Introduction

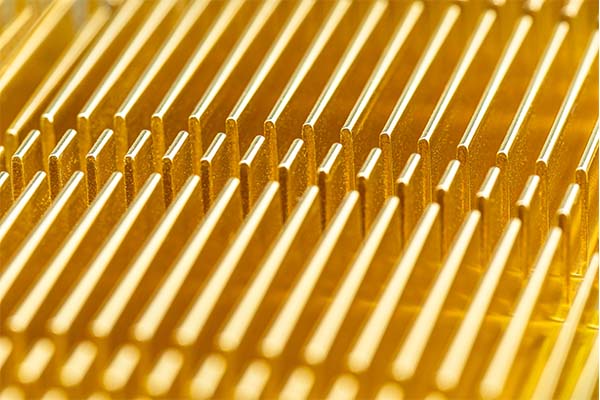

CNC machining is a critical component in modern manufacturing, offering precision and efficiency. One key element that impacts the overall effectiveness of CNC machining is the selection of the right drill bit size. This article will explore standard CNC machining drill bit sizes, why they matter, and how to select the best drill bits for your projects. Understanding these sizes ensures that you achieve the best results, from precision to efficiency.

1. What Are Standard CNC Machining Drill Bit Sizes?

Standard CNC machining drill bit sizes are predefined, commonly used measurements for drill bits that ensure consistency and precision in machining tasks. These sizes are based on a set of internationally recognized standards and allow for compatibility across various machines and industries. But here’s the kicker: using these standard sizes doesn’t just help with machine compatibility, it also streamlines the machining process and ensures that parts fit perfectly with minimal adjustments.

CNC drill bits come in a range of sizes, from the smallest micro drills to large diameter bits. The most common sizes for CNC drilling include 1mm, 2mm, 5mm, 6mm, and so on. These sizes help to prevent errors in part dimensions, ensuring a proper fit without having to create custom tooling for every job. Additionally, standard sizes provide a predictable outcome, which is vital for maintaining high-quality production runs.

By adopting these standard sizes, manufacturers can ensure that their operations are efficient, reducing both downtime and costs associated with custom tooling. The overall impact of using standard sizes means a more predictable workflow and increased productivity, all while ensuring consistent quality.

| Drill Bit Size | Common Use | Material Compatibility | Recommended Speed (RPM) |

|---|---|---|---|

| 1mm | Fine detail work | Steel, aluminum | 2000-3000 |

| 2mm | Precision drilling | Steel, plastic | 1500-2500 |

| 5mm | Medium-size holes | Aluminum, brass | 1000-2000 |

| 6mm | General-purpose | Steel, wood | 1000-1800 |

2. Why Are Standard Drill Bit Sizes Important in CNC Machining?

The importance of standard drill bit sizes cannot be overstated. These sizes are integral to ensuring precision and accuracy in CNC machining. Standard sizes ensure that the machining process is predictable, which is especially vital in high-volume production. Ready for the good part? By using these sizes, manufacturers avoid the costly and time-consuming process of custom tooling for every part they produce.

Precision is one of the top priorities in CNC machining, and drill bit size directly impacts the quality of the final product. For example, using the wrong size bit can cause holes that are either too small or too large, which can affect the function of a part. Standard sizes, on the other hand, allow for repeatability, ensuring that each part manufactured is consistent with the last, minimizing errors.

Standard sizes also make it easier to source drill bits. When you need a drill bit for a specific task, you can simply select from a catalog of well-established sizes rather than designing a custom tool. This not only saves time but also reduces operational costs. The predictability of these sizes further improves the reliability of the entire machining process.

| Benefit | Explanation |

|---|---|

| Precision | Ensures accuracy in part dimensions |

| Repeatability | Standard sizes lead to consistent results |

| Cost-efficiency | Reduces the need for custom tools |

| Time-saving | Faster setup and fewer errors |

3. How Are Standard CNC Machining Drill Bit Sizes Determined?

Standard CNC machining drill bit sizes are determined by international standards and engineering conventions, which set guidelines for the most common sizes. These guidelines ensure that drill bits are compatible with the most widely used CNC machines. This is where it gets interesting: drill bit sizes are generally based on both the application and the material being drilled, ensuring that each size is optimized for specific tasks.

