परिचय

CNC machining has become an essential part of modern manufacturing processes. Whether you’re working in automotive, aerospace, or medical device manufacturing, having a reliable CNC machining supplier is key to your business’s success. CNC machining is not just about precision; it’s about speed, cost efficiency, and the ability to deliver complex parts on time. The challenge many businesses face, however, is selecting the right CNC machining supplier that can meet their specific needs. This article will guide you through the process of choosing the best CNC machining suppliers, explore the benefits of outsourcing machining work, and provide insights into finding a supplier that aligns with your goals and requirements.

What to Look for in a CNC Machining Supplier

Key Criteria for Choosing the Right Supplier

When it comes to choosing the best CNC machining supplier, there are several key factors to consider. First and foremost, quality assurance is vital. CNC machining is all about precision, and your supplier must be able to consistently deliver high-quality parts that meet your specifications. You’ll also need to evaluate the reliability of their delivery schedules. Late deliveries can disrupt your entire supply chain and cost your business significantly.

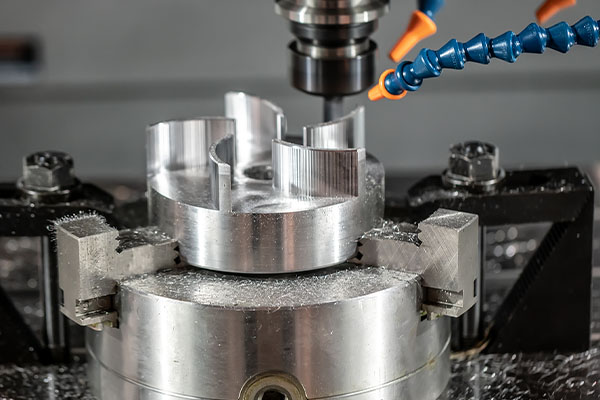

Another important factor is the supplier’s technological capabilities. CNC machining is an advanced process, and suppliers who utilize cutting-edge technology will provide better results. Suppliers that offer a range of services, such as multi-axis machining, 3D printing capabilities, or custom CNC designs, will be able to handle more complex projects.

Additionally, it’s essential to choose a supplier that can adapt to your needs. Whether you’re looking for a small batch of parts or large-scale production, your supplier must be flexible in adjusting production to meet demand.

Why Reliability and Quality Matter

The success of your manufacturing processes largely depends on the reliability and quality of your CNC machining supplier. If your supplier doesn’t consistently meet deadlines or fails to deliver parts to your exact specifications, it can create a ripple effect that negatively impacts your operations. You may find yourself scrambling for replacements or facing costly delays. Consistency is key when working with CNC suppliers, and only those who prioritize both quality and reliability should be considered.

Choosing a supplier that has the capacity to meet both your short-term and long-term needs will significantly reduce risk in your business. This will also help you build a solid, sustainable relationship that will carry your business through fluctuating demands.

Top CNC Machining Suppliers in the Market

A Look at Leading CNC Suppliers Worldwide

Finding the right CNC machining supplier starts with knowing the top players in the market. Some of the world’s most prominent CNC machining suppliers include companies like Makino, Haas Automation, और DMG Mori. These industry leaders have earned their reputation by consistently delivering high-quality products and investing in cutting-edge technology.

Makino, for example, is renowned for its high-performance CNC machining centers, making them a popular choice in sectors like automotive and aerospace. Similarly, Haas Automation has a global presence and offers CNC solutions that cater to industries ranging from metalworking to manufacturing intricate components for defense and medical industries.

Factors That Make These Companies Stand Out

What sets these suppliers apart is their ability to handle a wide range of industries with diverse needs. तकनीकी, expertise, और customer support are central to their success. These suppliers offer a mix of both standard CNC machining और customized solutions, allowing them to serve both large manufacturers and smaller businesses with specific needs. Their ability to adapt to unique business requirements and deliver exceptional products on time makes them standout players in the field.

Domestic vs. Overseas CNC Machining Suppliers

Is It Better to Source Locally or from Overseas?

Choosing between a domestic or overseas CNC machining supplier depends on a variety of factors. The primary considerations are cost, lead time, और communication. While overseas suppliers often offer more competitive prices, especially from countries with lower labor costs, they may come with challenges like longer lead times and potential communication barriers. On the other hand, domestic suppliers provide quicker turnaround times and easier communication, but their rates may be higher due to the cost of living and labor in developed countries.

How to Choose Between Domestic and Overseas Suppliers

When deciding between local and overseas CNC suppliers, consider the nature of your project. If you need quick prototypes or have tight production deadlines, a domestic supplier may be your best bet. However, if you’re looking for cost savings on larger orders and can afford a longer wait time, overseas suppliers may be more appropriate. Whichever you choose, ensure that you clearly understand the terms of the contract, including production timelines, shipping costs, and quality assurances.

