CNC Machining Service

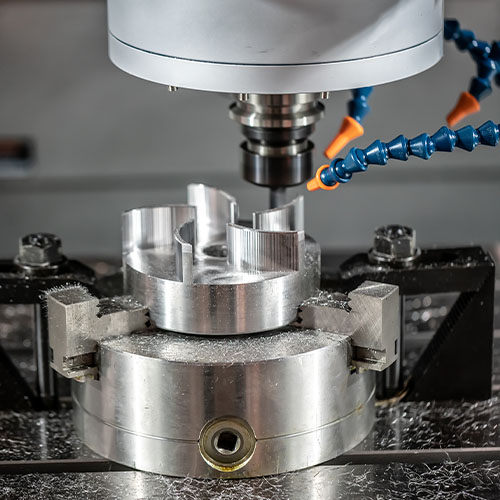

Online CNC machining

Precision on-demand CNC machining services for rapid prototyping and production, We ensure fast turnaround, exceptional quality, and reliable performance for every project.

CNC-bewerking

What is CNC Machining Technology?

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technology enables precise control over complex machinery, including lathes, mills, routers, and grinders. CNC machining can produce highly accurate and consistent parts from a variety of materials, such as metals, plastics, and composites. The process is ideal for both prototyping and mass production, ensuring high efficiency, minimal waste, and exceptional repeatability. With its ability to create intricate designs and meet tight tolerances, CNC machining is widely used across industries like aerospace, automotive, electronics, and medical equipment manufacturing.

- High precision and stability

- High production efficiency

- Complex parts processing

- Wide material applicability

- Reduce labor costs

- Strong repeatability

CNC Capabilities

Cutting-Edge Equipment & Expertise for Diverse Machining Solutions

Machining Scope:

* Precision components with complex geometries and multi-axis machining.

* Suitable for both large-scale production and small-batch manufacturing.

Equipment Capabilities:

* 3-axis, 4-axis, and 5-axis CNC machining centers to meet varying precision requirements.

* Flexible size capabilities, from micro parts to large-scale components, tailored to your specifications.

Aluminum is lightweight yet strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive parts, our aluminum CNC milling service ensures precise and high-quality machining tailored to your specific needs.

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

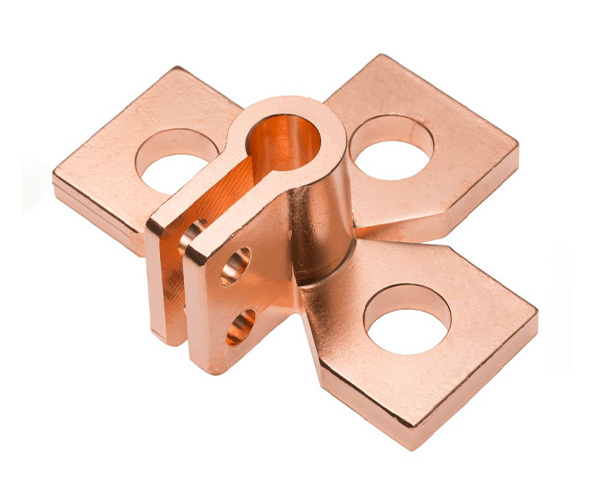

Copper is known for its superior electrical conductivity and thermal properties, making it perfect for electrical components and heat exchangers.

Copper C101(T2)

Copper C103(T1)

Copper C103(TU2)

Copper C110(TU0)

Beryllium Copper

Brass is durable and has a low friction coefficient, which makes it suitable for fittings, tools, and musical instruments that require precision.

Alloys

Brass C27400

Brass C28000

Brass C36000

Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

Alloys

Tin Bronze

Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

Alloys

Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36

Die steel

Alloy steel

Chisel tool steel

Spring steel

High speed steel

Cold rolled steel

Bearing steel

SPCC

Stainless steel is renowned for its corrosion resistance, making it a prime choice for medical devices and food processing equipment.

Alloys

Stainless Steel SUS201

Stainless Steel SUS303

Stainless Steel SUS 304

Stainless Steel SUS316

Stainless Steel SUS316L

Stainless Steel SUS420

Stainless Steel SUS430

Stainless Steel SUS431

Stainless Steel SUS440C

Stainless Steel SUS630/17-4PH

Stainless Steel AISI 304

Magnesium is the lightest structural metal, offering high strength-to-weight ratios, perfect for automotive and aerospace applications where weight is critical.

