Introduzione

CNC machining is a versatile and highly efficient way to create precise metal components, whether you’re a hobbyist or a professional. In this article, we will dive deep into metal CNC projects and explore the best projects to try in 2025. We’ll look at beginner-friendly ideas, the necessary tools, how CNC projects work, and much more. By the end, you’ll be ready to take on your own metal CNC creations, understanding everything from materials to advanced techniques. So, let’s get started and see what’s in store for metal CNC projects this year.

1. What Are Metal CNC Projects?

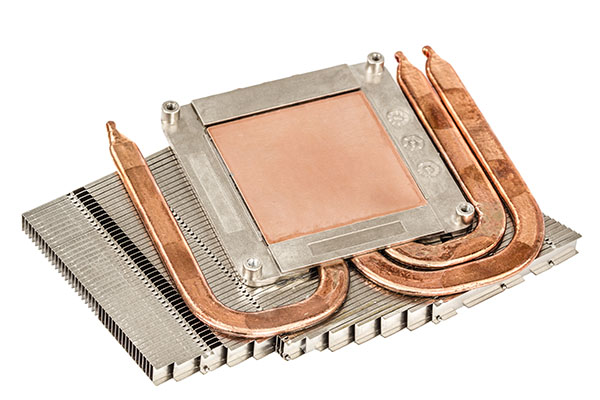

So, what exactly are metal CNC projects? Well, metal CNC projects are creations made using computer numerical control (CNC) machines that cut, mill, or shape metal into specific designs. CNC machining has become the go-to method for creating metal components due to its precision and versatility. It can be used to create a variety of products, ranging from simple parts for machinery to intricate designs for art and décor.

Metal CNC projects are typically made with materials such as aluminum, brass, stainless steel, or titanium, depending on the project’s requirements. But here’s the kicker – these projects can range from small components like screws to large-scale items like metal sculptures or even custom tools. The beauty of CNC machining lies in its ability to handle various materials and create both functional and decorative objects with unmatched precision.

Why Do Metal CNC Projects Matter?

The importance of metal CNC projects can’t be overstated. They’re not only central to manufacturing industries but also crucial in prototyping, custom fabrication, and even artistic endeavors. Here’s why they matter: CNC machines can replicate designs with incredible accuracy, which is essential for industries like aerospace, automotive, and medical devices. The same precision that makes CNC machining ideal for these high-stakes industries can also be used in smaller, more creative endeavors, like custom metal signage or unique home décor.

What You Need for Metal CNC Projects

If you’re planning on diving into metal CNC projects, you need to understand the necessary tools and equipment. A basic CNC machine is a good starting point, but you’ll also need to make sure that you have the right cutting tools, a computer for design, and materials. You don’t need a high-end setup to get started, but understanding the basics of CNC machines and the software that drives them is crucial. Now, let’s take a closer look at how these machines work and what makes them so effective for metal projects.

| Key Equipment | Descrizione | Scopo |

|---|---|---|

| CNC Machine | A device that reads CAD designs and performs milling, cutting, and drilling. | Core tool for creating precision metal parts. |

| CAD Software | Software used for designing the 3D models. | Used to create precise designs for CNC machining. |

| Cutting Tools | Tools that fit into the CNC machine to cut metal. | Essential for shaping and cutting metal accurately. |

| Material (e.g., aluminum) | Different metals used depending on project. | Provides the raw material for machining. |

2. Why Should You Try Metal CNC Projects?

Now, you might be wondering – why should you bother trying metal CNC projects? For one, metal CNC projects offer you the chance to create high-precision items that would be difficult or impossible to make by hand. Whether you’re in manufacturing, design, or a hobbyist making custom parts, CNC machining allows you to replicate designs with amazing accuracy. Ready for the good part? Metal CNC machining can be done on materials ranging from soft aluminum to tough stainless steel, giving you the flexibility to handle different types of projects.

Metal CNC projects are also extremely time-efficient. Once the design is loaded into the CNC machine, it can run on its own, producing parts or products with minimal supervision. This makes it an excellent choice for both large-scale production and prototyping. Plus, it’s perfect for creating highly customized pieces. Want a custom sign for your business or a unique piece of artwork? CNC machines can turn your ideas into a reality.

