Perkenalan

Brass C360 material is one of the most commonly used alloys in CNC machining due to its excellent machinability, high corrosion resistance, and strong performance in various applications. In this article, we’ll dive into everything you need to know about Brass C360, including its composition, applications, machinability, and more. Whether you’re a manufacturer, distributor, or machinist, this guide will provide the essential details to help you understand the benefits and potential challenges of using Brass C360 in your projects.

1. What is Brass C360 Material?

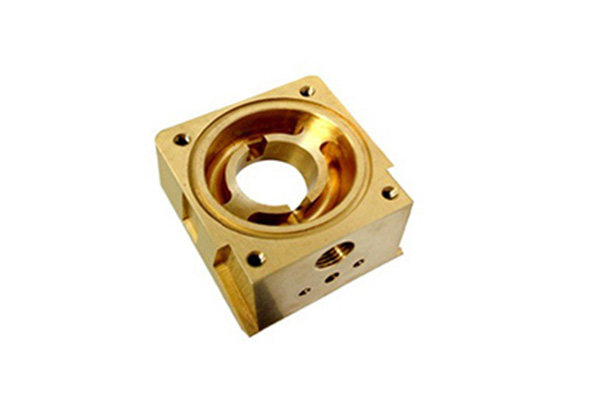

Brass C360 is a copper-zinc alloy known for its outstanding machinability. It is often chosen for CNC machining due to its ease of fabrication, making it a favorite in industries that require precision machining of complex parts. So, what’s in Brass C360 that makes it stand out? The alloy’s primary components include copper (Cu) and zinc (Zn), with small amounts of lead (Pb) to improve machinability. This makes the material softer and more ductile, allowing for quicker cutting speeds and reduced tool wear.

But here’s the kicker—Brass C360 also has a high resistance to corrosion, which is one of the reasons it’s used in harsh environments like plumbing and electrical components. When compared to other brass alloys, C360 offers a unique balance between strength, ductility, and machinability. In other words, it’s the ideal material when you need a product that’s durable, easy to work with, and cost-effective.

For example, it’s commonly used in parts like valves, fittings, and connectors. These components require precise machining, which Brass C360 is particularly suited for due to its low friction properties and smooth surface finish. Whether you’re creating intricate designs or high-volume components, Brass C360 can be the perfect choice for your needs.

| Composition Component | Percentage |

|---|---|

| Copper (Cu) | 60-70% |

| Zinc (Zn) | 30-40% |

| Lead (Pb) | 0.5-3% |

| Other Elements | Trace amounts |

2. Why is Brass C360 So Popular in CNC Machining?

Brass C360’s popularity in CNC machining comes down to its outstanding machinability and versatility. Ready for the good part? Unlike other metals that can be difficult to machine, Brass C360 allows for high cutting speeds with minimal tool wear. This is primarily due to its lead content, which reduces friction during the machining process. The result is a faster, more efficient production process, which ultimately leads to cost savings.

Additionally, Brass C360 offers excellent dimensional stability, meaning that parts made from this alloy maintain their shape and size even after long machining cycles. This makes it highly suitable for manufacturing precision parts like connectors, fittings, and fasteners, which require tight tolerances. But here’s the deal—its machinability doesn’t come at the cost of strength or durability. Brass C360 maintains a good balance of these qualities, making it ideal for use in demanding applications.

From a financial standpoint, Brass C360 also offers competitive pricing, particularly for high-volume production. It’s not just cost-effective for the initial machining process but also for post-processing, as it often doesn’t require extensive finishing work due to its smooth surface and fine grain structure.

| Fitur | Brass C360 |

|---|---|

| Machinability | Bagus sekali |

| Corrosion Resistance | Tinggi |

| Strength | Sedang |

| Aplikasi | Valves, fittings, connectors |

3. How Does the Composition of Brass C360 Affect Its Properties?

The composition of Brass C360 plays a pivotal role in determining its properties, making it one of the most widely used brass alloys for machining. So, what’s the real story? The high percentage of copper gives the material its strength and corrosion resistance, while zinc provides additional durability and machinability. The addition of lead improves machinability even further by lubricating the cutting tools, reducing friction, and allowing for faster machining speeds.

