מָבוֹא

Small batch CNC machining has become a go-to solution for industries requiring high precision and quality in manufacturing, without the need for mass production. As a method of producing a limited number of parts or products, this approach is particularly beneficial for industries like aerospace, automotive, medical devices, and more. In this article, we will explore small batch CNC machining, its benefits, challenges, and how it stacks up against traditional manufacturing methods. So, whether you’re a manufacturer looking for a flexible production option or a business owner interested in small-scale runs, you’re in the right place.

1. What is Small Batch CNC Machining?

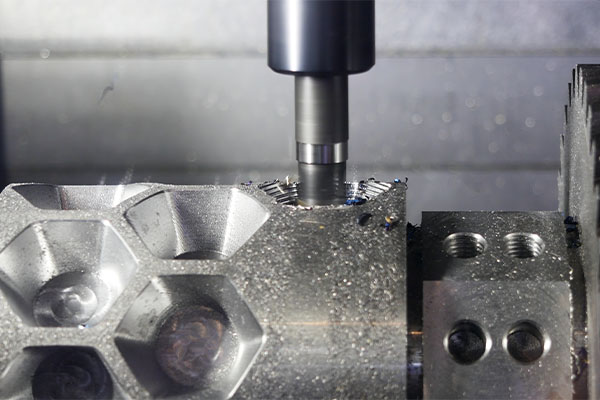

Small batch CNC machining refers to the process of manufacturing a limited number of custom parts using CNC (computer numerical control) machines. What’s the real story? CNC machines are controlled by computers, ensuring that parts are made with high precision, cutting down the margin for error. This method contrasts with large-scale production, which typically focuses on producing hundreds or thousands of identical parts.

This process is highly versatile. Whether it’s creating prototypes or custom parts for niche applications, small batch CNC machining allows manufacturers to produce products with precision, even in low quantities. Ready for the good part? It’s also cost-effective. The ability to use the same machines for different runs makes small batch machining an attractive choice, especially for businesses that don’t need to create products in bulk.

Common Applications of Small Batch CNC Machining

● Aerospace industry: Precision parts for airplanes and spacecraft.

● Automotive industry: Custom parts for high-performance vehicles or prototypes.

● Medical devices: Manufacturing custom components for medical equipment.

Benefits of Small Batch CNC Machining

● Customization: It allows for customized production tailored to specific needs.

● Quick Turnaround: Small runs mean faster production cycles, helping to reduce wait times for orders.

● Lower Risk of Error: The precision of CNC machining ensures high accuracy in every piece, reducing the chance of costly mistakes.

What’s the kicker? You get high-quality products with short lead times and flexibility to meet your exact specifications.

2. Why Choose Small Batch CNC Machining?

Why would a business opt for small batch CNC machining? The answer lies in the significant benefits that come with this method. But here’s the kicker, small batch CNC machining is an excellent choice when businesses want flexibility, customization, and cost efficiency.

Small batch CNC machining can be particularly useful when your business deals with unique or customized parts. With traditional manufacturing, the setup costs are often the same regardless of how many parts are produced. However, with small batch CNC machining, you can produce smaller quantities at a fraction of the cost.

One of the primary reasons why companies prefer small batch machining is the reduced upfront investment. For high-volume production, you need to invest in large machinery and tooling, which can be costly. However, small batch CNC machining allows companies to manufacture parts without needing those expensive investments, making it a more budget-friendly solution.

How It Benefits Small Businesses

For small businesses, this method allows them to produce products on demand without maintaining large inventories. This flexibility can be crucial for startups or businesses operating in markets that require constant innovation or product variation.

What’s the real story here? With small batch CNC machining, you get high-quality, cost-effective production without needing to worry about massive investments upfront.

3. What Are the Key Industries That Use Small Batch CNC Machining?

Small batch CNC machining isn’t limited to just one industry. The versatility of this method allows it to cater to a variety of sectors that need precision and flexibility in their manufacturing process. What’s the catch? Well, different industries rely on small batch CNC machining for different reasons.

