導入

The world of CNC machining technology is evolving rapidly. With advancements occurring at an unprecedented pace, businesses in manufacturing and machining need to keep up to stay competitive. This article will dive deep into the cutting-edge technologies shaping the industry today. From automation to new materials, AI, and software improvements, we’ll cover all the major advancements and why they matter for the future of CNC machining. Ready for the good part? Let’s break it down.

1. What Are the Latest CNC Machining Technologies?

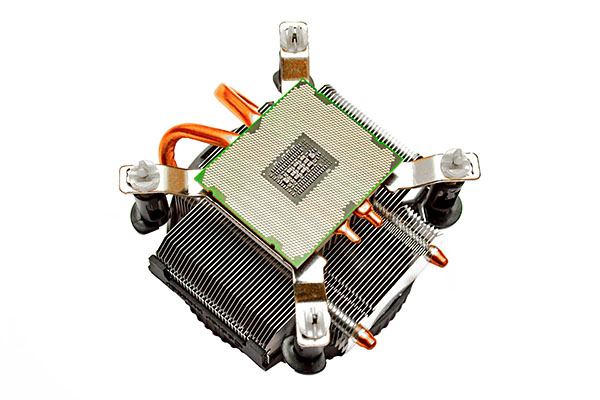

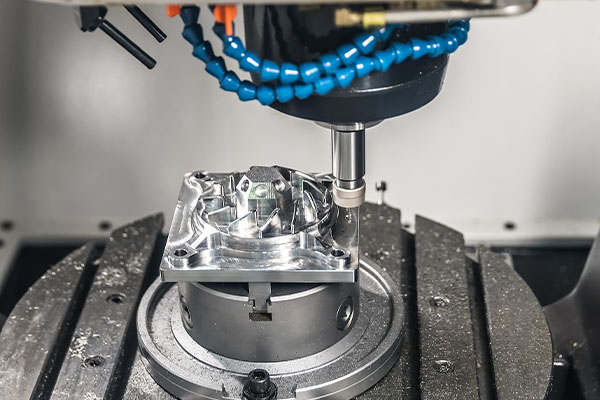

CNC machining has long been a staple in precision manufacturing, but new technologies are pushing the boundaries of what’s possible. The latest CNC machines are far more than just automated tools. They incorporate cutting-edge technology to deliver precision, efficiency, and versatility that was previously unimaginable.

What’s the real story? The industry has seen significant advancements in 5-axis machining, which allows for more complex cuts without having to reposition the workpiece multiple times. This reduces cycle time and increases the precision of each part. Additive manufacturing is also making its way into CNC, where 3D printing and CNC are used together for hybrid processes.

The key here is not just the new machines, but how they integrate with existing systems. Today’s CNC machines don’t just cut; they communicate with each other and other production equipment. In short, they’re becoming part of the larger industrial Internet of Things (IoT). What does that mean for businesses? You can expect faster production, fewer mistakes, and more flexibility in what can be created.

Here’s the kicker: these advancements don’t just help manufacturers get ahead—they help them stay ahead. By leveraging the latest CNC technologies, businesses are better equipped to meet the evolving needs of their clients, providing higher-quality products faster and more efficiently.

CNC Technology Overview

| テクノロジー | 利点 | Key Application Areas |

|---|---|---|

| 5-Axis Machining | High precision and flexibility | Aerospace, automotive, medical |

| Additive CNC | Hybrid process combining 3D printing | Prototyping, small batch runs |

| IoT Integration | Real-time data, machine communication | Automation, monitoring, efficiency |

2. How Do New CNC Machines Improve Precision?

Precision is the cornerstone of CNC machining, and new technologies are making it even better. The latest machines come with advanced software and hardware that fine-tune the manufacturing process to reduce error margins.

One major improvement is in the software. With modern CAM (Computer-Aided Manufacturing) systems, machinists can create simulations of their operations before any cutting happens. This drastically reduces the likelihood of errors that could otherwise occur during the real process. Moreover, CNC machines are now capable of adjusting their movements in real-time to correct for minute deviations, ensuring that every part is crafted to the exact specifications.

But here’s the kicker: machine hardware has also seen major improvements. For instance, some machines now feature enhanced sensors that measure both the workpiece and the tool in real-time. This allows for instant adjustments and guarantees precision across even the most complex jobs. These sensors are particularly helpful in industries like aerospace, where tolerances can be incredibly tight, sometimes down to the micrometer.

Finally, some new CNC systems also feature advanced cutting tools made from stronger, more durable materials. These tools can withstand higher speeds and temperatures, providing both precision and longevity.