What’s more, the specific ratio of copper to zinc helps maintain an optimal balance between strength and workability. While C360 is softer than other brass alloys like C37700, this softness allows for easier shaping and cutting, making it a better choice for complex geometries that require precision. This is especially important in industries like aerospace, automotive, and electrical, where precision components are in high demand.

But here’s the kicker—C360’s lead content, which is generally 0.5% to 3%, is often a point of consideration. While it improves machinability, the presence of lead can limit its use in certain industries, particularly in food or medical applications. However, for most other applications, the benefits far outweigh this limitation.

| Composition Component | Effect on Properties |

|---|---|

| Copper (Cu) | Increases strength and corrosion resistance |

| Zinc (Zn) | Enhances durability and machinability |

| Lead (Pb) | Reduces friction during machining |

4. What Are the Major Applications of Brass C360 Material?

Brass C360’s unique combination of machinability and corrosion resistance makes it an ideal material for a variety of applications. Ready for the good part? Brass C360 is widely used in the manufacturing of precision components that require tight tolerances and smooth finishes. Some of the most common applications include:

- Connectors and fittings: Due to its excellent electrical conductivity and resistance to corrosion, Brass C360 is used in electrical connectors and fittings that must endure harsh environmental conditions.

- Plumbing parts: Brass C360 is frequently used in plumbing parts such as faucets, valves, and fittings, as its ability to withstand water pressure and corrosion makes it perfect for these applications.

- Aerospace and automotive components: C360 is also used in aerospace and automotive industries, particularly for making fasteners, gears, and valves that require precise machining and high performance.

The versatility of Brass C360 means that it is found in countless products across different industries. Whether you’re dealing with high-pressure systems or electrical components, you can rely on Brass C360 to deliver the performance you need.

| Application | Industry |

|---|---|

| Electrical connectors | Electrical |

| Faucets and valves | Plumbing |

| Gears and fasteners | Aerospace/Automotive |

5. How Does Brass C360 Compare to Other Types of Brass Alloys?

When it comes to choosing the right brass alloy for a specific application, it’s essential to understand how Brass C360 compares to other common alloys. So, what’s the difference? Brass C360 stands out primarily due to its excellent machinability, which makes it easier to work with than other brass alloys. For instance, Brass C37700, while also used in precision machining, tends to be harder, making it more challenging to machine.

On the other hand, Brass C360’s lead content, which improves machinability, can make it less suitable for certain applications where lead exposure is a concern. However, in many manufacturing environments, the benefits of ease of machining outweigh this limitation.

Brass C360 also excels in applications where corrosion resistance and electrical conductivity are critical. It performs well in environments where moisture, salts, or acids may be present, making it an excellent choice for marine, plumbing, and electrical industries.

| Property | Brass C360 | Brass C37700 | Brass C86500 |

|---|---|---|---|

| Machinability | Bagus sekali | Bagus | Fair |

| Corrosion Resistance | Tinggi | Sedang | Tinggi |

| Lead Content | 0.5-3% | None | Trace |

6. What Are the Benefits of Using Brass C360 Over Other Metals?

When considering materials for CNC machining, Brass C360 offers several benefits over other metals. But here’s the kicker—unlike steel or aluminum, Brass C360 is much easier to machine, meaning faster production times and lower tooling costs. Additionally, its excellent corrosion resistance makes it more durable in harsh environments than metals like steel, which can rust over time.

Brass C360 also has superior electrical conductivity compared to many other metals, making it the material of choice for electrical connectors and components that need to maintain high conductivity while resisting corrosion. Its relatively low cost and ease of machining make it a great choice for both small and large-scale manufacturing.

However, it’s important to note that Brass C360 isn’t always the best choice for every application. While it is excellent for precision machining and components requiring high durability, it may not be the best option for parts exposed to extreme heat or heavy mechanical stress. In these cases, materials like stainless steel or titanium might be more appropriate.

| Metal | Corrosion Resistance | Electrical Conductivity | Machinability |

|---|---|---|---|

| Brass C360 | Tinggi | Bagus sekali | Bagus sekali |

| Baja | Sedang | Rendah | Fair |

| Aluminium | Sedang | Tinggi | Bagus |

7. What is the Machinability of Brass C360 Like?

Brass C360 is renowned for its exceptional machinability. So, why does machinability matter? In CNC machining, the ease with which a material can be shaped determines the efficiency of the production process. Brass C360 is one of the most machinable alloys due to its high lead content. The addition of lead reduces friction during the cutting process, allowing tools to cut through the material smoothly, without the heat buildup that can degrade tool life in other materials.

