การแนะนำ

การเขียนโปรแกรม CNC might seem daunting at first, but it’s an essential skill for anyone working in the manufacturing and machining industry. Whether you’re an aspiring machinist or someone looking to add CNC programming to your skill set, it’s important to start with the basics. By learning simple tips and gradually working your way up, you can gain the knowledge necessary to program CNC machines with confidence. Here’s the deal, CNC programming isn’t just for experienced engineers—it’s a skill that anyone with a keen interest and the right resources can master. In this article, we will walk you through the essentials of CNC programming, from the foundational concepts to practical tips for beginners.

Understanding CNC Machines: The Basics

What is a CNC Machine?

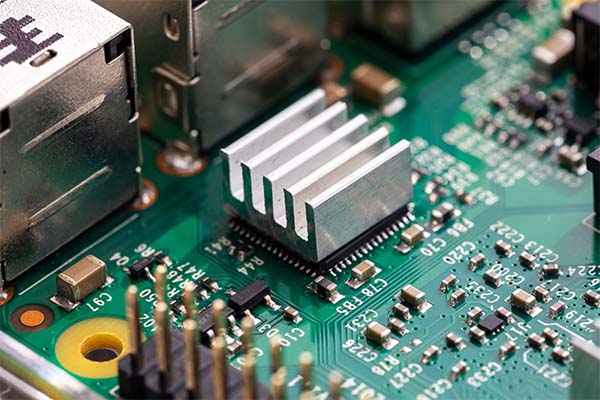

A CNC (Computer Numerical Control) machine is a manufacturing tool that automates the process of machining by following a set of programmed instructions. These machines are widely used in various industries, such as automotive, aerospace, and medical devices. CNC machines come in many types, including lathes, mills, and routers, each designed for specific tasks, but they all share the fundamental concept of automating complex movements. นี่คือข้อตกลง, if you’re starting out in CNC programming, understanding how these machines work is crucial, because this knowledge will help you write better programs and avoid common mistakes.

ประเภทของเครื่อง CNC

CNC machines vary depending on their applications, with each type serving a unique purpose. Lathes, for instance, are ideal for turning cylindrical materials, while mills are used for cutting and shaping parts that require more intricate designs. Routers are typically used for wood and composite materials, but they also work well for plastics and metals. คุณอาจสงสัย, how do these different machines impact the way we program them? Well, each machine requires different commands and programming sequences, so it’s important to understand the specific machine you’ll be working with to write the most efficient program.

How CNC Machines Work

CNC machines rely on precise movements controlled by computer software. The machine follows a set of instructions—typically written in a language called G-code—that directs the machine’s movements along various axes (X, Y, and Z). The machine’s control panel serves as the interface where operators input these instructions, monitor the program’s progress, and make adjustments as needed. The key takeaway here is that CNC programming is all about controlling the machine’s movements through code, and a basic understanding of how these movements work will give you a solid foundation for writing programs.

Key Concepts in CNC Programming

G-Codes and M-Codes

At the heart of CNC programming lies G-codes and M-codes, which are the building blocks of most programs. G-codes (Geometric codes) control the machine’s movements, such as linear motions or circular movements. For example, G01 tells the machine to move in a straight line, while G02 and G03 control clockwise and counterclockwise arcs. M-codes (Miscellaneous codes) handle non-geometric functions, such as turning on or off the spindle or coolant. So here’s the deal, mastering G-codes and M-codes is key to understanding how CNC machines execute commands, and they are essential for any beginner CNC programmer.

Coordinate Systems

CNC machines operate in a 3D coordinate system, which allows them to move in multiple directions. The primary axes are X (left/right), Y (forward/backward), and Z (up/down). Understanding these coordinate systems is crucial, as they define the movements the CNC machine makes during the machining process. คุณอาจสงสัย, how do these coordinates affect my programming? Well, knowing the right coordinates ensures that your tool moves in the correct direction, preventing costly mistakes and machine damage.

Work Coordinate System (WCS)

In CNC programming, the Work Coordinate System (WCS) defines the position of your workpiece in the machine. The WCS can be set in various locations on the machine, but typically the origin (0,0,0) is positioned at one corner of the workpiece. Here’s the thing: without a properly set WCS, your tool will not align correctly with the part, leading to errors and possible damage. For beginners, getting comfortable with WCS setup and understanding how to use it will make your programming more efficient and accurate.

Program Structure

A typical CNC program follows a structure that includes various blocks of code, each performing a specific function. Each line of code consists of several components, including the tool number, movement type (linear or circular), feed rate, and speed. Programs are usually organized in a sequence that ensures the machine makes the correct movements in the right order. คุณอาจสงสัย, what’s the best way to structure my programs? The best practice is to follow a logical flow—starting with tool changes, then moving on to the rough cuts, followed by finer cuts, and finishing with any finishing passes or detailing.

