Introduction

With the rapid development of artificial intelligence technology, the heat output of GPUs and dedicated AI accelerators continues to rise, and traditional heat dissipation materials are facing unprecedented challenges. Innovations in materials science are becoming a key force in driving the next generation of thermal solutions, providing more efficient and reliable cooling capabilities for AI hardware. This article will take a deep look at the latest innovations in the field of radiator materials and how they are reshaping GPU cooling technology in the AI era.

1. Limitations of Traditional Heat Dissipation Materials

Traditional heat dissipation materials are showing obvious limitations when dealing with the extreme thermal loads of modern AI hardware, and these limitations are becoming a bottleneck for improving AI performance.

The problem: The thermal conductivity of traditional heat sink materials is no longer efficient enough to meet the cooling needs of the latest generation of AI accelerators.

Imagine this scenario: A decade ago, a high-end GPU had a thermal design power (TDP) of about 250 watts, which was adequate for traditional copper-aluminum heat sinks. Today, top AI accelerators such as the NVIDIA H100 have TDPs of up to 700 watts, and the next generation is expected to exceed 1,000 watts. This surge in power density poses a fundamental challenge to traditional materials.

Here’s the kicker: The thermal conductivity of traditional heat sink materials such as copper and aluminum (about 400 W/m·K for copper and 240 W/m·K for aluminum) is already close to its physical limit, and heat is generated much faster than these materials can effectively conduct it.

Exacerbated: As chip architectures evolve and computing density increases, the hotspot problem becomes more serious.

More worryingly, modern AI chips are not only increasing in total heat, but also in hotspot density. The power density in some areas can be as high as 500W/cm², 5-10 times that of traditional CPUs. These concentrated hot spots can cause localized temperature spikes, which can lead to performance degradation or reliability issues even when the overall temperature appears to be under control.

According to recent research, these hot spots can cause temperature differences of up to 20-30°C inside the chip when using traditional heat dissipation materials, seriously affecting performance and lifespan.

Solution: A new generation of heat dissipation materials is breaking through these limitations to provide more efficient cooling capabilities for AI hardware.

Main types of traditional heat dissipation materials

Before exploring new materials, it is important to understand the characteristics and limitations of traditional heat dissipation materials:

- Copper:

- Thermal conductivity: about 400 W/m·K

- Advantages: excellent thermal conductivity, widely available

- Disadvantages: high density (8.96 g/cm³), high weight, rising cost

- Applications: high-end heat sinks, heat pipes, cold plates

- Aluminum:

- Thermal conductivity: about 240 W/m·K

- Advantages: light weight (2.70 g/cm³), low cost, easy processing

- Disadvantages: thermal conductivity is not as good as copper

- Applications: mid- and low-end heat sinks, heat sinks, chassis

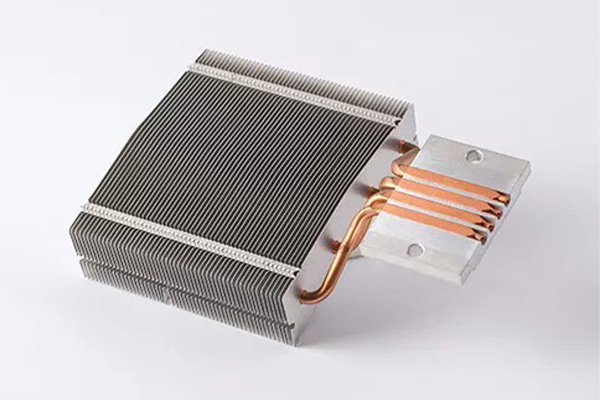

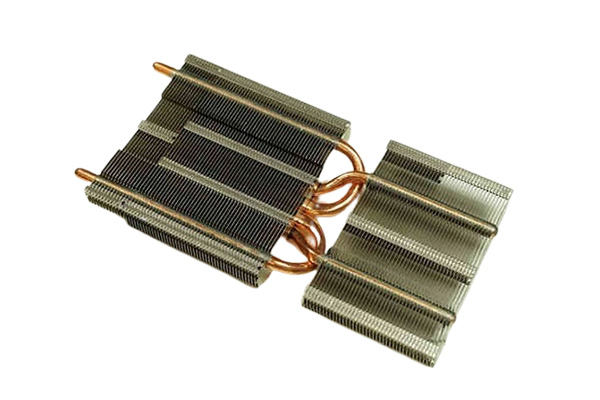

- Copper-aluminum composite:

- Combining the high thermal conductivity of copper and the lightweight advantages of aluminum

- Usually using a copper base + aluminum heat sink design

- A balance between cost and performance

- It is the most common heat sink design at present

Here is a key point: these traditional materials are not completely obsolete, but they have reached physical limits when dealing with extreme heat loads. For example, even a pure copper heat sink has difficulty maintaining ideal temperature under heat loads above 700 watts unless the volume and fan noise reach unrealistic levels.