What’s the real story here? The machinability of Brass C360 makes it a top choice for manufacturers looking for fast, efficient production. The material can be easily drilled, tapped, and turned, even at high cutting speeds. As a result, manufacturing times are significantly reduced, and the need for costly post-machining processes is minimized. In fact, machinists can typically achieve a finer surface finish with Brass C360 than with other metals, cutting down on the need for extensive polishing or grinding.

For example, if you need to create detailed components with complex geometries, Brass C360 can help you achieve precision without extensive tool wear. While other materials might require slower speeds or special tooling to machine, Brass C360 excels in these areas, making it a cost-effective option for high-precision applications.

| Machining Process | Brass C360 | Baja tahan karat | Aluminium |

|---|---|---|---|

| Cutting Speed | Tinggi | Sedang | Tinggi |

| Tool Wear | Rendah | Sedang | Rendah |

| Surface Finish | Fine | Rough | Smooth |

8. How Does Brass C360 Perform Under Different Conditions?

Brass C360 performs exceptionally well under a wide range of environmental conditions. But here’s the kicker—its corrosion resistance is one of the material’s most significant advantages. In environments that are prone to moisture, salt, or acidic conditions, Brass C360 holds up well, making it ideal for applications in plumbing, marine, and electrical industries. Whether exposed to water, chemicals, or weathering, this alloy maintains its integrity over time.

So, how does it perform under pressure? Brass C360’s strength and resistance to deformation make it a reliable choice in high-pressure environments. It remains stable under stress, ensuring that parts do not warp or degrade when exposed to mechanical forces. For instance, in plumbing applications where constant pressure is a factor, Brass C360 can withstand the demand without losing its shape or functionality.

Additionally, Brass C360 offers a relatively high temperature tolerance, making it suitable for environments where heat is a factor. While not as heat-resistant as materials like stainless steel, Brass C360 can handle temperatures up to 300°C (572°F) without significant degradation. This makes it a versatile material for use in both cold and hot environments.

| Environmental Factor | Brass C360 | Baja tahan karat | Aluminium |

|---|---|---|---|

| Corrosion Resistance | Tinggi | Tinggi | Sedang |

| Temperature Tolerance | Sedang | Tinggi | Rendah |

| Pressure Resistance | Sedang | Tinggi | Rendah |

9. What Are the Cost Considerations for Brass C360?

When considering Brass C360 for your next project, cost plays a key role in decision-making. Ready for the good part? Brass C360 offers a great balance between affordability and performance, making it one of the most cost-effective alloys in the machining world. While the raw material costs might be slightly higher than some other metals, its machinability reduces overall production costs. Faster machining speeds and longer tool life directly translate into reduced labor and tooling costs, helping keep the overall expenses down.

Additionally, the fact that Brass C360 requires less finishing work compared to other metals is another cost-saving factor. The smooth surface finish achieved during machining reduces the need for polishing, grinding, or additional treatments, saving both time and money. But here’s the deal—when you factor in the reduction in production time, the material’s relatively low cost can make a significant difference in your profit margins.

On the flip side, certain industries or projects may have more stringent requirements for material specifications, such as low lead content. If these specifications are important, the cost of Brass C360 might increase due to sourcing limitations or material alternatives. Nonetheless, Brass C360 still offers a competitive price point compared to alternatives like stainless steel, especially in applications where high machinability and corrosion resistance are priorities.

| Cost Factor | Brass C360 | Baja tahan karat | Aluminium |

|---|---|---|---|

| Material Cost | Sedang | Tinggi | Rendah |

| Machining Time | Short | Long | Sedang |

| Tool Wear | Rendah | Tinggi | Rendah |

10. What Are the Key Considerations When Choosing Brass C360 for Your Project?

Choosing the right material for your project is critical to ensuring both performance and cost-effectiveness. So, how do you determine if Brass C360 is the best option for your needs? First, consider the machinability requirements. If you’re working on a project that requires intricate machining and fast production times, Brass C360 is an excellent choice. Its high machinability means less wear on tools and faster processing times, making it an ideal choice for high-volume production.

