מָבוֹא

In the world of manufacturing, precision is key. When it comes to CNC machining, the need for accuracy, consistency, and quality is paramount. For companies across a wide range of industries, finding a reliable CNC machining manufacturer is crucial to ensuring the success of their projects. However, with so many options available, how do you choose the right one? In this article, we’ll explore the best CNC machining manufacturers, the key factors you should consider when selecting a partner, and what to look for to ensure your project meets the highest standards. Whether you’re working in aerospace, medical devices, or automotive, this guide will help you navigate the complex landscape of CNC machining manufacturers.

What is Precision CNC Machining?

Definition and Basics

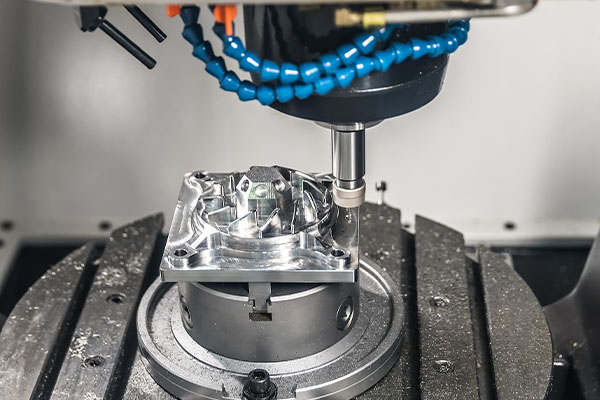

Precision CNC (Computer Numerical Control) machining is a process used to manufacture parts and components with extremely high precision. The process involves the use of computer-controlled machines, such as mills, lathes, and grinders, to create parts from a wide variety of materials, including metals, plastics, and composites. The main advantage of CNC machining is its ability to produce highly accurate, repeatable parts with tight tolerances that are often required in industries like aerospace, automotive, and medical devices.

Technologies Used in CNC Machining

There are various types of CNC machines available, each designed for specific applications. Some of the most common types include CNC milling machines, CNC lathes, and CNC grinders. These machines operate using pre-programmed software that controls their movement, ensuring that the parts are created with the desired dimensions and finishes. Multi-axis machines, which can move along multiple directions simultaneously, are often used for complex parts requiring intricate details and high precision.

יישומים

CNC machining is widely used in several industries where precision is essential. In aerospace, for example, components like turbine blades and fuselage parts are produced using CNC machines. In the automotive industry, CNC machining is used to create engine components, chassis parts, and even prototypes. Medical device manufacturers also rely on CNC machining to produce devices like surgical instruments and implants, where the smallest error can be critical. Essentially, CNC machining is the backbone of many advanced manufacturing processes.

Why Choosing the Right CNC Machining Manufacturer Matters

Importance of Precision

When it comes to CNC machining, precision is paramount. Parts that are even slightly off-spec can lead to catastrophic failures, particularly in industries like aerospace and medical devices. Choosing the right manufacturer ensures that your parts are produced with the accuracy required to meet industry standards and ensure safety and performance. A reliable CNC machining manufacturer will have a proven track record of producing high-quality, precise parts that meet your specific needs.

Risk of Poor Quality

Poor-quality machining can lead to several issues, including defective parts, increased waste, and delays in production. For example, if a manufacturer doesn’t adhere to the required tolerances or uses inferior materials, the parts may not fit correctly, function as expected, or may even fail entirely. This can result in costly repairs, production stoppages, and even recalls. That’s why selecting the right CNC machining manufacturer is so crucial to the success of your project.

Cost Considerations

While cost is always a consideration when choosing a manufacturer, it’s important not to prioritize price over quality. Opting for a cheaper manufacturer might save you money upfront, but it could lead to more costly problems down the line, such as delays, rework, or even scrapped parts. A manufacturer that offers a balance of quality and cost-effectiveness is often the best choice.