Specific challenges faced by traditional materials

Traditional heat dissipation materials face several key challenges in the AI era:

- Bottleneck of thermal conduction efficiency:

- The thermal conductivity of copper (about 400 W/m·K) is close to the theoretical upper limit of common metals

- Heat generation rate exceeds the material’s conductivity

- Leads to heat accumulation and hot spot formation

- Weight and space limitations:

- High-performance copper heat sinks can weigh up to 1-2 kg

- Causes physical stress on motherboard and chassis

- Particularly problematic in high-density server environments

- Thermal interface challenges:

- The thermal conductivity of traditional thermal grease is only 5-10 W/m·K

- Becomes the main bottleneck of the entire heat dissipation path

- Performance deteriorates over time

Comparison of performance of traditional heat dissipation materials

| Material | Thermal conductivity (W/m·K) | Density (g/cm³) | Relative cost | Main limitations |

|---|---|---|---|---|

| Pure copper | 385-400 | 8.96 | High | Heavy weight, high cost |

| Pure aluminum | 220-240 | 2.70 | Low | Limited thermal conductivity |

| Copper-aluminum composite | 250-350* | 4-6* | Medium | Thermal interface resistance |

| Aluminum alloy | 170-200 | 2.6-2.8 | Low-medium | Insufficient performance |

| Thermal grease | 5-10 | 2.3-2.6 | Low | Very low thermal conductivity |

*Note: Depends on the copper-aluminum ratio and structural design

Performance limits of traditional materials

In practical applications, the performance limits of traditional materials have become apparent:

- Heat dissipation density limitation:

- The actual upper limit of heat dissipation density of traditional copper heat sinks is about 0.5-0.7 W/cm²·K

- Modern AI accelerators require heat dissipation density of more than 1.0 W/cm²·K

- This gap requires the use of larger heat sinks or higher fan speeds

- Temperature uniformity issues:

- Traditional materials have difficulty in quickly dispersing hot spots

- Leading to large temperature differences inside the chip

- Affecting computing performance and stability

- Contradiction between heat sink size and efficiency:

- Increasing size can improve heat dissipation capacity

- But large heat sinks increase weight and space requirements

- Unsustainable in high-density computing environments

Ready for the exciting part? These limitations are not just theoretical concerns, they have become actual performance bottlenecks. For example, some high-end AI research institutions reported that when using traditional heat dissipation materials, they had to reduce GPU clock speeds by 15-20% to maintain safe temperatures, directly affecting training speed and efficiency. This performance loss can mean weeks or even months of R&D delays in the competitive field of AI research.

2. A new generation of high-performance heat dissipation materials

Faced with the limitations of traditional materials, materials scientists are developing a new generation of high-performance heat dissipation materials that are expected to revolutionize the way AI hardware is cooled.

Problem: Breakthrough material innovation is needed to meet the growing demand for heat dissipation.

As the heat output of AI accelerators continues to grow, simply improving existing materials is no longer enough to meet the challenge. The industry needs new materials with fundamental advantages that can provide significantly higher thermal conductivity efficiency.

Aggravation: New materials must meet multiple requirements simultaneously, including high thermal conductivity, manufacturability, cost-effectiveness, and environmental compatibility.

Even more challenging, theoretically excellent materials may face obstacles in mass production, integration, or long-term reliability. Many laboratory-grade “miracle materials” have encountered significant challenges in practical applications.

Solution: Explore several new generation heat dissipation materials that have shown potential for practical applications:

Graphene and its derivative materials

Graphene is known as a “miracle material” and has shown great potential in the field of heat dissipation:

- Basic properties of graphene:

- Theoretical thermal conductivity is as high as 5000 W/m·K, more than 10 times that of copper

- Single atom thickness, extremely light (surface density of about 0.77 mg/m²)

- Extremely high mechanical strength and good flexibility

- Excellent chemical stability

- Graphene heat dissipation application forms:

- Graphene film: used for thermal interface materials and heat diffusion

- Graphene composite materials: combined with metals or polymers

- Vertically aligned graphene (graphene forest): provides directional heat conduction

- Graphene aerogel: ultra-light heat dissipation material

- Progress in practical applications:

- Graphene enhanced thermal grease: thermal conductivity increased by 3-5 times

- Graphene thermal interface materials: 40-60% lower thermal resistance

- Graphene heat sinks: 30-50% lighter, 20-30% better performance

This is where things get interesting: While pure graphene has an extremely high theoretical thermal conductivity, practical applications often use graphene composites or multilayer graphene, which, while lower than the theoretical value, are still significantly better than conventional materials. For example, aluminum composites containing 20% graphene have a thermal conductivity of 600-700 W/m·K, about 3 times higher than pure aluminum.