Precision and Accuracy Improvements

| CNC Machine Type | Precision Benefits | Key Features |

|---|---|---|

| 5-Axis Machines | Increased precision for complex parts | Real-time adjustments |

| Advanced Cutting Tools | Less tool wear, sharper cuts | Higher speeds, durable tools |

| CNC Sensors | Real-time error correction | Measurement of tool and workpiece |

3. What Are the Benefits of Automation in CNC Machining?

Automation is one of the most significant changes to CNC machining in recent years. As labor costs rise and the demand for faster turnaround times increases, many manufacturers are looking for ways to automate their CNC operations.

So, what’s the big deal? Automated CNC machines can run 24/7 with minimal human intervention, cutting down on downtime and boosting productivity. This isn’t just about having machines running while operators sleep—it’s about making smarter decisions faster. Automation allows for the seamless integration of robotics, which can handle both loading and unloading parts automatically. This reduces the time spent manually setting up machines or moving finished parts.

What’s the real story here? Automation doesn’t just save time; it also ensures consistency. With automated CNC systems, each part can be produced to the same standards with little variation. This is a game-changer for industries like medical device manufacturing, where precision and reliability are critical.

Ready for the good part? The future of CNC automation includes not only robotics but also AI. Imagine CNC machines that can learn from past operations and make adjustments on the fly without human input. The efficiency gains from such systems could be massive, allowing for shorter lead times and more customized products.

Automation Impact

| Automated System | 利点 | 業界への影響 |

|---|---|---|

| Robotics Integration | Faster production, reduced labor | Medical, automotive |

| AI Optimization | Self-adjusting, efficient production | Manufacturing, aerospace |

| CNC Automation | 24/7 operation, reduced errors | Industrial, manufacturing |

4. How Does 3D Printing Fit Into CNC Machining?

3D printing, or additive manufacturing, has long been seen as a disruptive technology. But it’s now being integrated with CNC machining, creating hybrid manufacturing systems that offer the best of both worlds.

What’s the real story? 3D printing allows manufacturers to create complex geometries that would otherwise be difficult or impossible to machine. However, 3D printing alone isn’t always the most efficient process for high-volume manufacturing. That’s where CNC machining comes in. By using both technologies in tandem, manufacturers can produce parts with intricate details and then finish them with the precision of CNC machines.

This hybrid approach also opens the door to new materials. 3D printing is often limited to plastics, but CNC machines can work with a much broader range of materials, including metals. The combination of both processes allows for new, highly specialized components that can be used in industries ranging from aerospace to consumer electronics.

Here’s the kicker: hybrid CNC/3D printing systems also allow for faster prototyping. Designers can quickly print a part to test, then use CNC machining to refine it further. This significantly reduces the time between design and production, which is critical for industries like automotive, where getting to market quickly is key.

Hybrid Manufacturing Systems

| テクノロジー | 利点 | Use Cases |

|---|---|---|

| 3D Printing + CNC | Combines speed and precision | Aerospace, automotive, medical |

| CNC for Finishing | Higher material versatility | Prototyping, small batch runs |

| Hybrid Prototyping | Quick iteration, faster testing | Product development, innovation |

5. What Is the Impact of Artificial Intelligence on CNC Machining?

Artificial intelligence (AI) is gradually making its way into CNC machining, bringing even more innovation to the process. By integrating AI, CNC systems can become more autonomous, capable of optimizing their operations based on data collected from sensors and past performance.

But here’s the kicker: AI can also help predict potential problems before they happen. By analyzing data from past machine failures, AI can identify patterns that signal impending issues. This allows maintenance to be scheduled proactively, reducing downtime and extending the life of machines.

What’s the real story here? The integration of AI allows for the optimization of complex operations. For example, AI-powered CNC systems can automatically adjust parameters like cutting speed and feed rate to achieve the best balance between speed and precision.

Ready for the good part? The future of AI in CNC machining is vast. Imagine machines that can adjust themselves during operations, learning from each part they make and fine-tuning their processes to deliver better results over time. This will significantly enhance both efficiency and quality, helping manufacturers produce more complex parts faster and more precisely.

AI in CNC Machining

| AI Integration | 利点 | Key Industries |

|---|---|---|

| Predictive Analytics | Preventive maintenance, uptime | 航空宇宙、自動車 |

| Autonomous Systems | Self-optimization, precision | Manufacturing, medical devices |

| Data-Driven Systems | Real-time adjustments, better results | Electronics, high-tech |

結論

CNC machining technology is evolving at an incredible pace. From automation to AI, hybrid manufacturing to the integration of new materials, the future of CNC machining looks more exciting than ever. What’s the real story? These advancements are making CNC systems faster, more accurate, and more versatile than ever before. For businesses in manufacturing, staying on top of these innovations is crucial to remaining competitive.

