Introduction: Why CNC Machining Matters in the Semiconductor Industry

CNC machining has revolutionized manufacturing across a multitude of industries, and the semiconductor sector is no exception. This cutting-edge technology plays a crucial role in the production of semiconductor components, ensuring high precision, speed, and efficiency. As semiconductor devices become more advanced and miniaturized, the demand for exacting standards in manufacturing grows, making CNC machining an indispensable tool. In this article, we explore how CNC machining enhances the production of semiconductors, its significance in overcoming industry challenges, and why choosing the right CNC machining services is vital for success in the competitive semiconductor market.

Understanding CNC Machining: A Game Changer for Precision

What is CNC Machining and Why Is It Important?

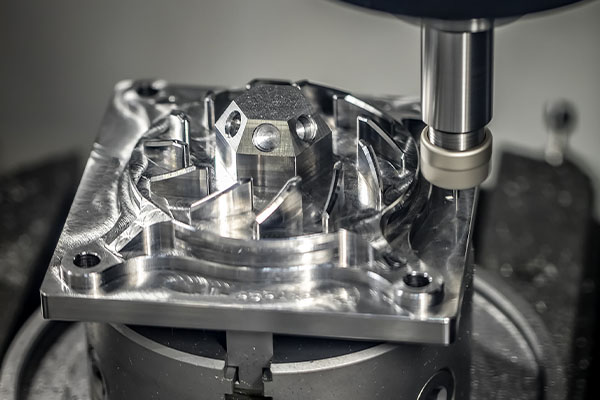

CNC (Computer Numerical Control) machining is a method of manufacturing that uses computerized systems to control the movement of tools and machinery. This technology allows for precise cuts, drilling, and shaping of materials, often with tolerances as small as a few microns. In the context of semiconductor manufacturing, where minute dimensions are critical, CNC machining enables manufacturers to meet these stringent requirements.

The primary reason CNC machining has become so integral to semiconductor manufacturing is its ability to achieve the exact specifications required for each component. The precision of CNC machines ensures that parts are fabricated with unparalleled accuracy, which is crucial in the production of devices such as microchips, transistors, and integrated circuits.

The Mechanics Behind CNC Machining

At its core, CNC machining utilizes a computer to control the machine’s movements through pre-programmed software. These machines can handle a variety of operations, including milling, turning, and drilling, and are capable of working with a wide range of materials like metals, plastics, and ceramics. In semiconductor manufacturing, materials like silicon and gallium arsenide are commonly used, requiring machines that can handle the delicate nature of these substances while maintaining their integrity.

The machinery’s versatility allows semiconductor manufacturers to create complex geometries and intricate features with a high degree of consistency. Furthermore, CNC machines can operate 24/7 with minimal supervision, reducing human error and increasing overall production efficiency.

Why Semiconductor Manufacturers Need Precision Machining

The Demand for High Precision in Semiconductor Manufacturing

In semiconductor manufacturing, the tolerance level of components is extremely tight. Even a slight deviation from the desired dimensions can result in faulty products that are unusable or inefficient. For example, the width of a microchip’s conductor might only be a few nanometers thick, and any imperfection in this can render the chip unreliable or ineffective. This is where CNC machining shines—its precision ensures that components are fabricated within the strictest of tolerances, meeting or exceeding the required standards for semiconductor applications.

Moreover, as the semiconductor industry evolves with increasingly complex designs, the need for advanced manufacturing technologies like CNC machining becomes even more pronounced. As electronics become smaller and more powerful, manufacturers must continually innovate their processes to keep up with new demands for higher performance and miniaturization.

Consequences of Low-Precision Machining in Semiconductor Applications

The stakes are high in semiconductor manufacturing. Low-precision machining can lead to a host of problems, including poor electrical conductivity, malfunctioning devices, or even complete failure of semiconductor products. The cost of errors in this field is significant—not only do defective components result in lost revenue, but they also damage the reputation of manufacturers. Therefore, the importance of using CNC machining for high-precision applications in the semiconductor industry cannot be overstated.

