Introduction: Understanding the Importance of CNC Machining Centers

CNC (Computer Numerical Control) machining centers are essential for modern manufacturing, offering precision and efficiency in producing complex parts. For businesses seeking high-quality manufacturing solutions, choosing the best CNC machining center manufacturer is crucial. This decision directly impacts production quality, turnaround time, and overall operational success. The right CNC machining center can ensure consistent performance, while subpar machines may lead to costly delays and inferior results. In this article, we’ll delve into the top CNC machining center manufacturers globally, highlighting the factors to consider when choosing a supplier and the key features that distinguish industry leaders.

1. What Makes a CNC Machining Center “Best”?

When evaluating CNC machining centers, it’s important to understand what defines the “best” in the industry. There are several factors that contribute to the excellence of a machining center. Точность is arguably the most crucial factor. A high-quality CNC machine must deliver consistent results with tight tolerances, ensuring the parts it produces are accurate and meet specifications. Durability is another key attribute. A machining center that offers long-lasting performance and is built to withstand the rigors of high-volume production can save businesses significant repair and replacement costs. Speed is also an essential factor. A top-tier machining center can complete tasks quickly without compromising quality, increasing throughput and reducing production time. Versatility is another important consideration, as manufacturers require machines that can handle a range of materials and processes with ease. Finally, a great CNC machining center should offer excellent customer support и after-sales service, ensuring that businesses receive timely assistance and can maintain optimal machine performance. These features combined create a machine that delivers high-quality, efficient, and cost-effective solutions for modern manufacturing challenges.

Key Features to Look For

When choosing a CNC machining center, focus on these essential features:

- Точность: Ensure the machine offers the accuracy required for your operations.

- Durability: Look for machines made from high-quality materials and backed by warranties.

- Speed: The ability to complete tasks quickly without sacrificing precision is crucial.

- Versatility: Opt for machines that can handle various materials and applications.

Understanding these core attributes will help businesses identify the best CNC machining centers for their specific needs.

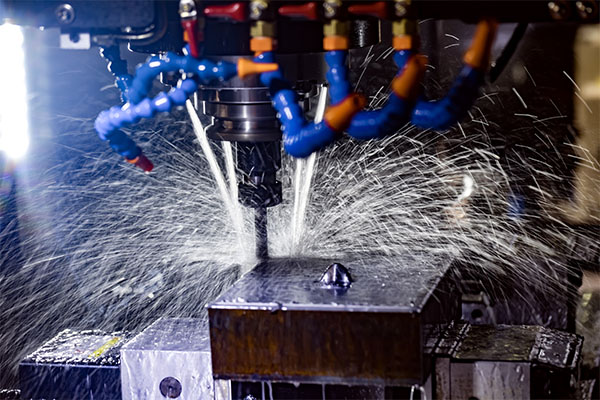

2. How CNC Machining Centers Work

CNC machining centers are highly automated machines that execute a range of tasks with minimal human intervention. At their core, these machines use a computer program to control the movement of tools and the workpiece, allowing for precise cutting, drilling, milling, and other operations. The process starts by inputting a design into the CNC machine, often via CAD (Computer-Aided Design) software. The machine then reads this design, and the CNC system guides the cutting tools through the material, ensuring that the design is followed with exact precision.

Types of CNC Machining Centers

CNC machining centers come in various configurations, each suited for specific tasks:

- Vertical Machining Centers (VMC): These are the most commonly used type, featuring a vertically oriented spindle. They’re well-suited for applications that require precision drilling and milling.

- Horizontal Machining Centers (HMC): These machines feature a horizontally mounted spindle, which is ideal for tasks that involve heavy-duty cutting or larger parts.

- Universal Machining Centers: These combine the features of both vertical and horizontal machines, offering greater flexibility.

These machines provide manufacturers with the ability to produce complex parts with high efficiency and accuracy, making them indispensable in industries like aerospace, automotive, and medical devices.

3. The Top CNC Machining Center Manufacturers in the Market

When it comes to choosing a CNC machining center, selecting a manufacturer with a proven track record of excellence is vital. Some of the top CNC machining center manufacturers in the world include:

- DMG Мори: Known for its innovation, DMG Mori offers a wide range of high-performance CNC machines that cater to various industries, including aerospace, automotive, and medical.

- Хаас Автоматизация: A leader in the American market, Haas offers a variety of CNC machines that deliver exceptional value for businesses seeking cost-effective solutions without compromising quality.

