Introduction

When you’re looking to purchase an aluminum CNC machine, cost is often one of the primary considerations. The price tag of these machines can vary significantly based on factors like size, brand, and features. However, there are strategies that can help you find an affordable option without compromising on quality. In this article, we’ll explore the most important factors to consider when buying an aluminum CNC machine, and guide you through how to make a smart, cost-effective decision.

1. What is an Aluminum CNC Machine?

An aluminum CNC machine is a type of computer-controlled machine designed for precision machining of aluminum parts. These machines use numerical control (NC) programs to automate the cutting, shaping, and drilling processes, ensuring high accuracy and repeatability. The most common types of aluminum CNC machines include CNC mills, CNC lathes, and multi-axis machines, each suited to different tasks.

But here’s the kicker, aluminum is one of the most popular materials for CNC machining due to its versatility, light weight, and resistance to corrosion. It’s used in a wide range of industries, including automotive, aerospace, and electronics.

In essence, choosing the right CNC machine for aluminum is critical to optimizing both cost and performance. CNC milling machines, for instance, are highly effective for complex cutting tasks. CNC lathes, on the other hand, are ideal for turning operations. Understanding these machines’ capabilities can help you make an informed decision based on the type of work you’ll be doing.

Table 1: Types of Aluminum CNC Machines and Their Functions

| Machine Type | Description | Ideal for |

|---|---|---|

| CNC Mill | Automated cutting tool used for complex parts | Detailed cutting, drilling, and shaping |

| CNC Lathe | Spins the material while cutting | Turning operations and cylindrical parts |

| Multi-Axis CNC | Uses multiple axes for cutting | Complex, high-precision parts with intricate designs |

2. How Does an Aluminum CNC Machine Work?

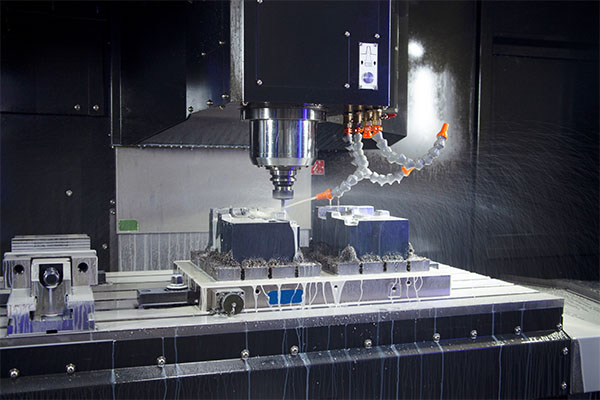

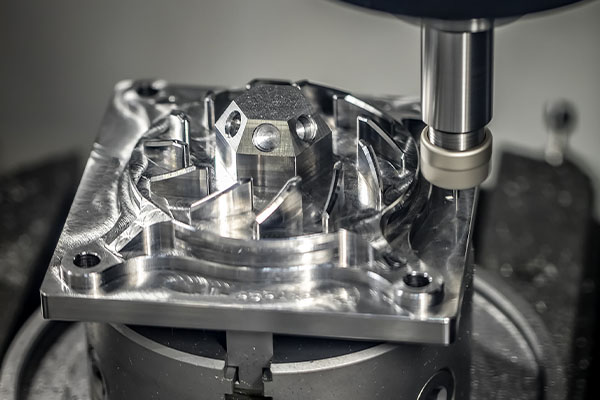

At the core of every aluminum CNC machine is a computer system that controls the movements of the machine’s tools. The process starts with the design phase, where a CAD (Computer-Aided Design) model is created. This design is then converted into a CNC program, which guides the machine’s toolpaths.

You might be wondering, how exactly does the machine know where to cut? CNC machines use servo motors and actuators to control the movement of the tools along various axes. The material, in this case, aluminum, is fixed on the machine’s worktable, and the cutting tool moves along the programmed path to shape the material accordingly.

