results than those attempting comprehensive deployments, even when the final technology is identical. This “learning dividend” comes from the ability to refine approaches, develop internal expertise, and optimize configurations based on real-world experience before full-scale deployment.

Vendor and Partnership Strategies

Strategic approaches to vendor relationships can create significant value:

- Vendor Selection Considerations:

- Technology leadership position

- Financial stability and longevity

- Support and service capabilities

- Innovation roadmap alignment

- Total partnership value beyond price

- Collaborative Development Approaches:

- Joint innovation initiatives

- Custom solution development

- Early access to emerging technologies

- Feedback loop for product improvement

- Mutual value creation opportunities

- Ecosystem Integration Strategies:

- Hardware vendor coordination

- Facility provider collaboration

- Utility and energy partnerships

- Research and academic relationships

- Industry consortium participation

Strategic Investment Approach Comparison

| Strategy | Risk Profile | Value Creation | Implementation Complexity | Best Applications |

|---|---|---|---|---|

| Comprehensive Deployment | High | High (if successful) | Very High | Organizations with mature capabilities |

| Phased Implementation | Medium | Medium-High | Medium | Most organizations |

| Pilot-First Approach | Low | Medium | Low-Medium | Organizations new to advanced cooling |

| Targeted Deployment | Medium | High | Medium-High | Organizations with clear priorities |

| Hybrid Ecosystem | Medium-High | Very High | High | Complex, diverse environments |

| Wait-and-See | Very Low | Low | Very Low | Non-critical AI applications |

Organizational Capability Development

Building internal capabilities is essential for long-term cooling strategy success:

- Skill Development Investments:

- Technical training programs

- Certification and education support

- Hands-on experience opportunities

- Knowledge transfer structures

- Career development pathways

- Process and Procedure Evolution:

- Operational documentation development

- Best practice implementation

- Continuous improvement mechanisms

- Knowledge management systems

- Institutional learning approaches

- Cultural and Organizational Factors:

- Cross-functional collaboration

- IT and facilities integration

- Innovation encouragement

- Risk management approaches

- Leadership engagement and support

Ready for the fascinating part? The organizations that achieve the greatest long-term value from cooling investments are often distinguished not by their technology choices but by their approach to organizational capability development. Those that treat cooling infrastructure as a strategic capability requiring dedicated skill development, executive attention, and continuous improvement typically achieve 2-3x better long-term outcomes than those viewing it as a purely technical implementation. This “capability premium” compounds over time as the organization builds institutional knowledge that enables increasingly sophisticated cooling strategies aligned with evolving AI requirements.

Frequently Asked Questions

Q1: How do I build a compelling business case for advanced cooling investments when traditional ROI calculations don’t capture the full value?

Building a compelling business case for advanced cooling requires a comprehensive approach that captures all value dimensions: First, expand beyond energy savings to include all direct cost impacts—hardware lifespan extension, space efficiency, maintenance requirements, and water usage. Quantify these based on your specific environment rather than industry averages. Second, incorporate performance benefits—calculate the economic value of throughput improvements, higher utilization, and development velocity for your specific AI workloads. For mission-critical applications, this often represents the largest value component. Third, quantify risk reduction value—analyze the cost of downtime, hardware failures, and performance variability specific to your organization, then calculate the expected value of risk reduction. Fourth, include strategic and competitive factors—assess how cooling enables capabilities that drive competitive advantage, such as larger models, faster training cycles, or more reliable services. Fifth, use scenario analysis rather than point estimates—develop multiple scenarios showing how value varies under different assumptions about energy costs, hardware evolution, and business requirements. The most persuasive business cases typically use a “value stack” approach that visually shows how multiple value components combine to create total return, making clear that energy savings alone may represent less than 30% of total value. For executive audiences, frame cooling not as infrastructure cost but as strategic enablement of AI capabilities that drive business outcomes.

Q2: What are the most common mistakes organizations make when evaluating the economics of GPU cooling for AI workloads?

The most common economic evaluation mistakes for GPU cooling, ranked by frequency and impact: First, focusing exclusively on capital costs while ignoring operational impacts—advanced cooling may cost more upfront but often delivers substantially lower lifetime costs through energy savings, extended hardware life, and reduced failures. Second, evaluating cooling in isolation rather than as part of the total infrastructure ecosystem—cooling choices affect power distribution, space requirements, and even building design, creating cascading economic effects that can dwarf direct cooling costs. Third, undervaluing or ignoring performance benefits—for high-value AI workloads, the economic value of preventing thermal throttling and enabling consistent performance often exceeds all other factors combined. Fourth, applying generic metrics rather than workload-specific analysis—the value of cooling varies dramatically based on specific AI applications, making standardized metrics potentially misleading. Fifth, using overly short time horizons—many organizations use 3-year horizons when 5-7 years better reflects infrastructure reality, significantly changing ROI calculations. Sixth, failing to consider future flexibility—some cooling approaches create option value by supporting higher densities or easier technology transitions, which has significant but often uncounted economic value. Seventh, ignoring the organizational learning curve—implementation quality dramatically affects results, making experience with advanced cooling technologies a critical success factor that should influence technology selection. Organizations that avoid these common mistakes typically identify 2-3x higher ROI for cooling investments and make substantially different technology choices than those using simplified evaluation approaches.