- Mazak: A global leader in CNC machine manufacturing, Mazak is known for its advanced technology, offering both vertical and horizontal machining centers with cutting-edge features.

- Okuma: Offering both vertical and horizontal machining centers, Okuma is renowned for its commitment to precision and reliability in high-end manufacturing applications.

Evaluating Top Manufacturers

When evaluating the top manufacturers, consider their reputation in the industry, their product offerings, and the technological innovations they incorporate into their machines. Top manufacturers invest heavily in R\&D to ensure their products remain competitive and meet the ever-evolving needs of the manufacturing industry.

4. Leading Manufacturers from the USA

The United States is home to some of the most well-regarded CNC machining center manufacturers in the world. Хаас Автоматизация stands out as a leading brand, offering cost-effective yet reliable CNC machines that are widely used across various industries. Their machines are known for their durability and ease of use, making them a popular choice for small to medium-sized businesses. Hardinge is another key player, known for producing high-precision machines that cater to industries requiring extreme accuracy, such as medical device manufacturing.

Why Choose American Manufacturers?

American manufacturers often emphasize customer service, providing comprehensive support and maintenance services. Additionally, they are known for offering excellent value for money, combining reliability and affordability. Хаас Автоматизация, in particular, offers a user-friendly experience, making it easier for companies to get started with CNC machining.

5. Leading Manufacturers from Europe

Europe has long been at the forefront of manufacturing innovation, and CNC machining center manufacturers are no exception. DMG Мори, headquartered in Germany, is one of the global leaders in CNC machine manufacturing. Known for their high-precision machines and cutting-edge technology, DMG Mori’s products are favored in industries where precision is paramount. Макино from Japan, although not European, is also a key player in Europe, with advanced machining centers known for their reliability and accuracy.

Advantages of European Manufacturing

European manufacturers often focus on precision and technological advancement, making their machines highly suited for high-end applications like aerospace, automotive, and electronics. Mazak, with its European operations, is renowned for integrating the latest automation and AI technologies into its machines, pushing the boundaries of CNC machining capabilities.

6. Leading Manufacturers from Asia (China, Japan, Korea)

Asia, particularly China, Japan, and Korea, is home to several top-tier CNC machining center manufacturers that play a major role in the global market. Хаас Автоматизация и Okuma are among the most well-known brands in Asia, offering affordable machines with excellent support networks. However, Chinese manufacturers such as DMTG (Dongguan Machinery) are rapidly gaining market share due to their lower prices without compromising on quality. Chinese CNC machining centers are increasingly sought after for their high-value, cost-effective solutions.

Why Choose Asian Manufacturers?

Asian manufacturers are highly competitive in terms of price and often offer machines with a broad range of features. Their products are perfect for businesses looking to scale up production quickly without significant upfront investments. With China’s growing reputation for manufacturing precision machines, Asian companies are becoming key players in global CNC machining.

7. Key Factors to Consider When Choosing a CNC Machining Center

When selecting a CNC machining center, several factors must be considered to ensure you make the right choice for your business. Price is one of the most obvious factors, but it should not be the only consideration. While cost-effective solutions are important, it is crucial to ensure that the machine you choose meets your specific needs in terms of precision, speed, и durability.

Assessing Your Business Needs

Understanding whether you need a machine for high-volume production or smaller, custom jobs can help you narrow down your options. Consider the machine’s flexibility, capacity, и maintenance requirements. Additionally, ensure the manufacturer provides robust customer support and training to help your team get up to speed quickly.

8. Comparing CNC Machining Centers: What Do the Reviews Say?

User reviews can provide invaluable insights into the performance of different CNC machining centers. While it’s important to keep in mind that reviews can vary depending on the specific use case, they offer useful information on a machine’s performance over time. Reviews often mention key aspects such as ease of operation, machine uptime, and any recurring issues with parts or service.

What to Look for in CNC Machining Center Reviews

Look for long-term feedback from users who have had the machine for several years. Надежность и customer service are often recurring themes in the best reviews, so be sure to check how well manufacturers handle after-sales service and warranty claims.

9. Customization and OEM Capabilities of Leading Manufacturers

Customization is crucial for businesses that require specific modifications to their CNC machining centers to meet unique production needs. Some manufacturers offer OEM (Original Equipment Manufacturer) capabilities, allowing businesses to tailor the machine to their exact specifications. This is particularly important in industries like aerospace or automotive, where unique tolerances and material handling are required.

