Sheet Metal Manufacturer

Sheet metal processing solutions to help precision manufacturing

Focusing on high-precision and high-efficiency sheet metal processing services, we provide comprehensive support from design to mass production for various industries.

Meaning

What is Sheet Metal Fabrication?

10+ years Experience Makes Us Confident

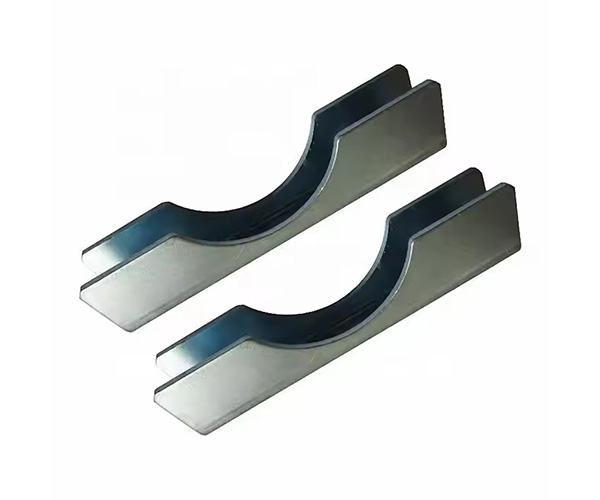

Sheet metal fabrication is the process of transforming flat sheets of metal into custom shapes and components using cutting, bending, and assembling techniques. This versatile method is widely used in industries like construction, automotive, and manufacturing to create durable, precise, and cost-effective solutions.

Sheet Metal Fabrication Services for Custom Parts

Equipped with over 100 state-of-the-art machines, including laser cutters, bending machines, and advanced welding equipment, our China-based facilities are capable of producing sheet metal parts for projects of any scale—from small prototype runs to large-scale production. Our skilled local fabricators and engineers ensure precise craftsmanship, competitive pricing, and prompt delivery to meet your business needs.

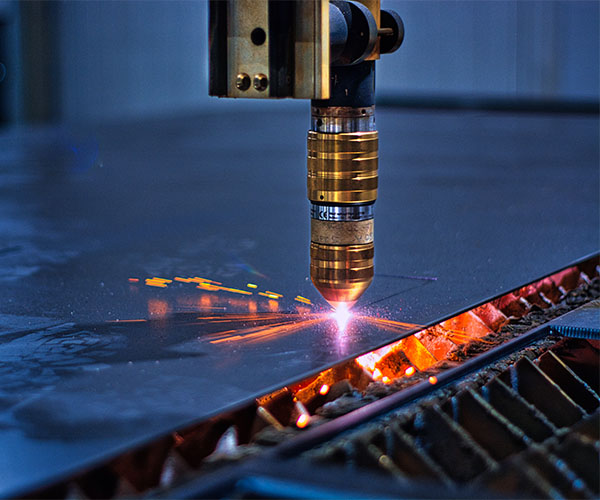

Laser Cutting

Laser cutting uses high-powered lasers to cut metal sheets with exceptional precision, creating clean edges and intricate designs for custom parts.

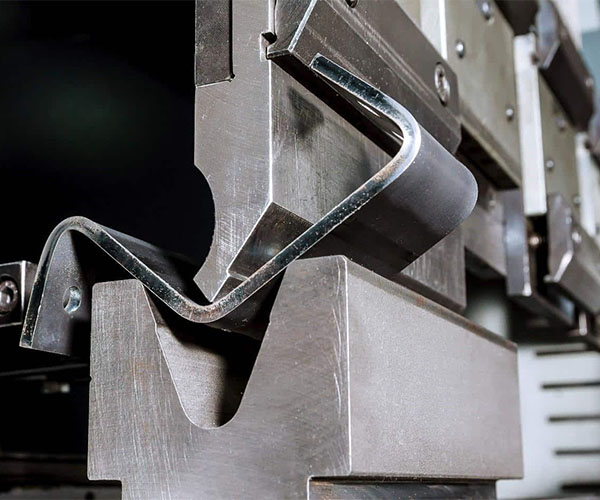

Bending

Bending involves using specialized machines to shape sheet metal into desired angles or curves without compromising material integrity.

Welding

Welding fuses metal parts together, creating strong and durable joints that meet structural and functional requirements.

Socos

Punching uses a press to create holes or shapes in sheet metal by shearing the material with a die.

Riveting

Riveting secures multiple metal pieces together using metal fasteners, ensuring a strong and lasting connection.

Stamping

Stamping employs high-pressure presses to shape or emboss sheet metal into complex forms, ideal for mass production.

