परिचय

In this article, we’ll explore the differences between Nylon vs. Polyamides in manufacturing. These materials play critical roles in various industries, and understanding their unique characteristics can help manufacturers make the best choice for their needs. From production processes to practical applications, we’ll delve into how these materials compare and when to choose one over the other.

1. What are Nylon and Polyamides?

Before diving into their uses, it’s important to understand exactly what these materials are.

Nylon is a synthetic polymer, widely used in both industrial and consumer applications. First synthesized in the 1930s by DuPont, it is known for its strength, flexibility, and resistance to wear. Nylon is a type of polyamide, a class of polymers that include materials derived from both aliphatic and aromatic compounds.

Polyamides, on the other hand, are a broader category of polymers. While Nylon is a type of polyamide, not all polyamides are Nylons. Polyamides are typically defined by their amide groups (-CONH) in their molecular structure, which gives them unique properties like high melting points and strength.

Now, you might be wondering, what’s the real story? Well, the real difference between Nylon and other polyamides lies in their specific chemical structure and properties. While Nylon tends to be made from specific monomers like hexamethylene diamine and adipic acid, other polyamides, such as aramids, are derived from different types of organic compounds, leading to varying physical properties. In other words, while Nylon is a type of polyamide, not all polyamides are Nylon.

Table 1: Comparison of Nylon and Polyamide

| संपत्ति | Nylon | Polyamides |

|---|---|---|

| Definition | A type of polyamide | A broad category of polymers |

| Chemical Structure | Based on specific monomers | Varies with different organic compounds |

| गुण | Strong, flexible, durable | Varies widely depending on specific polyamide |

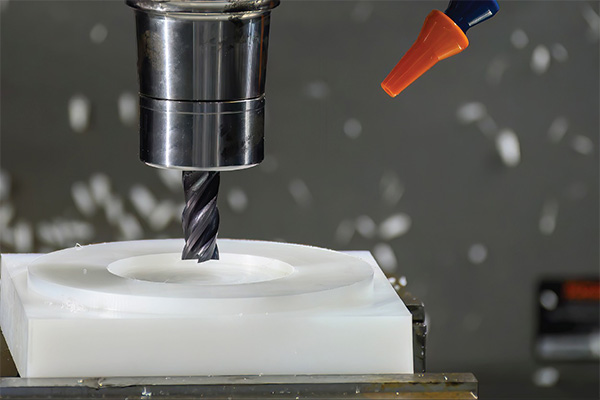

2. How are Nylon and Polyamides Made?

Nylon production involves a process called polymerization, which links the individual monomers (such as hexamethylene diamine and adipic acid) to form long chains. This polymerization process can be done through condensation or addition methods, depending on the specific type of Nylon being produced. In many cases, the process takes place under high temperatures and pressures, allowing the monomers to react and form the polymer chains that give Nylon its strength and durability.

Polyamide production, on the other hand, can involve a wider range of monomers and methods, depending on the type of polyamide being produced. For example, aramid polyamides are made using different chemical reactions, such as the reaction of a diamine with a diacid. This process results in polymers with even higher heat resistance and strength, making them suitable for special applications like aerospace and military products.

So what’s the kicker here? The main difference between Nylon and other polyamides in production lies in the diversity of monomers and processes used. While Nylon has a standard manufacturing process, the polyamide category is much broader, allowing manufacturers to tailor production methods for specific applications.

Table 2: Production Process Comparison

| Production Process | Nylon | Polyamides |

|---|---|---|

| Chemical Reaction | Hexamethylene diamine + Adipic acid | Varies based on type of polyamide |

| Production Method | Polymerization (condensation or addition) | Various methods, including condensation and addition |

| Specific Applications | Widely used in textiles, automotive, and industrial products | Varies depending on polyamide type (e.g., aramids for military) |

3. What Are the Key Differences Between Nylon and Polyamides?

Now that we’ve established what Nylon and polyamides are, it’s time to dive into their key differences.

Chemical Composition: Nylon is a specific type of polyamide, but not all polyamides are Nylon. Nylon typically consists of long chains of hexamethylene diamine and adipic acid. In contrast, polyamides can be made from a wide range of monomers, giving them different physical and chemical properties.