Synthetic diamond materials

Diamond has the highest thermal conductivity of any known material, and its artificial form is becoming the key to high-end cooling solutions:

- Diamond cooling properties:

- Thermal conductivity is as high as 2000-2200 W/m·K, more than 5 times that of copper

- Good electrical insulation, avoiding the risk of short circuits

- Extremely high hardness, wear resistance

- Chemical inertness, good long-term stability

- Synthetic diamond technology:

- Chemical vapor deposition (CVD) diamond

- Nano-diamond composites

- Diamond film coatings

- Diamond particle reinforced composites

- Actual application cases:

- Diamond coating for high-end GPU heat sinks

- Diamond-copper composite heat sink substrates

- Diamond-enhanced thermal interface materials

- Cooling solutions for photonic and quantum computing devices

Comparison of the performance of the new generation of heat dissipation materials

| Material | Thermal conductivity (W/m·K) | Density (g/cm³) | Relative cost | Technology maturity | Main advantages |

|---|---|---|---|---|---|

| Graphene (theoretical) | 5000+ | Very low | Very high | Low | Very high thermal conductivity |

| Graphene composites | 600-1200 | 2.5-6.0 | High | Medium | Lightweight and efficient |

| CVD diamond | 2000-2200 | 3.5 | Very high | Medium-high | Highest thermal conductivity |

| Diamond composites | 700-1500 | 4.0-7.0 | High | Medium | High performance, processable |

| Carbon nanotube materials | 3000-3500* | 1.3-1.4 | High | Low-medium | Directional thermal conductivity |

| Pure copper (reference) | 385-400 | 8.96 | Medium | Very High | Mature and Reliable |

*Note: Measured along the axial direction, usually much lower in actual composite materials

Carbon Nanotube (CNT) Materials

Carbon nanotubes offer unique thermal conductivity properties, especially in directional thermal conduction:

- CNT heat dissipation properties:

- Axial thermal conductivity up to 3000-3500 W/m·K

- Highly directional thermal conduction can be achieved

- Extremely light weight and high mechanical strength

- Can form a variety of composite structures

- CNT heat dissipation applications:

- Vertically aligned CNT heat dissipation interface

- CNT reinforced metal matrix composites

- CNT thermal interface materials (TIM)

- CNT-polymer composite heat sinks

- Actual application progress:

- CNT array thermal interface: 50-70% reduction in thermal resistance

- CNT reinforced copper composites: 40% weight reduction, 25% performance improvement

CNT thermal pads: ultra-thin and efficient thermal interface solutions

But here’s an interesting phenomenon: although the theoretical thermal conductivity of a single carbon nanotube is extremely high, in actual materials, the interfacial thermal resistance between CNTs severely limits the overall performance. Researchers are developing new technologies to address this challenge, such as chemical bonding and directional growth methods, to fully realize the potential of CNTs.

Phase Change Materials (PCM)

Phase change materials use the phase change process to absorb and release heat, providing unique temperature stability for cooling systems:

- How PCM works:

- Utilize materials to absorb/release latent heat during phase change

- Provide temperature stability within a specific temperature range

- Can absorb heat peaks and smooth temperature fluctuations

- Independent of active cooling systems

- Types and applications of PCM:

- Metal-based PCM: high thermal conductivity, suitable for high-performance systems

- Organic PCM: low cost, easy to integrate

- Salt hydrate PCM: high latent heat capacity

- PCM composites: combining the advantages of multiple materials

- PCM innovation in AI cooling:

- PCM-graphene composites: high thermal conductivity + phase change stability

- Microcapsule PCM thermal interface: good long-term stability

- 3D printed PCM structure: customized cooling solution

- Intelligent PCM system: temperature adaptive material

Are you ready for the exciting part? Phase change materials are unique in that they can provide a “thermal buffer” when temperatures fluctuate, which is particularly valuable for AI workloads. For example, during training, GPU loads may fluctuate in a short period of time, causing drastic temperature changes. PCM can absorb these thermal peaks, maintain a more stable temperature environment, reduce thermal throttling, and improve training stability. Some studies have shown that cooling systems with integrated PCM can reduce temperature fluctuations by 40-60%, significantly improving the consistency and reliability of AI training.

3. Application of nanomaterials in heat dissipation

Nanotechnology is revolutionizing the performance limits of heat dissipation materials. By manipulating nanoscale structures, scientists are able to create materials with unprecedented thermal performance.

Problem: The macroscopic structure of traditional materials limits their heat dissipation performance.

At the macroscopic scale, the thermal conductivity of materials is limited by grain boundaries, defects, and microstructures. These factors are difficult to accurately control in traditional manufacturing methods, resulting in actual performance far below the theoretical limit.

Intensification: As AI chips move towards smaller processes and 3D stacking architectures, heat dissipation challenges are shifting from macroscopic to microscopic and nanoscale.

More worryingly, the hot spot size of modern AI chips is shrinking, while the heat density is increasing, requiring heat dissipation materials to be able to efficiently conduct heat at the nanoscale. The performance of traditional materials at this scale is severely reduced.

