Introduction

Part deformation is a common issue faced by manufacturers working with aluminum CNC machining. As a crucial part of the process, ensuring that parts are accurately shaped without warping or bending is vital to maintaining product quality and performance. This article explores practical ways to prevent part deformation during the CNC machining process, providing insights into the key causes of deformation, strategies for mitigation, and essential tips for achieving high-quality results.

1. Why is Part Deformation a Concern in Aluminum CNC Machining?

In the world of CNC machining, part deformation refers to the unwanted alteration of a workpiece’s shape during the machining process. In aluminum machining, this can be a significant concern, especially when precision is paramount. You might be wondering, why does this even happen in the first place? Well, part deformation can stem from several sources, including thermal stress, improper tooling, and inadequate machine setup.

When machining aluminum, heat is generated through friction, which causes the material to expand. If the cooling rates are uneven, the material can warp. This is particularly problematic when working with thin-walled parts or delicate designs that require precision. Additionally, incorrect tool paths or improperly clamped workpieces can lead to deformed shapes, making the final part unusable. Here’s the kicker: when part deformation occurs, not only does the part need to be re-machined, but it also leads to delays in production and increased costs.

2. What Are the Common Causes of Part Deformation in CNC Machining?

Understanding the underlying causes of part deformation is essential for preventing it. Thermal effects play a major role, as aluminum is highly susceptible to expansion and contraction during machining. When the material heats up during cutting, it can distort, especially in areas that experience rapid cooling. One way to address this is by controlling the cooling system. Using appropriate coolants and ensuring an even flow of cooling fluids can help maintain consistent temperature levels across the part.

Another common cause is tooling issues. Incorrect tool paths, feed rates, and cutting speeds can all contribute to deformation. If the tool pressure is uneven or too high, it can warp the part. Clamping issues are another factor. If the workpiece isn’t held securely in place, vibrations during cutting can cause it to shift, leading to misalignment and deformation. Adjusting machine settings to ensure the proper clamping force is applied and maintaining a stable setup can mitigate this risk.

3. How Does Material Properties Affect Part Deformation?

The inherent properties of aluminum also play a major role in part deformation. Aluminum, while light and easy to machine, is not immune to thermal stress. You might be wondering, why does this matter? The expansion and contraction of aluminum due to heat fluctuations can significantly affect the shape of the part. This is especially true for softer aluminum alloys, which may lack the rigidity needed to maintain a precise shape during machining.

To minimize deformation, it’s crucial to choose the right aluminum grade. Some grades of aluminum are more resistant to thermal expansion than others. For example, 6061 aluminum, a commonly used alloy, is more stable under heat compared to other grades. Choosing the right material can help minimize deformation risks, allowing the CNC machining process to produce high-quality, accurate parts.

4. How Can Tool Selection Influence Deformation in CNC Machining?

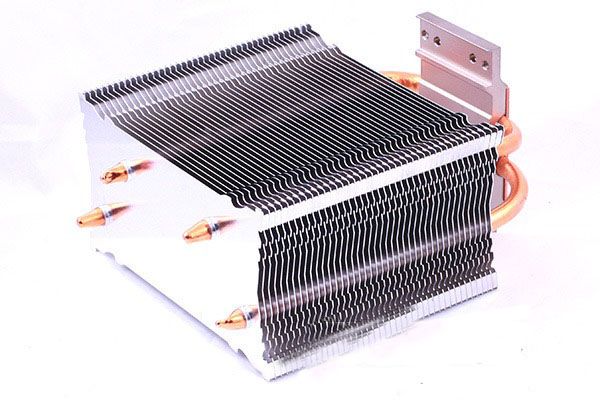

Tool selection is another critical factor in preventing part deformation. The right tools for your aluminum part can make a world of difference in terms of precision. For example, carbide tools are often recommended for aluminum machining due to their superior durability and heat resistance compared to high-speed steel tools. By using tools with appropriate cutting geometries, you can ensure smoother cuts that exert less stress on the material.

Another key aspect is tool maintenance. A worn tool can lead to poor cutting quality and uneven material removal, increasing the chances of deformation. Regular inspection and tool sharpening are essential to maintain the integrity of your tools and ensure consistent performance throughout the machining process. This is where it gets interesting – by investing in high-quality tools and keeping them well-maintained, you not only reduce part deformation but also extend the lifespan of your CNC equipment.

