מָבוֹא

When it comes to the aerospace industry, precision and reliability are non-negotiable. Aerospace components, such as turbine blades and structural parts, must meet the highest standards of quality, as any defect could lead to catastrophic consequences. For this reason, finding trusted manufacturers for CNC (Computer Numerical Control) aerospace parts is crucial. This article will explore everything you need to know about selecting reliable CNC aerospace manufacturers, from understanding the technology involved to the certifications that ensure a manufacturer’s trustworthiness. Whether you are looking to source parts for commercial aircraft or military projects, this guide is here to help you make informed decisions.

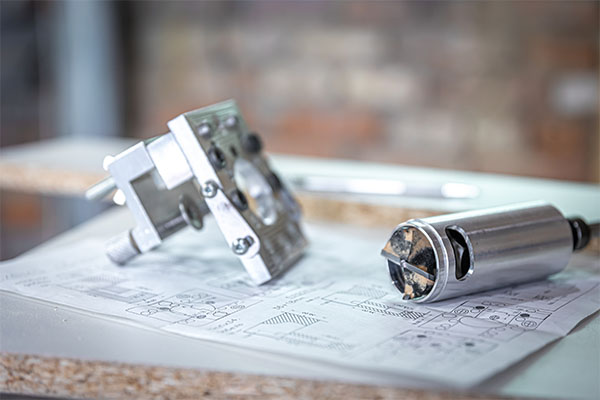

What Are Aerospace CNC Parts?

Aerospace CNC parts are precision-engineered components used in various aerospace applications, including commercial and military aircraft, spacecraft, and other aviation technologies. CNC machining refers to the process of using computer-controlled machines to produce highly accurate parts. In aerospace, these parts often include structural elements, airframe components, turbine blades, and engine parts. What sets CNC machining apart from traditional manufacturing methods is its ability to create highly complex designs with tight tolerances, which are essential in the aerospace industry.

Aerospace CNC parts must withstand extreme conditions, including high speeds, intense pressure, and fluctuating temperatures. Therefore, the materials used, such as titanium, aluminum, and high-performance composites, need to be selected carefully to ensure strength, durability, and lightweight properties. הנה העסקה: the process ensures that each part is manufactured with unparalleled precision, reducing the risk of failure and improving overall aircraft performance. אולי אתה תוהה, what makes CNC machining the best choice for these critical parts? It’s all about the level of control it provides over every aspect of the part’s design and production. With this technology, manufacturers can achieve tighter tolerances and complex geometries, which are essential for high-performance aerospace applications.

The Importance of Trust in Aerospace CNC Manufacturing

In the world of aerospace manufacturing, trust is everything. Aircraft manufacturers and operators rely on suppliers to deliver parts that are not only accurate but also durable and safe. Precision in aerospace components directly impacts the safety, efficiency, and performance of an aircraft. You see, any inconsistency in manufacturing could result in catastrophic failure, whether it’s a malfunctioning engine component or a structural part that can’t withstand the stresses of flight. This is why establishing a relationship with trusted CNC parts manufacturers is essential.

Building trust begins with a manufacturer’s reputation and the certifications they hold. The aerospace industry is highly regulated, with manufacturers needing to adhere to strict guidelines such as AS9100, which ensures a quality management system specific to aerospace. Here’s the catch: without these certifications, the reliability of a manufacturer becomes questionable, and the risks associated with poor-quality parts grow exponentially. Manufacturers who can demonstrate their expertise and commitment to quality assurance through certifications and experience are the ones to trust. Don’t be fooled: cutting corners or opting for cheaper options might save money upfront, but it can lead to much larger costs down the road.

Key Factors to Look for in a Trusted Aerospace CNC Parts Manufacturer

Choosing the right aerospace CNC manufacturer requires careful consideration of several factors. The first and most important is certifications and industry compliance. Aerospace manufacturers must comply with strict standards, and certifications such as AS9100 and ISO 9001 demonstrate that a company has implemented the necessary quality management systems to meet these high standards. These certifications are not just paper credentials—they are a reflection of the manufacturer’s commitment to quality, process control, and continuous improvement.

