Introduction

CNC milling for aluminum is one of the most crucial processes in modern manufacturing. This versatile technique offers precise and efficient methods for machining aluminum into a wide variety of parts used in various industries. The purpose of this article is to provide a detailed guide on CNC milling for aluminum, addressing key topics such as machine selection, tooling, and optimization techniques. By the end, you will have a comprehensive understanding of how to leverage CNC milling for producing high-quality aluminum parts.

1. What is CNC Machining and Why is it Important for Aluminum?

CNC machining is a manufacturing process that uses computer-controlled machines to precisely cut, drill, and shape materials into a desired form. When applied to aluminum, CNC machining provides numerous advantages, including high accuracy, repeatability, and the ability to produce complex geometries. Aluminum is one of the most popular materials in CNC machining due to its excellent machinability, lightweight nature, and versatility across various industries. From automotive to aerospace applications, aluminum’s ability to be easily shaped and its resistance to corrosion make it a top choice for precision parts.

But here’s the kicker: CNC machining for aluminum allows for the creation of highly intricate parts with very tight tolerances, making it indispensable in industries where precision is key. Aluminum, being a relatively soft metal compared to others like steel, presents fewer challenges during the machining process, allowing for faster production times and lower tool wear. Furthermore, aluminum’s ability to dissipate heat during the machining process makes it ideal for high-speed machining.

Table: Benefits of CNC Machining for Aluminum

| Benefit | Explanation |

|---|---|

| High Precision | CNC machines can achieve tight tolerances and accuracy. |

| Versatility | Aluminum can be shaped into complex geometries. |

| Speed | Aluminum machines quickly due to its softness. |

| Durability | Aluminum has a high resistance to corrosion. |

| Cost-Effective | CNC machining for aluminum offers an affordable option. |

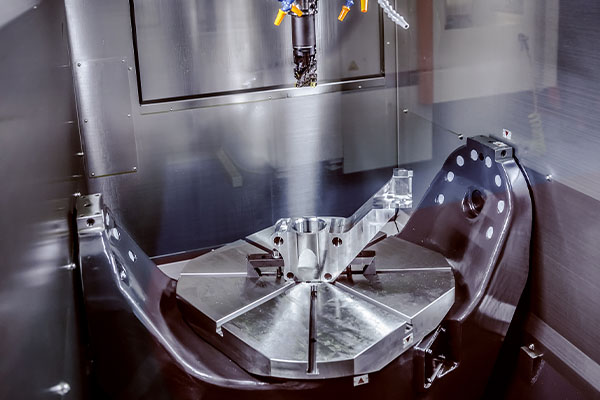

2. How Does CNC Milling Work on Aluminum?

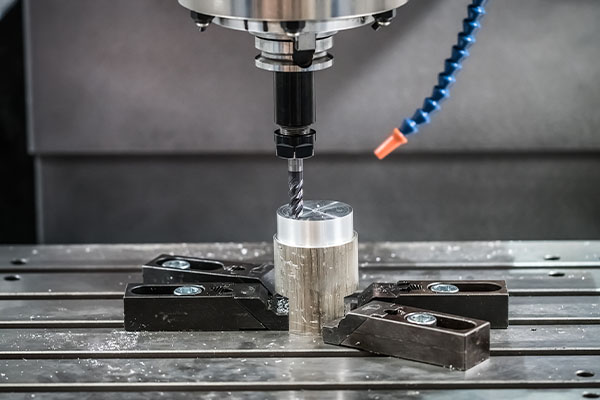

CNC milling involves using rotating cutters to remove material from a workpiece, which is mounted on a machine table. This process allows for the creation of complex shapes, holes, and surface finishes. Milling machines can perform both vertical and horizontal operations, depending on the orientation of the cutting tool and the workpiece. When it comes to aluminum, CNC milling works by using specialized end mills and cutting tools that are designed to handle the material’s properties.