5. How to Properly Set Up Your CNC Machine to Prevent Deformation?

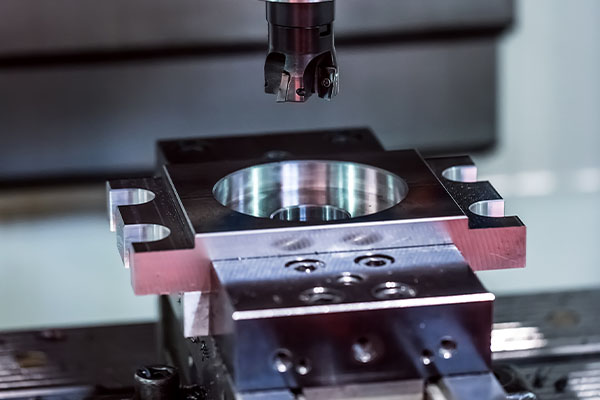

Proper setup of your CNC machine is essential in ensuring that part deformation is minimized. First, machine calibration plays a vital role. Ensuring that your CNC machine is properly calibrated ensures that the cutting tool is aligned correctly and the dimensions are accurate. Without proper calibration, even the best tool and material will result in dimensional inaccuracies and possible deformation.

It’s also essential to set the machine parameters according to the material’s properties and the complexity of the part. Cutting speeds, feed rates, and depth of cut should be tailored to the specific aluminum grade you’re working with. This is where proper preparation pays off: a well-prepared CNC setup ensures that the machine operates within the correct parameters, preventing unwanted deformation during the machining process.

6. What Is the Role of Cutting Speed in Avoiding Part Deformation?

Cutting speed plays a pivotal role in CNC machining, particularly when working with materials like aluminum. The right cutting speed is essential to ensure that heat is dissipated evenly, reducing the chances of thermal deformation. Cutting too fast can generate excessive heat, which leads to part expansion and, ultimately, deformation. On the other hand, cutting too slowly can lead to an inefficient machining process and cause excessive tool wear.

The optimal cutting speed for aluminum depends on several factors, including the grade of aluminum and the type of tool being used. Generally, a moderate cutting speed is recommended to balance heat generation and material removal efficiency. By maintaining the correct cutting speed, you can help prevent thermal expansion from distorting the part and ensure a smoother, more accurate finish.

7. How Can Clamping and Fixturing Methods Prevent Deformation?

One of the most overlooked yet crucial aspects of CNC machining is proper clamping and fixturing. If the workpiece isn’t securely clamped, it can move or shift during the machining process, leading to misalignment and part deformation. Proper clamping ensures that the part stays in place throughout the entire machining cycle, maintaining its shape and reducing the risk of distortion.

When selecting a clamping method, it’s essential to consider the material and part geometry. For example, soft aluminum alloys might require softer clamping methods, while harder alloys might need stronger clamping forces. The type of fixture used can also influence the machining process. A poorly designed fixture can exert uneven pressure on the workpiece, leading to deformation. By choosing the right clamping method and fixture design, you can significantly reduce the chances of deformation.

8. What Are the Best Cooling Techniques to Prevent Deformation?

Effective cooling techniques are vital for controlling the temperature during aluminum CNC machining. Improper cooling can cause uneven temperature distribution, which can lead to thermal expansion and deformation. The best cooling techniques involve flood coolant systems, which provide consistent and even cooling across the entire part surface.

Another method is dry machining, where minimal or no coolant is used. This technique is particularly useful for aluminum grades that are less prone to heat buildup. However, even with dry machining, it’s important to monitor the temperature closely to avoid thermal distortion. Proper coolant flow, temperature monitoring, and cooling strategies can significantly reduce the chances of part deformation during the machining process.

9. How to Adjust Tool Path Strategies to Reduce Deformation Risks?

Tool path optimization is another effective strategy for reducing part deformation in CNC machining. By adjusting the path that the tool follows during cutting, manufacturers can reduce material stresses and improve the overall machining process. For example, using multi-pass cutting can help minimize the amount of material removed in one pass, reducing the heat generated during the process.

Optimizing the tool path also involves choosing the right direction of cut. Cutting in the right direction minimizes the forces exerted on the workpiece, reducing the risk of deformation. The goal is to balance the cutting forces to minimize part distortion while achieving the desired shape and finish.

