Introdução

When considering a career in manufacturing, CNC machining often stands out as a promising option. But, is CNC machining a good career choice? This article delves into the pros and cons of pursuing a career as a CNC machinist. We’ll look at the key benefits, the challenges, and everything you need to know about whether this career is right for you. Let’s explore what makes CNC machining a viable career option and what to consider before you take the plunge.

1. What Are the Key Aspects of CNC Machining as a Career?

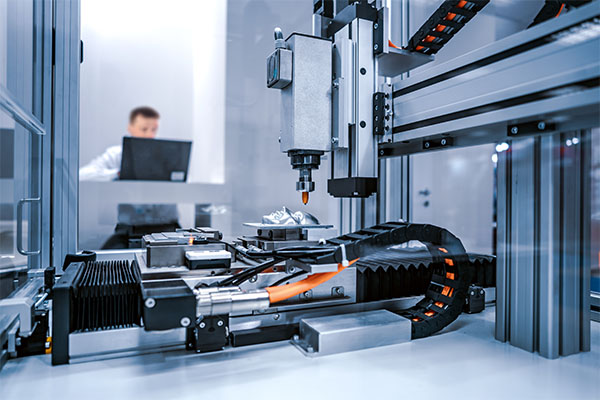

To begin with, CNC machining is a manufacturing process that uses computer-controlled machinery to produce highly precise parts. As a CNC machinist, you’ll be working with machines that can cut, shape, and finish materials like metal, plastic, and composite materials. It’s a skill-based job that requires hands-on experience and technical knowledge.

Ready for the good part? One of the most interesting aspects of CNC machining is that it offers a wide variety of job roles. From machine operators to CNC programmers, the options are diverse. For example, machine operators typically load materials and monitor machine performance, while CNC programmers write the code that controls the machines. The industry is versatile, offering jobs in aerospace, automotive, medical devices, and more.

But here’s the kicker… It’s not just about operating machines. CNC machinists are also responsible for ensuring that the parts produced meet high-quality standards. This requires not only technical skills but also a strong understanding of precision and attention to detail. While the work can be demanding, it’s also rewarding for those who thrive in problem-solving and hands-on environments.

| Key Role | Description | Skills Required |

|---|---|---|

| CNC Machine Operator | Operates CNC machines for various tasks | Attention to detail, mechanical aptitude |

| CNC Programmer | Writes code to control machine functions | Computer programming, problem-solving |

| CNC Setup Technician | Prepares machines for production | Machine setup, tool management |

2. What Are the Benefits of a CNC Machining Career?

So, why should you consider a career in CNC machining? Well, there are several benefits that make it an attractive option. First, there’s the high demand for skilled machinists. As industries continue to evolve, CNC machining has become more crucial for manufacturing precise components.

What’s the real story? CNC machining is not only in demand but also offers high earning potential. In the United States, the median salary for CNC machinists ranges from $40,000 to $60,000, depending on experience and location. Additionally, for those who take the time to develop expertise and specialize in certain sectors, the salary can increase significantly. In fact, senior machinists and CNC programmers can earn upwards of $80,000 annually.

Moreover, job stability is another key benefit. With the continuous need for high-quality, precision-manufactured products, machinists are needed across many industries. From the booming automotive sector to medical devices, the demand for skilled CNC professionals is expected to rise, making job security a strong factor in favor of this career.

| Beneficiar | Explanation |

|---|---|

| Job Security | Increased demand for skilled CNC machinists across industries |

| Competitive Salary | Median salary ranges from $40,000 to $60,000, with growth potential |

| Career Flexibility | Opportunities to work in various industries, such as aerospace, automotive, and medical devices |

3. What Are the Drawbacks of Pursuing CNC Machining?

Now, let’s be realistic—no career is without its challenges, and CNC machining is no exception. The most obvious drawback is that it can be physically demanding. Machinists often spend long hours on their feet, operating heavy machinery. In addition, working with metals and high-powered tools means there’s always a risk of injury if proper safety protocols aren’t followed.