Another reason why metal CNC projects are worth exploring is their versatility. From functional parts to complex sculptures, CNC machining allows you to create almost anything. In fact, CNC technology is used in a variety of industries, including automotive, aerospace, medical, and even jewelry making. What’s the real story? CNC is the backbone of modern manufacturing, allowing businesses to produce complex parts faster, more accurately, and at a lower cost than ever before.

| Beneficio | Details |

|---|---|

| High Precision | CNC machines offer unparalleled accuracy in metalworking. |

| Time Efficiency | Once programmed, CNC machines can operate independently, saving time. |

| Versatility | CNC can be used for a variety of projects, from tools to art. |

| Cost-Effectiveness | Reduces labor and material waste, leading to lower production costs. |

3. What Are the Best Metal CNC Projects for Beginners?

You might be thinking, “Is this something I can do as a beginner?” The short answer: absolutely! There are plenty of metal CNC projects that are perfect for those just starting out. Let’s explore a few beginner-friendly ideas that you can try out in 2025.

One great project for beginners is creating custom keychains or small metal tokens. These items are not only simple to design but also easy to cut with a CNC machine. What’s the real story here? These projects allow beginners to get comfortable with the design process and understand how the machine works without the pressure of a large-scale project.

Another beginner-friendly project could be making custom brackets or simple mechanical parts. These parts may seem basic, but they require precision, which is exactly what CNC machines are designed for. As you progress, you can start experimenting with more complex projects, like small gears or intricate pieces of jewelry.

For those with a bit more experience, metal signage is an excellent project to take on. Custom signs can be used for businesses, events, or even as artistic home décor. CNC machines can cut out precise shapes, letters, and logos with ease, making it an ideal project for anyone looking to create something personal and professional. Ready for the good part? Once you’ve mastered these beginner projects, you can start moving on to larger, more intricate designs.

| Project Idea | Difficulty | Skills Developed | Materials Needed |

|---|---|---|---|

| Custom Keychains | Easy | Design and basic CNC operations | Aluminum, Brass |

| Mechanical Brackets | Medio | Precision cutting, basic machining skills | Steel, Aluminum |

| Custom Signs | Medio | Advanced design, precision cutting | Stainless Steel, Aluminum |

4. How Do Metal CNC Projects Work?

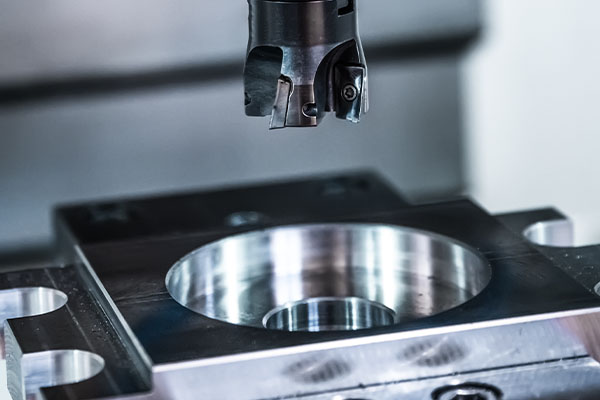

Now, let’s get into the nuts and bolts of how these metal CNC projects actually work. Metal CNC machining involves taking a computer-aided design (CAD) and converting it into a set of instructions that the CNC machine can follow. The machine uses tools to cut, drill, or mill the metal into the desired shape. But here’s the kicker – CNC machines are highly automated, which means they can operate without constant supervision, making them ideal for large-scale production.

The CNC process starts with designing the project in a CAD program. The design is then translated into G-code, which is a language that CNC machines understand. Once the design is loaded into the machine, it starts the cutting process, following the exact path outlined in the G-code. This allows for high precision and repeatability, which is essential when producing parts that need to meet strict specifications.

As the machine works, it uses different cutting tools to shape the material. The cutting tool is selected based on the type of metal and the complexity of the project. For example, a high-speed steel tool may be used for soft materials like aluminum, while a carbide tool might be better suited for harder materials like stainless steel. Once the cutting is complete, the part is ready for use or further processing.

| Process Stage | Descrizione | Tools Used |

|---|---|---|

| Design Creation | Create the project in CAD software. | CAD Software (e.g., SolidWorks) |

| G-code Generation | Convert the design into machine-readable instructions. | G-code generator tools |

| CNC Machine Operation | CNC machine cuts, drills, or mills the material. | CNC machine, cutting tools |

| Finalization | The final product is inspected and polished. | Inspection tools, finishing tools |

5. What Tools Do You Need for Metal CNC Projects?

If you’re just getting started with metal CNC projects, you’ll need the right tools to ensure the job is done right. A CNC machine is the centerpiece of any CNC project, but you’ll also need a variety of other tools to get the most out of your machine. These tools will help you cut, shape, and finish the metal with precision.