How Customization Enhances Manufacturing Efficiency

С customized CNC machining centers, businesses can improve their production processes and achieve greater operational efficiency. By ensuring that the machines meet their specific requirements, companies can minimize downtime, reduce errors, and improve overall product quality.

10. Price Range of CNC Machining Centers

CNC machining centers are available across a broad spectrum of prices. Entry-level models can cost as little as $20,000, while high-end machines can run into the millions of dollars. The price of a CNC machining center depends on various factors, including the machine’s size, precision, automation features, и material handling capabilities.

Determining the Right Budget

It’s important to match your business needs with the right price point. While premium machines offer top-tier features and long-term durability, entry-level models can be a good choice for businesses on a tighter budget or for those just starting with CNC machining. Do your research and consider factors like warranty, maintenance costs, и future scalability when making your decision.

11. How to Choose the Right CNC Machining Center for Your Business

Choosing the right CNC machining center for your business involves evaluating several key factors. First, assess your specific needs in terms of production volume and precision. Understand the features you need and match them with the appropriate machine model. Secondly, consider service and support; select a manufacturer that offers strong post-purchase support and training to ensure smooth operations.

Matching Your Needs to the Right Model

If you’re in the automotive industry, for example, you may require a machine with high-speed capabilities and versatility. On the other hand, if you’re in the aerospace sector, precision and tight tolerances might be your top priority. Customization options и industry-specific features will be important in this case.

12. Common Challenges and Mistakes in Choosing CNC Machining Centers

Choosing the right CNC machining center can be challenging, especially if you’re new to the technology. One common mistake is overestimating the capacity or features you need. Many businesses purchase machines with more features than required, driving up costs without necessarily increasing productivity.

Avoiding Pitfalls

Ensure that you understand your business requirements clearly and avoid being swayed by flashy features that don’t add value to your production process. Additionally, consider the long-term costs, including maintenance and downtime, when choosing your machine.

13. Innovations in CNC Machining Centers: The Future of Manufacturing

As technology advances, CNC machining centers are evolving to meet the needs of modern manufacturers. The integration of AI и автоматизация is changing the landscape of CNC machining. Future machines will offer большая точность, faster speeds, и increased efficiency through machine learning and real-time data analysis.

Future Trends in CNC Machining

Expect to see smart CNC machining centers that can adapt to various production tasks, optimize cutting paths in real-time, and communicate with other machines on the shop floor. These innovations will drive productivity and reduce operational costs.

14. What Should You Expect from a Good CNC Machining Center Manufacturer?

A top-tier CNC machining center manufacturer should offer more than just quality machines. They should provide excellent customer support, including installation, training, and ongoing maintenance services. Manufacturers should also offer upgrades и customization options to ensure that your machine can evolve alongside your business needs.

The Importance of Post-Purchase Support

Good customer service can make or break your experience with a CNC machining center. From offering installation services to providing quick-response troubleshooting, strong post-purchase support is crucial to maintaining productivity.

15. Conclusion: Selecting the Best CNC Machining Center Manufacturer for Your Needs

Choosing the best CNC machining center manufacturer requires a balance of several factors, including price, precision, durability, and customer support. It’s important to evaluate your needs carefully and select a machine that aligns with your business goals. By considering these factors, you can ensure that your investment in CNC machining technology will pay off in the long run.

Bucket Brigade: Whether you’re just starting or looking to upgrade, don’t rush—take the time to choose a manufacturer that provides not only the right machine but also ongoing support. This will ensure your business remains competitive in the fast-evolving manufacturing industry.

Раздел часто задаваемых вопросов

- What is the difference between a vertical and horizontal CNC machining center? Vertical machining centers are ideal for precision drilling and milling, while horizontal centers are better suited for heavier, more complex parts.

- How long do CNC machining centers typically last? With proper maintenance, CNC machining centers can last over 10-15 years, depending on usage and care.

- Can I customize my CNC machining center for specific projects? Yes, many manufacturers offer customization options, including special tooling and software tailored to specific tasks.

- Are CNC machining centers suitable for small businesses? Yes, entry-level CNC machining centers are available at lower costs and can be a good investment for small businesses.

- What maintenance does a CNC machining center require? Regular maintenance includes cleaning, lubricating parts, and replacing worn-out components to ensure optimal performance.