But here’s the kicker… The work environment can also be noisy and uncomfortable. CNC machinists often work in industrial settings where loud machines and potential hazards are part of the daily routine. For those not accustomed to such an environment, it might take some adjustment. Safety measures are essential, and although protective gear is provided, the noise and machinery can be overwhelming.

Moreover, CNC machinists need to continually upgrade their skills. With technological advancements, newer machines are becoming more sophisticated, and staying updated on the latest technology is crucial. This means ongoing education and training, which might be a downside for some individuals who prefer stable, unchanging job responsibilities.

| Drawback | Explanation |

|---|---|

| Physically Demanding | Long hours on your feet with heavy machinery |

| Risk of Injury | Working with tools and machines requires strict adherence to safety |

| Continuous Skill Development | The need for constant learning to keep up with technological advances |

4. How Does CNC Machining Compare to Other Manufacturing Careers?

CNC machining holds its own against other manufacturing careers in terms of earning potential, skill development, and job security. However, it’s important to understand how it compares to traditional machining jobs or roles in other factory settings.

So, what’s the real difference? Traditional machinists work with manual machines, which require more hands-on effort and less reliance on computer technology. CNC machinists, on the other hand, work with automated systems that significantly increase efficiency. While traditional machining may be better suited to those who prefer a more tactile and hands-on approach, CNC machining is ideal for those who are comfortable with technology and automation.

Ready for the good part? CNC machining often offers higher pay than manual machining due to the additional skillset required. CNC machinists are trained to operate advanced machinery, write and troubleshoot programs, and maintain precision manufacturing standards. These responsibilities increase the value of CNC machinists in the workforce, making them more sought after.

| Career Type | Key Responsibilities | Salary Range |

|---|---|---|

| CNC Machinist | Operates CNC machines, writes programs, maintains quality | $40,000 – $60,000 |

| Manual Machinist | Operates manual machines, skilled in tool work | $30,000 – $50,000 |

| Production Worker | Operates factory machines, assembly line tasks | $25,000 – $40,000 |

5. Is CNC Machining a Stable Career Choice in Today’s Economy?

Absolutely. CNC machining has proven to be a stable career, especially as industries continue to rely on precision manufacturing. One reason for the stability is that many of the sectors CNC machinists serve are growing, including aerospace, automotive, medical devices, and consumer electronics.

What’s the real story? Even in the face of economic fluctuations, industries still require high-quality parts that are precisely manufactured. The demand for skilled CNC machinists has remained strong, and many companies are actively seeking workers to fill these positions. In fact, the Bureau of Labor Statistics projects steady growth in the CNC machining industry over the next decade.

Furthermore, as automation continues to play a larger role in manufacturing, CNC machinists are increasingly being seen as essential workers. Their role in programming and troubleshooting automated systems makes them invaluable to companies that rely on automated processes for efficiency.

| Industry | Growth Potential | Key Areas of Demand |

|---|---|---|

| Aeroespacial | High demand for precision parts | Aircraft components |

| Medical Devices | Continuous need for specialized parts | Surgical instruments |

| Automotive | Growth in electric vehicles | Engine components |

6. What Qualifications Do You Need to Become a CNC Machinist?

So, how do you get started in CNC machining? It’s not just about operating a machine—it requires specific skills, training, and certifications. While a high school diploma is typically the minimum requirement, it’s highly beneficial to pursue specialized training.

Here’s the kicker… There are several paths to becoming a CNC machinist. Some individuals start with an apprenticeship, which provides hands-on experience and technical training. Others attend technical schools or community colleges that offer programs in CNC machining. These programs typically cover the fundamentals of CNC operations, blueprint reading, and the basics of machining technology.