Getting Started with CNC Programming

Choosing the Right CNC Software

Before diving into programming, it’s important to choose the right software for your needs. Popular CNC software options include Fusion 360, SolidWorks CAM, and Mastercam. These tools provide graphical interfaces that allow you to create programs more easily, even for beginners. So, here’s the deal, if you’re starting out, go with a user-friendly software that offers built-in tutorials and simulations. Over time, as you become more proficient, you can explore more advanced options.

Learning the CNC Control Panel

The CNC control panel is the interface that connects the machine to the program you’ve written. Familiarizing yourself with the buttons and functions of the control panel is crucial for successful programming. Here’s the thing, even though it might look complicated at first, it’s just a series of buttons that correspond to specific actions (like starting a program, adjusting feed rates, or pausing the machine). Take time to learn the panel, and soon you’ll feel confident operating the machine.

Setting Up Your CNC Machine

Once you’ve written your program, setting up your CNC machine correctly is vital. This includes loading the material, installing the proper tooling, and making sure the machine’s zero point is aligned with your workpiece. คุณอาจสงสัย, why is this step so important? Well, if the setup isn’t done correctly, your program could fail, or worse, cause damage to the machine or workpiece. Proper setup is an essential skill for any CNC programmer, and mastering it will make your programming process much smoother.

How to Read CNC Program Files

Understanding Program Codes and Comments

When you look at a CNC program, you’ll see a series of codes and numbers. Each code corresponds to a specific function, such as moving the tool or changing the spindle speed. For beginners, it can be overwhelming at first, but with practice, you’ll start recognizing the common codes. The key takeaway here is that comments (written using parentheses) are your friends. They provide context for the code, helping you understand the purpose of each section of the program.

Breaking Down an Example CNC Program

Let’s look at an example CNC program to break it down and explain what each line does. For instance, you might have a program that starts with a tool change (M06), followed by a linear move (G01), a circular arc (G02), and then a rapid move (G00). นี่คือข้อตกลง, understanding each of these commands will help you decipher the program and make the necessary adjustments when working on your machine.

Common CNC Programming Mistakes to Avoid

Incorrect Tool Paths

One of the most common mistakes in CNC programming is specifying the wrong tool path. This can happen if the program doesn’t correctly define the movement of the tool or if the coordinates are set incorrectly. คุณอาจสงสัย, how do I avoid this mistake? Double-check your tool paths before running the program, and always simulate the program to ensure that the tool follows the correct path.

Programming Errors

Programming errors, such as missing codes or incorrect syntax, can cause significant issues in CNC machining. For example, omitting a crucial G-code can lead to improper tool movements or even machine crashes. Here’s the thing, it’s important to check your program for errors before running it. Use software simulations to spot these issues early on and avoid costly mistakes.

Not Verifying the Program

Never run a CNC program without verifying it first. Whether you’re using a simulation or performing a dry run (without material), testing your program is essential to ensure that it works as expected. So, here’s the deal, take the time to verify your program to prevent accidents and save yourself from wasting time and materials.

Basic CNC Programming Tips for Beginners

Start with Simple Programs

If you’re new to CNC programming, it’s important to start with simple tasks. Begin by writing programs for basic movements like linear cuts, drilling holes, or engraving simple designs. The key takeaway here is to master the fundamentals before moving on to more complex tasks. As you become more confident, you can tackle more intricate designs and advanced machining operations.

Understand the Machine Limits

Before programming your CNC machine, it’s essential to know the machine’s limits, including its maximum speed, feed rate, and tool reach. คุณอาจสงสัย, why is this so important? Well, exceeding these limits can lead to machine crashes, tool wear, and other problems. Take time to learn your machine’s capabilities, and program within those limits to avoid costly mistakes.

Use Simulation Software

Simulation software is an invaluable tool for testing your CNC program before running it on the actual machine. Here’s the thing, running a simulation lets you visualize your tool’s movements and catch any mistakes before you start cutting material. It’s a crucial step in ensuring your program runs smoothly and efficiently.

The Importance of Precision in CNC Programming

Measuring Tolerances and Fits

In CNC programming, precision is key, especially in industries like aerospace and medical devices, where even a small deviation can lead to failures. The key takeaway here is that understanding and measuring tolerances is essential to ensure that your program meets the required specifications. CNC machines are capable of incredible precision, but only if the program is written correctly.