10. How Does Part Design Influence the Likelihood of Deformation?

The design of the part plays a critical role in preventing deformation during machining. Parts that are too thin or have sharp corners are more likely to experience distortion due to the stresses placed on them during cutting. When designing parts for aluminum CNC machining, it’s essential to consider the material’s properties and how they will react during the machining process.

For example, adding fillets to sharp corners can help reduce the concentration of stress at those points, making the part less prone to deformation. Similarly, thicker sections are more stable during machining, while thin-walled sections may need additional support or reinforcement. Considering the design features and potential deformation risks during the design phase can help reduce the chances of machining issues later.

11. Why Is Monitoring and Testing During Machining Crucial?

Monitoring and testing throughout the CNC machining process are vital for detecting early signs of deformation. By continuously measuring the part during machining, operators can identify issues before they become significant problems. Tools like laser displacement sensors and in-process measurement systems can be used to monitor dimensional changes in real-time, ensuring that any deviation from the desired shape is caught immediately.

Testing also involves post-machining inspection. After the machining process is complete, it’s essential to check the part for any signs of deformation. Using coordinate measuring machines (CMM) can provide highly accurate measurements to ensure that the part meets the required specifications.

12. What Post-Machining Processes Can Help with Part Deformation?

Even after the CNC machining process is complete, there are post-machining techniques that can help reduce or correct part deformation. One of the most common post-machining processes is heat treatment. Heat treating aluminum parts can relieve internal stresses caused during machining and prevent warping. This process involves heating the part to a specific temperature and then cooling it at a controlled rate.

Another post-machining process that can help with deformation is straightening. This process involves applying mechanical force to the part to straighten it if it has become deformed during machining. Straightening can help restore the part to its original shape and ensure that it meets the required specifications.

13. How to Optimize Your CNC Machine Settings for High-Precision Machining?

Optimizing your CNC machine settings is key to achieving high-precision machining. Setting the correct feed rates and cutting speeds is crucial for minimizing deformation. It’s also important to select the right tooling for the material being machined, as the wrong tools can create excessive heat or force, leading to part distortion.

Maintaining a rigid machine setup is also essential for precision. A machine that is not properly aligned can cause misalignment during the machining process, leading to deformation. Regular maintenance, calibration, and careful setup are all important aspects of achieving the desired results and reducing the risk of deformation.

14. What Are the Best Practices for Aluminum CNC Machining?

To ensure that your aluminum CNC machining process goes smoothly and that part deformation is minimized, there are a few best practices to follow. First, always choose the right material for your part’s specifications. Using aluminum alloys that are suitable for the intended application will reduce deformation risks. Additionally, optimize cutting conditions by adjusting feed rates, cutting speeds, and coolant flow to reduce heat buildup and material stress.

Another key practice is maintaining a stable machining environment. Ensure that the CNC machine is regularly calibrated, and all components are functioning correctly. Proper fixturing and clamping are also essential for preventing part movement during machining, reducing the chances of deformation.

15. How Can You Continuously Improve Your CNC Machining Process to Prevent Deformation?

Continuous improvement is essential for maintaining high-quality aluminum CNC machining. Start by evaluating the results of each project and analyzing any instances of deformation that occur. By identifying the root causes of deformation, you can refine your processes, adjust settings, or use different tools to achieve better results.

Monitoring technological advancements in the field of CNC machining can also help. New tools, machine technologies, and machining techniques can offer improved precision and reduced deformation risks. Stay updated with industry trends and continually seek feedback to refine your process for optimal results.

FAQ Section

Q1: What is part deformation in CNC machining?

Part deformation refers to the unwanted alteration of a workpiece’s shape during the CNC machining process, caused by thermal expansion, improper tooling, or other factors.

Q2: How does cutting speed affect part deformation?

Cutting speed impacts the amount of heat generated during machining. Too fast or too slow a cutting speed can cause thermal expansion, leading to deformation.

Q3: What is the role of clamping in preventing part deformation?

Proper clamping ensures the workpiece remains in place, preventing movement during machining and reducing the likelihood of misalignment and deformation.

Q4: How does tool selection prevent part deformation?

Using the right tools, such as carbide tools, ensures smoother cuts and reduces pressure on the material, helping to prevent deformation during the machining process.

Q5: Why is monitoring and testing important during machining?

Monitoring and testing throughout the process help identify any deformation early on, allowing for corrective measures to be taken before the part is ruined.