Additionally, many machinists pursue certifications from organizations like the National Institute for Metalworking Skills (NIMS) to demonstrate their expertise and improve job prospects. With these credentials, CNC machinists can command higher salaries and have access to more career advancement opportunities.

| Qualification | Description | Benefícios |

|---|---|---|

| High School Diploma | Basic education requirement | Entry-level positions available |

| CNC Machining Certificate | Specialized training from a technical school | Higher pay, specialized roles |

| NIMS Certification | National certification for machinists | Job security, career advancement |

7. What Skills Are Essential for CNC Machinists?

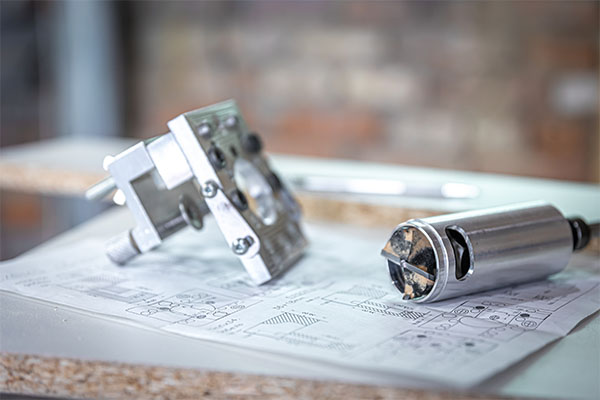

To succeed in CNC machining, it’s important to develop a variety of skills. Some are technical, such as the ability to read blueprints and use precision tools. Others are soft skills, like communication and problem-solving.

Ready for the good part? The most crucial technical skill is the ability to operate CNC machinery. This includes setting up machines, writing programs, and ensuring that parts are manufactured within the required tolerances. Furthermore, CNC machinists need to be proficient in CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to create and modify machine programs.

Additionally, CNC machinists need to be able to troubleshoot when things go wrong. Machines may break down, parts may not meet specifications, or software may have issues. The ability to think critically and solve problems on the fly is crucial to ensuring production runs smoothly.

| Skill | Importância | Example Application |

|---|---|---|

| CNC Machine Operation | Essential for job function | Operating CNC mills and lathes |

| Software CAD/CAM | Important for programming and design | Creating programs for machines |

| Troubleshooting | Necessary for problem-solving on the job | Diagnosing and fixing machine errors |

8. How Can You Start a Career in CNC Machining?

Starting a career in CNC machining is a journey that combines technical education, hands-on experience, and a passion for precision. So, how exactly do you get your foot in the door? It all begins with the right training and understanding the various paths that can lead you to a successful CNC machining career.

Ready for the good part? You don’t necessarily need a four-year degree to start. Many CNC machinists begin their careers by enrolling in a vocational school or community college where they can receive the training they need. These programs teach the basics, such as how to read blueprints, understand machine operation, and use the required tools.

But here’s the kicker… you don’t have to stop there. Apprenticeships offer an excellent alternative or supplement to formal education. Apprenticeships are on-the-job training programs where you can learn directly from experienced machinists while earning a paycheck. They usually last between one and four years, providing you with the real-world experience needed to thrive in the field. Plus, they often lead to full-time employment after completion.

Many companies offer these apprenticeships, allowing you to gain hands-on experience in a live production environment. After completing the necessary training, you’ll have the skill set needed to begin your CNC machining career.

| Path to Start Career | Description | Pros |

|---|---|---|

| Vocational School | Formal education in machining fundamentals | Structured learning, certifications |

| Apprenticeship | On-the-job training with experienced machinists | Real-world experience, paid opportunity |

| Technical Degree (optional) | In-depth education in CNC technologies | More advanced roles, higher salary potential |

9. How Much Can You Earn as a CNC Machinist?

One of the key considerations when choosing a career is the potential salary. So, how much can CNC machinists expect to earn? The good news is that CNC machining offers competitive salaries, and the pay increases with experience and skill development.

What’s the real story? The average salary for a CNC machinist in the United States is around $45,000 per year. However, this number can vary greatly based on location, level of experience, and industry. For example, machinists working in high-demand sectors like aerospace or medical devices can earn significantly more, with salaries reaching up to $70,000 or more.

But here’s the kicker… CNC programmers, who are responsible for writing the code that controls the machines, can command higher wages. They earn an average of $60,000 per year, with the top 10% earning upwards of $80,000 annually. The more specialized your skill set, the more you can expect to earn.