Factors to Consider When Choosing a CNC Machining Manufacturer

Experience and Reputation

One of the most important factors to consider when selecting a CNC machining manufacturer is their experience and reputation. Manufacturers with years of experience in the industry are more likely to have the knowledge and skills needed to produce high-quality parts. In addition, a strong reputation in the industry often indicates that the manufacturer is reliable, trustworthy, and capable of meeting customer expectations.

Certifications and Standards

Certifications like ISO 9001 and AS9100 are important indicators of a manufacturer’s commitment to quality and compliance with industry standards. ISO 9001 certification ensures that a company adheres to internationally recognized quality management practices, while AS9100 certification is specific to the aerospace industry and demonstrates a manufacturer’s ability to meet the rigorous demands of aerospace applications. When choosing a manufacturer, it’s essential to verify that they have the appropriate certifications for your specific industry.

Technology and Equipment

The technology and equipment used by a CNC machining manufacturer are also critical factors to consider. The type of CNC machines they use, as well as their ability to work with advanced technologies like multi-axis machining, automation, and additive manufacturing, can significantly affect the quality and precision of the final product. Additionally, some manufacturers may specialize in certain materials or industries, which could influence their ability to meet your needs.

Top Precision CNC Machining Manufacturers to Know

Global Leaders in CNC Machining

When it comes to top CNC machining manufacturers, several companies stand out as leaders in the field. These manufacturers are known for their high-quality standards, advanced technology, and ability to handle complex machining projects. Some of the global leaders include companies like Haas Automation, DMG Mori, and Mazak. These companies offer a wide range of CNC machining services and have a reputation for producing precise, high-quality parts for industries like aerospace, automotive, and medical devices.

Notable Regional Manufacturers

While global leaders dominate the CNC machining industry, many regional manufacturers also offer high-quality services. Companies like Protolabs, Xometry, and Fictiv are known for their specialized services and rapid prototyping capabilities. These manufacturers can be an excellent choice for small to medium-sized businesses looking for customized solutions and fast turnaround times. They often provide a more personal touch and are capable of offering tailored solutions for specific industries or applications.

Understanding CNC Machining Services

Custom vs. Standard Machining Services

CNC machining manufacturers typically offer both custom and standard machining services. Custom services are tailored to meet specific customer requirements, such as complex geometries, specific materials, or tight tolerances. Standard machining services, on the other hand, involve mass-producing parts using predefined designs and specifications. Understanding the differences between these two services can help you determine which is best for your project based on the complexity of the parts and your production needs.

Value-Added Services

In addition to basic CNC machining, many manufacturers also offer value-added services, such as assembly, coating, finishing, and packaging. These services can save you time and money by allowing you to source all aspects of the production process from a single manufacturer. For example, a manufacturer that offers coating and finishing services can ensure that your parts meet both functional and aesthetic requirements, reducing the need for additional suppliers.

Lead Time and Turnaround

Lead time and turnaround are critical factors to consider when choosing a CNC machining manufacturer. The lead time refers to the amount of time it takes from the initial order to the delivery of the finished product, while turnaround time refers to how quickly a manufacturer can respond to urgent orders. A reliable manufacturer should be able to provide you with an accurate estimate of lead times based on the complexity of your order and their production capacity.

CNC Machining for Various Industries

תעופה וחלל

In the aerospace industry, precision CNC machining is essential for producing high-quality, lightweight parts that meet strict safety and performance standards. Components like turbine blades, aircraft structural parts, and engine components are commonly machined using CNC technology. Manufacturers in this sector must adhere to rigorous quality control measures and comply with industry standards like AS9100 to ensure the safety and reliability of their products.

רְפוּאִי

CNC machining plays a crucial role in the production of medical devices, implants, and surgical instruments. Parts must be made with extreme precision and meet stringent regulatory requirements, such as those set by the FDA. CNC manufacturers specializing in medical machining often work with materials like titanium, stainless steel, and plastics that are biocompatible and can withstand sterilization processes.