Solution: Nanoengineered materials provide the ability to optimize heat transfer at the nanoscale:

Nanofluid Technology

Nanofluids significantly improve the thermal conductivity of liquids by suspending nanoparticles in the base liquid:

- Basic principles of nanofluids:

- Dispersing nanoscale particles (1-100nm) in traditional coolants

- Nanoparticles enhance the effective thermal conductivity of liquids

- Improve convective heat transfer performance

- Can be used in various liquid cooling systems

- Common types of nanoparticles:

- Metal nanoparticles: copper, silver, aluminum

- Metal oxides: aluminum oxide, copper oxide, titanium oxide

- Carbon-based nanomaterials: graphene, carbon nanotubes, fullerenes

- Ceramic nanoparticles: silicon carbide, aluminum nitride

- Advances in AI cooling applications:

- Graphene nanofluids: 40-80% increase in thermal conductivity

- Hybrid nanofluids: Optimize stability and performance

- Surface functionalized nanofluids: Improve long-term stability

- Smart Nanofluids: Highly Responsive to Temperature Changes

Here’s where things get interesting: Nanofluids not only improve thermal conductivity, they also significantly enhance convective heat transfer. Studies have shown that adding just 0.1-1% volume fraction of nanoparticles can increase liquid thermal conductivity by 15-40%, while the improvement in convective heat transfer may be as high as 60-100%. This dual enhancement makes nanofluids particularly suitable for high-performance liquid cooling systems.

Nanocomposite thermal interface materials (TIM)

Thermal interface materials are a key link in the heat dissipation path, and nanotechnology is revolutionizing TIM performance:

- Principle of nano-enhanced TIM:

- Add nanofillers to base materials (silicone grease, gel, gasket)

- Nanofillers form a heat conduction network

- Reduce interface thermal resistance

- Improve long-term stability

- Innovative nanofillers:

- Vertically aligned carbon nanotubes: provide directional thermal channels

- Graphene nanosheets: form an efficient thermal network

- Metal nanowires: create a continuous thermal conduction path

- Hybrid nanosystems: optimize multiple performance indicators

- Performance breakthrough:

- Thermal conductivity is increased from the traditional 5-10 W/m·K to 20-50 W/m·K

- Interface thermal resistance is reduced by 50-80%

- Reduced thickness and improved thermal conduction efficiency

- Improved long-term reliability and reduced pumping and drying problems

Comparison of nano-enhanced thermal interface materials

| TIM types | Thermal conductivity (W/m·K) | Interface thermal resistance (mm²·K/W) | Thickness range (μm) | Application scenarios |

|---|---|---|---|---|

| Traditional silicone grease | 3-8 | 15-30 | 20-150 | General CPU/GPU |

| Graphene-enhanced silicone grease | 12-25 | 5-15 | 20-100 | High-end GPU |

| CNT array TIM | 20-40 | 3-8 | 10-50 | AI accelerator |

| Metal nanowire TIM | 15-30 | 4-10 | 15-75 | Server CPU |

| Hybrid nano TIM | 25-50 | 2-6 | 10-60 | High-end AI hardware |

| Liquid metal TIM | 20-80 | 1-4 | 10-50 | Extreme performance requirements |

Nanoporous metal heat dissipation materials

Nanoporous metals offer a unique combination of lightweight and high performance:

- Nanoporous metal structures:

- Metal foams or networks with nanoscale pores

- Ultra-high specific surface area, improving heat dissipation efficiency

- 50-80% lighter than traditional metals

- Customizable porosity and structure

- Manufacturing technology:

- Template-assisted electrodeposition

- Selective corrosion of alloy components

- 3D printing and post-processing

- Self-assembled nanostructures

- AI heat dissipation applications:

- Lightweight high-performance heat sinks

- Phase change material carriers

- Efficient heat exchangers for liquid cooling systems

- Capillary structures for heat pipes and vapor chambers

But here’s an interesting phenomenon: the thermal conductivity of nanoporous metals is generally lower than their dense form, but their huge specific surface area and optimized fluid dynamics make them perform well in actual heat dissipation systems. For example, nanoporous copper may have only 30-50% of the thermal conductivity of dense copper, but in liquid cooling applications, its heat dissipation performance may be 2-3 times higher while being more than 70% lighter.