As these technologies continue to evolve, manufacturers will be able to produce more complex parts with less time and effort, reducing costs and improving quality. Ready for the good part? Embrace the new CNC technologies today, and watch your business thrive in the future.

6. What Are the Latest Materials Used in CNC Machining?

CNC machining has always been about precision, but the materials used in the process are just as important as the machines themselves. The latest advancements in CNC machining materials offer a blend of strength, durability, and versatility. In fact, material innovations are often the driving force behind the capabilities of modern CNC technology.

So, what’s the big deal? The emergence of advanced materials like titanium alloys, carbon fiber composites, and high-performance polymers is revolutionizing industries that rely on CNC machining. These materials offer enhanced strength-to-weight ratios, resistance to high temperatures, and improved overall performance, making them ideal for sectors such as aerospace, automotive, and medical devices.

Here’s the kicker: high-performance alloys like Inconel are now being machined with CNC, allowing manufacturers to create components that can withstand extreme conditions, such as high-pressure turbines in jet engines. Similarly, carbon fiber reinforced plastics (CFRP) are becoming increasingly popular for automotive parts, as they reduce weight while maintaining high strength, which is crucial for fuel efficiency.

What’s the real story here? The choice of material has a direct impact on the final product’s performance, lifespan, and cost-effectiveness. By utilizing these advanced materials, businesses can manufacture products that meet stricter regulatory standards while delivering higher-quality results in less time.

CNC Machining Material Benefits

| 材料 | Key Benefits | Key Applications |

|---|---|---|

| Titanium Alloys | High strength, corrosion resistance | Aerospace, medical implants |

| Carbon Fiber Composites | Lightweight, high strength | Automotive, sporting equipment |

| Inconel | Heat-resistant, durable | Aerospace, energy generation |

| High-Performance Polymers | Chemical resistance, flexibility | Electronics, medical devices |

7. How Is CNC Machining Benefiting the Aerospace Industry?

Aerospace is an industry where precision and safety are paramount, making CNC machining an indispensable tool. The aerospace industry relies heavily on CNC for manufacturing complex components like turbine blades, engine parts, and structural frames. So, what’s the real story? CNC machines are ideally suited for the high precision and intricate designs that aerospace components require.

Ready for the good part? The aerospace industry is seeing massive efficiency gains by using CNC machines with 5-axis capabilities. These machines can create complex geometries, such as cooling channels inside turbine blades, which would otherwise be difficult or impossible to achieve with traditional manufacturing methods. This means parts can be created with less material waste and reduced production time.

What’s the kicker here? CNC machining’s role in the aerospace industry isn’t just about creating parts that fit—it’s about creating parts that meet extremely tight tolerances. For example, tolerances of just a few microns are often required in aerospace components to ensure that parts fit perfectly and perform safely under extreme stress.

Aerospace CNC Machining Advantages

| Component | 利点 | CNC Machining Application |

|---|---|---|

| Turbine Blades | High precision, complex geometry | Engine manufacturing, testing |

| Aircraft Frames | Lightweight, strength-to-weight ratio | Structural parts |

| Engine Parts | Resistance to heat and stress | Jet engine manufacturing |

| Custom Components | Customization, quick prototyping | Prototyping and testing |

8. What Role Does CNC Machining Play in Automotive Manufacturing?

CNC machining is a major player in the automotive industry, where precision and speed are crucial for mass production. From car body parts to intricate engine components, CNC technology allows manufacturers to achieve high levels of accuracy, speed, and cost efficiency. So, what’s the real story? The automotive industry benefits from CNC machining by creating parts with highly consistent dimensions, which is essential for both performance and safety.

Here’s the kicker: one of the most significant advantages CNC machining offers the automotive industry is the ability to create complex, high-tolerance components that would otherwise be too costly or time-consuming to produce. For example, engine parts like cylinder heads and camshafts require extremely tight tolerances to ensure that engines run smoothly and efficiently.

Ready for the good part? Beyond just the precision of components, CNC machining helps streamline the production process itself. Automated systems ensure that parts are made faster, reducing cycle time and overall costs. This allows automotive manufacturers to meet the ever-increasing demands for faster production rates while maintaining high standards of quality.