The most commonly used standards include the metric system (for precise applications) and the imperial system (for more general use). Factors like the material being drilled, the type of machine, and the hole diameter influence the selection of drill bit size. For example, a larger drill bit might be chosen for softer materials like aluminum, while smaller bits are typically used for harder materials like steel.

As the industry advances, these standards may evolve to accommodate new machining technologies, but the foundation remains consistent. The goal is always to optimize the drilling process and ensure that parts are produced with maximum accuracy and minimal waste.

| Standard System | Use |

|---|---|

| Metric | Common in precision and fine detail work |

| Imperial | Often used in general manufacturing |

| Unified Thread Standard (UTS) | Used for thread cutting |

4. What Are the Common Types of CNC Machining Drill Bits?

In CNC machining, different drill bits serve different purposes. These range from basic twist drills to more specialized tools designed for specific tasks. What’s the real story? Understanding the different types of CNC machining drill bits is crucial for achieving the best results, whether you’re drilling large holes or fine details.

The most common types of drill bits used in CNC machining include:

- Twist drill bits: These are the most widely used and come in a variety of sizes for general-purpose drilling.

- Spade drill bits: Ideal for making larger diameter holes, spade bits are often used in woodworking and softer materials.

- Core drill bits: Designed to drill deeper holes, core drill bits are typically used for creating holes in thick materials.

- Countersink bits: These are used for creating countersunk holes, which allow screws to sit flush with the material surface.

Each type of drill bit is designed for a specific purpose, allowing manufacturers to use the best tool for their job. The choice of drill bit impacts not only the hole quality but also the speed and efficiency of the operation.

| Drill Bit Type | Common Use | Material Compatibility |

|---|---|---|

| Twist drill bits | General drilling | Steel, aluminum, plastic |

| Spade drill bits | Large diameter holes | Wood, plastic |

| Core drill bits | Deep holes | Concrete, steel |

| Countersink bits | Countersunk holes | Metal, wood |

5. What Are the Most Common Standard CNC Machining Drill Bit Sizes?

The most common standard CNC machining drill bit sizes range from very small bits for precision drilling to larger sizes for general machining. Here’s the kicker: knowing the standard sizes allows you to quickly choose the right tool for your machining needs, reducing setup time and increasing efficiency.

Common drill bit sizes include 1mm, 2mm, 5mm, 6mm, and up to 20mm, with a range of options in between for more specific applications. These sizes are typically chosen based on the material being drilled and the desired outcome. For instance, a 2mm bit might be used for intricate, precise holes in thin materials, while a 6mm bit may be used for larger holes in thicker materials.

Knowing which size to use can save you time and money. By sticking to standard sizes, manufacturers can avoid making custom tools, which saves on both production time and costs. Plus, many suppliers offer these sizes in bulk, which further lowers costs.

| Drill Size | Application | Material Compatibility |

|---|---|---|

| 1mm | Fine detail | Steel, aluminum |

| 2mm | Precision drilling | Steel, plastic |

| 5mm | General-purpose | Brass, aluminum |

| 6mm | Medium-sized holes | Steel, plastic |

6. How Do You Choose the Right Drill Bit Size for Your CNC Machine?

Choosing the right drill bit size for your CNC machine is critical for ensuring that you achieve the desired results while maintaining efficiency. But here’s the kicker: getting the right size can save you time and money in the long run by minimizing errors, reducing machine wear, and improving overall productivity.

The first step in choosing the correct drill bit size is understanding the material you’re working with. Different materials require different drill bit sizes due to varying hardness and machinability. For instance, softer materials like aluminum require larger drill bits compared to harder materials like steel.