Nanocoating Technology

Nanocoatings offer a cost-effective way to enhance the performance of existing cooling systems:

- Nanocoating Types:

- Diamond Nanocoatings: Extremely High Thermal Conductivity

- Carbon Nanotube Coatings: Directed Heat Transfer

- Graphene Coatings: Highly Thermally Conductive Thin Films

- Ceramic Nanocomposite Coatings: Durable and Highly Efficient

- Application Methods:

- Chemical Vapor Deposition (CVD)

- Physical Vapor Deposition (PVD)

- Solution Processing Technology

- Plasma Enhanced Deposition

- Performance Improvements:

- 30-200% increase in surface thermal conductivity

- Improve heat exchange between heat sink and air/liquid

- Enhanced hydrophobic/hydrophilic properties

- Provide additional corrosion and wear protection

Ready for the exciting part? A key advantage of nanocoatings is that they can be applied to existing cooling systems, providing a performance upgrade without completely replacing the hardware. For example, one study showed that applying a 10-micron-thick diamond nanocomposite coating on a traditional aluminum heat sink can improve overall heat dissipation performance by 25-35%, with only a 10-15% increase in cost. This “upgrade” approach provides a cost-effective performance improvement path for data centers and AI facilities.

4. Composites and hybrid solutions

A single material rarely meets all the needs of modern AI heat dissipation, and composites and hybrid solutions are becoming a key approach to balancing multiple performance indicators.

Problem: Different heat dissipation application scenarios require different combinations of material properties, and a single material is difficult to meet all requirements.

When selecting heat dissipation materials, engineers usually need to make trade-offs between multiple factors such as thermal conductivity, weight, cost, manufacturability, and reliability. These requirements often conflict with each other, making material selection complicated.

Exacerbation: The diversification and specialization of AI hardware further increases the complexity of heat dissipation requirements.

Even more challenging is that different types of AI accelerators (GPU, ASIC, FPGA, etc.) have different thermal characteristics and heat dissipation requirements. In addition, differences in deployment environments from edge devices to data centers also require different heat dissipation solutions.

Solution: Develop composites and hybrid cooling solutions optimized for specific applications:

Metal Matrix Composites (MMC)

Metal Matrix Composites combine the processability of metals with the special properties of a reinforcement phase:

- MMC Basic Structure:

- Metal matrix (usually aluminum, copper or silver)

- High thermal conductivity reinforcement phase (carbon fiber, graphene, diamond, etc.)

- Carefully designed interfaces to minimize thermal resistance

- Customizable reinforcement phase content and distribution

- Common MMC Types:

- Aluminum-graphene composites: lightweight and efficient

- Copper-diamond composites: extremely high performance

- Silver-carbon nanotube composites: high-end applications

- Aluminum-silicon carbide composites: cost-effective balance

- AI Cooling Applications:

- High-performance heat sink bases

- Heat spreaders and thermally conductive layers

- Liquid cooling cold plates

- Lightweight cooling solutions

This is where things get interesting: By precisely controlling the type, content, size and orientation of the reinforcement phase, MMCs with directional thermal conductivity can be created. For example, the thermal conductivity of an aluminum-based composite material containing 40% volume fraction of oriented carbon fibers can reach 500-600 W/m·K in the fiber direction, while it is only 150-200 W/m·K in the perpendicular direction. This anisotropy can be used to optimize the heat flow path and efficiently guide heat from the heat source to the heat dissipation area.

Carbon-based composites

Carbon-based composites use various allotropes of carbon to create high-performance heat dissipation solutions:

- Types of carbon-based composites:

- Graphene-carbon nanotube hybrids

- Pyrolytic graphite films

- Carbon-carbon composites

- Graphene aerogels

- Unique advantages:

- Extremely high thermal conductivity (up to 1000-1500 W/m·K)

- Ultra-light weight (density is typically 1.5-2.5 g/cm³)

- Excellent mechanical properties

- Customizable thermal expansion coefficient

- Application examples:

- Ultra-thin heat spreaders

- High-performance heat sink cores

- Flexible heat dissipation solutions

- Aerospace-grade heat dissipation systems

Comparison of composite heat dissipation material performance

| Material type | Thermal conductivity (W/m·K) | Density (g/cm³) | Relative cost | Main advantages | Typical applications |

|---|---|---|---|---|---|

| Aluminum-graphene (20%) | 500-700 | 2.4-2.6 | Medium-high | Lightweight and efficient | Heat sink base |

| Copper-diamond (40%) | 600-900 | 5.5-6.5 | High | Extremely high performance | High-end cold plate |

| Pyrolytic graphite film | 1000-1500* | 2.0-2.2 | Medium | Ultra-thin and flexible | Thermal diffusion layer |

| Carbon-carbon composites | 300-700* | 1.6-1.9 | High | Lightweight and high temperature | Aerospace applications |

| Graphene-CNT hybrid | 800-1200* | 1.5-1.8 | High | High performance networking | Research prototype |

*Note: Usually measured in the plane direction, vertical direction may be much lower

Phase Change Composites

Phase change composites combine the thermal stability of phase change materials with the efficiency of high thermal conductivity fillers:

- PCM composite design:

- Phase change matrix (paraffin, fatty acid, salt hydrate, etc.)