Experience and expertise in aerospace manufacturing are also vital. אולי אתה תוהה, why does experience matter? The aerospace industry requires highly specialized knowledge, and the ability to manufacture complex parts often depends on understanding the specific demands of aerospace design and performance. An experienced manufacturer will also have a proven track record of delivering high-quality parts and will be able to handle the complexities of aerospace machining. הנה העסקה: you want a manufacturer that understands the unique requirements of aerospace components and has a portfolio to prove it.

Another important consideration is reputation and reviews. Researching customer reviews and talking to other aerospace companies who have worked with a potential manufacturer can give you valuable insight into their reliability and quality. If a manufacturer has consistently delivered high-quality parts and demonstrated excellent customer service, they are likely a good choice. You wouldn’t want to settle for anything less when the safety and performance of your product are at stake.

CNC Machining Capabilities for Aerospace Parts

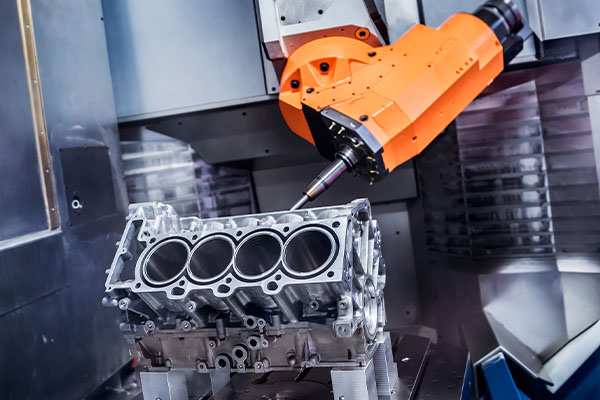

When selecting a CNC manufacturer for aerospace parts, understanding their machining capabilities is crucial. Aerospace parts require high precision, often with tolerances of just a few microns, and CNC machining is one of the best ways to achieve this level of accuracy. הנה העסקה: CNC machining can handle intricate and complex designs that would be impossible to create using traditional methods.

Multi-axis CNC machines are commonly used in aerospace machining. These machines can move in multiple directions simultaneously, allowing manufacturers to create parts with highly complex geometries. This is particularly important for parts like turbine blades and airframe components, which often feature curved or irregular surfaces. אולי אתה תוהה, how do manufacturers ensure the precision of each part? The answer lies in the use of advanced software, high-end CNC machines, and tightly controlled manufacturing processes that prevent errors. These machines can also automate repetitive tasks, which improves consistency and reduces human error, ensuring the parts produced meet exact specifications.

Advanced Technologies play a big role in improving the machining process. For instance, the use of 3D printing and additive manufacturing is becoming increasingly popular in aerospace. These technologies allow manufacturers to create lightweight components with complex internal geometries, offering improvements in both performance and weight reduction. As aerospace designs become more innovative, manufacturers who stay on top of these technologies will be better equipped to meet new demands.

Material Selection for Aerospace CNC Parts

The materials used in aerospace CNC parts are a crucial aspect of their design and functionality. You see, the materials must be lightweight yet incredibly strong to withstand the extreme conditions of air and space travel. Common materials used include aluminum, titanium, and high-performance composites, each chosen for its unique properties.

Aluminum is a popular choice because it is lightweight, strong, and relatively easy to machine. It is often used for airframe components and structural parts. Titanium, while more expensive, is stronger and more resistant to corrosion, making it ideal for parts that will be exposed to high stress or extreme environments, such as turbine blades and engine components. Here’s the catch: the choice of material must balance strength, weight, and machinability. For instance, while titanium offers exceptional strength, it is more challenging and costly to machine, so it’s typically used for critical components. אולי אתה תוהה, why use composites? Composites are increasingly being used because they offer a combination of light weight and high strength, and they are often used in newer aircraft designs to improve fuel efficiency.