Next, consider the hole size and depth required for your specific task. If you’re drilling small, precise holes, a smaller drill bit will provide better results, whereas larger bits are better suited for drilling deeper holes. It’s also crucial to factor in the machining speed and feed rate, as the right size will allow your CNC machine to operate at optimal efficiency, minimizing downtime and wear on the drill bit.

Lastly, understanding the tool compatibility with your CNC machine is essential. Not all machines can handle larger or smaller bits, so knowing the machine’s capabilities is key to selecting the right size.

| Factor | Consideration |

|---|---|

| Material | Soft materials require larger bits, harder materials require smaller bits |

| Hole Size | Match the bit size to the hole diameter and depth |

| Machining Speed | Ensure compatibility with optimal feed rates and speeds |

| Tool Compatibility | Check if the machine supports the drill bit size |

7. What Materials Are Standard Drill Bits Used For in CNC Machining?

CNC machining drill bits are used for a wide variety of materials, each of which requires specific considerations when selecting the drill bit size. Ready for the good part? Understanding the material’s properties and how they interact with the drill bit will help you achieve better results, whether you’re working with metals, plastics, or composites.

In metal machining, standard drill bits are frequently used on materials such as steel, aluminum, brass, and copper. Steel, being one of the hardest materials, often requires smaller drill bits with high precision to achieve clean holes, while aluminum is softer and can accommodate larger bits.

For plastics and composites, CNC machining drill bits are chosen based on the material’s flexibility and durability. Softer plastics, like acrylic, may require a different bit compared to harder materials like fiberglass composites. In fact, understanding the behavior of the material during drilling is crucial, as it can impact the tool’s lifespan and the accuracy of the hole.

When selecting a drill bit, it’s also important to consider the finish and surface quality of the material. Some materials, such as titanium, require specialized coatings on the drill bits to prevent excessive wear, while others may need more traditional high-speed steel or carbide drill bits for general purposes.

| Material | Drill Bit Size Recommendation | Material Compatibility |

|---|---|---|

| Steel | Small to medium size | Steel, stainless steel |

| Aluminum | Medium to large size | Aluminum, brass |

| Plastic | Small to medium size | Acrylic, PVC |

| Composites | Small to medium size | Carbon fiber, fiberglass |

8. How Do Drill Bit Sizes Affect Machining Efficiency?

Drill bit sizes play a pivotal role in CNC machining efficiency. The size you choose can directly affect how quickly and accurately your machine completes a task. So, why does this matter? Choosing the wrong size can lead to increased tool wear, errors, and inefficiencies that slow down the production process.

For example, using a larger drill bit than necessary for a smaller hole will cause the machine to work harder, leading to higher energy consumption and longer machining times. On the other hand, a bit that’s too small for the hole can result in additional steps to enlarge the hole, wasting both time and materials.

Using the correct drill bit size can help achieve optimal feed rates, ensuring that the machine runs smoothly without overloading. This not only improves efficiency but also extends the life of the drill bit and reduces operational costs. By selecting the right size bit, you can prevent tool wear, avoid rework, and ensure that each part is produced in the shortest amount of time possible.

Additionally, drill bit size directly affects the cutting forces on the material. The correct size minimizes excessive forces that could lead to chatter or uneven holes, improving the surface finish and reducing the need for post-machining operations.

| Factor | Effect on Efficiency |

|---|---|

| Bit Size Too Large | Higher energy consumption, slower speed |

| Bit Size Too Small | Additional steps needed, slower process |

| Correct Size | Optimized feed rates, faster machining |

9. What Are the Benefits of Using Standard Drill Bit Sizes Over Custom Sizes?

Using standard drill bit sizes rather than custom ones offers several key benefits. For one, standard sizes are more readily available, which means shorter lead times and lower costs. But here’s the kicker: not having to order custom bits for every job can significantly reduce the amount of time spent waiting for tools, ensuring smoother operations and quicker turnaround times.