CNC Machining Ensures Quality and Reliability

With CNC machining, manufacturers can produce components that meet rigorous quality standards, ensuring that each product functions as expected. This results in higher reliability, fewer defects, and a greater overall yield in production, making CNC machining the go-to solution for semiconductor companies worldwide.

Key Technologies Driving CNC Machining in Semiconductor Production

Advanced CNC Technologies for Precision

The technology behind CNC machining has come a long way, with numerous innovations making it more capable than ever. In semiconductor manufacturing, specific types of CNC machines and tools are often employed to meet the unique demands of the industry. These include multi-axis CNC machines that offer unparalleled flexibility and precision in shaping complex semiconductor components.

One of the leading technologies in CNC machining is 5-axis milling. This allows for the machining of complex shapes from any direction, significantly improving the versatility and efficiency of production. For semiconductor components that require intricate detailing, such as microchips with fine features, 5-axis machines offer the ideal solution. These machines can work from multiple angles without the need for manual repositioning, reducing the risk of errors and increasing production speed.

Laser and EDM Technologies

In addition to traditional CNC machining, laser cutting and Electrical Discharge Machining (EDM) are also used in semiconductor manufacturing. Laser cutting is an excellent method for cutting materials with high precision, and it is particularly useful for materials like silicon wafers. On the other hand, EDM utilizes electrical discharges to precisely remove material, allowing for intricate shapes and complex geometries that would be difficult to achieve with conventional machining methods.

These advanced CNC technologies ensure that semiconductor manufacturers can create components with exceptional accuracy and quality. As the industry continues to demand smaller, faster, and more powerful devices, these cutting-edge CNC technologies will be crucial in meeting the evolving needs of the semiconductor market.

Materials Used in Semiconductor Machining: The Need for Durability

The Varied Materials in Semiconductor Manufacturing

The materials used in semiconductor manufacturing are as diverse as the components themselves. Semiconductor manufacturers typically work with materials such as silicon, gallium arsenide, and other compounds, all of which require special handling and processing techniques. Each material has unique properties that influence how it is machined, making it essential to use CNC machining methods tailored to these specific substances.

For example, silicon wafers are extremely delicate, and even the slightest handling mistake can cause cracks or defects that compromise the component. CNC machines, with their precision and ability to automate processes, significantly reduce the risk of these types of errors. Similarly, other advanced materials like ceramics and metals, which are increasingly being used in semiconductor components, require precise machining to avoid material deformation or wastage.

Durability and Material Preservation

One of the major challenges in machining semiconductor materials is ensuring that the integrity of the material is preserved throughout the process. High-speed machining and excessive heat can damage materials like silicon, leading to defects that impact the performance of the final product. CNC machines, however, are designed to minimize heat generation and ensure that materials are cut and shaped with minimal risk of damage.

Additionally, CNC machines allow for highly efficient material usage, reducing waste and maximizing the yield from each batch. This not only helps manufacturers save costs but also contributes to a more sustainable production process.

Challenges in Semiconductor CNC Machining

Tool Wear and Heat Generation

Despite its numerous advantages, CNC machining in the semiconductor industry is not without challenges. One of the key issues is tool wear. Due to the delicate nature of semiconductor materials, machining tools can degrade quickly, particularly when working with harder substances like ceramics or metals. This can affect the quality of the final product and require frequent tool replacements, leading to increased downtime and costs.

Another challenge is heat generation. While CNC machines are designed to minimize heat buildup, it is inevitable that machining processes generate some level of heat. If not managed properly, excessive heat can warp materials, alter dimensions, or cause thermal stresses that impact the performance of the final product. Advanced cooling techniques and precise control of machining speeds are essential to mitigate these issues.

Addressing CNC Machining Challenges

Manufacturers are constantly working to overcome these challenges by investing in advanced CNC technologies that offer longer tool life and better heat dissipation. Additionally, regular maintenance of CNC machines helps ensure that they operate at optimal efficiency, reducing the risk of errors and delays. With the right equipment and practices, these challenges can be effectively managed, allowing for the continued growth and success of semiconductor machining.