How Small Mistakes Can Lead to Big Problems

Even a tiny mistake in CNC programming can lead to significant problems, including defective parts or damage to the machine. คุณอาจสงสัย, how can I avoid these mistakes? The best way is to double-check your work, verify your program through simulations, and take your time when writing code.

Using Precision Tools for Measurement

Using precision tools, like micrometers and calipers, is crucial when measuring parts after they’ve been machined. นี่คือข้อตกลง, accurate measurements ensure that the workpiece meets the required tolerances. Without proper measurement, you risk sending out defective parts, which could lead to delays and customer dissatisfaction.

Introduction to CNC Programming Languages

G-Code Overview

G-code is the standard language used to communicate with CNC machines. It tells the machine what movements to make, at what speed, and in which direction. Here’s the thing, understanding G-code is essential for any CNC programmer because it forms the foundation of most CNC programs. It may seem complex at first, but once you get the hang of it, it becomes a powerful tool for automating machine tasks.

Visual Programming Languages

Visual programming languages, like EZ-CAM or Fusion 360’s CAM, allow users to program CNC machines without directly writing G-code. These languages use graphical interfaces, where users can design parts and generate G-code automatically. คุณอาจสงสัย, why should I use visual programming languages? They simplify the programming process for beginners, making it easier to learn and create programs without delving too deep into G-code.

Comparison of CNC Programming Languages

Different CNC machines use different programming languages, such as Fanuc, Siemens, or Haas. So, here’s the deal, understanding the specific programming language of the CNC machine you’re working with is essential for writing programs that will work correctly on that machine. As you progress, you can start learning multiple programming languages to become more versatile as a CNC programmer.

Setting Up Your First CNC Program

Choosing a Simple CNC Task

When you’re just starting out with CNC programming, choose a simple task to practice. A basic drilling operation or a simple cut is a great starting point. The key takeaway here is that mastering the fundamentals of basic tasks will give you the confidence to tackle more complex operations down the road.

Step-by-Step Guide to Writing a Simple CNC Program

Writing your first program can be intimidating, but it doesn’t have to be. Start by defining the tool, then add movement commands (G00 for rapid moves, G01 for linear cuts). Follow up with spindle speed (S-code) and feed rate (F-code). คุณอาจสงสัย, what’s the best way to structure my program? The best way is to follow a step-by-step process and always double-check your work.

Verifying Your Program with Simulation

Once your program is written, it’s important to verify it with simulation software. Here’s the thing, using simulation software allows you to visualize how your tool will move, ensuring the program is correct before running it on your machine. Always verify your program to catch any errors and prevent mistakes.

How to Troubleshoot Common CNC Programming Issues

Machine Not Responding to Commands

Sometimes, CNC machines don’t respond as expected. This can happen for several reasons, including incorrect tool paths, wrong G-codes, or communication issues between the machine and the control panel. คุณอาจสงสัย, how can I fix this? Double-check your program for errors, make sure the machine is properly calibrated, and ensure that you’re using the correct settings for your tool.

Incorrect Cuts or Movements

Incorrect cuts or movements can happen if the program has errors or if the machine is not set up properly. นี่คือข้อตกลง, always verify your program before running it, and check that your tool offsets and work coordinates are correctly set. Ensuring that these variables are correctly inputted can prevent incorrect cuts.

Overcoming Communication Problems

Communication problems between the CNC machine and programming software can occur, especially when you’re using different types of machines or software. The key takeaway here is that keeping your software and hardware up to date, as well as ensuring compatibility, is crucial for smooth operation.

Safety Protocols in CNC Programming

Protecting Yourself and the Machine

Safety should always be your top priority when working with CNC machines. นี่คือข้อตกลง, you must follow safety guidelines, including wearing protective gear, using safety locks, and keeping the area clean. Make sure you know how to shut down the machine in case of emergency, and never skip these safety steps, no matter how experienced you become.

Emergency Stops and Safety Locks

Most CNC machines come equipped with emergency stop buttons and safety locks to prevent accidents. คุณอาจสงสัย, when should I use these features? You should use them whenever you suspect that something is going wrong with the machine, such as strange noises or sudden movements.

Proper Maintenance of CNC Machines

Routine maintenance is crucial for keeping CNC machines in optimal condition. The key takeaway here is that maintaining your machine will ensure safety, improve performance, and extend the machine’s lifespan. Always follow the manufacturer’s maintenance schedule and check for wear and tear regularly.

Advanced CNC Programming Tips (For When You’re Ready)

Complex CNC Programs for Advanced Machining

Once you’re comfortable with basic programming, you can explore more complex programs. Multi-axis machining, for example, requires writing programs that control movements in multiple directions simultaneously. So, here’s the deal, advanced CNC programming requires a deeper understanding of machine capabilities and programming logic, but with practice, it becomes more manageable.