Tolerance

Sheet Metal Fabrication Abilities & Tolerance

Sheet metal fabrication tolerances refer to the allowable variation in dimensions during the manufacturing process. They ensure parts meet design specifications while accounting for material properties and machine capabilities. Typical tolerances depend on factors like thickness, material type, and complexity of the design. Tight tolerances are achievable with advanced techniques, but balancing precision with cost is crucial for optimal results.

Metais

ISO 2768-c

Cutting Feature

± .00787”/0.2mm

Bend Angle

± 1.0°

Bend to Edge

±0.010″/0.254mm

Bend to Hole

±0.2 mm

Materials

Sheet Metal Fabrication Materials

Sheet metal fabrication utilizes a wide range of materials to meet diverse industry needs. Common options include stainless steel for corrosion resistance, aluminum for its lightweight and strength, and carbon steel for durability and cost-effectiveness. Other materials like copper and brass are used for their conductivity and aesthetic appeal. Each material is selected based on its specific properties, ensuring the final product meets functional and performance requirements.

Aluminium

Aluminum’s lightweight, corrosion-resistant, and has a great strength-to-weight ratio, so it’s ideal for aerospace, automotive, and construction. It’s also easy to machine.

Color: Silver

Subtypes: Aluminum 5052, Aluminum 5083, Aluminum 6061

Price: $

Lead Time: About 5 business days

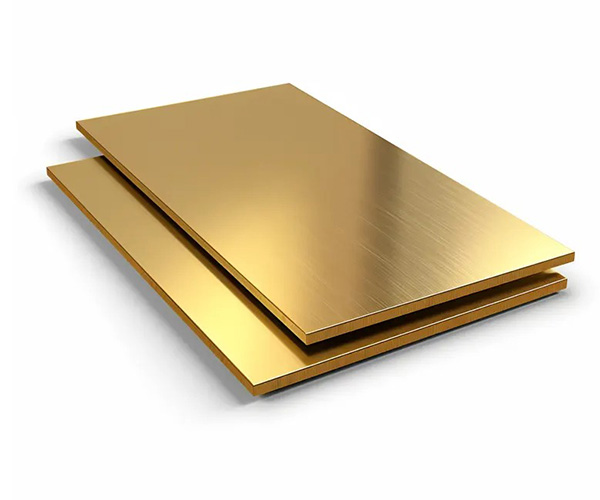

Latão

Brass is super malleable, corrosion-resistant, and has that gold-like look. It’s found in everything from decorative items to gears and valves.

Color: Golden-yellow

Subtypes: Brass C27400, Brass C28000, Brass C36000

Thickness: Up to 5mm

Price: $$$$$

Lead Time: About 6 business days

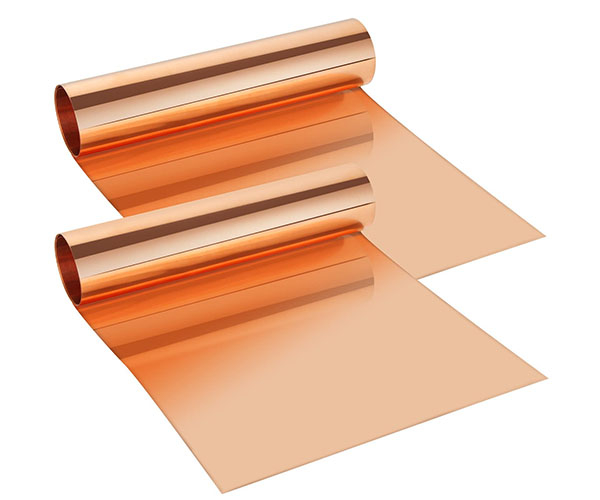

Copper

Copper’s known for its excellent electrical and thermal conductivity. It’s really ductile, making it perfect for electrical wiring, plumbing, and roofing.

Color: Red-orange

Subtypes: Copper C101(T2) Copper C103(T1) Copper C103(TU2) Copper C110(TU0)

Thickness: Up to 5mm

Price: $$$$$

Lead Time: About 6 business days

Aço

Steel’s super strong and durable, commonly seen in construction and heavy industries. You can mix it with other elements for enhanced hardness or corrosion resistance.

Color: Silver gray

Subtypes: SPCC, Galvanized Steel (SGCC / SECC), Q235, Steel 1020

Price: $$$

Lead Time: About 5 business days

Aço inoxidável

Stainless steel’s great for resisting corrosion, it’s strong, easy to clean, and maintains its shine. It’s used in medical devices, food processing equipment, and marine environments.