רכב

The automotive industry relies heavily on CNC machining for producing components like engine blocks, brake components, and transmission parts. CNC machining allows manufacturers to create high-performance parts with tight tolerances, ensuring optimal function and durability. The automotive industry is also increasingly relying on CNC machining for prototyping and small-batch production runs of custom parts.

מוצרי צריכה

Consumer electronics manufacturers use CNC machining to produce intricate, high-precision components used in products like smartphones, laptops, and wearables. These parts often require fine details and tight tolerances, which CNC machines are well-equipped to handle. Manufacturers in this sector must stay ahead of rapidly changing technology and consumer demands, making it essential to partner with a CNC machining company that offers flexibility and speed.

Common CNC Machining Materials and Their Benefits

Metal Materials

CNC machining is commonly used to work with a variety of metals, each offering unique properties. Aluminum is one of the most popular materials due to its lightweight, corrosion-resistant properties. Steel, particularly stainless steel, is known for its strength and durability, making it ideal for high-stress applications. Titanium is another common material used in CNC machining, valued for its strength-to-weight ratio and resistance to corrosion, making it essential in aerospace and medical device manufacturing.

פלסטיק

Plastics are also frequently used in CNC machining, especially for applications where lightweight and corrosion resistance are important. Materials like ABS, polycarbonate, and nylon are commonly machined for parts like housings, connectors, and structural components. CNC machining allows for precise cutting and shaping of plastic components, which is especially valuable in the automotive, medical, and consumer electronics industries.

חומרים מרוכבים

Composites, such as carbon fiber and fiberglass, are increasingly being used in CNC machining due to their high strength-to-weight ratio and durability. These materials are often used in industries like aerospace and automotive, where performance and weight are critical. CNC machining is ideal for shaping composite materials, as it allows manufacturers to achieve the necessary precision and finish for these high-performance parts.

How to Evaluate CNC Machining Capabilities

Tolerance and Accuracy

When evaluating a CNC machining manufacturer, one of the first things to consider is their ability to meet tight tolerances. Precision is at the core of CNC machining, and manufacturers should be able to consistently produce parts within specified tolerances. This is especially important for industries like aerospace and medical devices, where even the smallest deviation can have serious consequences.

Machine Capabilities

The capabilities of a manufacturer’s CNC machines will directly impact the quality of your parts. It’s important to understand what types of machines the manufacturer uses and their capabilities. For example, some machines are designed for high-volume production, while others are better suited for complex, low-volume runs. Multi-axis machines are often necessary for machining intricate parts, and it’s essential to verify that the manufacturer can handle the complexity of your project.

בקרת איכות

Quality control is a critical part of CNC machining, and a reliable manufacturer should have robust quality control processes in place. This may include the use of Coordinate Measuring Machines (CMMs), visual inspections, and other advanced testing methods. Manufacturers that prioritize quality control can ensure that each part meets the required specifications and that any issues are detected before parts are shipped.

The Role of Automation and Advanced Technologies in CNC Machining

Robotics in CNC Machining

Automation has become an integral part of CNC machining, with robotics playing a major role in improving efficiency and precision. Robotic arms can be used to load and unload parts, reducing human error and increasing production speed. Additionally, robots can work around the clock, allowing manufacturers to meet tight deadlines and increase output.

Additive Manufacturing and Hybrid Systems

The combination of CNC machining and additive manufacturing, also known as hybrid systems, is gaining popularity in industries that require complex parts with intricate details. Additive manufacturing, or 3D printing, allows manufacturers to create components that would be difficult or impossible to produce with traditional CNC machining alone. This hybrid approach offers greater design flexibility and can reduce production times and costs.

Data-Driven Production

The integration of data analytics and IoT (Internet of Things) technologies in CNC machining has revolutionized the industry. Manufacturers can now collect real-time data from machines, allowing for predictive maintenance, optimized production schedules, and improved quality control. This data-driven approach enhances efficiency and ensures that production runs smoothly, reducing downtime and increasing productivity.