Automotive CNC Machining Applications

| Component | 利点 | CNC Application |

|---|---|---|

| Engine Parts | Precision, durability | High-tolerance manufacturing |

| Car Body Components | Customization, lightweight | Mass production |

| Gear Systems | Complex geometries, strength | Precision manufacturing |

| Prototypes | Rapid prototyping, design testing | Model creation, design testing |

9. How Are CNC Machines Evolving for Medical Applications?

CNC machining in the medical industry is nothing short of revolutionary. The need for precision and customizability in medical devices and implants has led to an increased reliance on CNC machining for creating complex components like surgical instruments, implants, and prosthetics. But here’s the kicker—CNC machines are not just making things more accurate—they’re making things more personalized.

What’s the real story? CNC machining allows medical manufacturers to create highly customized components for patients, such as bespoke implants that fit the unique contours of an individual’s body. This level of personalization improves patient outcomes, reduces surgery time, and speeds up recovery. The use of titanium, which is both strong and biocompatible, is also common in medical machining, particularly for joint replacements and dental implants.

Ready for the good part? CNC machining also enables the production of complex, tiny parts that can be used in advanced medical devices. For example, intricate components found in pacemakers, dental equipment, and surgical instruments require high precision to function correctly and safely.

CNC for Medical Applications

| Component | 主な利点 | CNC Machining Use |

|---|---|---|

| Surgical Instruments | High precision, customized | Production of tools, instruments |

| Implants | Biocompatibility, durability | Joint replacements, dental implants |

| Prosthetics | Personalization, accuracy | Custom prosthetics production |

| Micro Components | Intricate design, accuracy | Pacemaker components, sensors |

10. What Are the Key CNC Software Advancements?

As CNC machines have evolved, so too have the software systems that control them. In fact, the software running a CNC machine is just as important as the hardware itself. So, what’s the big deal? The latest CNC software advancements are making machines smarter and more efficient than ever before. With advanced CAM (Computer-Aided Manufacturing) software, CNC machines can now interpret highly detailed designs and execute them with minimal human intervention.

Here’s the kicker: one of the most exciting advancements is the ability to simulate machining processes in virtual environments before physical production begins. This allows operators to identify potential issues early in the process, saving time and reducing costly errors. Additionally, more software systems are incorporating AI to optimize operations, analyzing past data to adjust machine settings for the best results.

What’s the real story here? These advancements aren’t just improving efficiency—they’re expanding what CNC machining can do. Today’s software allows for the creation of incredibly complex parts that would be nearly impossible to machine with traditional methods.

CNC Software Advancements

| Software Feature | 利点 | CNC Application |

|---|---|---|

| CAM Simulation | Error reduction, pre-production testing | Design validation, process planning |

| AI Integration | Self-optimization, real-time adjustments | Production efficiency, quality control |

| Advanced Toolpath | Improved precision, complex machining | High-precision part production |

| Cloud Integration | Remote monitoring, data storage | Machine status monitoring, reporting |

11. How Do CNC Machines Contribute to Sustainability in Manufacturing?

As environmental concerns grow, many industries are turning to sustainable manufacturing practices. CNC machining plays a key role in this shift by reducing waste, optimizing resource usage, and lowering energy consumption. What’s the big deal? CNC machines are inherently more precise than traditional methods, meaning they produce less scrap material during the manufacturing process.

Ready for the good part? Advances in CNC machining technology also allow manufacturers to utilize sustainable materials more effectively. By switching to recyclable materials or using energy-efficient machines, manufacturers can significantly reduce their environmental footprint.

What’s the kicker here? Automation in CNC machining further contributes to sustainability by reducing the need for human labor, leading to more efficient production with fewer resources. In short, the CNC machines of today are not only making production faster and more efficient—they’re also helping to protect the planet.

Sustainability in CNC Machining

| Sustainability Factor | 利点 | CNC Application |

|---|---|---|

| Precision Machining | Less scrap, efficient material usage | Metalworking, automotive |

| Energy-Efficient Machines | Reduced energy consumption | Green manufacturing practices |

| Recyclable Materials | Reduces waste, supports sustainability | Medical devices, aerospace |

| Automated Production | Fewer resources, lower labor costs | High-volume production |

12. What Are the Cost Implications of Adopting New CNC Technology?

As with any new technology, adopting cutting-edge CNC machining solutions comes at a cost. But here’s the kicker—the long-term benefits often far outweigh the initial investment. The question is: what’s the real cost? While the price of advanced CNC machines and software can be high, the efficiencies gained from automation, precision, and reduced waste can lead to significant cost savings over time.

What’s the big deal? When considering the cost of new technology, it’s important to look at the return on investment (ROI). More precise machining reduces rework and errors, lowering overall production costs. Additionally, automated systems can operate 24/7, increasing production rates without the need for additional labor.