What’s the real story? CNC machines eliminate human error, improving precision and reducing production time. With advanced software, these machines can execute highly intricate cuts that would be challenging for manual machining processes.

Table 2: CNC Machine Components and Their Functions

| Component | Function |

|---|---|

| Spindle | Holds and rotates the cutting tool |

| Worktable | Supports the material during machining |

| Servo Motors | Control movement of the tool and workpiece |

| Control Panel | Interface for programming and machine adjustments |

3. Why Should You Choose an Aluminum CNC Machine?

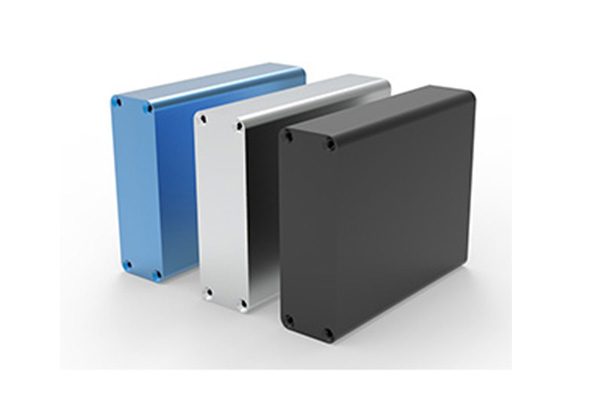

Aluminum CNC machines offer a range of benefits that make them ideal for various industries. One of the biggest advantages is the material itself: aluminum is lightweight, corrosion-resistant, and relatively easy to machine. It is also highly versatile, making it suitable for a wide array of applications, from aerospace components to custom parts for electronics.

Ready for the good part? Using an aluminum CNC machine provides a level of precision that is hard to match with manual methods. The automation allows for faster production times and higher accuracy, making it an essential tool for industries that require high-quality, complex parts.

Furthermore, aluminum is an excellent material for mass production. Its combination of low weight and strength allows manufacturers to create parts that are both durable and easy to handle. If your business requires high-volume production of aluminum parts, investing in a CNC machine can be a game-changer.

Table 3: Advantages of Aluminum CNC Machines

| Advantage | Explanation |

|---|---|

| High Precision | Automation ensures consistently accurate cuts |

| Cost-Effective | Aluminum is relatively cheap compared to other metals |

| Versatility | Suitable for a wide range of applications |

| Durability | Aluminum parts are lightweight and long-lasting |

4. What Factors Affect the Cost of an Aluminum CNC Machine?

The cost of an aluminum CNC machine can vary significantly based on several factors. One of the primary factors is the size of the machine. Larger machines, which can handle bigger workpieces and perform more complex tasks, tend to be more expensive.

This is where it gets interesting: the brand also plays a big role in determining price. Well-established brands with a reputation for quality and reliability often charge more for their machines. However, the investment might be worth it if you’re looking for a machine that will perform consistently over time.

In addition, the features of the machine—such as the number of axes, the type of control system, and the specific tools included—also affect pricing. Higher-end machines with advanced features, like automated tool changers or multi-axis capabilities, will naturally come at a higher price point.

Table 4: Factors Influencing CNC Machine Price

| Factor | Impact on Cost |

|---|---|

| Machine Size | Larger machines are more expensive |

| Brand | Reputable brands tend to be more costly |

| Features | Machines with more features are pricier |

| Automation | Automated systems increase the cost |

5. How to Find the Best Deals on Aluminum CNC Machines?

Finding an affordable aluminum CNC machine doesn’t mean you have to compromise on quality. Here’s the deal: the best deals are often found by comparing prices from multiple suppliers. Many manufacturers offer discounts, especially during trade shows or clearance sales.

You might be wondering, where else can you look for deals? Online marketplaces like Alibaba are great places to find competitive pricing on both new and used aluminum CNC machines. But remember, just because a machine is cheaper doesn’t mean it’s the right fit for your business. Make sure to check the specifications to ensure the machine meets your needs.