- High thermal conductivity nanofillers (graphene, CNT, metal nanoparticles)

- Packaging system to prevent leakage

- Structural support to maintain shape

- Performance characteristics:

- High latent heat capacity (100-300 J/g)

- Enhanced thermal conductivity (5-30 W/m·K)

- Customizable phase change temperature

- Good shape stability

- AI cooling applications:

- Thermal peak buffer layer

- Passive heat dissipation system

- Thermal energy storage unit

- Temperature stabilization solution

But here’s the interesting thing: the real value of phase change composites is not their peak heat dissipation capabilities, but their temperature stability. During AI training, the workload may fluctuate, causing temperature fluctuations. PCM composites can absorb these fluctuations, maintain a more stable temperature environment, reduce thermal throttling and improve training efficiency. Studies have shown that cooling systems that integrate PCM composites can reduce temperature fluctuations by 50-70% and reduce thermal throttling events by more than 80%.

Hybrid Cooling System

Hybrid cooling systems combine multiple materials and technologies to create synergistic effects:

- Hybrid system design concept:

- Use the most suitable materials for different parts of the thermal path

- Combine passive and active cooling elements

- Integrate phase change and thermal conductivity

- Optimize overall system performance rather than individual components

- Common hybrid configurations:

- Copper-graphene composite base + aluminum heat sink

- Liquid metal TIM + carbon nanotube coated heat sink

- Phase change material layer + high thermal conductivity diffusion layer

- Microchannel liquid cooling + nanofluid

- System-level optimization:

- Heat flow path analysis and optimization

- Computational fluid dynamics (CFD) simulation

- Multi-physics field coupling design

- Thermal-mechanical-electrical synergistic optimization

Ready for the exciting part? The key advantage of hybrid cooling systems is that they can use the most suitable materials and technologies for each link of the thermal path. For example, a hybrid cooling solution for a high-performance AI accelerator may include: a liquid metal TIM connecting the chip and a copper-diamond composite base, the base connected to a microchannel liquid cold plate, using graphene nanofluid as a cooling medium, and integrating a PCM buffer layer to cope with load fluctuations. This system-level approach can improve overall thermal performance by 40-60% while optimizing cost and reliability.

5. Future trends in thermal dissipation materials

The science of thermal dissipation materials is in a rapid development stage, and many breakthrough innovations will appear in the next few years. Understanding these trends is critical to developing forward-looking thermal dissipation strategies.

Problem: The thermal design power consumption of AI hardware is expected to continue to grow, requiring forward-looking thermal dissipation material solutions.

As the scale and complexity of AI models increase, the performance and power consumption of computing hardware are also increasing. It is expected that the TDP of the next generation of AI accelerators will exceed 1000 watts, or even reach 1500-2000 watts, which will require new thermal dissipation materials and technologies.

Intensification: The evolution of chip architecture, such as 3D stacking and heterogeneous integration, will create new thermal dissipation challenges.

What is more worrying is that future AI chips may adopt completely new architectures, such as 3D stacking, chip-level interconnection, and heterogeneous integration. These technologies will create unprecedented heat dissipation challenges, such as interlayer heat conduction and cooling of buried hot spots.

Solution: Explore the cutting-edge development trends of heat dissipation material science and prepare for future challenges:

Quantum Materials and Metamaterials

Quantum materials and metamaterials represent the forefront of heat dissipation science and are expected to revolutionize thermal management methods:

- Quantum heat dissipation materials:

- Enhanced thermal conduction using quantum effects

- Quantum dot and quantum well structures

- Phonon engineered materials

- Topological insulator thermal interfaces

- Thermal metamaterials:

- Artificially designed composite structures with thermal properties not found in nature

- Programmable thermal conductivity materials

- Thermal rectifiers and thermal diodes

- Thermally invisible and thermally focusing materials

- Research progress:

- Laboratory prototypes demonstrate 5-10 times improvement in thermal conductivity

- Materials with thermal rectification ratios of more than 200%

- Smart materials that can switch thermal conductivity in milliseconds

- Directed heat transfer efficiency increased by 300-500%

This is where things get interesting: these cutting-edge materials do more than just improve thermal conductivity, but offer entirely new methods of thermal management. For example, thermally rectifier materials allow heat to flow efficiently in one direction while being hindered in the opposite direction, similar to an electronic diode. This property can be used to precisely control the heat flow path, directing heat away from sensitive components while isolating heat sources.