The Importance of Post-Processing in CNC Machining

What is Post-Processing?

Post-processing refers to the steps taken after the CNC machining process to further refine or finish the part. This can include processes like deburring, polishing, coating, and heat treating, which are necessary to achieve the desired finish, appearance, and functionality of the part.

Types of Post-Processing

Different types of post-processing are used depending on the material and application of the part. For example, aluminum parts may need anodizing to improve corrosion resistance, while steel parts might require heat treatment to enhance strength. In some cases, additional machining steps like surface grinding or polishing may be required to achieve the desired surface finish.

Why Post-Processing is Essential

Post-processing is essential to ensure that the final part meets both functional and aesthetic requirements. Without proper post-processing, parts may have sharp edges, poor surface finishes, or insufficient strength. Post-processing also allows manufacturers to add additional features, like coatings or finishes, that improve the part’s performance or appearance.

Cost of CNC Machining: What You Should Know

Factors That Affect Cost

The cost of CNC machining is influenced by several factors, including the complexity of the part, the material used, the size of the batch, and the manufacturing process itself. For example, highly intricate parts with tight tolerances will generally cost more to machine than simple components. Similarly, materials like titanium or exotic alloys may increase the cost of machining due to their difficulty in handling and machining.

Comparing Costs Across Manufacturers

When comparing costs across CNC machining manufacturers, it’s important to ensure that you’re comparing apples to apples. Ensure that quotes include all relevant costs, such as materials, labor, machine time, and any value-added services. Keep in mind that the lowest price is not always the best option—quality and reliability are key to ensuring that your parts meet the required specifications.

Balancing Cost with Quality

While it’s tempting to opt for the cheapest option, it’s crucial to consider the long-term cost of poor quality. Substandard machining can lead to delays, defects, and the need for rework, ultimately driving up the overall cost of the project. Therefore, it’s essential to find a manufacturer that offers a balance of high-quality output at a reasonable price.

Challenges in CNC Machining and How to Overcome Them

Material Defects and Availability

One of the common challenges faced in CNC machining is material defects or issues with material availability. Materials that are in high demand or difficult to source may lead to delays in production, as manufacturers wait for the right materials to arrive. Additionally, some materials may have inherent defects that affect the final quality of the part. To overcome this, it’s important to work with a manufacturer that has reliable sourcing channels and stringent material inspection processes.

Machine Downtime

Machine downtime is another challenge that can impact production timelines. CNC machines are highly complex and require regular maintenance to ensure they operate at peak efficiency. Unexpected breakdowns or scheduled maintenance can delay production, which is why it’s essential to choose a manufacturer with a proactive maintenance schedule and contingency plans in place.

Supply Chain Issues

Global supply chain disruptions, such as those caused by the COVID-19 pandemic, have made it more difficult to source materials and components in a timely manner. CNC machining manufacturers need to be prepared for these challenges and have strategies in place to mitigate the impact of supply chain disruptions. This may involve working with multiple suppliers or increasing inventory levels to reduce the risk of delays.

Working with CNC Machining Manufacturers: What to Expect

תִקשׁוֹרֶת

Clear and effective communication is critical when working with CNC machining manufacturers. Ensure that you provide detailed specifications for your parts and maintain an open line of communication throughout the manufacturing process. You might be wondering how you can ensure smooth communication—frequent updates, clear drawings, and regular check-ins can go a long way toward avoiding misunderstandings and delays.

Project Management

Managing CNC machining projects requires a high level of coordination between the customer and the manufacturer. The manufacturer will need to know your expectations regarding timelines, quality, and any special requirements. הנה העסקה: proper project management involves clear timelines, milestones, and regular progress reports to keep things on track.

Managing Expectations

Setting realistic expectations from the start is crucial to the success of your CNC machining project. You may have questions about how long a project will take or the exact cost. It’s important to communicate these expectations early and be prepared for potential changes or delays. By managing expectations upfront, you can avoid misunderstandings and ensure that the final product meets your needs.