Material selection directly affects the performance and longevity of aerospace components. Therefore, manufacturers must carefully choose the right material based on the part’s intended application and the conditions it will face.

Manufacturing Processes Used in Aerospace CNC Parts Production

CNC machining offers several manufacturing processes that are widely used in aerospace parts production. These include turning, milling, and grinding, each of which serves a specific purpose depending on the design of the part. Turning involves rotating the part while a cutting tool is used to shape it, and is commonly used for cylindrical components like shafts and bolts. Milling, on the other hand, involves moving the part across a rotating tool to remove material, and is ideal for creating more complex shapes, such as airframe components or engine housings.

אולי אתה תוהה, what makes grinding important? Grinding is used to achieve a smooth finish on parts, and it is particularly useful for parts that require a high level of surface finish, such as turbine blades. These processes are not only essential for ensuring the dimensions and shape of the part are precise but also for meeting the required surface quality, which is critical for the performance and safety of the part.

The complexity of aerospace components means that manufacturers must be capable of combining multiple machining processes within a single part. You wouldn’t want to settle for a manufacturer that specializes in only one process. A skilled manufacturer can use a combination of turning, milling, and grinding to create complex parts with intricate features, ensuring both functionality and quality.

The Role of Quality Control in Aerospace CNC Manufacturing

In aerospace manufacturing, quality control is critical. A small defect in any part can compromise the integrity of the entire system, making it essential that each part meets exact specifications. הנה העסקה: strict quality control processes help ensure that aerospace CNC parts are manufactured to the highest standards, with no room for error.

Inspection and testing are integral components of the quality control process. Aerospace manufacturers use various techniques such as dimensional verification, X-ray inspection, and ultrasonic testing to ensure parts meet the required specifications. Dimensional verification involves checking that the part’s physical dimensions align with the design, while X-ray and ultrasonic testing help detect any internal defects that may not be visible to the naked eye.

אולי אתה תוהה, how do manufacturers maintain consistency? Manufacturers achieve consistency by using advanced software systems, automated machines, and real-time monitoring of the production process. These technologies allow for the continuous monitoring of each part during manufacturing, ensuring that no defects slip through.

How OEMs Choose CNC Parts Suppliers

Original Equipment Manufacturers (OEMs) are the companies responsible for designing and producing end products, such as aircraft and spacecraft. When selecting a CNC parts supplier, OEMs typically evaluate a range of factors, starting with quality and precision. After all, the parts will directly impact the overall performance of the final product. OEMs also consider a supplier’s ability to meet delivery deadlines, as timely deliveries are crucial to keeping production schedules on track.

OEMs may also assess a manufacturer’s production capacity and their ability to handle large production runs or meet complex design requirements. אולי אתה תוהה, what else do OEMs care about? OEMs look for long-term partnerships with manufacturers who can reliably meet their needs for quality, consistency, and cost efficiency.

Long-Term Relationships with Suppliers are highly valued, as maintaining a consistent supply of high-quality parts is vital to the success of aerospace projects. הנה העסקה: when you build a relationship with a trusted supplier, it can lead to more streamlined processes and reduced risks of production delays.

Cost Factors in Aerospace CNC Manufacturing

Cost is always a consideration when selecting a CNC parts manufacturer, but in the aerospace industry, it’s essential to weigh price against quality. הנה העסקה: low-cost manufacturers may offer cheaper parts, but their lack of quality control could lead to issues down the line, such as defective components or delays in production.

OEMs must also consider hidden costs, such as shipping fees, expedited delivery costs, and the potential for additional testing and rework if the parts do not meet specifications. אולי אתה תוהה, are cheaper options ever worth considering? In some cases, low-cost parts may be acceptable for less critical components, but when it comes to mission-critical aerospace parts, quality should always take precedence.

