การแนะนำ

Mild Steel 1018 is a versatile material widely used in CNC machining. This article delves into its properties, benefits, machining processes, and common applications. We’ll explore how this material stands out in the manufacturing world and why it is a go-to choice for many industries.

1. What is Mild Steel 1018 and Why is it Popular for CNC Machining?

Mild Steel 1018, also known as SAE 1018, is a low-carbon steel alloy with excellent machinability and good mechanical properties. It is composed primarily of iron, with a carbon content that typically ranges from 0.15% to 0.20%, making it soft and easy to work with. The low carbon content ensures that the material is more ductile than higher-carbon steels, which makes it an ideal candidate for various applications in CNC machining.

What’s the real story here? Mild Steel 1018 is widely used because it provides a great balance of strength, formability, and cost-effectiveness. Its ability to withstand significant stress while being easy to machine makes it a preferred material for many engineers and manufacturers.

Mild Steel 1018 is popular in industries like automotive, aerospace, and construction. It is used for producing a wide range of parts, including shafts, gears, and structural components. It also plays a significant role in industries requiring precise machining, as it is often used in parts that need to be fabricated to exacting specifications.

What’s the real story? The combination of affordability, ease of machining, and versatility ensures that Mild Steel 1018 is one of the most widely used materials for CNC machining across different sectors.

| คุณสมบัติ | Value |

|---|---|

| Carbon content | 0.15% – 0.20% |

| Tensile strength | 440 MPa (minimum) |

| Yield strength | 370 MPa |

| Hardness (Brinell) | 126-170 |

2. What Are the Benefits of Using Mild Steel 1018 in CNC Machining?

Mild Steel 1018 offers several benefits that make it an excellent choice for CNC machining. First and foremost, it is relatively inexpensive compared to other steel alloys, making it a cost-effective option for manufacturers. The material’s machinability is also superior, meaning that it can be shaped and cut with minimal tool wear and faster processing speeds.

Here’s the kicker—Mild Steel 1018 is also highly versatile. It can be welded, drilled, and turned with ease, allowing it to be used in a wide range of manufacturing processes. Its excellent machinability makes it ideal for complex designs, particularly in applications that require tight tolerances.

Another important benefit is its good mechanical properties. While not as strong as other steel alloys, it still offers decent strength, which makes it suitable for medium-load applications. Additionally, the material is highly resistant to fatigue and impact, which enhances the durability of the final product.

The ability to produce high-quality, durable parts at a lower cost is one of the main reasons why manufacturers prefer Mild Steel 1018 for CNC machining. Whether you’re working on automotive parts, industrial components, or precision engineering products, this material’s reliability and ease of use are unparalleled.

| ผลประโยชน์ | คำอธิบาย |

|---|---|

| คุ้มค่าคุ้มราคา | Affordable compared to other steel alloys |

| Easy to machine | Minimizes tool wear, increases processing speed |

| Versatile | Suitable for welding, turning, and other processes |

| Strong enough for medium-load applications | Durable for most industrial needs |

3. How Does the Composition of Mild Steel 1018 Affect Its Performance?

Mild Steel 1018 is known for its low carbon content, which plays a significant role in determining its performance. The carbon content in steel affects the hardness, strength, and overall machinability. In the case of Mild Steel 1018, the low carbon content makes it soft and ductile, which enhances its machinability.

What’s the real story here? While Mild Steel 1018 lacks the hardness of higher-carbon steels, this makes it easier to cut, shape, and form during CNC machining. This characteristic is crucial for industries that need precise parts without the high cost associated with harder, more expensive steels.

Moreover, the presence of trace elements like manganese, phosphorus, and sulfur further impacts the material’s properties. Manganese, for example, increases toughness and strength, while sulfur improves machinability. However, these trace elements can also have a slight impact on the material’s welding properties, which manufacturers should consider when using it in certain applications.

In addition, the alloy’s ability to withstand various manufacturing processes without cracking or deforming is a key factor that enhances its performance in CNC machining. It’s a material that can endure the mechanical stresses associated with machining while maintaining its structural integrity.

| Element | Effect on Performance |

|---|---|

| Carbon | Softens the material, improving machinability |

| Manganese | Increases toughness and strength |

| Phosphorus | Enhances machinability but may reduce weldability |

| Sulfur | Improves machinability but can affect weld quality |

4. What Are the Key Characteristics of Mild Steel 1018?

Mild Steel 1018 has several characteristics that make it a popular choice for CNC machining. These include its tensile strength, hardness, weldability, and formability. The material has a tensile strength of around 440 MPa, making it strong enough to handle various mechanical loads in most industrial applications.

