소개

When it comes to precision machining, selecting the right company can make all the difference in the quality and efficiency of your project. With numerous machining companies out there, each offering different technologies, expertise, and services, it can be overwhelming to know where to start. The stakes are high—poor machining can lead to delays, quality issues, and wasted resources. This guide is here to help you navigate the complexities of choosing a precision machining partner. By understanding the key factors that matter most, you’ll be able to make an informed and confident decision.

What is Precision Machining?

Definition

Precision machining refers to the use of specialized machines and tools to create parts and components with extremely tight tolerances. This manufacturing process involves removing material from a workpiece to achieve precise shapes and dimensions. The level of precision required varies depending on the specific project, but generally, precision machining is used for parts that need to meet specific dimensional requirements, typically in industries where functionality and reliability are critical.

Why It’s Important

Precision machining ensures that parts are manufactured with exact measurements, making them essential for high-performance applications in various sectors, including aerospace, medical devices, automotive, and electronics. Parts that are improperly machined can cause malfunctioning equipment, lead to safety risks, or create costly delays. Whether you’re producing a prototype or large-scale components, the accuracy and quality of machining play a critical role in the end product’s functionality.

Common Industries That Use Precision Machining

Precision machining serves a wide array of industries, each requiring parts that meet highly specific standards. For example, the aerospace sector demands parts with exceptionally tight tolerances for critical systems, while the medical industry requires components that ensure the safety and reliability of surgical instruments or implants. The automotive industry also relies on precision machining for components like engine parts and transmission systems. Industries like electronics, military defense, and renewable energy use precision machining for small, highly intricate components that must function without fail.

Key Factors to Consider When Choosing a Precision Machining Company

Quality Standards and Certifications

When selecting a precision machining company, it’s essential to ensure they meet high-quality standards. Companies that are ISO 9001 certified, for example, adhere to globally recognized quality management principles, ensuring consistency and reliability in their production processes. Additionally, certifications like AS9100 (for aerospace applications) indicate the company’s commitment to meeting industry-specific standards. By selecting a company with the right certifications, you can be confident in the precision and reliability of the parts they produce.

Expertise in Your Industry

Not all precision machining companies are equally suited to every industry. Some companies specialize in machining for specific sectors, such as automotive, aerospace, or medical devices, and understand the unique requirements and challenges of these industries. If your project requires specialized knowledge, working with a machining company with experience in your field can significantly improve the quality and success of your project.

Precision and Tolerance Capabilities

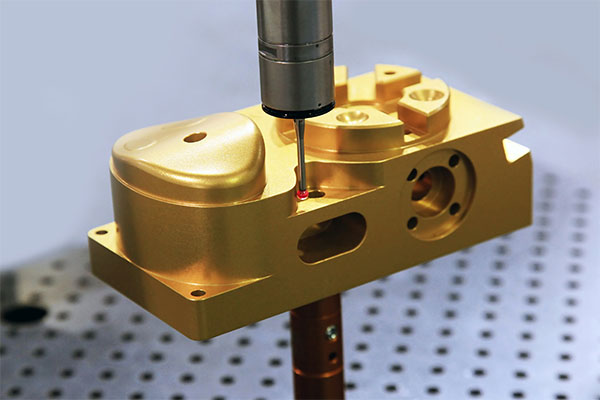

Another critical factor is the level of precision the company can achieve. Precision machining is all about tight tolerances—sometimes as small as a few microns. It’s important to ask about the company’s capabilities in achieving the required tolerances for your project. Companies with advanced equipment, like CNC machines, will generally have the ability to produce parts with high precision and minimal error.

Technology and Equipment

The technology and equipment used by a precision machining company can drastically affect the quality, speed, and cost of your project. Advanced technologies like CNC (Computer Numerical Control) machining, laser cutting, and 3D printing allow for greater precision, flexibility, and faster production times. Be sure to inquire about the types of machines the company uses, as well as how up-to-date and well-maintained they are.

Capacity and Flexibility

You’ll also want to choose a company that can handle the size and complexity of your orders. A good precision machining company should be able to scale its operations to meet both small and large-volume production needs. Whether you’re working on a single prototype or need to produce thousands of identical parts, the company must be capable of meeting your timeline without sacrificing quality.