Physical Properties: Nylon is known for its high strength, wear resistance, and flexibility. These properties make it ideal for use in a wide range of manufacturing applications, from textiles to automotive parts. Polyamides, in general, also possess excellent durability, but their specific properties can vary depending on the type of polyamide being used. For example, aramids, a specific type of polyamide, have even higher strength and heat resistance than Nylon, making them ideal for use in aerospace applications.

But here’s the kicker: the strength and wear resistance of Nylon make it highly valuable in many everyday applications. However, for more specialized uses—like electronics or military applications—other polyamides like aramids are preferred due to their superior heat resistance.

Table 3: Key Differences in Chemical Composition and Physical Properties

| संपत्ति | Nylon | Polyamides |

|---|---|---|

| Chemical Composition | Hexamethylene diamine + Adipic acid | Varies based on polyamide type |

| ताकत | उच्च | Varies (can be higher for aramids) |

| Wear Resistance | उत्कृष्ट | Excellent (varies by type) |

4. How Are Nylon and Polyamides Used in Manufacturing?

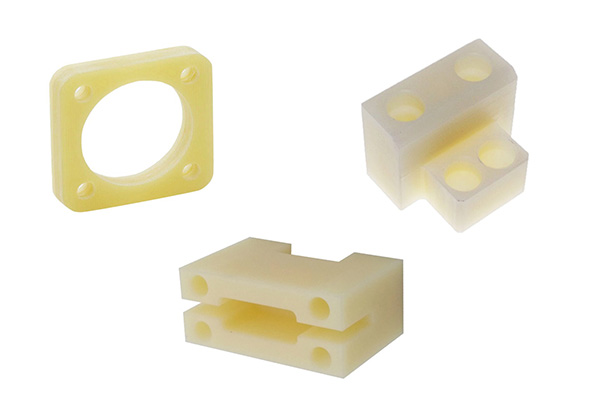

Nylon is incredibly versatile and widely used in manufacturing. It’s employed in everything from automotive parts and industrial equipment to clothing and ropes. The material’s strength, flexibility, and wear resistance make it an ideal choice for industries that require durable materials that can withstand harsh conditions.

Polyamides, too, are widely used across various industries. However, their specific applications often differ from Nylon. For example, aramid polyamides, known for their high strength and heat resistance, are used in aerospace, military, और electronics industries where performance under extreme conditions is essential.

Ready for the good part? While Nylon is often the go-to material for everyday items, polyamides such as aramids play a crucial role in specialized, high-performance applications where Nylon falls short.

Table 4: Applications of Nylon and Polyamides

| आवेदन | Nylon | Polyamides |

|---|---|---|

| Automotive Parts | Yes | Yes (but specific polyamides) |

| एयरोस्पेस | No | Yes (aramids) |

| Textiles | Yes | No |

| इलेक्ट्रानिक्स | No | Yes (specific polyamides) |

| Industrial Equipment | Yes | Yes (varies) |

5. Why is Nylon Preferred for Certain Manufacturing Applications?

Nylon is often the preferred choice in manufacturing due to its unique properties, such as strength, flexibility, और resistance to wear. This makes it ideal for use in a wide range of products, including textiles, automotive parts, और industrial machinery. Nylon is also relatively cost-effective, making it a popular choice for mass production.

What’s the real story here? The reason Nylon is so widely used in manufacturing is that it strikes an excellent balance between cost and performance. For industries that require durable materials that won’t break the bank, Nylon is the go-to option.

However, in industries like automotive manufacturing और textile production, Nylon offers a combination of properties that cannot be easily matched by other materials, including polyamides. It’s strong, yet lightweight, and can be produced in a wide range of forms—from films and fibers to solid plastics.

Table 5: Advantages of Nylon in Manufacturing

| फ़ायदा | Nylon | Polyamides |

|---|---|---|

| ताकत | उच्च | High (varies by type) |

| FLEXIBILITY | उत्कृष्ट | Varies |

| लागत | Relatively low | Higher (for specific polyamides) |

| Durability | उत्कृष्ट | Excellent (varies by type) |

6. When Should Polyamides Be Used Over Nylon?

Polyamides, including Nylon, have a wide range of applications due to their versatility, but there are specific circumstances where polyamides should be used over Nylon. One key benefit of polyamides is their superior performance in high-stress environments. For example, in electronics and engineering industries, polyamides excel in providing electrical insulation while offering resistance to wear, chemicals, and extreme temperatures. These properties make them ideal for the automotive and aerospace sectors, where high reliability and performance are critical.