Aerospace Industry

In the aerospace sector, precision and reliability are essential. Small batch CNC machining is used to produce critical components such as turbine blades and engine parts. The ability to produce small quantities of highly specialized parts makes CNC machining an attractive option.

Automotive Industry

The automotive industry often requires high-precision parts for prototype vehicles, low-volume production runs, or replacement parts for rare or vintage models. Small batch CNC machining allows manufacturers to produce these custom components efficiently.

מכשירים רפואיים

The medical industry uses small batch CNC machining to produce custom medical equipment such as surgical tools, implants, and diagnostic devices. The high level of customization and precision is particularly important in this sector to ensure patient safety and device effectiveness.

Ready for the good part? Small batch CNC machining allows companies in these industries to produce high-quality parts that meet their exact specifications without the need for mass production.

4. How Does the Small Batch CNC Machining Process Work?

The small batch CNC machining process is relatively straightforward but highly precise. Here’s the deal: CNC machines are programmed to follow exact instructions that guide them to cut, shape, and finish materials based on the design specifications provided.

It all starts with a CAD (computer-aided design) file, which provides the blueprint for the part. This file is then input into the CNC machine, which interprets the data and begins the manufacturing process. What’s the real story here? The precision of the CNC machine ensures that each part is made exactly as designed, with minimal human intervention.

Key Steps in the Small Batch CNC Machining Process

● Design and Prototyping: The initial design is created using CAD software.

● Programming: The CNC machine is programmed with the design.

● Machining: The material is cut, shaped, or drilled as per the design specifications.

● Finishing: The parts are cleaned and finished to meet quality standards.

With small batch CNC machining, the whole process is optimized for producing high-quality parts efficiently.

5. What Materials Are Commonly Used in Small Batch CNC Machining?

Materials play a huge role in small batch CNC machining, and selecting the right one can make all the difference in the final product. So, what materials are typically used in this process? Let’s break it down.

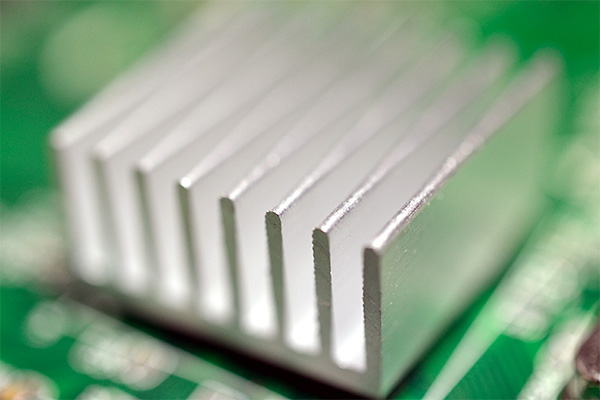

CNC machining can work with a wide range of materials. Common choices include metals such as aluminum, stainless steel, and titanium, as well as plastics like ABS and Nylon. What’s the kicker? CNC machines can handle a variety of material types, giving manufacturers the ability to choose the best material for the specific application.

Common Materials for Small Batch CNC Machining

● מתכות: Aluminum, stainless steel, brass, and titanium are commonly used due to their durability and machinability.

● פלסטיק: Nylon, polycarbonate, and ABS are often chosen for their flexibility and ease of machining.\

● חומרים מרוכבים: Carbon fiber and fiberglass are used for lightweight yet strong parts.

Ready to dive deeper? These materials are chosen for their properties, and manufacturers select them based on factors like strength, weight, and cost.

6. What Are the Benefits of Using CNC Machines for Small Batches?

Using CNC machines for small batches offers a variety of benefits that set it apart from traditional manufacturing methods. But here’s the kicker, the most important advantage is precision. CNC machines allow for extremely tight tolerances, meaning the parts produced are highly accurate and consistent. This is critical when manufacturing components that need to fit into complex assemblies or serve highly specialized purposes.