Color: Silver grey

Subtypes: Stainless Steel SUS 304

Price: $$$

Lead Time: About 5 business days

Tratamento de superfície

Enhancing Durability and Aesthetics: Surface Treatments for Sheet Metal Fabrication

Sheet metal fabrication surface treatments enhance the durability, appearance, and functionality of metal parts. Common treatments include powder coating for corrosion resistance, anodizing for a protective finish, and plating to improve strength and conductivity. Additional options like polishing and sandblasting provide smooth or textured finishes, meeting specific application needs.

Comprehensive Surface Treatments for Sheet Metal Fabrication

Achieve durability, precision, and style with diverse surface treatments, from anodizing and powder coating to polishing, embossing, and UV finishes.

Spray painting

Powder coating

Anodização

Galvanoplastia

Polishing

Sand blasting

Silk screening

Chromating

Transfer-printing

Scouring/ brushing

Bake finish

Embossing

Laser etching

High glaze

UV-finish

Cleaning

Fuming PC

Video

How Sheet Metal Products Made?

Sheet metal processing involves a series of precision techniques to transform flat metal sheets into functional components. The process typically includes cutting, bending, punching, and welding, ensuring high accuracy and durability.

First, laser cutting or stamping shapes the metal according to design specifications. Then, bending machines form the metal into desired angles, followed by punching or drilling to create holes and patterns. Welding and assembly further enhance the structural integrity of the final product.

Advanced CNC technology ensures consistency and efficiency, reducing material waste and production costs. Surface treatments such as powder coating or galvanization improve corrosion resistance and aesthetics.

Widely used in industries like automotive, construction, and electronics, sheet metal parts offer strength, flexibility, and precision. With advanced processing techniques, manufacturers can meet diverse requirements, delivering high-quality, cost-effective solutions for various applications.

CTA

Transform Your Ideas into Precision Metal Parts

Partner with experts in sheet metal fabrication to bring your designs to life. From prototypes to large-scale production, we deliver quality, speed, and reliability.

Solutions

Solving Your Sheet Metal Fabrication Challenges with Precision and Expertise

From quality assurance to on-time delivery, we address common sheet metal fabrication challenges with advanced technology, skilled teams, and efficient processes. Our tailored solutions ensure cost-effective production, seamless communication, and reliable supply chains to meet your business needs.

- Quality issues

- Delivery delays

- Cost control

- Material waste

- Design and manufacturing mismatch

- Poor communication

- Lack of flexibility

- Unstable supply chain

- Transportation and packaging issues

- Technology upgrades lag behind

Quality issues

We implement strict quality control processes, use high-precision equipment and professional testing tools to ensure that each part meets design specifications and high standards.

Delivery delays

We optimize production processes and maintain sufficient production capacity reserves, and ensure that each batch of orders is delivered on time through efficient management and flexible scheduling.

Cost control

Relying on large-scale production and automated equipment, we provide customers with competitive prices, especially small batch orders can also maintain reasonable costs.

Material waste

We use optimized typesetting and fine processing technology to maximize material utilization, reduce waste and reduce customer costs.

Design and manufacturing mismatch

Provide technical support from design to manufacturing to assist customers in optimizing designs to make them more suitable for actual production needs.

Poor communication

We are equipped with a professional international business team to provide timely and clear communication support to ensure that customer needs are accurately understood and implemented.

Lack of flexibility

We have a flexible production system that can respond quickly from low-volume trial production to large-scale production to meet different customer needs.

Unstable supply chain

Establish a stable supply chain network, strictly screen suppliers, and reserve key materials to reduce the risk of supply interruptions.

Transportation and packaging issues

Use customized packaging solutions and protective measures to ensure that parts are intact during transportation, and cooperate with high-quality logistics service providers.

Technology upgrades lag behind

Continuously invest in advanced equipment and new technologies, and regularly upgrade production lines to ensure that they can meet complex designs and high-precision requirements.

QUESTION ANSWER I

Frequently Asked Questions About Sheet Metal Fabrication

Get quick answers to common questions about our sheet metal fabrication services, from production capabilities and surface treatments to delivery times and quality assurance.

We work with various materials, including stainless steel, aluminum, carbon steel, and more, to suit diverse project requirements.

We handle both low-volume prototypes and high-volume production runs, ensuring flexibility for all your project needs.

Yes, we provide a range of surface treatments, including powder coating, anodizing, polishing, and more for enhanced durability and aesthetics.

Lead times vary depending on project complexity, but we typically deliver within 7-15 business days.

We follow strict quality control processes, using advanced testing equipment to ensure all products meet your exact specifications.