But here’s the kicker: polyamides also outperform Nylon when it comes to long-term performance. Their superior resistance to high temperatures, oxidation, and harsh chemicals means that they can maintain their integrity over longer periods, even under demanding conditions. This makes polyamides more suited for industries such as manufacturing of electrical components, oil, and gas pipelines, where longevity is crucial.

For engineers and manufacturers, selecting polyamides over Nylon means opting for enhanced durability and performance in tough environments. However, in less demanding applications, Nylon may still be the more cost-effective solution.

Table: Comparison of Polyamide vs. Nylon in Specific Applications

Application | Polyamide | Nylon

| आवेदन | Polyamide | Nylon |

| इलेक्ट्रानिक्स | Excellent electrical insulation | Suitable for low-voltage applications |

| ऑटोमोटिव | High resistance to wear and chemicals | Effective for general use, but less heat-resistant |

| एयरोस्पेस | Superior performance under extreme conditions | Suitable for general parts, but not high-performance components |

7. How Do Nylon and Polyamides Affect the Environment?

When it comes to the environmental impact, both Nylon and polyamides share some similarities, but there are also notable differences. Nylon production requires significant energy, and the material itself does not biodegrade easily, leading to challenges in waste management. The primary environmental concerns associated with Nylon include pollution during its production process, primarily from fossil fuels, and its non-biodegradability.

What’s the real story? Polyamides, on the other hand, are produced in a way that tends to be more environmentally friendly. Though still synthetic, some polyamide manufacturing processes incorporate bio-based feedstocks, making them slightly more sustainable than Nylon in certain applications. Additionally, polyamides tend to have a longer lifespan, reducing the frequency of disposal and thus lowering environmental impacts over time.

In both cases, sustainable manufacturing practices, such as the use of renewable energy in production and recycling efforts, are gaining traction. These practices help reduce the environmental footprint of both Nylon and polyamides, making them better choices for eco-conscious manufacturers.

Table: Environmental Impact of Nylon vs. Polyamides

| कारक | Nylon | Polyamides |

| ऊर्जा की खपत | उच्च | मध्यम |

| Biodegradability | कम | कम |

| Sustainability in Production | Requires significant fossil fuel inputs | Can use bio-based feedstocks |

| Recycling Potential | Available but not widespread | More recyclable in certain forms |

8. How Are Nylon and Polyamides Recycled?

Recycling is a critical factor when considering the environmental impact of both Nylon and polyamides. Nylon is primarily recycled through mechanical processes, where it is ground into small pellets and reprocessed into new materials. Additionally, chemical recycling methods are being explored to further improve the efficiency and sustainability of the Nylon recycling process.

Ready for the good part? Polyamides are also recyclable, but the process differs slightly. While polyamide recycling can include mechanical and chemical methods, the focus is on reclaiming high-quality material for reuse in critical applications, especially in aerospace and automotive sectors. This makes polyamide recycling a more specialized process, requiring precise sorting and advanced techniques to ensure high performance in reused parts.

Understanding these differences is crucial for manufacturers looking to improve sustainability efforts. Nylon recycling may be more widely available, but polyamide recycling offers higher material integrity, making it more suitable for industries where quality and performance are paramount.

Table: Recycling Methods for Nylon vs. Polyamides

| Recycling Type | Nylon | Polyamides |

| Mechanical Recycling | Commonly used for textiles and consumer goods | Limited to specialized industries |

| Chemical Recycling | Emerging technology | Widely used for high-quality material recovery |

| Recycling Efficiency | Widely available but varies in quality | More complex, ensures material integrity |

9. What Are the Pros and Cons of Nylon vs. Polyamides in Manufacturing?

Both Nylon and polyamides have their strengths and weaknesses when used in manufacturing, and the choice between the two largely depends on the specific application. Nylon is a versatile, cost-effective material that works well in a variety of general manufacturing processes, such as textiles and consumer goods. It offers good durability, flexibility, and resistance to wear, making it the go-to choice for everyday products like clothing, ropes, and plastic components.

But here’s the kicker: polyamides, though generally more expensive, excel in performance under high stress and extreme conditions. They offer superior resistance to high temperatures, chemicals, and wear, which makes them a better choice for demanding applications in aerospace, automotive, and electronics. However, this high performance comes at a higher cost, which is an important consideration for manufacturers when choosing between the two.