The benefits extend beyond just accuracy. CNC machines also minimize human error, ensuring that the parts produced in small batches are uniform. This consistency is key for industries such as aerospace and medical devices, where even a minor deviation can lead to serious consequences.

Benefits of CNC Machining for Small Batches

● דִיוּק: CNC machining ensures that each part meets the required specifications, with tight tolerances and consistency.

● Minimal Human Error: The automation of the process reduces the chances of errors that can occur in manual machining.

● Flexibility in Design: With CNC machines, it’s easy to modify designs or produce prototypes to test before committing to full-scale production.

What’s the real story here? CNC machining provides manufacturers with an efficient way to produce small quantities of parts with unmatched precision, all while saving time and money.

7. How Do Lead Times Compare in Small Batch CNC Machining?

Lead time is a critical factor in any manufacturing process. Small batch CNC machining offers faster turnaround times compared to traditional manufacturing methods, making it an ideal choice for businesses with tight deadlines or those requiring quick production runs. So, what’s the catch? The lead time for small batch CNC machining can vary depending on the complexity of the part, the material used, and the machine’s capabilities.

However, compared to large-scale production, small batch CNC machining typically has a quicker lead time. With traditional manufacturing, you often need to go through tooling and setup processes that can take weeks. On the other hand, CNC machining requires less setup time, especially for smaller runs, which significantly reduces lead times.

Factors Affecting Lead Times in Small Batch CNC Machining

● Part Complexity: The more complex the part, the longer it may take to machine.

● Material Type: Some materials may take longer to machine than others, especially harder metals.

● Machine Availability: The availability of the necessary CNC machine or tooling can also affect lead time.

Ready for the good part? Even with complex parts, small batch CNC machining can still offer lead times that are much shorter than traditional manufacturing, which helps businesses meet urgent demands.

8. What Are the Common Challenges of Small Batch CNC Machining?

Despite its many advantages, small batch CNC machining comes with its own set of challenges. So, what are the hurdles you might face? One of the primary challenges is the initial setup cost. While small batches are generally more cost-effective than large-scale runs, the setup process can still be expensive, especially if the design is complex or the required tools are not readily available.

Another issue is material costs. Small batch machining often requires purchasing materials in smaller quantities, which can be more expensive than buying in bulk. Additionally, maintaining quality control across small batches can sometimes be challenging, especially if the process is not carefully monitored.

Common Challenges in Small Batch CNC Machining

● High Setup Costs: The cost of machine setup can be expensive, particularly for intricate designs or specialized parts.

● Material Costs: Purchasing small quantities of material can increase the per-unit cost of parts.

● בקרת איכות: Maintaining consistent quality across small batches can be difficult without proper monitoring.

What’s the real story here? While small batch CNC machining offers numerous benefits, it’s important to consider these challenges and address them with proper planning and efficient workflows.

9. How Can Small Batch CNC Machining Save Costs?

One of the primary reasons businesses turn to small batch CNC machining is its ability to reduce production costs. But how exactly does it work? For one, small batch CNC machining allows businesses to produce custom parts without the need for large-scale machinery or expensive tools. The flexibility to make small runs helps companies avoid the costs associated with mass production.

Additionally, CNC machining’s precision ensures that there is less waste. This is critical in industries where material costs are high, such as aerospace or medical manufacturing. By producing only the necessary number of parts, businesses can avoid overproduction and reduce waste.

How Small Batch CNC Machining Saves Costs

● Lower Tooling Costs: Small batch runs reduce the need for expensive molds or specialized tooling.\

● Reduced Waste: The precision of CNC machining minimizes material waste, helping businesses save on materials.

● Customization: Companies can produce only what’s needed, avoiding the costs associated with overproduction.

Ready for the kicker? Small batch CNC machining isn’t just about quality and flexibility—it’s also an effective way to reduce costs while maintaining high standards.