The Importance of Customization in Semiconductor CNC Machining

Tailored Solutions for Unique Semiconductor Components

One of the standout benefits of CNC machining in the semiconductor industry is its ability to provide customized solutions. Semiconductor components often require specialized designs to meet the unique needs of different applications. Custom CNC machining services allow manufacturers to tailor every aspect of the machining process to the specific requirements of each component, ensuring the highest level of precision and functionality.

For example, a semiconductor manufacturer may need a component with highly specific dimensions, such as a microchip with intricate patterns or an integrated circuit with tiny, precise connections. CNC machining can easily accommodate these specifications, providing the exact shape and size required, while maintaining the integrity of the material.

Customized Tools and Machines for Specific Needs

Customization also extends to the tools and machinery used in the production process. Many semiconductor manufacturers require specialized tooling for their components, such as diamond-coated tools for cutting extremely hard materials or tools with specialized geometries for intricate designs. CNC machining provides the flexibility to create these custom tools and ensures that the manufacturing process runs smoothly.

How CNC Machining Supports the Rise of Miniaturization in Semiconductors

Miniaturization and the Role of CNC Machining

As the demand for smaller, more powerful semiconductor devices continues to grow, miniaturization has become a central trend in the industry. CNC machining plays a critical role in enabling this trend by allowing manufacturers to produce components that are incredibly small and precise.

The development of microchips, for example, involves creating components that are only a few microns in size. This level of miniaturization requires not only high precision but also the ability to work with ultra-thin materials, all while maintaining structural integrity. CNC machining allows manufacturers to meet these demands by providing the fine control necessary for producing such tiny, complex parts.

Challenges and Solutions in Miniaturization

While miniaturization presents significant opportunities, it also comes with its own set of challenges. As components become smaller, the need for even greater precision becomes critical. Any slight deviation can cause failure or malfunction in the final product. CNC machining is uniquely suited to meet these challenges, offering the precision and control required to manufacture these tiny components with unparalleled accuracy.

Real-World Applications of CNC Machining in Semiconductor Manufacturing

Common Semiconductor Components Made Using CNC Machining

CNC machining is used to produce a wide variety of components for the semiconductor industry, including microchips, integrated circuits, sensors, and transistors. These components are essential to the functioning of electronic devices such as smartphones, computers, and medical equipment. Without the precision provided by CNC machining, many of these components would not meet the high-performance standards required in today’s fast-paced technological landscape.

Case Studies in Semiconductor CNC Machining

For instance, one case study highlights a semiconductor company that used CNC machining to produce a series of microchips for a high-end mobile device. The company faced strict size and performance requirements but was able to meet these needs by using advanced CNC machines with multi-axis capabilities. The result was a set of microchips that were both highly precise and reliable, leading to a successful product launch.

The Role of CNC Machining in R\&D for Semiconductor Innovation

Prototyping and Testing New Designs

In the world of semiconductor manufacturing, research and development (R\&D) is crucial for driving innovation. CNC machining plays an important role in this process by enabling quick prototyping and testing of new designs. With CNC machines, manufacturers can create prototypes of semiconductor components rapidly, allowing for faster iterations and improvements before moving to full-scale production.

Accelerating Innovation with CNC Machining

The ability to quickly test and refine new designs accelerates the pace of innovation in the semiconductor industry. CNC machining allows engineers to create precise prototypes with the necessary tolerances, helping them identify potential design flaws early in the development process. This speeds up time-to-market and ensures that the final product is both cutting-edge and reliable.

Energy Efficiency and Sustainability in CNC Machining

Reducing Environmental Impact

Sustainability is a growing concern in all industries, and semiconductor manufacturing is no exception. CNC machining offers a more energy-efficient alternative to traditional manufacturing processes, reducing the environmental footprint of production. By using advanced technologies that optimize energy consumption and minimize waste, CNC machining helps semiconductor manufacturers achieve both economic and environmental goals.

Improving Resource Efficiency

CNC machines are designed to maximize the use of materials, ensuring that there is minimal waste. By minimizing material waste and improving precision, CNC machining helps semiconductor manufacturers reduce costs and improve the overall efficiency of the production process. This leads to more sustainable practices that benefit both the bottom line and the environment.