But here’s the kicker—its hardness is relatively low compared to higher-carbon steels, which makes it easier to machine and work with during manufacturing. It’s important to note that while it may not be as hard as other alloys, it can still perform well under many types of stress.

Additionally, the material has excellent weldability. When compared to other steels, 1018 is easier to weld and form, making it ideal for a wide range of welding applications. Whether you’re producing components that need to be welded or simply looking for a material that can withstand various processing methods, Mild Steel 1018 is an ideal choice.

In terms of impact resistance, the material exhibits good toughness, meaning it can handle shock and vibration without easily cracking or breaking. Its ability to withstand repeated mechanical stress ensures that parts made from Mild Steel 1018 are durable and long-lasting.

| Characteristic | Value |

|---|---|

| Tensile strength | 440 MPa |

| Hardness (Brinell) | 126-170 |

| Weldability | ยอดเยี่ยม |

| Formability | ดี |

5. What Are the Common Uses of Mild Steel 1018 in CNC Machining?

Mild Steel 1018 is used in a wide range of applications across various industries due to its cost-effectiveness and excellent machinability. One of the most common uses is in the manufacturing of automotive parts. It is frequently used for producing shafts, gears, and other components that require strength and precision but don’t need the hardness of high-carbon steels.

What’s the real story here? Mild Steel 1018 is also commonly found in machinery and equipment manufacturing. Its ability to withstand moderate loads and perform well in high-stress environments makes it ideal for producing machine components such as pulleys, axles, and brackets.

In addition to automotive and machinery parts, Mild Steel 1018 is often used for structural components in construction projects. It’s frequently used for producing beams, columns, and other elements that require strength without the need for expensive materials. The versatility of Mild Steel 1018 ensures that it can be found in almost any industry where durable, cost-effective components are needed.

| อุตสาหกรรม | แอปพลิเคชัน |

|---|---|

| ยานยนต์ | Shafts, gears, axles |

| Machinery | Pulleys, brackets, axles |

| Construction | Structural beams, columns |

6. What Are the Differences Between Mild Steel 1018 and Other Steel Grades?

Mild Steel 1018 is often compared to other steel grades, such as 1045 and 4130 steel, to understand how it stands out. Unlike 1018, which has low carbon content, 1045 steel contains a higher percentage of carbon, making it stronger and more wear-resistant but harder to machine.

Ready for the good part? The main difference between Mild Steel 1018 and 4130 steel is the presence of chromium and molybdenum in 4130, which provides higher strength and toughness, making it suitable for high-stress applications such as aerospace and motorsports. However, these elements also make 4130 more difficult and expensive to machine compared to 1018.

Mild Steel 1018 stands out because of its low cost, ease of machining, and versatility. For industries that do not require the superior strength of higher-carbon steels, 1018 offers an affordable and easy-to-work-with option.

| Steel Grade | Carbon Content | Strength | ความสามารถในการแปรรูป | แอปพลิเคชั่น |

|---|---|---|---|---|

| 1018 | 0.15% – 0.20% | Medium | ยอดเยี่ยม | General use |

| 1045 | 0.40% – 0.50% | สูง | Fair | Heavy-duty components |

| 4130 | 0.30% – 0.40% | Very high | Poor | Aerospace, motorsports |

7. How Is Mild Steel 1018 Processed for CNC Machining?

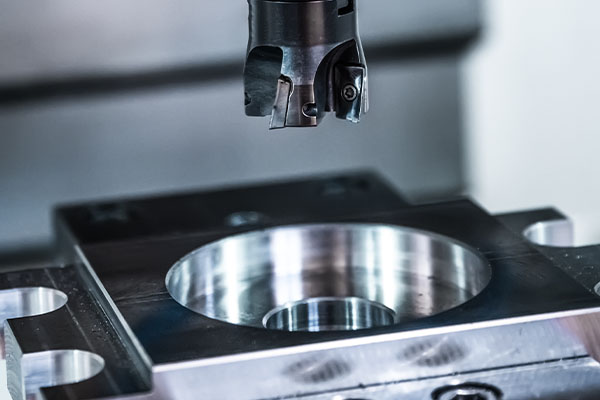

CNC machining of Mild Steel 1018 involves several steps, including milling, turning, and drilling, depending on the part being manufactured. The material’s low carbon content and excellent machinability allow it to be processed using standard cutting tools and machinery.

What’s the real story here? One of the key steps in processing Mild Steel 1018 is selecting the right cutting speed and feed rate. CNC machines must be set at optimal speeds to ensure a clean cut and minimize tool wear. When machining Mild Steel 1018, it is essential to use sharp tools to reduce friction and avoid heat buildup.