What’s the real story? Milling aluminum requires careful consideration of several factors, including cutting speed, feed rates, and tool choice. The material’s softness makes it easier to machine, but it can also lead to issues such as excessive heat buildup and tool wear. Therefore, using the right cutting fluid and tool material is critical to achieving the desired finish and prolonging tool life.

Table: CNC Milling Process for Aluminum

| Step | Description |

|---|---|

| Clamping the Part | Secure the aluminum workpiece on the machine table. |

| Setting Up the Tool | Select appropriate cutting tools for aluminum. |

| Programming the CNC | Input the design specifications into the CNC machine. |

| Cutting | Perform the milling process by removing material. |

3. What are the Benefits of CNC Milling for Aluminum?

CNC milling for aluminum brings numerous advantages that contribute to its widespread use in various industries. First and foremost, the precision and repeatability offered by CNC machines ensure that each part is manufactured to the same exact standards. This high level of consistency is crucial for parts that must meet strict tolerances, such as those used in the aerospace industry.

So, why does this matter? The benefits of CNC milling for aluminum also extend to cost savings and faster production times. Since aluminum is relatively easy to machine compared to harder metals, it leads to reduced tool wear, lower labor costs, and quicker production cycles. Additionally, aluminum’s excellent thermal conductivity helps dissipate heat during machining, reducing the risk of part warping and tool damage.

The versatility of aluminum also cannot be overlooked. CNC milling enables the production of a wide range of part shapes, from simple to highly complex geometries. Its ability to be used in a variety of industries, including automotive, electronics, and medical devices, highlights why it remains a go-to choice for manufacturers.

Table: Key Benefits of CNC Milling for Aluminum

| Benefit | Explanation |

|---|---|

| Precision | Achieves high accuracy and tight tolerances. |

| Cost Savings | Reduces tool wear and speeds up production time. |

| Versatility | Aluminum can be used in many industries with various shapes. |

| Thermal Conductivity | Helps prevent overheating and tool damage. |

4. What Are the Key Considerations When CNC Milling Aluminum?

When it comes to CNC milling aluminum, there are several factors to keep in mind. First, the material itself plays a significant role in determining how the machining process will proceed. Aluminum is relatively soft, which allows for quicker cutting speeds, but it also means that the tools can wear out more rapidly compared to harder metals. This requires frequent tool changes to maintain accuracy.

Ready for the good part? Another consideration is the choice of cutting tools. Because aluminum tends to generate a lot of heat, using the right tooling material and cutting fluids is vital to ensure a smooth process. For example, carbide tools are often preferred due to their hardness and ability to withstand the heat generated during milling. Cutting fluids, such as synthetic oils, are essential to reduce friction and extend tool life.

The machining environment also affects the process. Aluminum tends to produce fine chips that can clog the machine and reduce efficiency. Proper chip management and coolant delivery are essential to prevent this.

Table: Key Considerations for CNC Milling Aluminum

| Factor | Consideration |

|---|---|

| Tooling | Use carbide tools for better performance and heat resistance. |

| Cutting Fluids | Essential for cooling and extending tool life. |

| Chip Management | Proper evacuation of chips is necessary to maintain machine efficiency. |

| Material Properties | Aluminum’s softness requires careful speed and feed rates. |

5. What Types of CNC Milling Machines are Best for Aluminum?

Selecting the right CNC milling machine for aluminum is critical for ensuring the highest quality parts and the most efficient production. Vertical milling machines are ideal for simple operations, such as drilling and cutting flat surfaces, while horizontal milling machines offer greater versatility and are better suited for more complex operations.

This is where it gets interesting: The decision to use a vertical or horizontal machine largely depends on the type of parts you are producing. For example, complex parts with multiple features may require a horizontal machine that allows for better access to the workpiece. On the other hand, simple aluminum parts might be produced more effectively on a vertical milling machine, which is typically faster and more cost-effective.

When selecting a CNC machine, consider the material capacity, tool changers, and the type of control system. Machines with automatic tool changers and advanced control systems are more efficient and reduce setup time, ultimately leading to faster turnaround times.