First and foremost, you’ll need the CNC machine itself. There are several types of CNC machines, but for metal projects, a CNC milling machine is typically the best option. CNC mills use rotary tools to cut through metal, and they come in various sizes and configurations depending on your needs. Next, you’ll need cutting tools. These tools come in various shapes, such as end mills, drills, and reamers, and are selected based on the material you’re working with and the shape you need to achieve. What’s the real story? High-quality cutting tools are essential for achieving the precision and finish you want in your metal CNC projects.

In addition to the CNC machine and cutting tools, you’ll need other supporting equipment, such as clamps, measuring instruments, and possibly a rotary table. Clamps are used to secure the material in place during machining, while measuring instruments like calipers and micrometers are needed to ensure the part meets the required dimensions. Finally, a computer running CAD software is essential for creating the designs and generating the G-code for the CNC machine.

| Attrezzo | Descrizione | Scopo |

|---|---|---|

| CNC Milling Machine | A machine that uses rotary tools to cut metal. | Core tool for cutting metal. |

| Cutting Tools | Tools for cutting, drilling, and shaping metal. | Used for shaping and cutting parts. |

| Clamps | Devices to hold the material steady during machining. | Secure the material during work. |

| Measuring Instruments | Tools for measuring the part’s dimensions. | Ensure precision in finished product. |

6. How to Design Metal CNC Projects?

Designing a metal CNC project requires a solid understanding of both the design process and the capabilities of the CNC machine. CAD software is used to create the design, and it’s essential to understand how to use the software effectively. What’s the real story here? Your design needs to be practical for machining, meaning it should take into account tool paths, material allowances, and machining constraints.

When designing a metal project, start by selecting the material you want to use. Different materials will require different tool paths and cutting speeds. For example, softer materials like aluminum can be machined at higher speeds, while harder materials like stainless steel will require slower speeds to avoid tool wear. Once the material is selected, you can move on to designing the part. The design should be created with precise dimensions and tolerances in mind, ensuring that the part will fit into its intended application.

Once the design is complete, the next step is to generate the G-code. G-code is the language that tells the CNC machine what to do, from moving the tool to cutting the material. The G-code should be generated based on the machine’s capabilities and the specific material being used. Now, let’s move on to the process of setting up the CNC machine for your project.

| Fare un passo | Details | Tools/Software |

|---|---|---|

| Select Material | Choose the appropriate metal based on the project. | CAD Software, Material Guide |

| Design the Part | Create the design with accurate measurements. | CAD Software |

| Generate G-code | Convert the design into machine-readable code. | G-code Generator Tools |

7. How to Set Up Your CNC Machine for Metal Projects?

Setting up your CNC machine properly is critical to the success of your metal CNC project. If you don’t set everything up correctly, the machine won’t be able to cut the material precisely, and you could end up wasting time and resources. What’s the real story here? Proper machine setup ensures a smooth, efficient process with minimal errors.

First, start by ensuring that the machine is calibrated and aligned correctly. This includes checking the tool alignment, making sure the cutting tools are securely in place, and verifying that the machine’s coordinates are correct. After the machine is set up, load the G-code that was generated for your design. Double-check that the machine is reading the code correctly and that it will follow the right tool paths.

Next, secure your material onto the CNC machine bed using clamps. The material needs to be firmly held in place to prevent movement during machining. Once the material is secured, it’s time to test the machine with a dry run. A dry run simulates the cutting process without actually cutting the material, allowing you to spot any potential problems before the real cut begins.

| Setup Step | Details | Tools/Equipment |

|---|---|---|

| Machine Calibration | Ensure the CNC machine is aligned and calibrated. | Calibration tools, manuals |

| Load G-code | Import the G-code into the CNC machine. | CAD software, G-code generator |

| Secure Material | Clamp the material to the CNC bed. | Clamps, securing tools |

8. What Are Some Popular Metal CNC Projects to Try?

Now that you understand the basics of metal CNC projects, let’s take a look at some popular projects you can try. Whether you’re a beginner or an experienced CNC machinist, there are countless metal projects to explore. From functional components to artistic creations, the possibilities are endless. Ready for the good part? Here are a few project ideas to get you started.