What’s the real story? Research is key. Don’t rush into a purchase. Spend time comparing options, checking reviews, and asking for recommendations from other businesses in your industry. It’s also worth considering financing options or leasing a machine if upfront costs are too high.

Table 5: Tips for Finding Affordable CNC Machines

| Tip | Explanation |

|---|---|

| Compare Multiple Suppliers | Get quotes from various sources for the best deal |

| Check Online Marketplaces | Platforms like Alibaba often have competitive prices |

| Look for Seasonal Discounts | Purchase during trade shows or clearance events |

| Consider Financing Options | Financing can help spread out the cost over time |

6. Should You Buy a New or Used Aluminum CNC Machine?

The decision to buy new or used depends largely on your business’s budget and specific needs. New machines often come with warranties, the latest technology, and greater reliability. However, they also come with a higher price tag.

Here’s the kicker, used aluminum CNC machines can offer significant savings, but they come with their own risks. It’s important to thoroughly inspect any used machine to ensure it’s in good working condition. Look for signs of wear and tear, and ask the seller for a full history of the machine’s usage.

What’s the real story? If you’re just starting out or need a machine for basic tasks, a used machine might be a good option. But for high-volume or complex projects, a new machine may offer better long-term value and peace of mind.

7. What Are the Most Common Brands for Aluminum CNC Machines?

When considering which aluminum CNC machine to buy, brand reputation plays a crucial role in determining both price and performance. Well-known brands tend to offer superior reliability, advanced features, and better customer support. Some of the most reputable CNC machine brands in the market include Haas, Mazak, and DMG Mori.

But here’s the kicker, while these brands are generally more expensive, their machines are built to last, with robust service networks and a high resale value. Haas, for instance, is renowned for offering a wide range of machines suited for various industries, including aerospace, automotive, and metalworking. They also provide extensive training materials and technical support to help businesses get the most out of their machines.

What’s the real story? It’s not just about the brand name; consider the features you need and match them to the capabilities of the machine. If you’re in need of precise machining for lightweight parts, some brands may offer more specialized machines that fit your specific requirements.

Table 6: Popular CNC Machine Brands and Their Features

| Brand | Notable Features | Best Suited For |

|---|---|---|

| Haas | Wide range, user-friendly controls | General machining, flexibility |

| Mazak | High-speed machining, advanced automation | Aerospace, automotive parts |

| DMG Mori | High precision, global support network | High-end precision manufacturing |

8. How to Choose the Right Size Aluminum CNC Machine for Your Needs?

Choosing the right size aluminum CNC machine depends largely on the scope of your operations and the types of parts you plan to produce. Machines come in various sizes, from small desktop units for prototyping to large industrial machines for high-volume production.

Ready for the good part? Bigger machines tend to have a higher capacity and can handle larger pieces of material. However, larger machines also require more space, higher power consumption, and a larger initial investment. On the other hand, smaller machines are more compact, cost-effective, and perfect for small batch or prototype work.

In essence, the size of the machine you choose should align with the scale of your production. If you expect to process large aluminum panels or complex parts, a bigger machine is the way to go. But for smaller operations, a compact, more affordable CNC machine may be the perfect fit.

Table 7: CNC Machine Size Comparison

| Machine Size | Ideal Use Case | Pros | Cons |

|---|---|---|---|

| Small | Prototyping, small parts | Cost-effective, compact | Limited material capacity |

| Medium | Low to mid-volume production | Balanced cost and capacity | May not handle large parts |

| Large | High-volume, complex part production | High capacity, versatile | High upfront costs, large space requirements |

9. How to Maintain an Aluminum CNC Machine?

Maintenance is essential to keep your aluminum CNC machine running smoothly and efficiently. Regular upkeep can significantly extend the life of your machine, reduce downtime, and improve the quality of your parts.

What’s the real story? Routine tasks like cleaning the work area, checking for wear on tools, and lubricating moving parts are crucial. Most manufacturers provide maintenance schedules for their machines, which include daily, weekly, and monthly tasks. For example, checking the coolant system is vital to prevent overheating and ensure the longevity of both the machine and its tools.