Standard drill bits are also more consistent, which leads to higher-quality results. When you use the same size bit across multiple projects, it’s easier to ensure repeatability in your work. This consistency helps maintain tight tolerances, especially in industries where high precision is required.

Furthermore, because standard sizes are commonly used in the industry, they’re available from a wide range of suppliers. This availability ensures that replacements are easy to find, reducing downtime in case a bit gets worn out or damaged. In addition, using standard sizes simplifies inventory management and part sourcing, making your operations more efficient.

| Benefit | Explanation |

|---|---|

| Availability | Standard bits are easy to source from multiple suppliers |

| Cost-efficiency | Reduces the need for custom tooling |

| Consistency | Helps ensure repeatable results and high precision |

| Time-saving | Shorter lead times, quick replacements |

10. How Do You Maintain CNC Machining Drill Bits for Longevity?

Maintaining CNC machining drill bits is crucial for ensuring their longevity and performance. Ready for the good part? Proper maintenance not only extends the life of the tool but also ensures that your machines continue to operate at their highest efficiency.

One of the key aspects of maintenance is proper cleaning after each use. Residues from cutting fluids, chips, and debris can build up on the drill bit, affecting its cutting performance. Regular cleaning prevents this buildup and ensures the tool stays sharp for longer. Additionally, inspecting drill bits for wear and tear before each use allows you to catch small issues early, preventing major problems down the line.

Sharpening is another important part of maintenance. Over time, drill bits naturally lose their sharpness due to the wear and tear of cutting hard materials. Regular sharpening, either through manual or automated methods, helps maintain the bit’s precision and cutting ability.

Storing drill bits correctly is also essential. Storing them in a dry, clean environment and protecting them from excessive moisture or corrosive substances helps prevent rust and prolongs their lifespan.

| Maintenance Task | Purpose |

|---|---|

| Cleaning | Prevents buildup of residues and ensures sharpness |

| Sharpening | Maintains cutting performance and precision |

| Inspection | Identifies wear early, preventing tool failure |

| Storage | Protects drill bits from rust and damage |

11. How Do CNC Operators Handle Variations in Drill Bit Sizes?

In CNC machining, variations in drill bit sizes can occur due to tolerances in manufacturing, tool wear, and environmental factors. So, how do CNC operators handle these variations? They do so by carefully adjusting machine settings to accommodate small differences in drill bit sizes, ensuring the final product remains within the required tolerances.

When a drill bit shows signs of wear, the operator may need to recalibrate the machine or adjust the feed rate to prevent any inaccuracies. For instance, if the diameter of a bit becomes slightly smaller due to wear, the machine may need to compensate for this change by slightly adjusting the feed rate to maintain the same cutting force.

Additionally, some CNC machines allow operators to input tool offsets, which can account for slight variations in drill bit size. By doing this, the operator can ensure that the hole diameter remains accurate, even when the tool has undergone slight wear.

| Tool Wear | Adjustment Action |

|---|---|

| Small wear | Adjust feed rate or cutting force |

| Significant wear | Recalibrate machine or replace tool |

| Tool offset | Use CNC machine’s offset feature |

12. What Are the Limitations of Using Standard Drill Bit Sizes in CNC Machining?

While standard drill bit sizes offer numerous benefits, they aren’t always suitable for every application. In some cases, custom drill bits may be required to meet specific machining needs. For example, high-precision applications might require specialized sizes that are not available in the standard catalog.

Additionally, certain materials or tasks may demand drill bits that are not available in standard sizes. For example, drilling through very thick materials or creating very deep holes may require custom-sized bits to achieve the desired results.