Alloys

Magnesium Alloy AZ31B

Magnesium Alloy AZ91D

Titanium boasts the highest strength-to-density ratio among metals, highly resistant to corrosion and fatigue, ideal for aerospace, medical, and marine applications.

Alloys

Titanium Alloy TA1

Titanium Alloy TA2

Titanium Alloy TC4/Ti-6Al 4V

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

PC Black

PC Transparent

PC White

PC Yellowish White

PC+GF30 Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

PE Black

PE White

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

PMMA Black

PMMA Transparent

PMMA White

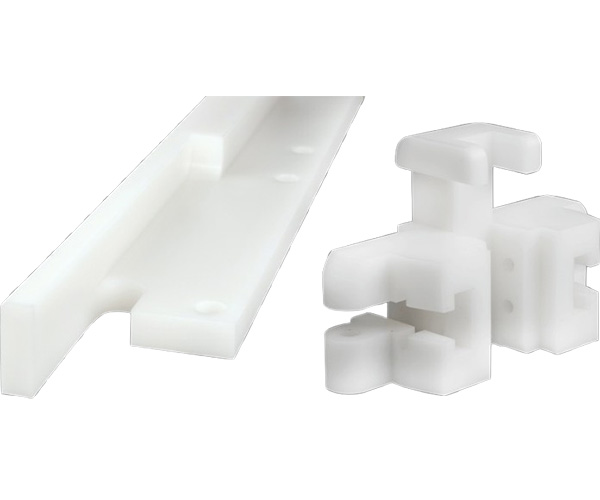

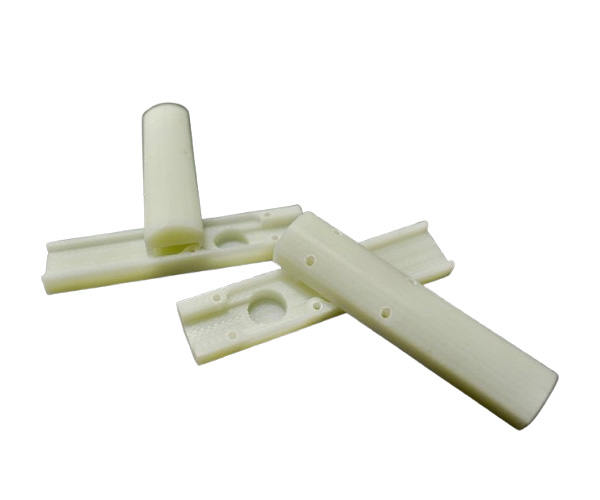

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

Dark brown (coffee) POM 100AF

POM Black

POM Blue

POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

PA(Nylon) Blue

PA6 (Nylon)+GF15 Black

PA6 (Nylon)+GF30 Black

PA66 (Nylon) Beige(Natural)

PA66 (Nylon) Black

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

PEEK Beige(Natural)

PEEK Black

PET is strong, resistant to moisture and chemicals, and widely used in food containers and textile fibers.

PET Black

PET White

PET+GF30 Black

PET+GF30 White

PVC is robust, cheap, and has good chemical resistance, used in plumbing, medical devices, and cables.

PVC Grey

PTFE is known for its outstanding chemical resistance and low friction, making it perfect for non-stick coatings and gaskets.

Teflon (PTFE) Black

Teflon (PTFE) White

FR-4 is a flame-resistant material, primarily used in the electronics industry for circuit boards and insulators.

FR-4 Aqua Green

FR-4 Yellow

Metals

Plastics

Supported Materials:

- Metals: Aluminum, stainless steel, titanium alloys, and more.

- Plastics: POM, ABS, polycarbonate, and other engineering plastics, etc.

Our Products

We Provide Complete Services

Precision CNC Machining Solutions for Reliable Performance

Delivering high-precision CNC machined products with exceptional accuracy, durability, and consistency. Ideal for industries requiring reliable and cost-effective manufacturing solutions.