Why Choose Your CNC Machining Services for Semiconductor Projects

Tailored Solutions for High-Precision Components

When choosing a CNC machining partner for semiconductor manufacturing, it’s crucial to select a company that offers high-quality, customizable solutions. Your company’s expertise in sourcing raw materials and providing tailored machining services positions you as the ideal partner for semiconductor manufacturers looking for precision and reliability. With advanced machinery and an experienced team, you can provide semiconductor companies with the components they need to succeed.

Competitive Advantage in the Semiconductor Market

By choosing your CNC machining services, semiconductor manufacturers can benefit from faster turnaround times, higher-quality components, and more cost-effective production. These advantages make your company an attractive choice for businesses in the semiconductor industry looking to stay competitive in a fast-paced market.

Global Trends and the Future of CNC Machining in Semiconductor Manufacturing

Technological Advancements on the Horizon

The future of CNC machining in the semiconductor industry looks bright, with new technologies constantly emerging. Innovations like artificial intelligence and machine learning are being integrated into CNC systems, allowing for even greater precision and efficiency. These advancements will enable semiconductor manufacturers to create even smaller, more powerful components, supporting the continued growth of the industry.

Opportunities for Growth and Development

As the demand for semiconductor components increases, CNC machining will play an even larger role in meeting these needs. Companies that embrace the latest technologies and invest in advanced CNC equipment will be well-positioned to capitalize on the opportunities presented by the growing semiconductor market.

How Your Company Solves Industry Challenges with Custom CNC Machining Solutions

Tailored Solutions to Meet Client Needs

Your company’s commitment to providing customized CNC machining solutions makes you an ideal partner for semiconductor manufacturers. By understanding the unique challenges and requirements of each client, you can offer tailored solutions that ensure the highest levels of precision, quality, and efficiency.

Streamlining the Production Process

By offering a full suite of services—from sourcing raw materials to final product machining—you can streamline the production process for semiconductor manufacturers, allowing them to focus on innovation while you handle the complexities of manufacturing.

Conclusion: The Future of CNC Machining and Semiconductor Manufacturing

The Ongoing Evolution of CNC Machining in the Semiconductor Industry

CNC machining will continue to play a pivotal role in the semiconductor industry’s evolution. With ever-increasing demands for precision and miniaturization, CNC machining provides the technology necessary to meet these challenges. As advancements in machining technology continue to emerge, companies that embrace these innovations will be able to stay ahead of the competition and meet the growing demands of the semiconductor market.

자주 묻는 질문

What is CNC machining and how does it help semiconductor manufacturing?

CNC machining is a precision manufacturing technique that uses computer-controlled machines to shape materials. It is essential in semiconductor manufacturing because it allows for high-precision production of components with exact tolerances, critical for the functionality of semiconductor devices.

Why is precision important in semiconductor machining?

Semiconductor components require extreme precision to function properly. Even the slightest deviation from the desired dimensions can result in defects that impact performance or lead to product failure. CNC machining ensures that components are manufactured to exact specifications.

What types of materials are used in semiconductor machining?

Common materials used in semiconductor machining include silicon, gallium arsenide, and ceramics. These materials require specialized machining techniques to maintain their integrity and meet the precision demands of semiconductor manufacturing.

What challenges does CNC machining face in semiconductor manufacturing?

CNC machining in semiconductor manufacturing faces challenges such as tool wear, heat generation, and the delicate nature of semiconductor materials. These issues can affect the quality of the final product, but with proper equipment and maintenance, they can be mitigated.

How does CNC machining contribute to sustainability in semiconductor production?

CNC machining helps reduce waste by using materials efficiently and producing high-precision components that require minimal rework. Additionally, advanced CNC machines are more energy-efficient, contributing to more sustainable manufacturing practices.

Can CNC machining be customized for specific semiconductor projects?

Yes, CNC machining is highly customizable and can be tailored to meet the specific needs of semiconductor manufacturers. This allows for the creation of custom components with intricate designs and high precision, ensuring that the end products meet the necessary standards for performance.