10. How Do Small Batch CNC Machining Services Ensure Quality Control?

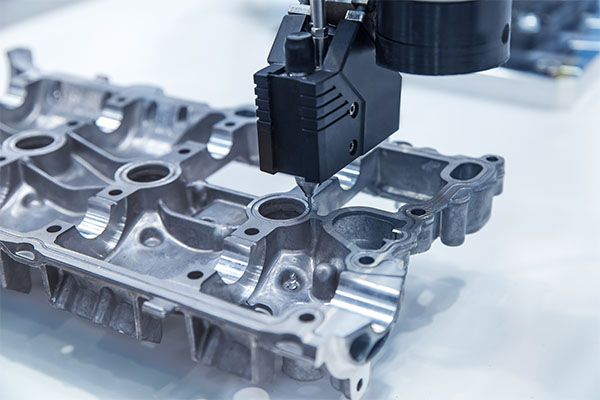

Quality control is critical in any manufacturing process, but it becomes even more important in industries that rely on high-precision components, such as aerospace or medical devices. What’s the kicker? Small batch CNC machining services implement several methods to ensure that every part meets the required specifications, even in small runs.

One of the most common methods is the use of Computer Numerical Control (CNC) machines equipped with inspection tools like laser scanners and coordinate measuring machines (CMM). These devices can verify that the dimensions of each part are within the required tolerance, ensuring that the final product is of the highest quality.

Methods of Quality Control in Small Batch CNC Machining

● Laser Scanning: This tool ensures that parts are measured with high precision, identifying any potential defects.

● מכונות מדידת קואורדינטות (CMM): These machines measure the physical geometrical characteristics of parts and ensure they meet the desired specifications.

● Material Testing: Some CNC services conduct material testing to ensure that the chosen materials meet required standards.

What’s the real story here? Small batch CNC machining services go the extra mile to ensure that every part produced is of the highest quality, even in small volumes.

11. What Makes a Good Small Batch CNC Machining Provider?

Choosing the right small batch CNC machining provider is crucial for ensuring that you get high-quality, reliable parts. But what should you look for in a provider? One of the most important factors is experience. The more experience a CNC machining service has, the better they will be at handling complex designs and offering recommendations for materials or processes.

Another important factor is the provider’s range of capabilities. A good provider should have a variety of CNC machines and the flexibility to work with different materials and designs. Additionally, the provider’s customer service should be top-notch, offering clear communication and quick response times to address any concerns.

Key Factors to Consider When Choosing a CNC Provider

● הִתנַסוּת: A seasoned provider will have the skills and knowledge needed to tackle complex projects.\

● יכולות: The ability to work with various materials and designs is crucial for flexibility in production.

● שֵׁירוּת לָקוֹחוֹת: Clear communication and fast response times can make a significant difference in the quality of service.

Ready for the good part? By selecting a CNC provider with the right experience and capabilities, you can ensure that your small batch production runs smoothly and efficiently.

12. How Can Customization Be Achieved in Small Batch CNC Machining?

Customization is one of the key advantages of small batch CNC machining. But how does it work in practice? The beauty of CNC machining lies in its flexibility—manufacturers can easily make changes to the design or specifications, producing parts that are tailored to specific needs.

Customization can range from simple design tweaks to producing completely unique parts based on client specifications. The ability to prototype quickly and refine designs ensures that customers get exactly what they need without committing to a large run of products.

How Customization Works in Small Batch CNC Machining

● Design Flexibility: CNC machines allow for quick adjustments to designs based on customer feedback.

● Prototyping: Small batch CNC machining is perfect for prototyping and refining designs before full-scale production.

● Tailored Production: Customers can specify unique materials, finishes, or dimensions to meet their needs.

What’s the kicker? With small batch CNC machining, customization is as easy as it gets—allowing manufacturers to produce exactly what clients need.

13. How Does Small Batch CNC Machining Compare to Traditional Methods?

Small batch CNC machining stands out when compared to traditional manufacturing methods, especially when it comes to precision and customization. What’s the real story here? Traditional manufacturing often involves large-scale production with a focus on efficiency at the expense of customization. On the other hand, small batch CNC machining offers flexibility and precision that traditional methods can’t match.