But here’s the kicker: preventive maintenance not only helps avoid costly repairs, but it also boosts productivity by reducing unexpected breakdowns. Developing a strong maintenance routine and training your team on machine care is key to maintaining an efficient operation.

Table 8: Key Maintenance Tasks for CNC Machines

| Task | Frequency | Importance |

|---|---|---|

| Tool inspection and replacement | Daily | Ensures accuracy and performance |

| Lubrication of moving parts | Weekly | Prevents friction and wear |

| Coolant system check | Weekly/Monthly | Prevents overheating and improves longevity |

| Cleaning of machine surfaces | Daily/Weekly | Reduces buildup and maintains cleanliness |

10. What Are the Limitations of Aluminum CNC Machines?

While aluminum CNC machines are versatile and efficient, they do come with certain limitations. One limitation is that aluminum is relatively soft compared to other metals like steel, meaning it can wear down tools faster. As a result, machine operators need to be mindful of tool life and ensure they are using the correct cutting parameters.

Ready for the good part? Despite these limitations, aluminum is still one of the easiest metals to machine, and many of the challenges posed by its softness can be overcome by using the right tools, cutting speeds, and feeds. Another limitation is that, while aluminum is ideal for many applications, it may not be the best choice for high-strength parts that need to endure extreme conditions.

What’s the real story? Although there are limitations, aluminum CNC machines remain an essential tool for a wide range of industries due to their flexibility and ease of use.

Table 9: Limitations of Aluminum CNC Machines

| Limitation | Impact | Solution |

|---|---|---|

| Tool wear | Soft material leads to quicker tool wear | Use high-quality cutting tools |

| Limited material strength | Aluminum isn’t as strong as other metals | Consider alternative materials |

| Surface finish challenges | Can require more fine-tuning for a smooth finish | Use correct machining parameters |

11. How to Set Up Your Aluminum CNC Machine?

Setting up your aluminum CNC machine properly is key to ensuring smooth operation and high-quality output. First, you’ll need to make sure the machine is properly installed in a safe, clean environment with sufficient power and ventilation.

What’s the real story? After installation, you’ll need to calibrate the machine to ensure precise operation. This includes aligning the tool and workpiece, setting zero points, and verifying all safety systems. The machine’s software also needs to be installed and configured, as this is what communicates with the machine to execute your CNC programs.

But here’s the kicker, a proper setup ensures accuracy and prevents errors during machining. For optimal results, always follow the manufacturer’s setup guidelines and take time to properly calibrate before beginning production.

Table 10: Setup Checklist for Aluminum CNC Machine

| Setup Task | Description |

|---|---|

| Install machine and ensure power | Set up the machine in a safe location and connect to power |

| Calibrate tools and workpieces | Align tools and set zero points for precision |

| Install and configure software | Ensure the CNC program runs smoothly on the machine |

| Conduct dry run | Test the machine to check for errors before full operation |

12. How to Improve Efficiency with an Aluminum CNC Machine?

To make the most out of your aluminum CNC machine, improving efficiency is essential. One of the best ways to enhance efficiency is by optimizing your tool paths. The right tool path reduces machine time and increases the speed of production.

You might be wondering, how can you optimize tool paths? One strategy is to use software tools like CAD and CAM programs that can help plan and simulate the machining process before actual cutting. These programs analyze your design and automatically generate the most efficient tool path, minimizing waste and time spent on setup.

What’s the real story? Improving efficiency doesn’t just save time—it can lead to higher profitability. With better machine performance, you can meet tight production schedules, increase throughput, and reduce costs, all while maintaining high-quality output.