מגמות עתידיות בעיבוד שבבי CNC

The Rise of Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are transforming CNC machining by enabling predictive maintenance, improving machining precision, and optimizing production schedules. AI can analyze vast amounts of data from CNC machines to predict when maintenance is needed, reducing downtime and increasing efficiency. Additionally, ML algorithms can optimize machining parameters to improve precision and reduce material waste.

Sustainability in CNC Machining

As industries increasingly focus on sustainability, CNC machining manufacturers are adopting environmentally friendly practices. אולי אתה תוהה how manufacturers are reducing their environmental impact—some are using eco-friendly materials, while others are adopting energy-efficient machining techniques to minimize waste and energy consumption.

Global Shifts in Manufacturing

The global manufacturing landscape is shifting, with more companies looking to nearshore or reshore their CNC machining operations to reduce lead times and supply chain risks. This trend is particularly evident in industries like aerospace and medical devices, where precise and reliable manufacturing is critical. הנה העסקה: manufacturers who adapt to these trends will be better positioned to meet the evolving needs of their customers.

מַסְקָנָה

In conclusion, CNC machining is a critical process for producing high-quality, precise parts across a variety of industries. When selecting a manufacturer, it’s important to consider factors like experience, technology, certifications, and cost. By working with the right CNC machining partner, you can ensure that your projects meet the highest standards of quality and precision. אולי אתה תוהה what your next steps should be—start by researching top manufacturers, comparing capabilities, and reaching out for quotes to find the best fit for your needs.

מדור שאלות נפוצות

What is CNC machining used for?

CNC machining is used to produce highly accurate and complex parts for a wide variety of industries, including aerospace, automotive, medical, and consumer electronics. It is commonly used to create parts with tight tolerances and intricate geometries that are difficult to achieve with traditional manufacturing methods.

How do I choose the right CNC machining manufacturer?

When choosing a CNC machining manufacturer, consider factors such as their experience, reputation, certifications, technology, and capabilities. Make sure they specialize in the materials and parts you need, and verify that they can meet your production timelines and quality standards.

אילו תעשיות משתמשות בעיבוד CNC?

CNC machining is used in a wide range of industries, including aerospace, automotive, medical devices, electronics, and manufacturing. Its precision and versatility make it ideal for producing parts that require high accuracy and complex designs.

What materials can be machined with CNC technology?

CNC machining can be used with a variety of materials, including metals like aluminum, steel, and titanium, as well as plastics, composites, and other advanced materials. The choice of material depends on the requirements of the part, such as strength, weight, and durability.

How much does CNC machining cost?

The cost of CNC machining depends on several factors, including the complexity of the part, the material used, the size of the order, and the manufacturing processes involved. Custom machining services typically cost more than standard production runs, and materials like titanium may increase the cost.

How accurate is CNC machining?

CNC machining is known for its high level of accuracy, with tolerances typically ranging from ±0.001″ to ±0.0001″, depending on the machine and the complexity of the part. It’s ideal for producing parts that require tight tolerances and intricate details.

Can CNC machining be used for both prototypes and production?

Yes, CNC machining can be used for both prototype development and full-scale production. It is commonly used for rapid prototyping, allowing companies to create and test prototypes quickly, while also being suitable for high-volume production runs once the design is finalized.

What is the lead time for CNC machining projects?

Lead times for CNC machining vary depending on the complexity of the project, the materials used, and the manufacturer’s capacity. Simple projects may take only a few days, while more complex parts may require several weeks. It’s important to discuss lead times with the manufacturer before starting the project.

Are there any environmental concerns with CNC machining?

CNC machining can generate waste materials, such as metal shavings and cutting fluids, which need to be properly managed and disposed of. Many manufacturers are adopting more sustainable practices, such as using eco-friendly materials and reducing energy consumption during the machining process.