Введение

In today’s manufacturing world, precision and efficiency are essential for producing high-quality parts at scale. Whether you’re designing intricate aerospace components or medical devices, machining plays a pivotal role in shaping these products. 4-axis machining is one of the most powerful techniques to achieve these goals. But, what exactly is 4-axis machining, and why should you care? If you’ve ever wondered how complex parts are created, this guide will help you understand the intricacies of 4-axis machining. Here’s the deal: We’ll dive into the process, benefits, and applications of 4-axis machining in a way that’s easy to grasp for beginners. Let’s get started!

What is 4-Axis Machining?

Understanding the Basics of 4-Axis Machining

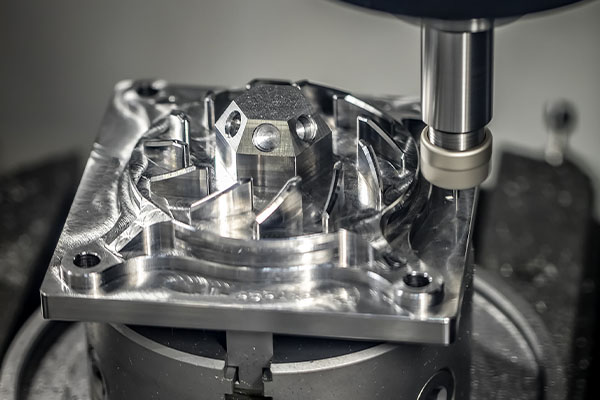

4-axis machining refers to a type of Computer Numerical Control (CNC) machining that allows for movement along four axes to produce complex parts with greater accuracy and flexibility. Вам может быть интересно how this differs from the more common 3-axis machining, where a machine moves along three axes: X, Y, and Z. The additional fourth axis in 4-axis machining enables the part to rotate, allowing for a more dynamic range of movements.

How Does 4-Axis Machining Compare to 3-Axis?

While 3-axis machining can only move in the X, Y, and Z planes (the basic horizontal, vertical, and depth movements), 4-axis adds a rotational movement around the X-axis, enabling the machine to manipulate the part more thoroughly. This additional rotation helps create parts with more complex geometries in a shorter amount of time, ultimately improving efficiency and production rates. Другими словами, 4-axis machining is ideal for tasks like milling, drilling, and other machining processes that require a high level of precision and detail.

The Role of CNC in 4-Axis Machining

CNC machining is the backbone of this process. With a 4-axis CNC machine, computer programs control the movements of the machine’s tool, ensuring accuracy, repeatability, and faster production speeds. The machine executes pre-programmed movements that are critical for cutting intricate designs in various materials, such as metals, plastics, and composites.

How Does 4-Axis Machining Work?

Exploring the Four Axes in 4-Axis Machining

In 4-axis machining, the machine moves the tool along four different axes:

- X-Axis: The horizontal movement from left to right.

- Y-Axis: The vertical movement from front to back.

- Z-Axis: The depth movement (up and down).

- Fourth Axis (Rotational Movement): This axis allows the part to rotate, typically around the X-axis, which adds another dimension to the machining process.

This rotational feature is what distinguishes 4-axis machining from simpler 3-axis systems. Вам может быть интересно how this rotational feature works in real-world applications. Imagine you’re working on a complex part, like a turbine blade, which requires milling on multiple sides. With 4-axis machining, you can mill different sections of the part without having to manually reposition it multiple times.

Types of 4-Axis Machines

There are two main types of 4-axis CNC machines: vertical and horizontal. Vertical machines are designed with a rotating table and a stationary tool, while horizontal machines have the rotating axis integrated into the tool spindle itself. Both designs offer advantages depending on the complexity and orientation of the parts being machined.

Benefits of 4-Axis Machining

Increased Precision and Accuracy

4-axis machining improves the accuracy of complex designs because the part can be rotated and machined from various angles. Here’s the deal: This ability reduces the need for repositioning parts, which can introduce errors or inconsistencies. By machining the part all at once, the machine ensures a higher degree of precision.