What’s the real story here? Next, think about the environmental conditions. If your parts need to withstand moisture, salt, or other corrosive elements, Brass C360’s high corrosion resistance makes it a top contender. On the other hand, if your project requires high-strength materials that will be exposed to extreme pressures or temperatures, Brass C360 might not be the best option. In such cases, other materials like stainless steel or titanium could provide the necessary performance.

Another important factor to consider is lead content. While Brass C360’s lead content enhances machinability, it can be a drawback for certain applications where low lead exposure is a concern, such as in food or medical industries. Understanding these trade-offs is essential to choosing the right material for your specific needs.

| Consideration | Brass C360 | Baja tahan karat | Aluminium |

|---|---|---|---|

| Machinability | Bagus sekali | Bagus | Bagus |

| Corrosion Resistance | Tinggi | Tinggi | Sedang |

| Lead Content | 0.5-3% | None | None |

11. How to Properly Store and Handle Brass C360?

Proper storage and handling are key to maintaining the quality of Brass C360 and ensuring that it remains in excellent condition throughout the manufacturing process. Ready for the good part? Brass C360 should be stored in a dry, cool environment to prevent corrosion. Humidity can lead to oxidation, so it’s important to keep the material sealed and stored away from moisture. If the material is exposed to moisture, it may lose its shine and become susceptible to rust or corrosion, which can impact its performance.

What’s the best approach to handling Brass C360? Always wear gloves when handling the material to avoid transferring oils or other contaminants from your skin. Contaminants can interfere with the machining process and lead to poor surface finishes. Additionally, Brass C360 should be transported carefully to avoid any mechanical stress that could cause deformation. Using proper lifting equipment and following safety protocols will help prevent damage.

When it comes to storage, make sure the material is kept away from direct sunlight and heat sources, which can cause unwanted changes in the material’s structure over time.

| Storage Factor | Brass C360 | Baja tahan karat | Aluminium |

|---|---|---|---|

| Moisture Sensitivity | Tinggi | Rendah | Rendah |

| Temperature Sensitivity | Sedang | Tinggi | Rendah |

| Handling Precautions | Tinggi | Sedang | Rendah |

12. Can Brass C360 Be Recycled?

Yes, Brass C360 is fully recyclable. But here’s the kicker—recycling Brass C360 can help reduce waste and conserve valuable resources. This is especially beneficial in industries where materials are in high demand. Brass C360 can be melted down and reused to create new products, minimizing the need for new raw materials. This contributes to a more sustainable manufacturing process and helps reduce environmental impact.

So, what’s the real story? When Brass C360 is recycled, it retains most of its original properties, including machinability and corrosion resistance. This makes it a highly sustainable option for manufacturers looking to reduce their carbon footprint while maintaining performance. Additionally, recycling Brass C360 can help save on costs, as the price of recycled brass is often lower than that of virgin brass.

But here’s the deal—proper recycling practices must be followed to ensure that the material is reused correctly. Not all recycling facilities are equipped to handle Brass C360, so it’s essential to find certified recyclers that specialize in metal alloys.

| Recycling Factor | Brass C360 | Baja tahan karat | Aluminium |

|---|---|---|---|

| Recyclability | Tinggi | Tinggi | Tinggi |

| Property Retention | Bagus sekali | Bagus | Bagus sekali |

| Penghematan Biaya | Sedang | Tinggi | Rendah |

13. What Are the Environmental Benefits of Using Brass C360?

Brass C360 is a highly sustainable material, making it a great choice for environmentally conscious manufacturers. What’s the real benefit? Because Brass C360 can be recycled, it helps reduce the need for mining and extracting new raw materials. This, in turn, reduces environmental pollution and conserves natural resources.