Ready for the good part? The earnings also tend to improve as you advance in your career. Senior positions, such as CNC supervisor or machine shop manager, can see salaries rise to six figures, especially if you have experience in a niche industry.

| Job Title | Average Salary | Impacto na indústria |

|---|---|---|

| CNC Machinist | $45,000 – $60,000 | Varies by experience and industry |

| CNC Programmer | $60,000 – $80,000 | Higher pay due to specialized skills |

| CNC Supervisor/Manager | $75,000 – $100,000+ | Leadership roles command higher salaries |

10. What Are the Career Advancement Opportunities in CNC Machining?

CNC machining is a field with plenty of room for growth. Whether you want to move into management, expand your technical skills, or transition to a related career, CNC machining offers many career advancement opportunities.

But here’s the kicker… It’s not just about operating machines forever. One of the most common career paths for CNC machinists is to move into programming. As a CNC programmer, you’ll be responsible for writing and modifying the code that tells machines how to perform specific tasks. This role requires an in-depth understanding of programming languages and CAD/CAM systems. However, it offers more responsibility and, often, a higher salary.

Ready for the good part? You can also move into supervisory or managerial roles. CNC machinists with significant experience can take on leadership positions in a machine shop, overseeing teams of operators and programmers. With this transition, you’ll be responsible for ensuring that projects are completed on time, managing resources, and meeting production targets. These leadership roles are well-compensated and come with added job security.

Furthermore, you could choose to specialize in a particular type of CNC machine, such as 5-axis machining, which offers a unique set of skills that can lead to higher-paying positions in specialized industries.

| Career Path | Description | Salary Impact |

|---|---|---|

| CNC Programmer | Writing code and programming CNC machines | Higher salary, specialized role |

| CNC Supervisor/Manager | Overseeing operations, managing teams | Significant pay increase, leadership responsibilities |

| CNC Specialist | Expertise in a specialized machine or process | Niche expertise = higher wages |

11. What Industries Hire CNC Machinists?

CNC machinists are in high demand across various industries. From aerospace to automotive to medical devices, CNC machining plays an essential role in producing precision components. Let’s dive into some of the key industries where CNC machinists are needed.

What’s the real story? Aerospace is one of the most prominent industries for CNC machinists. Aircraft components require the highest level of precision, and CNC machining is often the only method that can meet those exacting standards. As the aerospace industry grows, so does the demand for skilled CNC machinists.

But here’s the kicker… Medical device manufacturing is another industry with an increasing need for CNC machinists. The demand for highly specialized parts, such as surgical instruments and implants, has led to the growth of CNC machining in the medical field. Machinists working in this sector must have a keen eye for detail, as even the smallest error can have serious consequences.

Ready for the good part? The automotive industry also relies heavily on CNC machining to produce precision parts for vehicles. With the shift towards electric vehicles, the demand for CNC machinists in automotive manufacturing is only expected to increase. CNC machinists are also needed in smaller, niche industries such as robotics and electronics.

| Industry | Key Role | Demand for CNC Machinists |

|---|---|---|

| Aeroespacial | Precision manufacturing of aircraft parts | High demand for machinists in aerospace |

| Medical Devices | Manufacturing of surgical instruments | Growth in demand for specialized parts |

| Automotive | Producing components for vehicles | Increased demand due to electric vehicle growth |

12. How Does Technology Impact CNC Machining Careers?

As with any other industry, technology plays a crucial role in the evolution of CNC machining. In recent years, technological advancements have revolutionized how CNC machines operate, leading to greater precision, faster production times, and more efficient workflows.

Ready for the good part? CNC machinists who stay up to date with the latest technology have a distinct advantage in the job market. New machines, like multi-axis CNC machines, are increasingly used to create more complex parts. These machines allow for higher precision, faster speeds, and the ability to produce intricate parts that were once impossible to make. Machinists who learn how to operate these advanced machines are in high demand and can command higher salaries.

But here’s the kicker… Automation is also having a significant impact on the industry. More and more, CNC machines are being automated to increase production efficiency. While automation reduces the need for some manual labor, it also creates new opportunities for machinists who are skilled in programming and machine troubleshooting. These roles focus on overseeing the automated systems and ensuring that everything runs smoothly.

| Technological Advancement | Impact on CNC Machining | Job Opportunities |

|---|---|---|

| Multi-axis CNC Machines | Maior precisão e complexidade | High demand for advanced machine operators |

| Automation | Reduced need for manual labor, increased efficiency | New roles for CNC programmers and troubleshooting experts |

| Computer-Aided Design (CAD) | Streamlined design and programming | Increased demand for machinists skilled in CAD software |

13. What Are the Job Requirements for CNC Machinists?

To work as a CNC machinist, certain job requirements must be met. First and foremost, a high school diploma or equivalent is typically necessary. However, the level of education required increases depending on the complexity of the machines and the specific industry.