Faster Production Times

Thanks to the rotating capability of the 4th axis, parts can be worked on multiple sides without requiring the operator to stop and reposition them manually. Другими словами, this reduces downtime and accelerates production times, especially in mass manufacturing settings.

Complex Part Production

4-axis machines excel at producing intricate parts that would be difficult or impossible with 3-axis systems. Вам может быть интересно what kind of parts can be created with 4-axis machining. Some examples include turbine blades, medical devices, and aerospace components—parts that require multi-angle cutting.

Cost-Effective for High-Volume Production

With faster production and reduced handling time, 4-axis machining becomes a more cost-effective solution, especially for businesses that need to produce high quantities of parts in a short time frame. This also translates to reduced labor costs and improved consistency in part quality.

Comparing 4-Axis Machining with Other Types

3-Axis vs. 4-Axis Machining

3-axis machining is a standard method for simple parts that don’t require multiple angles or complex geometries. However, 4-axis machining offers far more flexibility, as it allows for parts to be rotated and worked on from multiple angles without repositioning. Here’s the deal: If you’re producing parts with intricate details or shapes, 4-axis machining is the superior option.

5-Axis Machining: The Next Level

If you need even more versatility, 5-axis machining introduces a second rotational axis, which can work on parts from virtually any angle. While 4-axis machining is ideal for many applications, 5-axis machining provides even greater freedom for extremely complex designs. However, in other words, 4-axis machines are typically sufficient for most industries and are much more cost-effective than their 5-axis counterparts.

Industries Using 4-Axis Machining

Аэрокосмическая промышленность

The aerospace industry relies heavily on 4-axis machining to produce high-precision parts like turbine blades, landing gears, and engine components. Вам может быть интересно why 4-axis machining is so crucial for this industry. The complexity and precision required for aerospace parts make 4-axis machining an ideal choice, as it allows for the production of detailed components that meet strict safety and performance standards.

Автомобильный

4-axis machining is also widely used in automotive manufacturing, especially for engine parts, transmission components, and suspension systems. The ability to produce parts with tight tolerances ensures that they fit perfectly and perform reliably in vehicles.

Medical Devices

In the medical field, 4-axis machining plays a role in producing surgical instruments, implants, and other high-precision devices. Here’s the deal: The need for both accuracy and speed makes 4-axis machining a valuable tool for medical device manufacturers who must adhere to strict regulatory standards.

Defense and Military

Defense contractors rely on 4-axis machining to create parts for military vehicles, weapons systems, and more. The ability to create complex, durable parts that can withstand harsh conditions is critical for defense applications.

Components and Parts Manufactured Using 4-Axis Machining

Examples of Complex Parts Made Possible by 4-Axis Machining

4-axis machining is particularly suited for creating parts with complex geometries, such as engine components, aerospace parts, and medical implants. Вам может быть интересно what makes 4-axis machining the best choice for these applications. The rotational ability allows for precise cuts on multiple faces of the part without requiring time-consuming and error-prone rework.

Real-World Applications and Case Studies

Case studies and examples of real-world applications can provide insight into the versatility of 4-axis machining. Другими словами, manufacturers in industries ranging from aerospace to automotive regularly rely on this technology to produce essential parts with high precision.

The Process of 4-Axis Machining Step-by-Step

Preparing the Material and Workpiece

Before the machining begins, the material must be selected and prepared. Here’s the deal: The workpiece is securely fixed onto the CNC machine, ensuring stability during the cutting process. Material selection depends on the intended use of the part, and may include metals, plastics, or composites.

Setting Up the CNC Machine

The CNC machine must be calibrated for the specific job at hand. This includes setting parameters like tool speed, cutting depth, and feed rate. Вам может быть интересно how machines are programmed—CNC machines use CAD/CAM software to translate 3D designs into machine instructions.