Table: Pros and Cons of Nylon vs. Polyamides in Manufacturing

| मानदंड | Nylon | Polyamides |

| लागत प्रभावशीलता | Low cost, widely available | High cost, niche applications |

| Durability | Good for general use | Excellent for high-stress environments |

| FLEXIBILITY | Highly flexible | Less flexible, but more robust |

| Performance | Suitable for moderate conditions | Superior performance in extreme conditions |

10. How Do Temperature and Chemical Exposure Affect Nylon and Polyamides?

Temperature and chemical resistance are two of the most important factors in determining the suitability of a material for specific applications. Nylon performs well in moderate temperature ranges but begins to lose its strength and flexibility when exposed to extreme heat. While it resists certain chemicals, it is not as durable in highly corrosive or high-temperature environments.

This is where it gets interesting: polyamides, on the other hand, offer superior heat resistance, making them ideal for environments that demand durability under high temperatures. They also have better resistance to aggressive chemicals and solvents, which is why they are used in industries like oil and gas and automotive.

For manufacturers working in industries requiring material performance in extreme environments, polyamides are often the preferred choice. Nylon may work for standard applications, but when the conditions get harsh, polyamides stand out.

Table: Temperature and Chemical Resistance of Nylon vs. Polyamides

| कारक | Nylon | Polyamides |

| Heat Resistance | मध्यम | उच्च |

| Chemical Resistance | सीमित | उत्कृष्ट |

| Long-Term Performance | Suitable for standard conditions | Ideal for extreme environments |

11. What Are the Most Common Manufacturing Defects in Nylon and Polyamides?

Manufacturing defects can occur in both Nylon and polyamide products, and it’s important to be aware of them to prevent issues down the line. Common defects in Nylon include warping, shrinkage, and dimensional instability, especially when the material is exposed to extreme temperatures or moisture. These defects can compromise the integrity and functionality of Nylon-based products.

What’s the real story? Polyamides, while more resistant to environmental factors, are not immune to defects. Common issues include cracking due to stress or brittleness under cold temperatures, and challenges with processing during molding or extrusion. Proper handling and the use of additives can help mitigate these issues and improve material performance.

For manufacturers, preventing defects in production requires strict quality control, appropriate storage conditions, and careful selection of processing methods. Identifying the right material for the job is just the first step; ensuring its proper treatment and handling is equally crucial.

Table: Common Manufacturing Defects in Nylon vs. Polyamides

| Defect Type | Nylon | Polyamides |

| Warping | Common with temperature and moisture exposure | Less prone but still possible with poor processing |

| Cracking | Can occur under stress | Common at low temperatures |

| Dimensional Instability | Can occur due to temperature fluctuations | Less likely, but quality control is key |

12. How Do Manufacturers Test Nylon and Polyamides for Quality?

Quality assurance is an essential part of the manufacturing process for both Nylon and polyamides. Manufacturers typically test for factors like strength, flexibility, and resistance to environmental stresses to ensure that their products meet industry standards. For Nylon, standard tests include tensile strength, elongation at break, and impact resistance, which help determine its suitability for a wide range of applications.

Polyamide testing is more specialized and typically includes higher-level tests to evaluate resistance to extreme temperatures, chemicals, and mechanical stress. For example, testing for melt flow index, heat deflection temperature, and chemical resistance are crucial for ensuring the polyamide’s performance in demanding environments.

Understanding these testing methods is vital for manufacturers to ensure the quality and longevity of their products. Adhering to industry standards and implementing a robust quality control system helps minimize defects and improve the overall performance of the final product.

Table: Quality Testing Methods for Nylon vs. Polyamides

| Test Type | Nylon | Polyamides |

| Tensile Strength | Standard test for general durability | Used for high-performance applications |

| Heat Deflection Temperature | Not commonly tested | Crucial for high-temperature environments |

| Chemical Resistance | Tested for general use | Extensive testing for harsh chemicals |

13. What Are the Future Trends in Nylon and Polyamide Manufacturing?

The future of Nylon and polyamide manufacturing is exciting, with numerous innovations on the horizon. For Nylon, the trend is moving toward more sustainable production methods, with an increasing focus on bio-based feedstocks. Advances in recycling technology are also paving the way for a more circular economy, allowing manufacturers to reuse Nylon waste materials and reduce environmental impact.