First up, metal sculptures are a fantastic way to showcase the precision of CNC machining. With the right tools and techniques, you can create intricate, detailed sculptures out of metal. These projects allow for a lot of creativity, as you can design sculptures in a variety of shapes and sizes. Another great project is creating custom metal tools or mechanical parts. From wrenches to gears, CNC machines are perfect for creating custom, high-precision parts that you can use in other projects.

Functional items like metal brackets, frames, and even custom signage are also popular CNC projects. Custom metal signage can be a great way to advertise a business or add a personal touch to your home décor. Once you’ve mastered the basics, you can experiment with more complex projects, such as creating custom motorcycle parts or even aerospace components. But here’s the kicker – the more projects you complete, the more you’ll learn, and soon you’ll be tackling larger and more intricate designs.

| Project Type | Difficulty | Tools Needed | Outcome |

|---|---|---|---|

| Metal Sculptures | Medio | CNC Milling Machine, CAD Software | Unique artistic creations |

| Custom Tools | Hard | CNC Milling, Lathe, CAD Software | Precision mechanical parts |

| Custom Signage | Medio | CNC Milling, Laser Cutter | Professional, personalized signage |

9. How Can You Improve Your Skills in Metal CNC Projects?

Improving your skills in metal CNC projects requires practice and learning from your experiences. It’s essential to start with small, simple projects and gradually work your way up to more complex ones. Want to take your skills to the next level? One of the best ways to improve is by joining online forums or communities where CNC machinists share tips, techniques, and project ideas. You can learn from others, get feedback, and stay motivated to push your abilities further.

Another key to improvement is experimenting with different materials. Working with various metals, such as aluminum, steel, and brass, will help you understand their properties and how they respond to different cutting techniques. As you experiment, don’t be afraid to make mistakes. What’s the real story here? Making mistakes is part of the learning process. Every mistake provides an opportunity to improve your technique and learn something new.

Taking online courses or attending workshops can also be beneficial. Many professionals offer courses that can help you hone your skills and stay up to date with the latest CNC machining technology. The more you learn, the more confident you’ll become in taking on more complex projects. Keep pushing your boundaries and challenging yourself to create better, more intricate metal CNC pieces.

| Improvement Strategy | Beneficio | Tools/Resources |

|---|---|---|

| Join CNC Communities | Learn from others, share experiences | Online forums, social media |

| Experiment with Materials | Understand the properties of different metals | Various metals, CNC machine |

| Take Online Courses | Learn new skills, stay up-to-date with technology | CNC machining courses, workshops |

10. What Materials Are Best for Metal CNC Projects?

When it comes to metal CNC projects, choosing the right material is crucial. The material you select affects the outcome of your project, including factors like strength, durability, and ease of machining. Some metals are easier to machine than others, and understanding these differences is essential. What’s the real story here? Choosing the right material isn’t just about the end product but also about optimizing your machining process.

One of the most popular materials for metal CNC projects is aluminum. It’s lightweight, easy to machine, and highly versatile. Aluminum is commonly used in a wide range of industries, from aerospace to automotive, and it’s ideal for projects that require high strength and low weight. The beauty of aluminum is that it’s also relatively inexpensive compared to other metals, making it a great option for beginners.

Steel is another excellent choice, especially for projects that require more strength and durability. While steel is harder to machine than aluminum, CNC machines can handle it with the right cutting tools and settings. Stainless steel, in particular, is known for its resistance to corrosion, making it a great choice for outdoor applications or parts exposed to harsh environments. Other metals you might consider include brass, copper, and titanium, each with its own set of benefits depending on your project’s requirements.

Choosing the best material for your CNC project depends on the specific needs of the project, including its function, strength requirements, and budget. Let’s take a look at a quick comparison of some common materials used in metal CNC machining.

| Materiale | Properties | Usi comuni | Ease of Machining |

|---|---|---|---|

| Alluminio | Lightweight, corrosion-resistant | Aerospace, automotive, and consumer products | Easy |

| Acciaio | Strong, durable, versatile | Structural components, automotive | Moderate |

| Acciaio inossidabile | Strong, corrosion-resistant | Medical devices, outdoor equipment | Difficult |

| Ottone | Malleable, corrosion-resistant | Musical instruments, electrical components | Easy |

| Titanio | Extremely strong, lightweight, corrosion-resistant | Aerospace, medical implants | Difficult |

11. How Do You Achieve Precision in Metal CNC Projects?

Achieving precision in metal CNC projects is essential for producing high-quality parts and components. What’s the real story here? The precision of CNC machining is one of its biggest advantages, but it requires careful planning and execution. Whether you’re machining simple brackets or intricate parts, precision ensures that everything fits together perfectly and functions as intended.