Using CAD/CAM for CNC Programming

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software allow you to design parts and create the corresponding CNC program in a more intuitive way. คุณอาจสงสัย, why should I use CAD/CAM software? It simplifies the design process and automates many aspects of CNC programming, making it easier to produce complex parts.

Optimizing Programs for Efficiency

As you progress in CNC programming, you’ll learn how to optimize your programs to reduce machining time and increase efficiency. The key takeaway here is that small tweaks, such as adjusting feed rates or tool paths, can make a significant difference in your program’s overall performance.

Resources for CNC Programmers

Books, Courses, and Tutorials

If you want to further your knowledge of CNC programming, there are a wealth of resources available. Online courses, books, and tutorials can help you deepen your understanding of CNC machining and programming. Here’s the thing, starting with beginner-friendly materials is crucial for building a strong foundation before advancing to more technical resources. Websites like Coursera, Udemy, and LinkedIn Learning offer courses that cater to beginners, while books by authors such as Peter Smid provide in-depth knowledge on G-code programming. Additionally, many CNC machine manufacturers provide free resources and guides on their websites.

CNC Programming Forums and Communities

Joining a CNC programming forum or community can be incredibly beneficial, especially when you’re just starting. These communities offer a wealth of knowledge from experienced CNC programmers and machinists who have faced the same challenges you’re encountering. คุณอาจสงสัย, where can I find these communities? Websites like CNCZone and Practical Machinist have active forums where you can ask questions, share your experiences, and learn from others. These communities also offer helpful troubleshooting advice and programming tips.

Certification Programs

CNC programming certification programs are available for those who want to prove their skills and enhance their career prospects. นี่คือข้อตกลง, obtaining a certification shows potential employers that you have the technical expertise to handle complex programming tasks. Several certification programs are recognized in the industry, such as the CNC Programming and Operation Certification by the National Institute for Metalworking Skills (NIMS). Certifications not only boost your credibility but also give you a competitive edge in the job market.

บทสรุป

Summary of Key CNC Programming Tips for Beginners

CNC programming can seem overwhelming at first, but by taking it step by step, you can develop the skills necessary to become proficient in programming CNC machines. Start by understanding the fundamentals, like G-codes and M-codes, machine coordinates, and basic program structure. So here’s the deal, with practice, you’ll become more confident and comfortable programming, which will help you avoid common mistakes and improve your efficiency.

Encouragement for Getting Started

Don’t be discouraged if you don’t understand everything right away. คุณอาจสงสัย, where do I begin? Start small—create simple programs, work with simulation software, and gradually build your knowledge. It’s okay to make mistakes along the way; it’s all part of the learning process. Over time, you’ll be able to tackle more complex tasks with ease.

เรียกร้องให้ดำเนินการ

Now that you have a basic understanding of การเขียนโปรแกรม CNC, it’s time to put it into practice! Start by writing your first program, test it out with simulation software, and then move on to real-world tasks. Here’s the thing—the more you practice, the better you’ll become. So, don’t hesitate to dive into the world of CNC programming today and begin your journey toward becoming an expert.

ส่วนคำถามที่พบบ่อย

What is CNC programming?

CNC programming involves writing code to control the movements of a CNC machine, enabling it to perform precise manufacturing tasks. It uses specialized languages like G-code to communicate with the machine and tell it what to do. It’s essential for creating parts and components in industries such as aerospace, automotive, and medical devices.

How long does it take to learn CNC programming?

The amount of time it takes to learn CNC programming depends on the individual and the complexity of the tasks they want to accomplish. For beginners, learning the basics can take a few weeks to a couple of months. However, mastering more advanced concepts, like multi-axis machining and complex program optimizations, can take several months to a year.

Do I need prior knowledge of CAD/CAM for CNC programming?

While knowledge of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) can certainly enhance your CNC programming abilities, it’s not a strict requirement for beginners. You can start by learning basic G-code programming, and as you become more experienced, you can transition to using CAD/CAM software for more complex tasks.

What software should I use for CNC programming?

Several CNC programming software options are suitable for beginners, including Fusion 360, SolidWorks CAM, and Mastercam. These programs are user-friendly and come with built-in tutorials and simulation tools to help you get started. As you gain more experience, you may choose more advanced software depending on your needs.

Can I learn CNC programming without having access to a CNC machine?

Yes, you can learn CNC programming without a machine by using simulation software. These tools allow you to visualize tool paths, test your programs virtually, and ensure they will work correctly on an actual machine. Many CNC programming courses and tutorials also offer virtual training environments where you can practice programming.