Table: Types of CNC Milling Machines for Aluminum

| Machine Type | Description |

|---|---|

| Vertical Milling | Best for simple operations and high-speed cutting. |

| Horizontal Milling | Ideal for complex geometries and large-scale production. |

| 5-Axis Milling | Allows for intricate cuts and multi-directional work. |

6. How Do You Choose the Right CNC Milling Tools for Aluminum?

Choosing the right tools for CNC milling aluminum is crucial for optimizing the machining process. The type of tools used depends on the specific aluminum grade and the complexity of the part being produced. Generally, carbide tools are a good choice for aluminum due to their durability and heat resistance. For larger milling tasks, multi-flute cutters can help improve cutting efficiency.

So, what’s the secret? For best results, choose tools with sharp edges and appropriate coatings, like TiN (Titanium Nitride), which enhance the tool’s hardness and performance during the milling process. The number of flutes on the cutting tool also plays a role in achieving the desired surface finish and cutting efficiency. Fewer flutes are suitable for deeper cuts, while more flutes are ideal for fine finishes and higher speeds.

Another factor to consider is the tool geometry. Proper geometry can reduce cutting forces and improve surface finish. For aluminum, tools with a positive rake angle help minimize the cutting force and reduce heat buildup.

Table: CNC Milling Tools for Aluminum

| Tool Type | Recommended Use |

|---|---|

| Carbide Tools | Ideal for aluminum due to hardness and heat resistance. |

| Multi-Flute Cutters | Best for high-efficiency cutting and finish quality. |

| TiN Coated Tools | Provides extended tool life and better performance. |

| Positive Rake Angle | Reduces cutting forces and heat buildup. |

7. What Are the Challenges of CNC Milling Aluminum?

While CNC milling for aluminum is highly efficient, it is not without its challenges. One of the primary issues is the potential for excessive tool wear due to the material’s softness. This leads to frequent tool changes and maintenance, which can increase costs over time. Additionally, aluminum’s tendency to produce fine chips can clog up the machine, reducing its efficiency and requiring careful chip management.

But here’s the kicker: Another challenge is managing the heat generated during the milling process. Although aluminum has excellent thermal conductivity, the cutting action can still create localized heat that affects tool life and part quality. To address this, effective coolant application is crucial to dissipate heat and prevent tool damage.

Finally, achieving the desired surface finish can be difficult, especially for parts with tight tolerances. Proper cutting speeds, feed rates, and tooling must be selected to achieve the highest quality.

Table: Challenges in CNC Milling Aluminum

| Challenge | Explanation |

|---|---|

| Tool Wear | Aluminum’s softness leads to faster tool wear. |

| Chip Management | Fine chips can clog machines, requiring effective removal. |

| Heat Generation | Heat buildup can affect tool life and part quality. |

| Surface Finish | Achieving a smooth finish requires precise settings. |

8. How Do You Optimize CNC Milling for Aluminum Parts?

Optimizing the CNC milling process for aluminum involves adjusting various factors to improve efficiency, surface finish, and tool life. First, it’s essential to choose the right cutting speed and feed rate. Too high a speed can lead to excessive heat, while too low a speed can cause the tool to chip or wear unevenly.

This is where it gets interesting: The key to optimization lies in balancing speed and feed rates to achieve an efficient cut while avoiding unnecessary wear. Additionally, selecting the proper cutting fluid or coolant is crucial. Coolants help to dissipate heat, flush away chips, and lubricate the cutting area, reducing friction and wear on the tools.

Another optimization technique is to adjust the depth of cut and the tool path. Shallow cuts and frequent tool retractions help avoid heat buildup and reduce the chances of tool failure.

Table: CNC Milling Optimization for Aluminum

| Factor | Optimal Setting |

|---|---|

| Cutting Speed | Balance speed to prevent overheating and tool wear. |

| Feed Rate | Match feed rate to cutting speed for best results. |

| Coolant | Use water-soluble coolants for better chip removal. |

| Depth of Cut | Use shallow cuts to reduce tool stress and heat buildup. |

9. What Are Some Common Applications of CNC Milling for Aluminum?

CNC milling for aluminum is used in a wide range of industries, including aerospace, automotive, and consumer electronics. In the aerospace industry, aluminum is commonly used for creating lightweight structural components such as wings, fuselages, and brackets. The material’s strength-to-weight ratio makes it ideal for these applications, where weight reduction is crucial.