The first step in achieving precision is machine calibration. CNC machines need to be calibrated to ensure that they’re operating correctly. This involves checking the machine’s alignment and adjusting the settings to make sure the tools are positioned correctly. If the machine is off by just a tiny fraction, it can lead to errors in the final product, so calibration is a critical part of the process.

Next, tool selection plays a significant role in achieving precision. Different cutting tools are used depending on the material and the type of cut needed. For example, using a high-quality carbide tool is ideal for cutting hard metals like stainless steel, as it will maintain its sharpness longer and produce more accurate cuts. Additionally, the speed and feed rate of the machine should be adjusted for the material being cut. Faster speeds can work for softer materials, while harder metals require slower speeds to avoid tool wear and maintain accuracy.

Finally, measuring the workpiece during the machining process is vital. Calipers, micrometers, and other precision measurement tools are used to check the dimensions of the part. Even a slight deviation in size can affect the part’s performance, so accuracy is essential. Regular measurements throughout the machining process help ensure that everything is on track and that the final product meets the required tolerances.

| Precision Factor | Descrizione | Tools Used |

|---|---|---|

| Machine Calibration | Ensures that the CNC machine is aligned correctly. | Calibration tools, manuals |

| Tool Selection | Choosing the right tool for the material and project. | Cutting tools, carbide inserts |

| Speed and Feed Rate | Adjusting cutting speed to match the material. | CNC machine settings |

| Measuring the Part | Checking the dimensions of the part for accuracy. | Calipers, micrometers, inspection tools |

12. What Are the Common Challenges in Metal CNC Projects?

While metal CNC projects offer incredible advantages, they also come with their fair share of challenges. Understanding these obstacles is key to overcoming them and producing successful projects. Ready for the good part? Let’s break down some of the most common challenges and how you can tackle them.

One of the biggest challenges is managing material costs. Metals like titanium and stainless steel can be expensive, and wastage due to errors or miscalculations can drive costs even higher. To combat this, it’s essential to carefully plan your designs and optimize the machining process. Reducing tool wear and improving efficiency can help minimize material waste, keeping costs down.

Another common issue is machine downtime. CNC machines require regular maintenance, and technical issues can arise, leading to unplanned stoppages. Regular maintenance and routine checks can help prevent many of these problems. It’s also a good idea to have spare parts on hand for quick repairs.

Finally, another challenge in metal CNC projects is the potential for human error. Even the most experienced machinists can make mistakes, especially when working with complex designs. The best way to avoid errors is through thorough planning and testing. Before starting a large project, run a test piece to ensure everything is working as expected. If any adjustments are needed, make them before proceeding with the final part.

| Sfida | Soluzione | Tools/Equipment |

|---|---|---|

| Material Costs | Plan and optimize the design to minimize waste. | CAD software, material calculator |

| Machine Downtime | Regular maintenance and spare parts availability. | Maintenance tools, manuals |

| Human Error | Conduct test runs and ensure precision. | Test pieces, inspection tools |

13. How Can Metal CNC Projects Benefit Businesses?

Metal CNC projects aren’t just for hobbyists; they can bring significant benefits to businesses as well. What’s the real story here? CNC machining is a game-changer for companies in various industries, allowing them to produce high-quality parts quickly and efficiently. Let’s dive into how these projects can benefit your business.

One of the primary benefits is the ability to create custom parts at scale. CNC machining allows businesses to produce complex parts with a high degree of accuracy and repeatability. Whether you’re making custom brackets for machinery or producing high-volume parts for consumer products, CNC machines ensure consistency across all items, which is essential for maintaining quality.

Another major advantage is cost savings. While CNC machines may have an upfront cost, they reduce labor costs, material waste, and production time. In many cases, CNC machines can operate 24/7, producing parts without needing constant supervision. This leads to higher throughput, reduced lead times, and ultimately, greater profitability.