Another important factor is the use of coolants and lubricants during the machining process. These help to maintain optimal cutting conditions, prevent excessive heat buildup, and ensure a smooth finish on the material. Depending on the specific application, different types of coolants or lubricants may be used to enhance tool life and part quality.

| กระบวนการ | Tooling Needed | Best Practices |

|---|---|---|

| การสี | Carbide tools | Use sharp tools, optimize feed rate |

| การเปลี่ยนแปลง | High-speed steel | Apply lubricants to reduce friction |

| การเจาะ | Drill bits with coating | Use proper cooling techniques |

8. What Are the Challenges When CNC Machining Mild Steel 1018?

While Mild Steel 1018 is easy to machine, it does present some challenges. One of the main challenges is work hardening, which occurs when the material becomes harder and more resistant to cutting as it is processed.

But here’s the kicker—if not managed properly, work hardening can lead to excessive tool wear and poor surface finishes. To avoid this, manufacturers must carefully control the cutting speed and feed rate during machining.

Another challenge is managing heat buildup during machining. Since Mild Steel 1018 has good thermal conductivity, it can quickly absorb heat, leading to thermal expansion and deformation of parts. Using coolants effectively is essential to maintain machining accuracy and minimize thermal effects.

| ท้าทาย | สารละลาย |

|---|---|

| Work hardening | Control cutting speed, use sharp tools |

| Heat buildup | Use effective cooling methods |

| Tool wear | Optimize feed rate and cutting conditions |

9. What Types of CNC Machines Are Best for Working with Mild Steel 1018?

When working with Mild Steel 1018, it is essential to use CNC machines that can handle the material’s machining requirements effectively. Vertical and horizontal CNC milling machines are commonly used for producing parts from this material.

Ready for the good part? CNC lathes are also ideal for turning Mild Steel 1018 into cylindrical parts, such as shafts and gears. The key is to use machines that offer precise control over cutting speed, feed rate, and tool movement, ensuring high-quality parts with tight tolerances.

Another important consideration is the choice of cutting tools. CNC machines that can hold carbide tools or high-speed steel tools are ideal for machining Mild Steel 1018, as these materials offer excellent resistance to wear and heat.

| Machine Type | Ideal Use |

|---|---|

| CNC Milling Machine | General machining, complex parts |

| เครื่องกลึงซีเอ็นซี | Turning cylindrical parts |

| CNC Drilling Machine | Precision drilling |

10. How Does Heat Treatment Affect Mild Steel 1018?

Heat treatment is an essential process that can enhance the properties of Mild Steel 1018. While the material is already relatively soft, heat treatment can improve its strength and hardness, making it more suitable for specific applications.

What’s the real story here? Processes like quenching and tempering can significantly improve the mechanical properties of Mild Steel 1018. Quenching involves heating the material to a high temperature and then rapidly cooling it, which hardens the steel. Tempering, on the other hand, involves reheating the steel to a lower temperature to relieve stresses and increase toughness.

This makes heat-treated Mild Steel 1018 more suitable for applications that require higher strength without compromising its machinability.

| Heat Treatment Process | Effect on Material |

|---|---|

| Quenching | Increases hardness |

| Tempering | Increases toughness |

| Annealing | Improves machinability |

11. How Does the Surface Finish of Mild Steel 1018 Impact Its Applications?

The surface finish of Mild Steel 1018 plays a significant role in determining its performance in different applications. A smooth, high-quality surface finish is crucial in parts that will be subject to friction, wear, or exposure to corrosive environments.

But here’s the kicker—improper surface finishing can lead to parts that wear out prematurely or fail under stress. To achieve the best results, it’s important to use the right finishing techniques for specific applications.

Whether it’s polishing, coating, or simply improving the surface texture, Mild Steel 1018’s surface finish can enhance its overall performance. This ensures that parts retain their durability and function effectively throughout their lifespan.

| Surface Finish | แอปพลิเคชัน |

|---|---|

| Polished | Precision components |

| Coated | Corrosion resistance |

| Textured | Parts subject to wear |

12. How Does the Cost of Mild Steel 1018 Compare to Other Materials?

Mild Steel 1018 is known for its affordability. Compared to other steel alloys, such as 1045 or 4130, Mild Steel 1018 is a much more cost-effective option. The price advantage lies in its ease of manufacturing and the abundance of raw material, which lowers the overall production cost.

What’s the real story? While it might not be as strong as high-carbon steels, Mild Steel 1018’s affordability and versatility make it a popular choice for manufacturers looking to balance cost and performance. It provides the best value for projects that don’t require the additional strength of other alloys.