The Actual Cutting Process

Once everything is set up, the machine begins the cutting process. The tool moves across the workpiece, cutting material with high precision. The fourth axis rotation allows the tool to access multiple sides of the part without reloading it, significantly improving efficiency.

Finishing and Quality Checks

After the part is cut, it undergoes finishing processes such as polishing, grinding, or coating. Другими словами, quality control checks ensure that the part meets the necessary specifications and tolerances.

Tools and Equipment Used in 4-Axis Machining

Overview of Common Tools

The cutting tools used in 4-axis machining vary depending on the material being worked on and the part’s design. These can include end mills, drills, and taps. Here’s the deal: Choosing the right tool for the job is crucial for achieving high-quality results. The right tool can reduce wear and tear on the machine, as well as ensure the desired finish.

Importance of Tool Selection

When selecting tools for 4-axis machining, factors like material hardness, cutting speed, and the desired finish must be considered. The wrong tool can lead to subpar parts or damage to the CNC machine itself.

Types of CNC Machines

CNC machines for 4-axis machining come in various configurations. Vertical mills with rotary tables or horizontal machines with integrated rotary axes are both common. Другими словами, the choice of machine depends on the complexity of the part and the orientation required during machining.

Accessories and Attachments

Rotary tables and indexing heads are often added to 4-axis CNC machines to facilitate the rotational movement needed for the fourth axis. These attachments help create more efficient workflows and enhance machine capabilities.

Common Challenges in 4-Axis Machining

Setup Complexity

Setting up a 4-axis machine can be more challenging than working with simpler 3-axis systems. Вам может быть интересно how to ensure that the workpiece is perfectly aligned. Proper alignment is essential to avoid errors during the cutting process.

Material Challenges

Some materials, especially those that are harder or have irregular properties, can present challenges during machining. Другими словами, certain materials may require specialized tools or additional machine settings to ensure precision.

Learning Curve for Operators

4-axis machining requires operators to be well-trained, especially when it comes to programming and machine setup. Here’s the deal: Operators must be familiar with both the mechanical aspects of the machine and the software used for programming.

Machine Maintenance and Tool Wear

Over time, tools and machines will naturally experience wear and tear. Regular maintenance is essential to prevent breakdowns and ensure high precision. Другими словами, proactive maintenance can help extend the life of both tools and machines.

How to Set Up a 4-Axis CNC Machine

Preparing the Machine for a Specific Project

The first step in setting up a 4-axis CNC machine is to prepare the workpiece and ensure that it’s properly aligned. Вам может быть интересно how to achieve perfect alignment. Using measuring tools like dial indicators can help achieve the necessary precision.

Aligning and Securing the Workpiece

Once the workpiece is in place, it must be securely fastened to avoid shifting during machining. Другими словами, clamps and fixturing systems are often used to hold the material in place.

Calibration and Setting Machine Parameters

After securing the workpiece, the machine must be calibrated. This includes setting the correct speeds, feeds, and cutting depths. Here’s the deal: Proper calibration ensures that the machine performs at its best and that the part meets its specifications.

Safety Precautions

Safety is a top priority when working with CNC machines. Вам может быть интересно what steps should be taken for machine safety. Always wear protective equipment, ensure the machine is well-maintained, and follow proper shutdown procedures.

How to Program for 4-Axis Machining

Introduction to CNC Programming

CNC programming involves creating instructions that the machine will follow to create the desired part. Вам может быть интересно how 4-axis programming differs from 3-axis programming. The addition of the fourth axis requires extra commands to handle the rotational movement.

Basics of 4-Axis Programming

At its core, 4-axis CNC programming uses G-codes and M-codes to control the machine’s movements. Другими словами, programmers use CAD/CAM software to design the part, and the software generates the necessary code for the machine to follow.