Ready for the good part? Brass C360 also has a relatively low environmental impact compared to other metals, such as stainless steel or aluminum, during its production and processing. The process of creating Brass C360 requires fewer resources and less energy than producing more complex alloys or materials that are harder to machine. As such, its overall carbon footprint is lower, making it a more eco-friendly option for your next project.

Additionally, because Brass C360 is highly durable and resistant to corrosion, it has a long service life. This reduces the need for frequent replacements, further minimizing the consumption of resources over time.

| Environmental Impact | Brass C360 | Baja tahan karat | Aluminium |

|---|---|---|---|

| Carbon Footprint | Rendah | Sedang | Rendah |

| Recyclability | Tinggi | Tinggi | Tinggi |

| Durability | Tinggi | Tinggi | Sedang |

14. How to Find the Right Supplier for Brass C360?

When sourcing Brass C360 for your project, it’s essential to find a reliable supplier that offers high-quality material at competitive prices. So, how do you find the right one? First, you want to look for a supplier with experience in providing Brass C360 for CNC machining applications. An experienced supplier will understand the specific requirements of your industry and be able to provide materials that meet your exact needs.

What’s the real story here? It’s also important to check the supplier’s certifications and quality control processes. A reputable supplier should provide certificates of authenticity and undergo regular quality checks to ensure the consistency and reliability of the material. Don’t forget to compare prices from different suppliers, but always prioritize quality over cost. Choosing a supplier who offers consistent quality will help avoid delays or issues in production.

Additionally, consider the supplier’s shipping times and customer service. A supplier that can quickly deliver Brass C360 to your location and responds to inquiries promptly will save you time and hassle in the long run.

| Supplier Factor | Brass C360 Supplier 1 | Brass C360 Supplier 2 | Brass C360 Supplier 3 |

|---|---|---|---|

| Experience | Tinggi | Sedang | Tinggi |

| Certification | Yes | Yes | No |

| Delivery Speed | Fast | Sedang | Slow |

15. What Are the Future Trends in Brass C360 Usage?

As industries evolve, so too does the demand for materials like Brass C360. So, what’s on the horizon? The future of Brass C360 looks promising, with increased demand expected in the electronics, automotive, and plumbing sectors. As manufacturing processes continue to improve, the use of Brass C360 in precision parts will grow, especially in industries that require high performance and durability.

What’s the real story here? The future of Brass C360 also lies in its potential for customization. Advances in metallurgy could lead to new versions of Brass C360 that offer enhanced properties, such as even higher corrosion resistance or improved machinability. These innovations will make the material even more valuable in high-demand industries where performance is paramount.

The key takeaway? Brass C360 is likely to remain a go-to material in many industries, with growing applications in advanced manufacturing processes.

| Trend | Brass C360 | Baja tahan karat | Aluminium |

|---|---|---|---|

| Market Demand | Increasing | Stable | Increasing |

| Innovation Potential | Tinggi | Sedang | Tinggi |

| Industry Adoption | Tinggi | Tinggi | Sedang |

Bagian FAQ

Pertanyaan 1: What is Brass C360 material?

Brass C360 is a copper-zinc alloy that contains small amounts of lead. It is known for its excellent machinability and corrosion resistance, making it ideal for precision CNC machining and a variety of applications.

Pertanyaan 2: How does Brass C360 work in CNC machining?

Brass C360 is easy to machine due to its high lead content, which reduces friction during machining. This allows for faster cutting speeds and reduced tool wear, making it an ideal choice for precision machining.

Pertanyaan 3: What is the difference between Brass C360 and other brass alloys?

Brass C360 stands out for its excellent machinability due to its lead content. It is softer than other alloys like C37700, making it easier to machine, but it may not be suitable for all applications, such as those requiring low lead content.

Pertanyaan 4: Is Brass C360 more expensive than other materials?

Brass C360 is generally more affordable than other high-strength materials like stainless steel and titanium. Its ease of machining and competitive pricing make it an economical choice for high-volume production.

Pertanyaan 5: Can Brass C360 be recycled?

Yes, Brass C360 is recyclable. Recycling Brass C360 helps conserve resources and reduce environmental impact, making it a sustainable material choice for manufacturing industries.