Benefits of Working with Established CNC Machining Suppliers

Why Experience Matters in CNC Machining

Experience is a crucial factor when selecting a CNC machining supplier. Suppliers with years of experience have honed their processes and understand the intricacies of different machining techniques. This means they can troubleshoot issues more efficiently and offer customized solutions based on your needs. Experienced suppliers are also more likely to offer competitive prices without compromising on quality.

Additionally, well-established CNC machining suppliers typically have strong quality control processes in place. With years of experience comes the ability to deliver consistent, high-quality results over time, which is essential for maintaining product integrity in industries that require precise specifications.

The Role of Certifications in Ensuring Quality

Certifications such as ISO 9001 or ISO 13485 can give you confidence that a CNC machining supplier adheres to strict quality standards. ISO-certified suppliers follow internationally recognized guidelines, ensuring that the parts produced meet the required specifications and quality benchmarks. This is especially important if your business operates in highly regulated industries like aerospace or medical device manufacturing, where compliance with stringent quality standards is non-negotiable.

How CNC Machining Can Boost Your Business’s Production Efficiency

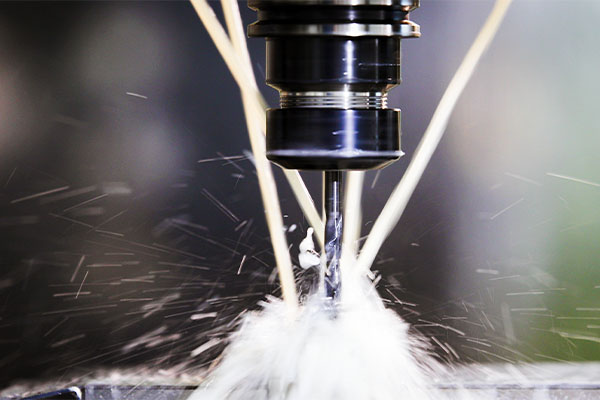

Increased Production Speed

CNC machining can significantly improve your business’s production speed. Traditional methods of machining often involve a lot of manual labor, which can slow down production times. With CNC technology, machines are programmed to perform tasks with greater accuracy and in less time. This allows you to scale production without sacrificing quality. CNC machines are designed for high-volume production, which means you can manufacture large batches of parts quickly and efficiently, helping you meet customer demands faster.

Cost Savings

Although CNC machining can be expensive upfront due to the cost of the machinery and software, the long-term savings are substantial. CNC machines reduce material waste and human error, ensuring that the parts you produce are accurate, which means fewer defective products and a reduction in rework costs. Additionally, CNC machining often reduces the need for manual labor, which lowers overhead costs and improves overall profitability.

Technological Advancements in CNC Machining

The Latest Technologies Shaping the CNC Industry

The CNC machining industry is evolving rapidly with the adoption of new technologies. Advances in 5-axis machining, additive manufacturing, और hybrid machining are revolutionizing the way manufacturers create complex parts. 5-अक्ष सीएनसी मशीनें can handle more intricate designs, allowing for greater precision and versatility. एडिटिव मैन्यूफैक्चरिंग, which combines 3D printing with CNC machining, is also gaining ground as it allows for the creation of more intricate designs with less material waste.

How Technological Advancements Can Benefit Your Business

Embracing these new technologies can give your business a competitive edge. For instance, 5-axis machining can allow you to produce parts that would otherwise require multiple machines or setups. This reduces production time and improves accuracy. Additionally, hybrid machining offers the flexibility to use both additive and subtractive processes, making it possible to create complex parts that meet your exact specifications.

Custom CNC Machining: Tailoring Solutions for Your Needs

Understanding Custom CNC Machining

Custom CNC machining is essential when you need specific parts that can’t be made using standard machining processes. With custom CNC machining, a supplier can design and produce parts tailored to your exact requirements. Whether it’s a unique material, a specific shape, or a part that needs to meet particular industry standards, custom CNC machining ensures that the finished product aligns perfectly with your needs.

Why Custom CNC Parts Are Vital for Some Businesses

In industries like medical device manufacturing, automotive engineering, and aerospace, custom parts are often necessary to ensure functionality and safety. Standard parts may not fit or function correctly in highly specialized machinery or equipment, and custom CNC parts help fill this gap. By partnering with a supplier that specializes in custom CNC machining, your business can ensure that you receive high-quality, precisely engineered parts that meet all of your specifications.

How to Evaluate CNC Machining Suppliers

Questions to Ask Your Potential Supplier

When choosing a CNC machining supplier, it’s crucial to ask the right questions to ensure they’re a good fit for your needs. Key questions include:

- What is your production capacity?

- Can you provide samples or prototypes before full-scale production?

- What industries have you worked with in the past?

- How do you handle quality control?

Red Flags to Look for When Choosing a Supplier

If a supplier seems unresponsive or unwilling to provide clear answers to your questions, this can be a red flag. Also, avoid suppliers that cannot show evidence of certifications or do not provide clear quality control processes. A lack of transparency is often indicative of problems in the supplier’s operations, which could impact your business in the long run.