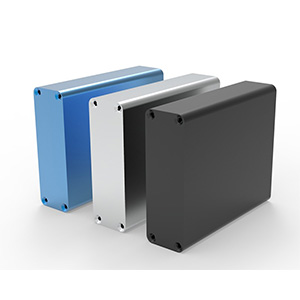

Aluminum Auto Parts

Precision Instrument Housing

Brass Machine Part

Steel Automation Machine Part

Surgical Instrument Part

PE CNC Machining Spacer

Delrin Component

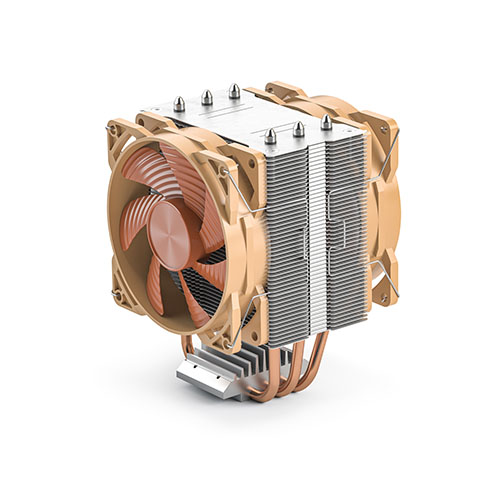

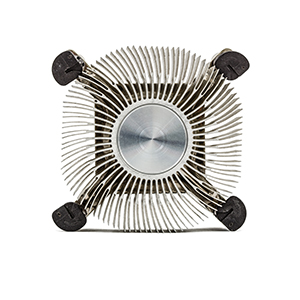

Aluminum Heat Sink

Years Experience

Advantages of CNC Machining

Precision, Consistency, and Efficiency in CNC Milling Machining

CNC machining offers exceptional precision with an accuracy of ±0.01mm, ensuring flawless production of complex components. Its fully automated processes guarantee consistency, whether for single prototypes or large-scale production runs. With high operational efficiency, CNC machines deliver faster turnaround times after programming. They support a wide range of materials, including metals, plastics, and composites, making them versatile for diverse applications. Additionally, optimized tool paths minimize material waste, reducing overall production costs and enhancing sustainability.

Industry Integration

CNC machining is closely linked to various industries, providing precise and efficient solutions for complex manufacturing needs.

Process Compatibility

CNC machining seamlessly integrates with multiple processes, ensuring versatility and consistency across different production requirements.

Applications & Case Studies

What Industries Do We Provide CNC Machining Services for?

Toepassingen

CNC machining plays a crucial role across diverse industries, delivering precision, efficiency, and reliability in manufacturing complex components.

Automotive Industry: CNC machining is widely used for manufacturing engine components, drive shafts, and structural body parts, ensuring durability and precision in high-performance vehicles.

Aerospace Industry: Known for handling complex structural components and high-strength lightweight materials, CNC machining meets the stringent quality and safety standards of aerospace applications.

Medical Devices: CNC technology enables the production of high-precision surgical instruments and implant components, ensuring strict compliance with medical safety requirements.

Electronics Industry: CNC machining supports the manufacturing of housings, heat sinks, and small connectors, contributing to reliable and compact electronic devices.

Case Study

Client Requirement: A client needed highly precise engine components for a new automotive prototype, with strict tolerances and short delivery deadlines.

Challenges: The components required intricate designs, exceptional precision, and material durability while maintaining a fast production cycle.

Solution: By utilizing advanced CNC machining techniques and optimized tool paths, we ensured accuracy and reduced waste.

Outcome: The client received precision-engineered components ahead of schedule, enhancing the vehicle’s performance and meeting all quality standards.

This case highlights our ability to deliver tailored CNC solutions across various industries with excellence.

Unique CNC Machining Technology

CNC machining encompasses a range of specialized techniques designed to deliver precision, efficiency, and consistency in manufacturing. Below are the key processes, categorized for clarity:

01 Cutting Processes

CNC Cutting: Cuts materials into desired shapes using precision blades or lasers. Delivers clean edges and reduces material waste. Suitable for metals, plastics, and composites.

02 Material Removal Processes

CNC Milling: Removes material from a solid workpiece using rotary cutting tools. Ideal for creating complex shapes, slots, and holes with high precision. Commonly used for prototypes and production parts.

CNC Turning: Rotates the workpiece while a cutting tool removes material. Suitable for cylindrical or round components like shafts and bushings, delivering excellent surface finishes and tight tolerances.

CNC Drilling: Precisely drills holes into workpieces at specific locations and depths, ensuring accuracy in hole size, alignment, and depth control. Common in automotive and aerospace components.

03 Surface Finishing Processes

CNC Grinding: Achieves fine surface finishes and tight dimensional tolerances. Often used for high-precision components requiring smooth surfaces. Suitable for both metallic and non-metallic materials.

04 Specialty Machining Processes

Electrical Discharge Machining (EDM): Uses electrical discharges to shape hard metals and intricate designs. Ideal for materials difficult to machine with traditional tools. Often applied in aerospace and mold manufacturing.

CNC Machining Tolerance

Why Are CNC Machining Tolerances So Important?