Understanding Your Project Requirements

Material Requirements

Before choosing a machining company, you must clearly define the materials required for your project. Some materials, like titanium or specialized alloys, require specific machining techniques and equipment. Make sure the company you choose has the expertise and equipment to work with the materials you need.

Complexity of the Design

The complexity of your design will also influence your choice of company. Simple parts with basic dimensions might not require a high-tech machine shop, but more intricate parts with tight tolerances will need advanced equipment and highly skilled machinists. Companies with experience in complex designs, such as those used in aerospace or medical devices, will be able to handle the challenges of your project.

Tolerances and Specifications

Every precision machining project has a set of specifications and tolerances that need to be met. It’s essential to communicate the required tolerances upfront to ensure the company can meet your expectations. Companies that specialize in tight tolerances and high precision are ideal for projects where small deviations from the specifications can result in failure or malfunction.

Lead Time Expectations

Speed is often a critical factor when selecting a precision machining company. It’s important to establish clear lead time expectations and ensure the company can meet them. Be prepared to discuss your project timeline, including how soon you need prototypes, production runs, or deliveries.

Experience and Expertise: How Does it Affect Your Decision?

Years in Business

One of the most important factors when choosing a machining company is their experience. A company that has been in business for several years is likely to have developed a refined process, skilled workforce, and reputation for reliability. Experience also means they’ve likely encountered and solved a wide variety of challenges, making them better equipped to handle unexpected issues in your project.

Portfolio and Case Studies

Another indicator of a machining company’s capabilities is their portfolio or case studies. Ask to see examples of their previous work to get an idea of the quality and types of projects they’ve handled. A well-established company will have a portfolio that showcases a range of projects similar to your own, offering insight into their expertise and capabilities.

Specializations

Some precision machining companies focus on specific types of machining, such as CNC turning, CNC milling, or wire EDM. If your project requires a specific type of machining, it’s worth seeking out companies that specialize in that area to ensure you’re getting the best results.

Skilled Workforce

The skills of the machinists working for a company can make a big difference in the quality of the finished product. Experienced machinists can spot issues early in the production process and make adjustments to ensure the parts meet exact specifications. Be sure to inquire about the experience and qualifications of the machinists working at the company.

Technological Capabilities of Precision Machining Companies

CNC 가공

CNC machining has revolutionized the precision machining industry, allowing companies to create highly complex and detailed parts with greater accuracy and efficiency. Companies with state-of-the-art CNC equipment can handle high-precision tasks and produce parts at faster speeds than traditional methods. CNC technology also allows for the automation of various processes, improving consistency and reducing the chances of human error.

Advanced Technologies

In addition to traditional CNC machining, newer technologies such as 3D printing, additive manufacturing, and laser cutting can be valuable additions to a machining company’s capabilities. These technologies can reduce lead times, cut down on waste, and allow for the production of highly customized parts. Make sure to ask if the company has adopted these newer technologies.

Automation and AI

The integration of automation and AI into machining processes can significantly improve productivity and reduce costs. Automation ensures that parts are consistently produced with minimal human intervention, while AI can optimize production schedules and detect potential quality issues before they occur. Choosing a company that incorporates automation and AI can lead to faster turnaround times and higher quality.

Price vs. Quality: Finding the Right Balance

Why Cheap Isn’t Always Best

When selecting a precision machining company, it’s tempting to choose the lowest-priced option. However, going for the cheapest option can lead to subpar work, missed deadlines, or a failure to meet quality standards. While price is important, it should never be the only factor in your decision. Focus on value—consider how the company’s pricing aligns with their capabilities and the quality of their work.

Understanding Pricing Structures

Machining companies typically use a variety of pricing structures, including hourly rates, per-piece pricing, and setup fees. It’s essential to fully understand the pricing model of the company you’re considering to ensure there are no hidden fees or unexpected costs. Make sure to discuss all pricing details upfront to avoid surprises down the road.