Bio-inspired materials

Nature has evolved over millions of years to create many efficient thermal management structures that are inspiring a new generation of heat dissipation materials:

- Bionic heat dissipation structures:

- Branching heat sinks that mimic leaf veins

- High surface area structures inspired by corals

- Adaptive heat dissipation surfaces that mimic skin

- Microfluidic networks that mimic mammalian vascular systems

- Self-assembling materials:

- Nanostructures using biomolecular templates

- DNA-guided nanomaterial assembly

- Self-healing heat dissipation interfaces

- Environmentally responsive adaptive materials

- Sustainable biomaterials:

- Cellulose nanocrystal-reinforced composites

- Wood-derived carbon-based heat dissipation materials

- Biodegradable thermally conductive polymers

- Algae-derived graphene

Future trends in heat dissipation materials

| Material categories | Expected thermal conductivity | Technology maturity time | Potential applications | Main challenges |

|---|---|---|---|---|

| Quantum heat dissipation materials | 5-15 times copper | 5-10 years | High-end AI chips | Mass production, cost |

| Thermal metamaterials | Directional control, 3-8 times copper | 3-7 years | 3D stacked chips | Complex structure manufacturing |

| Bio-inspired materials | 2-5 times copper, adaptive | 2-5 years | Edge AI devices | Reliability, consistency |

| Smart responsive materials | Variable, 1-10 times copper | 3-6 years | Dynamic load systems | Control system integration |

| Atomic engineering materials | 10-20 times copper | 7-15 years | Quantum computing | Basic science breakthroughs |

Smart responsive materials

Smart responsive materials can adjust their thermal properties according to environmental conditions, providing new possibilities for dynamic heat dissipation management:

- Temperature responsive materials:

- Change thermal conductivity at a specific temperature threshold

- Phase change microcapsule composites

- Temperature sensitive polymer networks

- Reversible thermal switch materials

- Electric field/magnetic field responsive materials:

- Electric field regulated thermal conductive materials

- Magnetorheological heat dissipation fluids

- Electroactive polymer heat sinks

- Programmable thermal conductive interfaces

- Multiple stimulus response systems:

- Temperature-electric field dual response materials

- Light-thermal responsive nanocomposites

- Pressure-temperature sensitive interfaces

- Self-sensing self-regulating heat dissipation systems

But here’s an interesting phenomenon: the value of smart responsive materials lies not only in their peak performance, but in their adaptability. AI workloads are often dynamic, from training to inference, from batch processing to real-time response. Smart materials can adjust heat dissipation performance according to actual needs, providing maximum heat dissipation capacity at high loads and saving energy at low loads. This dynamic adaptation can improve system-level energy efficiency by 15-30% while providing better temperature stability.

Atomic and molecular engineered materials

The most cutting-edge research is designing heat dissipation materials at the atomic and molecular scale, pursuing theoretical extreme performance:

- Atomically precise materials:

- Atomic layer deposition (ALD) thermal interface

- Molecular beam epitaxy (MBE) heat dissipation layer

- Single atomic layer thermal management materials

- Atomic level doping optimization

- Molecularly designed materials:

- Computer-aided molecular design

- Custom synthesized high thermal conductivity polymers

- Molecular level thermal interface engineering

- Self-assembled monolayers

- Computationally predicted materials:

- AI-assisted material discovery

- High throughput computational screening

- Quantum computing optimized thermal materials

- Digital twin material development

Ready for the exciting part? Atomic and molecular engineering represents the ultimate frontier in heat dissipation materials science. Theoretical calculations show that by precisely controlling atomic arrangement and interfaces, it is possible to create materials with thermal conductivity of 5000-8000 W/m·K, 12-20 times that of copper. While these materials are still theoretical and early experimental, they demonstrate the long-term potential of thermal science and could be commercialized in the next 10-15 years, revolutionizing the way AI hardware is cooled.

Frequently Asked Questions

Q1: Why can’t traditional heat dissipation materials meet the needs of modern AI hardware?

Traditional heat dissipation materials such as copper and aluminum face multiple limitations, making it difficult to meet the heat dissipation needs of modern AI hardware: First, the physical limit problem. The thermal conductivity of copper is about 400 W/m·K, and that of aluminum is about 240 W/m·K. These values are close to the theoretical upper limit of these materials, while modern AI accelerators such as NVIDIA H100 have a TDP of up to 700 watts, and the next generation of products is expected to exceed 1000 watts; second, the hot spot density problem. Modern AI chips not only increase the total heat, but also the hot spot density is rising sharply. The power density in some areas may be as high as 500W/cm², which is 5-10 times that of traditional CPUs; third, weight and space limitations. High-performance copper heat sinks can weigh up to 1-2 kg, causing physical stress in high-density server environments; finally, the thermal interface challenge. The thermal conductivity of traditional thermal grease is only 5-10 W/m·K, which becomes the main bottleneck of the entire heat dissipation path. These limitations mean that when using traditional heat dissipation materials, high-end AI accelerators must reduce clock speeds by 15-20% to maintain safe temperatures, which directly affects training speed and efficiency.

Q2: What is the actual application status of graphene heat dissipation materials?