In such cases, manufacturers may need to invest in custom tooling, which can increase costs and lead times. However, these custom bits are necessary to ensure that the machining process remains efficient and accurate.

| Limitation | Explanation |

|---|---|

| High-precision tasks | Custom bits may be required for exact dimensions |

| Thick materials | Larger or deeper drill bits may be needed |

| Increased costs | Custom tooling can lead to higher expenses |

13. How Can You Achieve Precise Hole Sizes with Standard CNC Drill Bits?

Achieving precise hole sizes with standard CNC drill bits is all about the right preparation and setup. The key is ensuring the machine is calibrated correctly and using the proper drilling techniques to minimize errors. What’s the real story? Small adjustments, such as controlling feed rates and speeds, can go a long way in improving the accuracy of drilled holes.

Calibrating your CNC machine and tool offsets helps to achieve consistent hole sizes with each pass. Additionally, monitoring tool wear and promptly replacing bits that have lost their sharpness can prevent size discrepancies.

Using standard drill bit sizes also helps simplify this process, as these sizes have been tested and proven to work well across many applications, ensuring that your machining process is reliable and efficient.

| Technique | Purpose |

|---|---|

| Machine calibration | Ensures accurate hole sizes |

| Tool offsets | Compensates for minor tool wear |

| Speed and feed rate | Controls material removal and hole accuracy |

14. How Do Different CNC Machines Impact the Selection of Drill Bit Sizes?

Different CNC machines have different capabilities, which can affect the size of drill bits you use. This is where it gets interesting: some machines can handle larger or smaller bits more efficiently than others, depending on their design and intended use. For instance, a high-speed CNC machine may work better with smaller drill bits due to its higher spindle speeds, while a larger machine might be better suited for larger drill bits used in heavy-duty operations.

Additionally, machine rigidity, available tooling, and power output all influence the type and size of drill bits you should use. Using the wrong drill bit for your CNC machine could lead to inefficiencies, increased wear, or inaccurate cuts.

| CNC Machine Type | Recommended Drill Bit Size |

|---|---|

| High-speed CNC | Small to medium size |

| Heavy-duty CNC | Large size |

| Precision CNC | Small, precise bits |

15. What Are Some Tips for Optimizing CNC Machining with Standard Drill Bit Sizes?

Optimizing CNC machining with standard drill bit sizes requires a good understanding of both the machine and the material being worked on. Here’s the kicker: choosing the right combination of drill bit size, material, and machine settings can significantly improve efficiency and quality.

One key tip is to always use the smallest bit size that still achieves the required hole diameter. This minimizes tool wear and speeds up the machining process. Additionally, selecting drill bits with coatings that match your material can enhance the tool’s life and reduce cutting forces.

Finally, maintaining consistent speeds and feed rates is crucial. By selecting the optimal settings for your material and drill bit size, you’ll ensure that your CNC machine runs smoothly and efficiently, producing high-quality parts with minimal downtime.

| Tip | Explanation |

|---|---|

| Smallest bit size | Minimizes tool wear, speeds up process |

| Tool coatings | Improves tool life and efficiency |

| Optimal feed rates | Ensures smooth machining process |

FAQ Section

Q1: What is standard CNC machining drill bit size?

Standard CNC machining drill bit size refers to predefined, commonly used sizes designed to fit various machining tasks. These sizes are essential for ensuring precision and consistency in CNC operations.

Q2: How does drill bit size affect CNC machining?

Drill bit size impacts the accuracy of the drilled hole, influencing the overall part quality. Using the correct size ensures the hole fits perfectly, avoiding errors and rework.

Q3: Why should I use standard drill bit sizes instead of custom sizes?

Standard drill bit sizes are widely available, cost-effective, and reduce the need for custom tooling, making the machining process more efficient and predictable.

Q4: How do I know if a drill bit size is suitable for a material?

The material’s hardness, thickness, and machinability should guide the selection of the drill bit size. Standard sizes are optimized for specific materials, ensuring better results.

Q5: Can standard CNC drill bits work for all types of machining tasks?

While standard CNC drill bits are suitable for most tasks, some specialized jobs may require custom sizes for specific results, such as precision work or large holes.