But here’s the kicker… Physical fitness is important for CNC machinists. The job often requires standing for long periods of time and working in environments that can be noisy or have other physical demands. This means that machinists must be comfortable with the physicality of the role and be able to work under pressure.

Ready for the good part? Technically, CNC machinists must be proficient in reading blueprints and understanding machine specifications. They must also be able to operate a variety of tools and understand how to use different machinery. This requires a solid foundation in mechanical principles and problem-solving skills.

| Requirement | Explanation | Importância |

|---|---|---|

| High School Diploma | Basic education required for entry-level positions | Essential for job eligibility |

| Physical Stamina | Ability to stand for long periods, lift, and work in physically demanding environments | Ensures safety and performance on the job |

| Technical Knowledge | Ability to read blueprints, operate machinery | Critical for quality control and precision |

14. What is the Work Environment Like for CNC Machinists?

CNC machinists work in a variety of settings, but most commonly, they are employed in factory or workshop environments. So, what’s it really like to work as a CNC machinist? The work environment is typically loud, filled with industrial equipment, and can be quite physically demanding.

What’s the real story? The job often requires long hours, sometimes including night shifts or overtime, depending on production schedules. While the noise can be overwhelming, ear protection is provided to ensure machinists’ safety. Additionally, the job requires a high level of concentration to operate machinery accurately, with the goal of minimizing errors that could cost both time and money.

But here’s the kicker… Despite the physically demanding nature of the job, CNC machinists often find the work to be rewarding. There is a strong sense of pride in creating precise, high-quality products that contribute to industries like aerospace, automotive, and medical devices.

| Fator | Impact on CNC Machinists | Job Environment |

|---|---|---|

| Noise Levels | Must wear ear protection to protect hearing | High noise environment |

| Physical Demands | Long hours standing, lifting, and maneuvering parts | Physically demanding |

| Job Satisfaction | Pride in producing high-quality, precision parts | High satisfaction for skilled workers |

15. Is CNC Machining a Good Career for You?

By now, you’ve learned about the many aspects of CNC machining, from job opportunities and salary potential to the challenges that come with the job. But how do you know if it’s the right career for you?

Here’s the kicker… If you enjoy working with your hands, solving problems, and working with advanced technology, CNC machining could be a fantastic career choice. The industry is constantly evolving, offering new opportunities for career growth and specialization.

Pronto para a boa parte? CNC machining offers excellent job security and competitive salaries, making it a stable choice for anyone looking to enter the manufacturing field. However, if you’re someone who prefers a less physically demanding job or a more static role, this career might not be for you.

| Fator | Should You Choose This Career? |

|---|---|

| Interest in Technology | If you enjoy working with advanced technology and machinery, CNC machining could be a good fit. |

| Physical Stamina | If you’re prepared for a physically demanding job, this career is right for you. |

| Desire for Career Growth | CNC machining offers room for growth and advancement. |

Seção de perguntas frequentes

Q1: O que é usinagem CNC?

CNC machining is a manufacturing process that uses computer-controlled machines to produce precise parts from raw materials.

Q2: How does CNC machining work?

CNC machining works by converting digital designs into machine instructions, allowing CNC machines to create complex parts with high precision.

3º trimestre: What qualifications do you need to become a CNC machinist?

Most CNC machinists require a high school diploma and specialized training, such as an apprenticeship or technical school certification.

4º trimestre: How much do CNC machinists make?

The average salary for a CNC machinist ranges from $40,000 to $60,000 annually, with more experienced machinists earning up to $80,000 or more.

Q5: What are the career growth opportunities in CNC machining?

CNC machinists can advance to roles like CNC programmer, supervisor, or even move into specialized fields like quality control or machine maintenance.