Q3: How should cooling investment strategies differ between enterprise AI deployments and cloud service providers?

Cooling investment strategies should differ significantly between enterprise AI and cloud providers due to fundamental differences in scale, business model, and operational context: For enterprises, cooling investments should typically prioritize flexibility and risk reduction—enterprises face greater uncertainty about future AI requirements and typically have less specialized operational expertise, making adaptable solutions with lower complexity more valuable despite potentially higher costs. Hybrid approaches that combine conventional cooling for general infrastructure with advanced cooling only for AI clusters often provide the best balance of performance and manageability. For cloud providers, cooling investments should emphasize standardization and efficiency at scale—the economics of cloud businesses demand relentless cost optimization, while operational scale justifies specialized expertise development. Total cost of ownership dominates decision-making, with performance consistency as a critical secondary factor to meet service level agreements. The investment time horizon also differs significantly—enterprises typically evaluate on 3-5 year horizons aligned with hardware refresh cycles, while cloud providers often use 7-10 year horizons aligned with facility lifespans. Risk profiles differ as well—enterprises typically face greater consequences from individual system failures but have lower overall utilization, while cloud providers optimize for fleet-wide reliability with higher average utilization. These contextual differences mean that cooling technologies offering the best ROI for cloud providers may not be optimal for enterprise deployments, despite addressing similar technical challenges.

Q4: How do I balance the higher capital costs of advanced cooling against the operational benefits when facing budget constraints?

When facing budget constraints while evaluating advanced cooling, several approaches can help balance capital limitations with operational benefits: First, consider financing and alternative acquisition models—cooling-as-a-service, lease arrangements, or vendor financing can convert capital expenses to operational expenses while still capturing efficiency benefits. Second, implement phased deployment strategies—start with cooling upgrades only for the most critical or highest-density AI infrastructure where the ROI is strongest, then expand incrementally as operational savings materialize. Third, explore hybrid cooling approaches—implement advanced cooling only for the components that benefit most (typically GPUs) while maintaining conventional cooling for the rest of the infrastructure. Fourth, leverage utility incentives and rebates—many utilities offer significant financial incentives for data center efficiency improvements that can offset 10-30% of capital costs. Fifth, partner with hardware refreshes—synchronizing cooling upgrades with planned hardware replacements can reduce implementation costs and create natural budget alignment. Sixth, implement a “cooling upgrade fund” model—dedicate a portion of demonstrated operational savings from initial cooling improvements to fund subsequent phases, creating a self-sustaining improvement cycle. The most successful organizations typically combine multiple approaches, starting with limited deployments that demonstrate value and build internal expertise, then scaling based on validated operational benefits rather than theoretical projections. This measured approach typically delivers 70-80% of the benefits of comprehensive deployment at 40-50% of the capital requirement, creating compelling economics even under significant budget constraints.

Q5: How should organizations factor future AI hardware evolution into current cooling infrastructure decisions?

Organizations should address future AI hardware evolution in cooling decisions through several strategic approaches: First, design for power density headroom—implement cooling infrastructure capable of handling 2-3x current maximum densities, as AI accelerator power consumption has consistently increased 30-50% per generation. Second, prioritize cooling technologies with scaling advantages—some approaches (particularly liquid and immersion cooling) become relatively more efficient as density increases, creating future-proofing benefits. Third, implement modular and adaptable designs—use standardized interfaces, modular components, and flexible distribution systems that can evolve without complete replacement as requirements change. Fourth, develop multi-generation roadmaps—create cooling infrastructure plans that explicitly consider multiple future hardware generations and include defined upgrade paths rather than point-in-time solutions. Fifth, maintain technology diversity—avoid complete standardization on a single cooling approach to maintain flexibility as hardware and cooling technologies evolve. Sixth, establish vendor partnerships with innovation roadmaps—work with cooling providers that demonstrate clear understanding of AI hardware evolution and have development plans aligned with future requirements. The most forward-thinking organizations are implementing “cooling zones” with different technologies and capabilities, allowing them to place workloads optimally based on cooling requirements and to test new approaches without disrupting production environments. This portfolio approach to cooling infrastructure creates valuable flexibility to adapt as AI hardware continues its rapid evolution, potentially saving 30-50% in long-term infrastructure costs compared to single-technology standardization approaches.