Understanding the Costs of CNC Machining Services

Breaking Down the Costs of CNC Machining

The cost of CNC machining is determined by several factors, including the material used, the complexity of the design, and the quantity of parts being produced. Generally, more complex designs or high-quality materials will incur higher costs, but the precision and speed of CNC machining often offset these costs by reducing waste and improving efficiency.

How to Negotiate with CNC Machining Suppliers for Better Prices

To negotiate a better price with your supplier, consider discussing the order volume और long-term partnerships. Suppliers are often willing to offer discounts on larger orders or provide more favorable terms to businesses looking to establish a long-term relationship.

How CNC Machining Suppliers Ensure Consistency and Quality Control

The Role of Quality Control in CNC Machining

CNC machining suppliers implement strict quality control measures to ensure that each part meets the required specifications. From initial design को final inspection, multiple checks are carried out throughout the production process to catch any potential issues before the parts are shipped out. This includes measuring the tolerance levels of parts and conducting final inspections to verify that each part meets industry standards.

Importance of Consistency in Production

Maintaining consistent quality is crucial for ensuring that all parts fit seamlessly into the larger product. Inconsistent parts can cause major problems in assembly or functionality, leading to increased production costs or faulty end products. Working with a supplier that guarantees consistent quality control helps ensure the success of your manufacturing process.

The Best CNC Machining Suppliers for Different Industries

एयरोस्पेस

In the aerospace industry, precision and reliability are of the utmost importance. Top CNC machining suppliers for the aerospace sector specialize in creating highly accurate, high-performance parts for aircraft engines, landing gear, and structural components. These parts must adhere to strict aerospace standards, and suppliers must demonstrate extensive experience in working with this industry.

ऑटोमोटिव

The automotive sector requires CNC machining suppliers that can produce high-quality, durable parts quickly and efficiently. CNC machining for automotive parts includes everything from engine components को braking systems. Automotive suppliers must also be able to produce parts in high volumes, making production scalability a key consideration.

चिकित्सा

In the medical industry, CNC machining suppliers are tasked with producing precise components for medical devices such as surgical tools, implantable devices, और diagnostic equipment. The parts must meet strict regulatory requirements and be made from biocompatible materials to ensure safety and functionality.

CNC Machining for Small Businesses and Startups

Is CNC Machining Affordable for Small Businesses?

CNC machining might seem intimidating for smaller businesses due to its perceived high cost. However, many suppliers offer scalable services that cater to small businesses and startups. Whether you need prototypes or small production runs, you can often find affordable solutions. By outsourcing CNC machining to a supplier that offers flexible pricing, small businesses can save on equipment costs and achieve high-quality production without significant upfront investments.

How Small Companies Can Leverage CNC Technology

Small businesses can leverage CNC machining to produce complex parts with greater precision and at lower costs than traditional machining methods. Whether you’re launching a new product or need one-off parts for your designs, CNC machining gives small companies the ability to quickly create prototypes and bring ideas to market faster.

Trends Shaping the Future of CNC Machining

What’s Next for CNC Machining?

The future of CNC machining looks promising, with new technologies like AI-powered machines, automation, और predictive maintenance on the horizon. These advancements will allow manufacturers to produce higher-quality parts faster and more efficiently, while reducing the risk of human error and improving consistency.

Adapting to Industry Changes and Staying Competitive

To stay competitive, businesses must embrace these technological innovations and continuously adapt their processes. Companies that invest in the latest CNC technologies will not only enhance efficiency but also maintain their competitive edge in the market.

Conclusion: Finding the Right CNC Machining Supplier for Your Business

सही का चयन CNC machining supplier can have a profound impact on your business. By carefully evaluating potential suppliers based on their experience, technological capabilities, और quality control processes, you can ensure that your business gets the best possible service. Consistency, reliability, and precision are the key qualities to look for, and by establishing a solid relationship with the right supplier, you can significantly boost your production capabilities.

Ready to find the best CNC machining supplier for your business? Start by asking the right questions and conducting thorough research to ensure a successful partnership that will help your business thrive.

अक्सर पूछे जाने वाले प्रश्न अनुभाग

- What makes a CNC machining supplier reliable?

A reliable CNC machining supplier is one that consistently delivers high-quality parts on time, communicates effectively, and has proven experience in the industry. Certifications such as ISO 9001 or ISO 13485 are also indicators of reliability. - How do I know if a CNC supplier is a good fit for my business?

Ask about their capabilities, experience in your industry, production capacity, and customer service. Request samples and ensure that they meet your specific requirements. - How do I reduce costs when working with a CNC machining supplier?

You can reduce costs by optimizing your designs, ordering in bulk, and building a long-term relationship with the supplier for better pricing. - Is CNC machining only for large-scale businesses?

No, CNC machining can be a cost-effective solution for small businesses as well, especially for prototypes or small production runs. - What industries use CNC machining?

CNC machining is used in industries like aerospace, automotive, medical device manufacturing, electronics, and many others requiring precise, high-quality parts.