Software Tools for 4-Axis Programming

CAD and CAM software are essential tools for creating 3D models and generating machine instructions. Here’s the deal: Popular programs for 4-axis programming include Autodesk Fusion 360, SolidWorks, and Mastercam.

Tips for Beginner Programmers

If you’re new to CNC programming, it’s essential to start with simple designs and gradually build your skills. Другими словами, practice is key to mastering the art of 4-axis programming.

Cost and Time Efficiency of 4-Axis Machining

Understanding the Costs

While the initial setup for 4-axis machining can be expensive, it’s more cost-effective for high-volume production. Вам может быть интересно why this is the case. The ability to produce more parts in less time leads to a better return on investment in the long run.

Time-Saving Advantages

4-axis machining saves time by eliminating the need for manual reorientation of the workpiece. Here’s the deal: This efficiency is crucial in fast-paced industries where time is money.

Cost-Effectiveness for Mass Production

For businesses that need to produce large quantities of parts, 4-axis machining is a highly efficient and cost-effective option. Другими словами, it reduces the time and labor required for machining, which ultimately lowers production costs.

Comparing Cost-Effectiveness

When compared to other types of machining, 4-axis systems provide a good balance between capability and cost. Вам может быть интересно if it’s worth the investment. For industries with high-demand production needs, it’s often the best choice.

Maintenance and Troubleshooting for 4-Axis CNC Machines

Regular Maintenance for Long-Term Performance

Maintaining your 4-axis CNC machine is critical for consistent performance. Here’s the deal: Regular lubrication, cleaning, and part inspection help prevent breakdowns and keep the machine running smoothly.

Troubleshooting Common Issues

Issues such as tool wear, incorrect calibration, or software glitches can cause problems. Вам может быть интересно how to identify these problems early. Monitoring the machine’s performance regularly can help you detect issues before they affect production.

Extending Machine Lifespan

Proper maintenance not only ensures better performance but also extends the lifespan of your machine. Другими словами, taking the time to care for your machine will result in fewer repairs and a longer operational life.

Заключение

4-axis machining is a powerful tool in modern manufacturing, offering speed, precision, and versatility. Другими словами, it’s the ideal choice for industries that require high-quality, complex parts at scale. Whether you’re a beginner looking to get started or an industry expert refining your skills, understanding the principles and applications of 4-axis machining is crucial. Вот в чем дело: By mastering this technique, you’ll be well on your way to producing superior parts in less time and at a reduced cost. Start learning today and explore the endless possibilities of 4-axis machining!

Frequently Asked Questions (FAQ)

- What is the main advantage of 4-axis machining over 3-axis machining?

4-axis machining allows for more flexibility by adding rotational movement, making it easier to machine parts from multiple angles without repositioning. - Can 4-axis machining handle all types of materials?

Yes, 4-axis machines can work with a wide range of materials, including metals, plastics, and composites, depending on the tools and settings used. - What are the main industries that use 4-axis machining?

Aerospace, automotive, medical devices, and defense industries frequently use 4-axis machining to produce complex, high-precision parts. - How do I learn 4-axis CNC programming?

To learn 4-axis programming, start by studying basic CNC concepts, then practice with CAD/CAM software like Mastercam or Fusion 360. - What are the safety precautions when working with 4-axis machines?

Always wear protective gear, follow machine startup and shutdown procedures, and regularly inspect the machine to ensure safety during operation. - Can a 4-axis machine be upgraded to 5-axis?

Some 4-axis machines can be upgraded with additional components to add a fifth axis, but it’s typically more cost-effective to purchase a dedicated 5-axis machine. - How do I maintain my CNC machine for better performance?

Regular maintenance includes cleaning, lubrication, tool inspection, and calibration. Following a maintenance schedule can extend your machine’s lifespan. - What software should I use to program a 4-axis CNC machine?

Popular software for programming 4-axis machines includes Autodesk Fusion 360, SolidWorks, and Mastercam. These tools help generate the necessary G-code for machining.