But here’s the kicker: The automotive industry also relies heavily on CNC milling to create parts such as engine blocks, transmission components, and chassis parts. Aluminum’s high strength-to-weight ratio and corrosion resistance make it the material of choice for these components.

In consumer electronics, CNC milling is used to manufacture parts such as heat sinks, housings, and enclosures. Aluminum’s ability to dissipate heat effectively makes it ideal for use in devices like smartphones, laptops, and gaming consoles.

Table: Applications of CNC Milling for Aluminum

| Industry | Common Applications |

|---|---|

| Aerospace | Wings, fuselages, structural components. |

| Automotive | Engine blocks, transmission parts, chassis components. |

| Electronics | Heat sinks, enclosures, housings for consumer devices. |

10. How Do You Maintain CNC Milling Machines for Aluminum Work?

Maintaining CNC milling machines is crucial for ensuring the longevity and efficiency of the equipment. Regular cleaning is essential to remove aluminum chips, dust, and coolant buildup. A clean machine ensures optimal performance and reduces the risk of part contamination.

What’s the real story? Machine calibration is also vital to maintain accuracy. Regular checks for alignment and leveling can prevent parts from being machined out of tolerance. Furthermore, lubricating the moving parts of the machine helps reduce wear and tear, ensuring smoother operation.

Tool maintenance is equally important. Keeping the cutting tools sharp and free from chips will ensure that the milling process runs smoothly and that the desired surface finish is achieved.

Table: CNC Machine Maintenance for Aluminum

| Maintenance Task | Explanation |

|---|---|

| Cleaning | Regular cleaning removes chips and coolant buildup. |

| Calibration | Check machine alignment to ensure part accuracy. |

| Lubrication | Lubricate moving parts to prevent wear and ensure smooth operation. |

11. What are the Different Types of Aluminum Used in CNC Milling?

Aluminum alloys come in various grades, each with different properties suitable for specific CNC milling applications. Common aluminum alloys used in CNC milling include 6061, 7075, and 2024. The 6061 alloy is known for its excellent machinability and is often used for general-purpose applications. The 7075 alloy, on the other hand, is much stronger and is typically used in aerospace and military applications.

So, why does this matter? The choice of aluminum alloy affects machining conditions, such as cutting speed, tool wear, and the overall surface finish. For example, while 6061 is easier to machine, it may not have the strength required for high-stress applications like 7075.

Table: Types of Aluminum Used in CNC Milling

| Alloy Type | Common Uses |

|---|---|

| 6061 | General-purpose parts, structural components. |

| 7075 | Aerospace, military applications, high-stress components. |

| 2024 | Aircraft structures, high-performance parts. |

12. How Does CNC Milling Impact Aluminum Part Design?

CNC milling plays a significant role in part design, as it allows for greater flexibility and precision. Designers can create complex geometries that would be impossible with traditional machining methods. With CNC milling, features such as deep holes, complex curves, and intricate cutouts can be easily incorporated into the design.

But here’s the kicker: The accuracy provided by CNC milling means that tight tolerances can be maintained, ensuring that parts fit perfectly within an assembly. This level of precision is essential in industries such as aerospace and medical device manufacturing, where even slight variations can lead to failure.

Table: CNC Milling Design Considerations

| Design Element | Consideration |

|---|---|

| Tolerances | CNC milling allows for tight tolerances in part design. |

| Geometries | Complex shapes can be machined with ease. |

| Fit and Function | Ensures parts fit precisely within an assembly. |

13. How Do CNC Milling Techniques Compare to Other Machining Methods for Aluminum?

CNC milling is just one of several machining methods used for aluminum parts. Compared to other methods like turning and electrical discharge machining (EDM), CNC milling offers higher precision and the ability to produce complex geometries.