Graphene heat dissipation materials have gradually transitioned from laboratory research to commercial applications, but still face some challenges: There are currently a variety of graphene-enhanced heat dissipation products on the market, including graphene-enhanced thermal grease (thermal conductivity increased by 3-5 times), graphene thermal interface materials (thermal resistance reduced by 40-60%), and graphene heat sinks (weight reduced by 30-50%, performance improved by 20-30%); the main application forms include graphene films for thermal interface materials and heat diffusion, graphene composites combined with metals or polymers, vertically arranged graphene to provide directional heat conduction, and graphene aerogels as ultra-light heat dissipation materials; however, the theoretical thermal conductivity of pure graphene is as high as 5000 W/m·K, but graphene composites are usually used in practical applications, and their performance is lower than the theoretical value. For example, the thermal conductivity of aluminum composites containing 20% graphene is about 600-700 W/m·K; the main challenges include cost control for large-scale production, quality consistency, compatibility with existing manufacturing processes, and long-term reliability verification. Despite this, the graphene heat dissipation material market is growing at a rate of 25-30% per year and is expected to reach approximately $1.5 billion by 2026.

Q3: What are the advantages and disadvantages of liquid metal as a thermal interface material?

Liquid metal thermal interface materials provide excellent performance, but also have obvious limitations: In terms of advantages, liquid metal TIM has extremely high thermal conductivity, typically 20-80 W/m·K, which is 5-15 times that of traditional silicone grease; it fits the contact surface perfectly and almost eliminates the interface air gap; the thermal resistance is extremely low, typically 1-4 mm²·K/W, which can reduce the chip temperature by 5-15°C; it has good fluidity and can fill tiny surface unevenness; it has stable long-term performance and there is no pumping or drying problem. In terms of disadvantages, liquid metal is conductive, there is a risk of short circuit, and it requires precise application and sealing; it reacts with aluminum, causing corrosion and performance degradation, and cannot directly contact aluminum heat sinks; it is difficult to apply and requires professional skills and tools; there is a risk of overflow, which may damage surrounding components; the cost is high, usually 5-10 times that of traditional silicone grease; it is difficult to remove and clean. Liquid metal TIM is mainly suitable for high-end AI accelerators and overclocking scenarios, especially systems using copper heat sinks. To reduce risks, some manufacturers have developed semi-solid liquid metal formulas and pre-coating solutions to provide safer application methods while retaining most of the performance advantages.

Q4: How to evaluate the cost-effectiveness of new heat dissipation materials?

Evaluating the cost-effectiveness of new heat dissipation materials requires considering multiple factors, rather than just focusing on the initial cost: first, performance improvement evaluation, calculating the temperature reduction or performance improvement brought by each unit cost increase. For example, if a new material costs 50% more but reduces the temperature by 15°C, it may be more cost-effective than a material that costs 20% more but only reduces the temperature by 3°C; second, system-level impact, considering how the new material affects the overall system performance, including allowing higher sustained clock speeds, reducing thermal throttling, and increasing training throughput. For example, for an 8-GPU AI server worth $250,000, investing an additional $1,000 in advanced heat dissipation materials to improve performance by 10% is usually very reasonable; third, long-term cost-effectiveness, including reduced energy consumption, extended hardware life, and reduced maintenance requirements, which are particularly important in large-scale deployments; finally, risk assessment, considering the reliability, compatibility, and long-term stability of the new material, as well as the cost of potential failures. For most AI applications, a layered approach is recommended: use high-performance materials for critical thermal interfaces and hot spots, and use more cost-effective solutions on secondary thermal paths. In general, high-end AI systems can often justify investments in high-performance heat sink materials because the value of performance gains and improved reliability far outweighs the increased material costs.

Q5: What are the most promising innovation directions in the field of heat sink materials in the next five years?

In the next five years, the most promising innovation directions in the field of heat dissipation materials include: first, hybrid nanomaterial systems, which combine the advantages of multiple nanomaterials (such as graphene, CNT, and nanometals) to create synergistic effects. It is expected to be commercialized in 2-3 years, and the thermal conductivity will be improved by 3-5 times; second, intelligent responsive heat dissipation materials, which can adjust the thermal conductivity according to temperature, load or external signals, and provide adaptive cooling for dynamic AI workloads. It is expected to be used in high-end systems in 3-4 years; third, chip-level integrated cooling solutions, which integrate the heat dissipation function directly into the chip package, such as silicon microchannels, chip-embedded heat pipes, etc., are expected to be adopted in high-end AI accelerators in 4-5 years; fourth, bio-inspired self-assembly materials, which use biomolecular templates to create highly optimized heat conduction networks, provide lightweight, efficient, and sustainable heat dissipation solutions, and are expected to enter the market in 4-5 years; finally, quantum engineered thermal interface materials, which use quantum effects and phonon engineering to improve interface thermal conduction, are expected to start commercialization in 5 years, and may reduce interface thermal resistance by 5-10 times. Together, these innovations will drive significant improvements in the performance of heat dissipation materials, supporting the development of next-generation AI hardware while improving energy efficiency and reliability. Market research shows that the market for advanced heat dissipation materials is expected to grow at an average annual rate of 20-25%, reaching approximately $30 billion by 2028.