When comparing costs, it’s essential to consider the trade-offs in strength and performance. For many applications, the cost savings of using Mild Steel 1018 far outweigh the need for a stronger material.

| วัสดุ | ค่าใช้จ่าย | Strength | แอปพลิเคชัน |

|---|---|---|---|

| Mild Steel 1018 | ต่ำ | Medium | General use |

| Steel 1045 | Medium | สูง | Heavy-duty parts |

| Steel 4130 | สูง | Very high | การบินและอวกาศ |

13. How Can You Improve the Machining Process for Mild Steel 1018?

Improving the machining process for Mild Steel 1018 involves optimizing the cutting speed and feed rate. By choosing the right tools and settings, you can increase the efficiency of your CNC machines, reduce tool wear, and improve the final product quality.

What’s the real story? Using the right lubricants and coolants is also essential for ensuring that the machining process runs smoothly. These not only help cool down the material but also improve surface finishes and extend tool life.

Ensuring that the machines are calibrated correctly and that the material is properly prepared before machining can also make a significant difference in the quality of the finished parts.

| Improvement Method | ผลประโยชน์ |

|---|---|

| Optimize cutting speed | Reduces tool wear |

| Use proper lubrication | Improves finish and tool life |

| Calibrate machines | Ensures precision |

14. What Are the Environmental Considerations When Machining Mild Steel 1018?

Machining Mild Steel 1018 can produce waste materials, including metal chips and scrap. Proper waste management and recycling are crucial to minimizing the environmental impact of the machining process.

Ready for the good part? Using sustainable machining practices, such as optimizing cutting parameters and using eco-friendly lubricants, can significantly reduce the carbon footprint of the manufacturing process.

By recycling scrap material and minimizing waste, manufacturers can also reduce costs and contribute to a more sustainable manufacturing process.

| Environmental Impact | สารละลาย |

|---|---|

| Metal waste | Recycle scrap material |

| Energy consumption | Use energy-efficient machines |

| Coolant disposal | Use eco-friendly lubricants |

15. What Are the Future Trends in CNC Machining of Mild Steel 1018?

The future of CNC machining for Mild Steel 1018 looks promising. With advances in technology, we can expect improvements in the precision and speed of machining processes. New machining techniques, like additive manufacturing, are also being explored for creating parts with complex geometries.

What’s the real story? Automation and smart manufacturing techniques are poised to make CNC machining even more efficient. These advancements will allow manufacturers to produce higher-quality parts faster and at lower costs.

As the demand for precision and customization continues to grow, Mild Steel 1018 will likely remain a popular material for CNC machining, thanks to its versatility and affordability.

| แนวโน้ม | Impact |

|---|---|

| ระบบอัตโนมัติ | Increases efficiency and reduces cost |

| การผลิตแบบเติมแต่ง | Enables complex designs |

| Smart manufacturing | Enhances precision and quality |

บทสรุป

Mild Steel 1018 remains one of the most widely used materials in CNC machining due to its balance of cost, strength, and machinability. Its versatility makes it suitable for a wide range of applications, from automotive parts to structural components. By understanding its properties and applications, manufacturers can make informed decisions when choosing this material for their machining projects. The future of Mild Steel 1018 in CNC machining is bright, with ongoing innovations enhancing the material’s performance and making it even more valuable in modern manufacturing.

ส่วนคำถามที่พบบ่อย

คำถามที่ 1: What is Mild Steel 1018?

Mild Steel 1018 is a low-carbon steel alloy known for its excellent machinability and good mechanical properties. It is commonly used in CNC machining for parts that require strength and precision but do not need the hardness of high-carbon steels.

คำถามที่ 2: How does CNC machining of Mild Steel 1018 work?

CNC machining of Mild Steel 1018 involves cutting, milling, turning, or drilling the material using computer-controlled machines. The material’s ease of machinability makes it a popular choice for producing precise, high-quality parts.

ไตรมาสที่ 3: What are the common applications of Mild Steel 1018?

Mild Steel 1018 is used in automotive, machinery, and construction industries. It is often used for parts such as gears, shafts, and structural components that require strength and durability without the need for expensive materials.

ไตรมาสที่ 4: How does heat treatment affect Mild Steel 1018?

Heat treatment can improve the hardness and toughness of Mild Steel 1018. Processes like quenching and tempering enhance the material’s performance for applications requiring higher strength and wear resistance.

คำถามที่ 5: Why is Mild Steel 1018 preferred for CNC machining?

Mild Steel 1018 is preferred for CNC machining because of its affordability, excellent machinability, and versatility. It can be easily processed into complex parts with high precision, making it a cost-effective choice for many industries.