How to Identify Red Flags in CNC Aerospace Manufacturers

בחירה נכונה CNC aerospace parts manufacturer is not always straightforward, especially when you’re faced with many potential suppliers. Here’s the catch: there are red flags you should look out for when evaluating manufacturers. A lack of certifications or compliance with industry standards is one of the most glaring warning signs. If a manufacturer does not hold key certifications like AS9100, it’s a sign they may not be adhering to the strict quality control standards required for aerospace parts.

Other warning signs include poor communication, inconsistent lead times, and an inability to provide clear answers about their manufacturing processes. You see, if a manufacturer is vague about their capabilities or unwilling to provide documentation about their processes, it’s a major red flag.

What to Avoid: Avoid manufacturers who do not have a proven track record in aerospace manufacturing. You do not want to risk the safety and performance of your aircraft components on an untested supplier.

Case Studies of Trusted Aerospace CNC Parts Manufacturers

Many trusted CNC aerospace parts manufacturers have earned their reputation by consistently delivering high-quality parts and building strong relationships with their clients. For instance, companies like Pratt & Whitney ו General Electric are renowned for their precision-engineered aerospace components. Their commitment to excellence is backed by decades of experience and a rigorous quality control process.

Lessons Learned: These manufacturers have shown that success in aerospace CNC machining comes down to understanding the unique needs of the industry, investing in state-of-the-art technologies, and building strong, transparent relationships with clients. You wouldn’t want to settle for anything less when selecting a manufacturer for critical aerospace components.

Trends in Aerospace CNC Machining

As the aerospace industry continues to evolve, so do the technologies used in CNC machining. Emerging technologies, such as additive manufacturing (3D printing), are having a major impact. These technologies allow for the creation of highly complex parts that would be difficult or impossible to make with traditional methods. אולי אתה תוהה, how does this affect the aerospace industry? Additive manufacturing opens up new possibilities for lightweight, high-performance parts that could improve fuel efficiency and reduce manufacturing costs.

Sustainability and green manufacturing are also becoming more important in aerospace CNC machining. Manufacturers are adopting more environmentally friendly practices, from reducing waste to using more sustainable materials. Here’s the catch: these practices help manufacturers stay ahead of the competition while meeting growing demands for eco-friendly solutions in aerospace.

Working with an Aerospace CNC Manufacturer: What to Expect

When working with a CNC manufacturer, the process typically begins with providing design specifications for the parts you need. הנה העסקה: the manufacturer will review your designs, offer feedback, and work with you to make any necessary adjustments before proceeding to production. Once everything is finalized, the manufacturer will begin the machining process, which involves setting up the machines, sourcing materials, and starting production.

Throughout the process, you might be wondering, what about communication? Clear, regular communication with your manufacturer is key to ensuring the project stays on track. Here’s the catch: by maintaining a collaborative relationship, you can address issues early and ensure the final parts meet your expectations.

Conclusion: Choosing the Right Aerospace CNC Manufacturer for Your Needs

In conclusion, selecting a trusted aerospace CNC parts manufacturer is essential to ensuring the safety, reliability, and performance of your components. You see, by carefully considering factors such as certifications, experience, reputation, and machining capabilities, you can make an informed decision that benefits your business in the long run. Don’t settle for less when it comes to aerospace manufacturing. הנה העסקה: choose a manufacturer who meets the highest standards and has the expertise to handle the complexities of aerospace CNC machining.

Call to action: Start your search for a trusted aerospace CNC parts manufacturer today. Don’t compromise on quality and safety.

מדור שאלות נפוצות

- What are the most important certifications for aerospace CNC parts manufacturers?

Certifications like AS9100, ISO 9001, and NADCAP are essential for aerospace CNC parts manufacturers. AS9100 is a widely recognized standard for quality management systems in aerospace, ensuring that manufacturers adhere to rigorous quality and safety standards. ISO 9001 is a more general certification but is also crucial for ensuring consistent quality across industries. NADCAP focuses on special processes like heat treatment and coating, making it relevant for aerospace manufacturers that deal with specialized materials and processes. - How do I ensure the CNC manufacturer I choose has experience in aerospace machining?