The Importance of Cost-Effectiveness

Cost-effectiveness means balancing quality with price. Choosing a company that provides high-quality work at a reasonable price can help you achieve your goals without overspending. Don’t just opt for the cheapest option; weigh all factors, including expertise, technology, and customer service, to make the most cost-effective choice for your project.

Lead Times and Production Schedules

How Lead Times Affect Your Business

Lead time is a crucial factor to consider when choosing a precision machining company. If a machining company can’t deliver your parts on time, it can delay your entire project, affecting production schedules and your bottom line. Be clear about your lead time expectations from the beginning and ensure the company can meet them before entering into a contract.

Negotiating Lead Times

Sometimes, lead times can be negotiated depending on the project’s complexity and the machining company’s capabilities. It’s important to communicate your project needs clearly and work with the company to find a realistic timeline that works for both parties.

Flexible Scheduling

A company that offers flexibility in its production schedule can be invaluable if unexpected delays or issues arise. This flexibility can help you keep your project on track, even when things don’t go according to plan.

Communication and Customer Support

The Importance of Clear Communication

Clear communication between you and the machining company is key to ensuring the project runs smoothly. You need to be able to easily communicate your requirements, ask questions, and clarify any issues that arise. Poor communication can lead to mistakes, delays, and frustration, so be sure to evaluate the company’s responsiveness and willingness to engage early on.

Customer Support and Responsiveness

Good customer support is vital to a positive experience when working with a machining company. A company with a dedicated customer service team can quickly address any concerns or problems that may arise during the project. Be sure to ask how the company handles customer support and what the process is for reaching out if you have any issues.

Project Management Tools

Many machining companies use project management tools to keep clients informed about the progress of their orders. These tools allow for real-time updates and make it easier to track deadlines, shipping, and any changes to the order. Ensure the company provides you with access to these tools for better communication and visibility.

Location and Shipping Considerations

Proximity to Your Business

The location of a machining company can significantly impact shipping times and costs. Choosing a local company can reduce shipping times and costs, ensuring faster delivery of your parts. However, it’s also important to consider the company’s capabilities and pricing. Sometimes, working with a company located farther away may still be the best choice due to their expertise and technological advantages.

International vs. Local Machining Companies

When deciding between local and international machining companies, consider the benefits and drawbacks of each. Local companies can provide faster delivery times, while international companies may offer cost savings or specialized capabilities that local companies lack. Weighing these factors carefully will help you make the right choice.

Shipping Options

Shipping logistics are another consideration when selecting a precision machining company. Some companies may offer expedited shipping options to help meet tight deadlines. Be sure to ask about the available shipping methods and associated costs to make an informed decision.

Evaluating Reviews and Testimonials

Online Reviews

Reading online reviews can give you valuable insight into a company’s reputation and the quality of their work. Check multiple sources for reviews, including Google, industry-specific forums, and the company’s website. Look for reviews from businesses that have similar needs to yours to get the most relevant feedback.

Word-of-Mouth and Referrals

One of the best ways to evaluate a precision machining company is through word-of-mouth referrals. Ask colleagues, partners, or industry peers for recommendations on reputable machining companies. A recommendation from someone who has firsthand experience is invaluable when making your decision.

References from the Company

Ask the company for references or case studies showcasing their previous work. A reputable company will be happy to provide references from satisfied customers who can attest to the quality and reliability of their services. This helps build trust and reassures you that you’re making the right choice.

Customer Satisfaction and After-Sales Support

Warranty and Guarantees

Most precision machining companies offer warranties or satisfaction guarantees. This can provide peace of mind, knowing that if something goes wrong, you can request corrections or replacements. Make sure you understand the terms of the warranty before moving forward.

After-Sales Service

After-sales service is an often overlooked but crucial aspect of the machining process. A good company will offer support even after the project is completed, providing assistance with installation, maintenance, or any issues that arise. This ensures that you have ongoing support as you use the parts in your final product.

Dealing with Issues and Errors

Even with the best planning, issues can arise during the machining process. Be sure to ask the company how they handle mistakes or quality control issues. A reliable company should have a clear process for addressing errors and making corrections quickly.