The cost-effectiveness of CNC machining also sets it apart. While traditional manufacturing methods often require expensive tools and molds, small batch CNC machining can produce parts without such investments. This makes it an attractive option for businesses that need low-volume runs without the need for heavy upfront costs.

Comparison: Small Batch CNC Machining vs. Traditional Manufacturing

| Aspect | Small Batch CNC Machining | Traditional Manufacturing |

|---|---|---|

| גְמִישׁוּת | גָבוֹהַ | נָמוּך |

| Setup Cost | Low to moderate | גָבוֹהַ |

| Customization | Easy to customize | Difficult to customize |

| Lead Time | Quick turnaround | Slow setup time |

Ready for the good part? Small batch CNC machining offers businesses greater flexibility, faster lead times, and lower setup costs compared to traditional methods.

14. What Are the Environmental Impacts of Small Batch CNC Machining?

In today’s world, sustainability is more important than ever. Small batch CNC machining offers several environmental benefits that make it a greener choice compared to traditional manufacturing methods. But how does it work? Well, the precision of CNC machining reduces material waste by ensuring that only the necessary amount of material is used for each part. This is critical for industries where raw material costs are high.

Additionally, many CNC machining services are adopting energy-efficient practices and sustainable materials to reduce their environmental impact. The ability to produce parts on demand also eliminates overproduction and excess inventory, which helps to minimize waste and reduce the carbon footprint.

Environmental Benefits of Small Batch CNC Machining

● Reduced Waste: CNC machines minimize material waste by cutting parts to precise measurements.

● יעילות אנרגטית: Many CNC machining services are investing in energy-efficient machines and processes.

● On-Demand Production: Small batch production reduces the risk of overproduction, cutting down on excess inventory and waste.

What’s the kicker here? Small batch CNC machining is an environmentally friendly solution that not only helps reduce waste but also minimizes energy consumption, making it a sustainable choice for businesses.

15. How Will Small Batch CNC Machining Evolve in the Future?

The future of small batch CNC machining looks bright. As technology advances, CNC machines are becoming faster, more precise, and more energy-efficient. What’s the real story? Automation and artificial intelligence are poised to play a major role in the evolution of small batch CNC machining. Machines will become more capable of adapting to complex designs and adjusting processes in real time, further improving efficiency.

Additionally, advancements in materials science will allow CNC machines to work with a wider variety of materials, opening up new possibilities for industries that require specialized parts.

Future Trends in Small Batch CNC Machining

● אוטומציה: Increased automation will streamline production processes and reduce lead times.\

● AI Integration: Artificial intelligence will help optimize designs and improve machine efficiency.\

● חומרים מתקדמים: New materials will become available, offering more choices for manufacturers.

Ready for the good part? The future of small batch CNC machining promises even more customization, faster lead times, and lower costs, ensuring that this manufacturing method remains a valuable solution for industries worldwide.

מדור שאלות נפוצות

שאלה 1: What is small batch CNC machining?

Small batch CNC machining refers to the production of small quantities of custom parts using CNC machines, offering high precision and flexibility at a lower cost than mass production.

שאלה 2: How does small batch CNC machining work?

Small batch CNC machining involves designing a part with CAD software, programming the CNC machine, and using it to cut, shape, and finish the material to create the desired part.

שאלה 3: What are the key benefits of small batch CNC machining?

Small batch CNC machining provides customization, precision, reduced waste, and quicker turnaround times, making it a cost-effective option for businesses needing low-volume, high-quality parts.

שאלה 4: How does small batch CNC machining compare to mass production?

Small batch CNC machining allows for more flexibility, lower upfront costs, and precision compared to mass production, which is better suited for producing large quantities of identical parts.

שאלה 5: Can small batch CNC machining be used for prototyping?

Yes, small batch CNC machining is ideal for prototyping, as it allows businesses to quickly produce small quantities of custom parts for testing before moving to large-scale production.