CNC machining tolerance ensures precision, consistency, and proper fit of components. Tight tolerances are critical for maintaining quality, functionality, and reliability in industries requiring high-performance parts, such as aerospace, automotive, and medical. Our metal machining tolerances can reach 2768-M, while plastic part tolerances can achieve 2768-C.

3-Axis

4-Axis

5-Axis

Maximum Size

1000*500*500MM

1000*500*500MM

4000*1500*600MM

Minimun Size

5*5*5MM

5*5*5MM

5*5*5MM

General Tolerance

±0.1 mm

±0.05 mm

±0.1 mm

Lead Time

1 day for simple sample

5-7 days for general project

5-7 days for general project

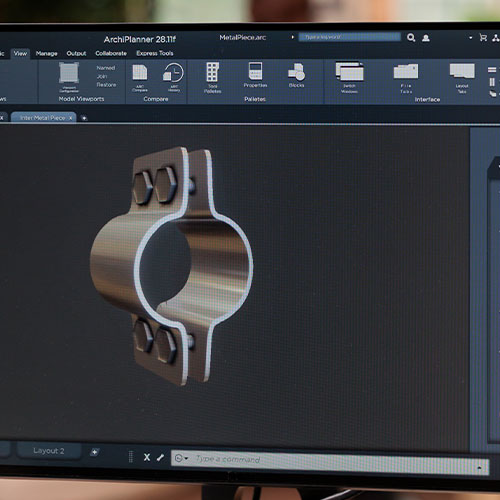

CNC Machining Design

Precision CNC Machining Design for Optimal Performance

Our CNC machining design process ensures every detail is meticulously planned for accuracy and efficiency. With expertly crafted CNC machine drawings, we translate complex designs into precise components. Whether it’s CNC prototype machining for initial testing or full-scale production, our design expertise guarantees optimal performance and seamless manufacturing. Trust us to bring your concepts to life with precision and reliability.

Radii

Internal radii should be no less than one-third of the cavity depth. Whenever possible, opt for larger radii to improve strength and manufacturability.

Threads and Tapped Holes

Diameter Φ1.5-5 mm: Depth up to 3 times the diameter.

Diameter Φ5 mm or larger: Depth up to 4-6 times the diameter.

Vation can manufacture threads in any specification En size to meet customer requirements.

Minumum Wall Thickness

For metals: 0.8 mm; For plastics: 1.5 mm. Increased wall thickness enhances structural integrity and ensures greater durability and reliability in final components.

Text

CNC Milling: Minimum width of 0.5 mm and depth of 0.1 mm. We can precisely engrave standard text using CNC engraving or laser engraving, tailored to meet customer specifications.

Holes

The minimum hole diameter is 1 mm, and for optimal results, the hole depth should not exceed 4 times its diameter.

What We Offer

How can we solve your processing challenges?

High Precision Requirements: Multi-axis machining centers ensure exceptional accuracy, meeting the demands of complex structural components with tight tolerances.

Tight Deadlines & Mass Production: Efficient production lines and flexible scheduling guarantee on-time delivery, even for large-scale orders.

Surface Treatment Standards: Comprehensive surface treatment processes ensure both visual appeal and functional durability for every product.

QUESTION ANSWERS

FAQs About CNC Machining Service

Explore common inquiries about our CNC machining services to better understand our capabilities, processes, and commitment to quality. If your question isn’t answered here, feel free to contact us directly.

We work with a wide range of materials, including metals (aluminum, stainless steel, titanium), plastics (ABS, PEEK), and composites. Our advanced CNC equipment ensures precision machining regardless of material type, delivering consistent quality and performance across every project.

Quality is our top priority. We use advanced CNC machines, strict quality control systems, and multi-stage inspections throughout the production process. Each part is checked for precision, durability, and compliance with customer specifications before delivery.

Lead times vary depending on project complexity and volume. However, our flexible scheduling and efficient production lines enable us to deliver prototypes within days and bulk orders within a few weeks, ensuring timely delivery every time.

Yes, we offer fully customized CNC machining solutions tailored to your specific requirements. From prototyping to mass production, our team collaborates closely with clients to deliver optimal results.

Absolutely. Our facility is equipped with advanced machinery and scalable production capabilities, allowing us to efficiently manage both small batches and large-scale production orders without compromising quality or delivery timelines.

We provide a variety of surface treatments, including anodizing, powder coating, polishing, and plating. These finishes not only enhance appearance but also improve durability and resistance to environmental factors.