Table 11: Tips for Improving CNC Machine Efficiency

| Tip | Explanation |

|---|---|

| Optimize tool paths | Use CAD/CAM software for better planning |

| Minimize tool changes | Automate tool changes for faster operations |

| Use high-quality tools | High-quality tools ensure precision and efficiency |

13. What Safety Precautions Should You Take When Using an Aluminum CNC Machine?

Operating an aluminum CNC machine requires strict adherence to safety protocols to protect both the operator and the machine. First and foremost, proper training is essential. Operators should understand the machine’s functions, as well as the risks associated with handling machinery and tools.

What’s the real story? Safety also involves ensuring the work area is clear of obstructions, that all guards and safety features are in place, and that the operator uses appropriate personal protective equipment (PPE) such as safety glasses, gloves, and ear protection.

But here’s the kicker, implementing regular safety checks and ensuring compliance with OSHA regulations can significantly reduce the likelihood of accidents and improve workplace safety.

Table 12: Essential CNC Machine Safety Equipment

| Safety Equipment | Purpose |

|---|---|

| Safety Glasses | Protect eyes from debris and cutting tools |

| Ear Protection | Reduce exposure to loud machine noise |

| Protective Gloves | Safeguard hands from sharp tools |

| Machine Guards | Prevent accidental contact with moving parts |

14. How to Train Employees on Aluminum CNC Machines?

Training your team is one of the most important steps in ensuring successful machine operations. Proper training ensures that employees understand not only how to use the machine but also how to maintain it, troubleshoot issues, and adhere to safety standards.

What’s the real story? Offering hands-on training is essential to developing the skills needed to operate aluminum CNC machines effectively. Employees should also have access to user manuals, troubleshooting guides, and regular refresher courses to stay updated on machine operations.

But here’s the kicker, the better trained your staff, the more efficient and safer the workplace will be, resulting in higher productivity and fewer mistakes.

Table 13: CNC Machine Training Resources

| Resource | Description |

|---|---|

| Hands-on Training Sessions | Practical, in-person training for operators |

| Online Courses | Digital learning materials for remote education |

| User Manuals and Guides | Reference documents for troubleshooting and setup |

15. What Are the Future Trends in Aluminum CNC Machining?

The future of aluminum CNC machining is bright, with new technologies and trends emerging to improve precision, speed, and automation. One such trend is the integration of artificial intelligence (AI) and machine learning (ML) into CNC machines. These technologies can predict tool wear, optimize cutting paths, and even monitor machine health in real-time.

Ready for the good part? In addition to AI, 3D printing and hybrid machining technologies are beginning to play a role in aluminum CNC machining. These innovations allow for more complex parts to be made with less material waste, reducing costs and improving sustainability.

What’s the real story? As technology advances, aluminum CNC machines will continue to evolve, offering even greater capabilities and efficiencies. Staying updated on these trends will help you remain competitive in the fast-paced manufacturing industry.

Conclusion

In this article, we’ve covered the key aspects of purchasing an aluminum CNC machine, from understanding the technology behind it to finding the best deals and deciding whether to buy new or used. Choosing the right machine involves weighing factors like size, features, and cost, as well as considering your specific machining needs.

Whether you’re upgrading your existing equipment or investing in CNC machining for the first time, there’s a wealth of options available to meet your requirements. Make sure to take the time to compare suppliers, check for deals, and choose the machine that best suits your business needs.

FAQ Section

Q1: What is an aluminum CNC machine?

An aluminum CNC machine is a precision tool used for shaping and cutting aluminum parts through automated processes.

Q2: How does an aluminum CNC machine work?

It uses a computer program to control the movement of tools, shaping aluminum materials with high accuracy.

Q3: What factors influence the cost of an aluminum CNC machine?

Machine size, brand, features, and automation all contribute to the price of an aluminum CNC machine.

Q4: Should I buy a new or used aluminum CNC machine?

The decision depends on your budget and requirements. New machines are reliable but more expensive, while used machines offer savings but may require more maintenance.

Q5: How can I find the best deals on aluminum CNC machines?

Compare prices, check online marketplaces, look for seasonal discounts, and consider financing options.