Ready for the good part? Polyamide manufacturing is evolving in similar ways, with a focus on enhancing material properties for high-performance applications. New manufacturing techniques, such as 3D printing with polyamides, are opening up new possibilities for the material, making it more versatile and cost-effective. Furthermore, advancements in the development of high-performance polyamides are set to revolutionize industries like aerospace and automotive.

For manufacturers, staying ahead of these trends will be crucial for remaining competitive and meeting growing demand for sustainable and high-performance materials.

Table: Future Trends in Nylon and Polyamide Manufacturing

| रुझान | Nylon | Polyamides |

| Sustainable Production | Focus on bio-based materials | Increase in sustainable production methods |

| Recycling Innovations | Enhanced mechanical recycling | Focus on chemical recycling for high-performance parts |

| 3डी प्रिंटिंग | Emerging technology | Growing in high-performance sectors |

14. How Do Nylon and Polyamides Compare in Terms of Cost?

When comparing Nylon and polyamides in terms of cost, Nylon generally comes out as the more affordable option for manufacturing. This is largely due to its widespread availability and versatility in a wide range of applications. Nylon is suitable for low to mid-performance requirements, making it an attractive option for manufacturers working with budget constraints.

But here’s the kicker: polyamides, while more expensive, offer better long-term performance and durability, especially in extreme environments. For high-performance applications that demand superior heat and chemical resistance, polyamides are worth the investment. In sectors like aerospace, automotive, and electronics, the cost is often justified by the material’s ability to perform in demanding conditions.

Manufacturers must carefully consider the specific needs of their applications to determine which material offers the best value. While Nylon might be the more cost-effective option for general use, polyamides provide better value in high-performance, long-lasting applications.

Table: Cost Comparison of Nylon vs. Polyamides

| लागत कारक | Nylon | Polyamides |

| Material Cost | कम | उच्च |

| Manufacturing Cost | Affordable | Higher due to specialized processes |

| Long-Term Value | Suitable for standard applications | High value in demanding environments |

15. What Are the Alternatives to Nylon and Polyamides in Manufacturing?

Although Nylon and polyamides are popular materials in manufacturing, they are not always the best option for every application. Alternatives such as polyester, polypropylene, and PEEK (Polyether ether ketone) are increasingly being used as substitutes in various industries. For example, polyester offers a lower-cost alternative to Nylon in textile applications, while PEEK is gaining popularity in industries that require high-performance materials with exceptional strength and resistance to heat.

What’s the real story? When comparing these alternatives, it’s important to evaluate factors such as cost, performance, and application needs. While alternatives like PEEK provide exceptional performance, they also come with a much higher cost. For manufacturers on a budget, polyester or polypropylene may offer a good balance between performance and cost.

Table: Alternatives to Nylon and Polyamides in Manufacturing

| Alternative Material | Performance | लागत |

| Polyester | Good for textiles | Low cost |

| Polypropylene | Suitable for general use | Low cost |

| PEEK | Excellent for high-performance applications | High cost |

अक्सर पूछे जाने वाले प्रश्न अनुभाग

प्रश्न 1: What is Nylon?

Nylon is a synthetic polymer commonly used in manufacturing for its durability, elasticity, and resistance to wear and tear. It is widely used in textiles, automotive parts, and industrial applications.

प्रश्न 2: How does Polyamide work?

Polyamides, like Nylon, are synthetic polymers but with different chemical structures, making them more resistant to heat and wear in certain applications. Polyamides are often used in high-performance environments such as aerospace and electronics.

प्रश्न 3: What are the differences between Nylon and Polyamides?

Nylon and Polyamides differ in their chemical composition and properties. Nylon tends to be more versatile, while Polyamides offer better heat resistance and chemical stability, making them suitable for specialized applications.

प्रश्न 4: Can Nylon and Polyamides be recycled?

Yes, both Nylon and Polyamides can be recycled, although the process varies. Nylon recycling involves mechanical and chemical methods, while Polyamide recycling focuses on reclaiming high-quality materials for reuse in manufacturing.

प्रश्न 5: Which material is more cost-effective for manufacturing?

Nylon is generally more cost-effective for most manufacturing needs, especially in high-volume applications like textiles and consumer goods. However, Polyamides may be more cost-efficient for industries that require higher performance under extreme conditions.