What’s the real story? CNC milling provides more versatility than turning, especially when it comes to machining complex shapes. However, turning can be more efficient for cylindrical parts. EDM, while excellent for precise cuts, is slower and typically used for harder materials or fine details.

Table: CNC Milling vs. Other Machining Methods

| Machining Method | Pros | Cons |

|---|---|---|

| CNC Milling | High precision, versatile for complex shapes. | Slower than turning for simple shapes. |

| Turning | Faster for cylindrical parts. | Limited to round shapes. |

| EDM | High precision for intricate details. | Slower, higher cost. |

14. What Are the Cost Factors in CNC Milling Aluminum Parts?

The cost of CNC milling aluminum parts depends on several factors, including material cost, machine time, tooling, and labor. Material costs vary depending on the aluminum alloy used and the quantity ordered. For example, higher-strength alloys like 7075 are more expensive than 6061.

Ready for the good part? Machine time is another major cost factor, as longer machining times result in higher labor and overhead costs. Tooling and maintenance also contribute to the cost, as specialized tools may be required to handle specific aluminum alloys or part designs.

Table: CNC Milling Cost Factors

| Cost Factor | Explanation |

|---|---|

| Material Cost | Depends on the aluminum alloy chosen and the order quantity. |

| Machine Time | Longer machining time increases labor and overhead costs. |

| Tooling and Maintenance | Specialized tools may increase initial setup costs. |

15. What Are the Future Trends in CNC Milling for Aluminum?

The future of CNC milling for aluminum is shaped by advancements in machine technology, automation, and materials. CNC machines are becoming more automated, with features like tool changers and robotic arms that reduce human intervention and speed up production.

This is where it gets interesting: The integration of artificial intelligence (AI) into CNC milling machines is improving efficiency, enabling real-time adjustments during machining. Additionally, advancements in materials science may lead to the development of new aluminum alloys that are even easier to machine or offer better performance.

Table: Future Trends in CNC Milling for Aluminum

| Trend | Explanation |

|---|---|

| Automation | Reducing human intervention with robotic systems. |

| AI Integration | Real-time adjustments and optimization in milling. |

| Material Advancements | New aluminum alloys that improve machining efficiency. |

Conclusion

In conclusion, CNC milling for aluminum is a highly efficient and precise method that offers significant benefits across various industries. By understanding the basics, optimizing the process, and choosing the right tools and machines, manufacturers can produce high-quality aluminum parts that meet demanding specifications. With continuous advancements in technology, CNC milling for aluminum will remain a key player in the manufacturing sector.

FAQ Section

- Q1: What is CNC milling for aluminum?

CNC milling for aluminum is a precise machining process that uses computer-controlled machines to remove material from an aluminum workpiece. It’s widely used in manufacturing for creating parts with high precision and complex shapes. - Q2: How does CNC milling work?

CNC milling uses rotating cutters to remove material from a solid block of aluminum. The machine follows pre-programmed instructions to create precise and repeatable cuts. The machine can operate both vertically and horizontally, depending on the part design. - Q3: What are the advantages of CNC milling for aluminum?

The main advantages of CNC milling for aluminum include high precision, repeatability, cost-effectiveness, and the ability to produce complex geometries. Additionally, aluminum is easy to machine, which results in faster production times and reduced tool wear. - Q4: How can I optimize CNC milling for aluminum parts?

Optimizing CNC milling for aluminum involves adjusting cutting speeds, feed rates, and tool selection. Choosing the right cutting fluids and ensuring proper chip removal also helps reduce tool wear and improve surface finish. Fine-tuning these factors can lead to better efficiency and part quality. - Q5: What types of aluminum are used in CNC milling?

Common types of aluminum used in CNC milling include alloys like 6061, 7075, and 2024. Each alloy has specific properties, such as strength, machinability, and corrosion resistance, that make them suitable for different applications. For example, 6061 is commonly used for general-purpose parts, while 7075 is used in high-stress applications like aerospace.