Sustainability and Environmental Considerations

Environmental Standards

Sustainability is becoming increasingly important in the manufacturing industry. Ask potential machining companies about their environmental practices, including waste management, energy use, and the materials they use. Companies that prioritize sustainability can help you meet your own environmental goals.

Sustainable Manufacturing

Many machining companies are adopting sustainable practices, such as using recyclable materials or minimizing waste. Choosing a company that follows sustainable practices can reduce your environmental impact and align your project with broader corporate responsibility goals.

Energy Efficiency

Energy-efficient machining processes can help reduce both operational costs and environmental impact. Inquire about the company’s energy efficiency practices and whether they use energy-efficient machines or production methods.

How to Vet a Precision Machining Company: Questions to Ask

Key Questions to Ask Before Signing a Contract

Before committing to a machining company, ask about their capabilities, experience, certifications, and past projects. Ensure they can meet your quality and timeline requirements. Some key questions include: What are your lead times? Do you have experience with my type of project? What certifications do you hold?

What to Look for in a Response

The answers you receive can tell you a lot about the company’s capabilities and reliability. Look for clear, thorough, and honest answers that reflect the company’s experience and expertise. If a company hesitates or seems unsure, it may be a red flag.

Red Flags to Watch Out For

Watch out for companies that promise unrealistic timelines, provide vague answers, or have a history of poor reviews. Be wary of companies that offer significantly lower prices than competitors, as this could indicate compromised quality.

Common Mistakes to Avoid When Choosing a Precision Machining Company

Focusing Only on Cost

While cost is an important consideration, choosing a company based solely on price can lead to problems down the road. If a company offers rock-bottom prices, they may be cutting corners in other areas, such as quality control or customer service.

Ignoring Capabilities and Certifications

Some companies may offer low prices but fail to meet the required quality standards. Ignoring a company’s certifications or their ability to meet your specific project needs can result in subpar products that don’t meet industry standards.

Not Checking References

Failing to check references or review a company’s portfolio can lead to choosing a less-qualified machining partner. Always ask for references and review the company’s past work to ensure they are capable of handling your project.

Conclusion: Making the Right Choice

Choosing the right precision machining company is a critical decision that can impact the success of your project. By carefully considering factors like quality standards, expertise, technology, and communication, you can make an informed decision that ensures the success of your machining needs. Don’t rush the process—take the time to thoroughly vet potential companies, ask the right questions, and choose a partner who can meet your specifications and deliver high-quality work on time. Remember, the right machining partner will help you bring your project to life with precision and reliability.

자주 묻는 질문 섹션

1. What is the difference between CNC machining and traditional machining?

CNC machining is a more modern, automated method that offers greater precision, efficiency, and repeatability compared to traditional machining, which often involves manual processes.

2. How do I determine the best precision machining company for my project?

Look for a company with the right experience, certifications, technology, and a solid reputation. Always ask for references and examples of similar projects.

3. How do I know if a precision machining company is qualified?

Check for industry-specific certifications like ISO 9001 and review their portfolio or case studies. A qualified company should have proven experience in your industry.

4. What factors should I consider when choosing a machining company for mass production?

Consider their capacity to handle large orders, their lead times, and their ability to meet the specific tolerances and quality standards required.

5. How do lead times impact my decision when choosing a precision machining company?

Long lead times can cause delays in your project. Ensure the company’s lead times align with your needs and discuss any potential scheduling issues upfront.

6. How important is communication when choosing a machining partner?

Clear communication is crucial for ensuring that your needs are understood and met, avoiding delays or misunderstandings throughout the project.

7. What type of warranty should I expect from a precision machining company?

Look for a company that offers a warranty or satisfaction guarantee to ensure they stand behind their work and will address any issues that arise.

8. Can a machining company handle both simple and complex parts?

It’s important to choose a company that can handle a wide range of projects, from simple parts to highly complex and intricate components.

9. Why is it important to consider the company’s environmental practices?

Choosing a company that follows sustainable practices can reduce your environmental impact and align your project with corporate responsibility goals.

10. What common issues should I watch out for when choosing a machining company?

Watch out for companies that provide unclear answers, have poor reviews, or offer unusually low prices that may indicate compromised quality or service.