Look for manufacturers that have a proven track record in the aerospace industry. This could include past projects, customer testimonials, or certifications that specifically relate to aerospace machining. אולי אתה תוהה, how do I verify this? One of the best ways is to ask for case studies or examples of previous aerospace projects they’ve completed. הנה העסקה: manufacturers with extensive aerospace experience will better understand the complexities involved and can offer advice on materials, processes, and design considerations. - What materials are typically used in CNC aerospace parts?

Materials like aluminum, titanium, and high-performance composites are commonly used in CNC aerospace parts. Aluminum is lightweight and strong, making it ideal for airframe components. Titanium offers superior strength and resistance to corrosion, which is essential for parts exposed to high stress, such as turbine blades. Composites, on the other hand, are increasingly used in modern aerospace designs due to their lightweight nature and ability to withstand high temperatures. - How do manufacturers maintain the precision and accuracy of CNC parts?

Manufacturers ensure precision by using state-of-the-art CNC machines with multi-axis capabilities, advanced software, and high-quality materials. They often conduct extensive testing and inspection throughout the production process, including dimensional verification, X-ray inspection, and ultrasonic testing. You see, CNC machines offer unparalleled accuracy and repeatability, but it’s the combination of technology and expertise that ensures the final product meets exact specifications. - What are the risks of choosing a low-cost CNC manufacturer for aerospace parts?

While low-cost CNC manufacturers may seem appealing, they often come with significant risks, especially in the aerospace industry. אולי אתה תוהה, why pay more? Cheaper manufacturers may cut corners in terms of quality control, leading to potential defects, delayed deliveries, or non-compliance with industry standards. הנה העסקה: aerospace parts need to meet extremely tight tolerances and perform under high stress, and low-cost suppliers may not have the capability to produce parts that meet these stringent requirements. - What should I do if the aerospace CNC parts I receive don’t meet specifications?

If the parts you receive don’t meet specifications, you should immediately contact the manufacturer and request a detailed explanation. אולי אתה תוהה, what if it’s a critical part? In such cases, manufacturers should be willing to work with you to rectify the situation, whether through rework or replacement. Here’s the catch: having a manufacturer with a robust quality control system in place means they can address any issues quickly and efficiently, minimizing disruption to your production schedule. - How long does it take to manufacture aerospace CNC parts?

The manufacturing time for aerospace CNC parts can vary depending on the complexity of the design, the material used, and the number of parts being produced. Simple components might be produced in a few days, while more complex parts can take several weeks. הנה העסקה: be sure to discuss lead times upfront with your manufacturer to ensure they can meet your production schedule. Delays in the manufacturing process can lead to costly setbacks, so it’s important to work with a manufacturer who can deliver on time. - Can CNC machining handle both small and large production runs for aerospace parts?

Yes, CNC machining is highly flexible and can handle both small and large production runs. You see, CNC machines are automated, so they can easily switch between different jobs and produce parts in varying quantities. However, it’s important to consider the volume of parts needed when choosing a manufacturer. Here’s the catch: while small production runs can be more time-consuming and costly per unit, larger runs typically benefit from economies of scale, resulting in lower costs per part.

מַסְקָנָה

In conclusion, selecting the right aerospace CNC parts manufacturer is crucial for ensuring the safety, reliability, and performance of your components. הנה העסקה: by carefully considering factors such as certifications, experience, reputation, and machining capabilities, you can make an informed decision that benefits your business in the long run. You see, choosing a trusted manufacturer not only ensures that your parts meet the highest quality standards but also establishes a partnership that can help your business succeed in the competitive aerospace industry. Don’t be fooled by low-cost options or manufacturers with limited experience—opt for those who offer the precision, expertise, and reliability that aerospace components demand.