楽しい部分の準備はできていますか? New CNC technologies also open up opportunities for higher-quality, more complex products. With the ability to manufacture parts that were previously impossible or too expensive to produce, businesses can access new markets and generate more revenue.

Cost Implications of CNC Tech

| Investment Type | Initial Cost | Long-Term Benefit | 業界への影響 |

|---|---|---|---|

| Advanced CNC Machines | 高い | Precision, reduced waste | 航空宇宙、自動車 |

| Automation Systems | Medium | Increased efficiency | Manufacturing, medical devices |

| CAD/CAM ソフトウェア | 適度 | Improved design and prototyping | High-tech, electronics |

13. What Are the Limitations of Current CNC Technology?

CNC machining is far from perfect, and despite its many advancements, there are still some limitations to consider. So, what’s the big deal? Despite all the innovations, CNC machines can be expensive to maintain, and not every machine is suitable for every type of material. Additionally, while CNC machining has come a long way in terms of precision, certain materials, such as those with extremely high hardness or irregular shapes, can still present challenges.

Here’s the kicker: while the technology has made great strides, it still requires skilled operators to manage and optimize machine settings. CNC machines are not entirely autonomous, and there is still a need for human oversight in some cases.

What’s the real story here? Even with limitations, CNC machining is a powerful tool for modern manufacturing. By understanding these limitations and adapting to them, manufacturers can use CNC technology to its fullest potential.

CNC Limitations

| Limitation | インパクト | Mitigation Strategies |

|---|---|---|

| Maintenance Costs | High long-term costs | Regular upkeep, efficient use |

| Material Compatibility | Limited for certain materials | Selection of appropriate materials |

| Skilled Labor | Need for trained operators | Training programs, automation |

| Shape Complexity | Difficulty with certain geometries | Custom tools, new technologies |

14. How Can Small Businesses Benefit from Advanced CNC Technology?

Small businesses have often struggled to compete with larger manufacturers due to limited resources. But here’s the kicker—advanced CNC technology is leveling the playing field. Small manufacturers can now access the same high-quality, efficient machinery that was once only available to big corporations.

What’s the big deal? With more affordable CNC machines and advanced software options, small businesses can reduce their overhead, cut costs, and compete in global markets. The ability to create customized, high-quality products on a smaller scale has allowed many small businesses to thrive.

Ready for the good part? Advanced CNC technology has also made it easier for small businesses to offer faster turnaround times and more flexibility in their product offerings. This makes them more competitive in niche markets, offering tailored solutions that larger companies can’t match.

CNC for Small Business

| 利点 | Key Advantage | 業界への影響 |

|---|---|---|

| Lower Operating Costs | Affordable machines, reduced overhead | Small manufacturers, startups |

| Increased Flexibility | Fast production, custom parts | Custom products, niche markets |

| High-Quality Production | Precision, reduced waste | High-precision manufacturing |

| Quick Turnaround | Faster production, efficient process | Local businesses, small batches |

15. What Are the Future Trends in CNC Machining?

The future of CNC machining looks incredibly promising. So, what’s the big deal? As new technologies continue to emerge, CNC machining is poised to become even more efficient, precise, and versatile. But here’s the kicker—AI, robotics, and more will soon transform CNC machines into fully autonomous production systems.

Ready for the good part? The integration of AI into CNC machines will lead to even smarter machines capable of learning from each operation. Expect a future where machines make real-time adjustments to optimize cutting speeds, tool paths, and other parameters based on data analysis.

What’s the real story here? The future of CNC machining is not just about better machines, but about a fully connected and automated manufacturing ecosystem. With advancements in materials, robotics, and AI, the next generation of CNC technology will be faster, smarter, and more capable than ever before.

FAQセクション

Q1: CNC加工とは?

CNC machining is a manufacturing process where computer-controlled tools are used to create precise parts and components from various materials.

Q2: How does AI improve CNC machining?

AI improves CNC machining by enabling real-time adjustments, predicting maintenance needs, and optimizing operations for better speed and precision.

Q3: What are the benefits of hybrid CNC and 3D printing?

The hybrid system combines the speed of 3D printing with the precision of CNC machining, allowing for complex designs and high material versatility.

Q4: How does automation benefit CNC machining?

Automation allows CNC machines to run continuously, reducing human error, cutting production time, and increasing consistency.

質問5: What is the role of 5-axis machining?

5-axis machining enhances precision by allowing complex cuts and reducing the need for multiple setups, making it ideal for intricate parts.