Furthermore, CNC projects are highly flexible. Companies can quickly adapt to new designs and customizations without needing to retool or change their manufacturing processes. Whether it’s a small batch of parts or a large-scale production run, CNC machining can handle it all. The flexibility of CNC allows businesses to stay competitive in rapidly changing markets, responding to customer demands with speed and accuracy.

| Beneficio | Descrizione | Impact on Business |

|---|---|---|

| Custom Parts at Scale | Produce highly precise custom parts quickly. | Consistency and high quality across products. |

| Risparmio sui costi | Reduce labor costs, material waste, and production time. | Increased profitability and efficiency. |

| Flessibilità | Easily adapt to new designs and customizations. | Ability to stay competitive and meet customer needs. |

14. What Are the Future Trends in Metal CNC Projects?

The world of CNC machining is constantly evolving, and staying ahead of the curve is key to maintaining a competitive edge. What’s the real story here? In the next few years, we can expect significant advancements in technology, materials, and techniques that will further enhance the capabilities of metal CNC projects.

One major trend is the integration of automation and artificial intelligence (AI) into CNC machines. AI will allow for smarter machines that can adjust cutting speeds, tool paths, and even detect errors in real-time. This will improve efficiency, reduce waste, and increase overall productivity. Automation is also making it easier for businesses to scale production without needing to increase labor costs.

Another trend to watch is the development of new materials for CNC machining. While metals like aluminum and steel are widely used, researchers are working on creating lighter, stronger, and more sustainable materials for machining. Innovations in additive manufacturing (3D printing) are also influencing CNC projects, allowing for more intricate designs and customizations.

Finally, sustainability will be a key focus in the future of metal CNC projects. Companies are looking for ways to reduce energy consumption, minimize waste, and recycle materials. As more companies embrace sustainability, we can expect to see an increase in the use of eco-friendly materials and energy-efficient CNC machines.

| Trend | Descrizione | Future Impact |

|---|---|---|

| AI and Automation | Smarter CNC machines that adjust based on real-time data. | Increased efficiency, reduced errors. |

| New Materials | Development of lighter, stronger materials for machining. | Broader range of applications. |

| Sostenibilità | Focus on reducing waste and energy consumption. | Environmentally friendly practices. |

15. How Can You Start Your Own Metal CNC Projects?

Starting your own metal CNC projects might seem intimidating at first, but with the right tools, materials, and knowledge, you can create incredible results. Ready for the good part? Let’s break down how you can get started with metal CNC machining.

First, invest in a CNC machine that suits your needs. There are different types of CNC machines available, ranging from entry-level desktop models to large industrial machines. For beginners, a small desktop CNC machine is a great starting point. These machines are affordable and capable of handling smaller projects. As you gain more experience, you can upgrade to a larger machine that offers more capabilities.

Next, learn how to use CAD software to create your designs. Many CNC machines come with software packages that are compatible with popular CAD programs like SolidWorks or AutoCAD. Once you’ve created your design, generate the G-code to tell the machine what to do. From there, you can load the code into your CNC machine and begin the cutting process.

Finally, practice makes perfect. Don’t expect to master CNC machining overnight. Start with simple projects, and gradually work your way up to more complex ones. Over time, you’ll gain confidence and skill, allowing you to tackle more ambitious metal CNC projects.

| Fare un passo | Azione | Tools Needed |

|---|---|---|

| Choose a CNC Machine | Select a machine based on your needs and budget. | CNC Machine, manuals |

| Learn CAD Software | Familiarize yourself with software to design your projects. | CAD Software |

| Practice Projects | Start with simple designs and work your way up. | Test material, measuring tools |

Sezione FAQ

Domanda 1: What is a Metal CNC Project?

A Metal CNC project involves using CNC machines to cut, shape, and manipulate metal into precise designs or functional parts. These projects range from simple parts for machinery to intricate designs for art and décor.

D2: How does CNC machining work for metal projects?

CNC machining for metal works by feeding a computer-aided design (CAD) file into a CNC machine, which then guides cutting tools to shape the metal accurately according to the design specifications.

D3: What tools do I need to start a metal CNC project?

To start a metal CNC project, you need a CNC machine, suitable cutting tools (e.g., drills, mills), CAD software for design, and materials like aluminum, steel, or brass.

D4: How do I design a CNC project for metal?

To design a CNC project for metal, use CAD software to create a detailed design, ensuring it matches the capabilities of the CNC machine and selecting the appropriate material.

D5: What are some examples of metal CNC projects?

Examples of metal CNC projects include creating custom metal parts, prototypes, functional items like tools and brackets, and artistic sculptures.