การแนะนำ

อลูมิเนียม 6063 is a versatile alloy known for its excellent workability and corrosion resistance, making it a go-to material for CNC machining applications. In this article, we will explore the properties of Aluminum 6063, its common uses, and why it’s favored in the CNC machining industry. We’ll also dive into the benefits, challenges, and how to optimize CNC machining for this alloy. By the end of this article, you will understand why Aluminum 6063 is a preferred choice for many industries worldwide.

1. What is Aluminum 6063?

Aluminum 6063 is an alloy primarily used in manufacturing processes that require high precision and strength. It’s often referred to as the “architectural aluminum” due to its application in building structures like window frames and doors. The alloy is composed mainly of aluminum, with small additions of magnesium and silicon to enhance its properties. What’s remarkable about Aluminum 6063 is its ability to be extruded into complex shapes, which makes it particularly valuable in industries requiring detailed and intricate components.

But here’s the kicker—this alloy also offers an excellent surface finish. Its smooth, polished surface makes it a favorite in industries where aesthetics and precision are important. It’s also highly resistant to corrosion, which increases its durability even in harsh environments. These factors make Aluminum 6063 an all-around excellent choice for a wide variety of uses, from architectural elements to automotive parts.

Table 1: Aluminum 6063 Composition

| Element | Percentage (%) |

|---|---|

| อลูมิเนียม | 97.0–98.0 |

| แมกนีเซียม | 0.45–0.9 |

| Silicon | 0.2–0.6 |

| ทองแดง | 0.1 max |

| Iron | 0.35 max |

2. Why is Aluminum 6063 Popular in CNC Machining?

Aluminum 6063 stands out in the CNC machining industry for several key reasons. One of the biggest advantages is its ease of machinability. It’s soft and easy to cut, which reduces tool wear and makes it a cost-effective option for high-volume production runs. CNC machinists prefer Aluminum 6063 because it offers good dimensional accuracy, and it’s easier to process than other aluminum alloys like 7075 or 6061. This makes the alloy particularly suited for applications where fine tolerances are required.

What’s the real story? Aluminum 6063’s high corrosion resistance and lightweight nature make it ideal for industries such as construction, automotive, and aerospace. Moreover, its ability to retain strength even at higher temperatures adds to its versatility in different environments.

Table 2: Machinability of Aluminum 6063 vs Other Alloys

| คุณสมบัติ | อลูมิเนียม 6063 | Aluminum 6061 | Aluminum 7075 |

|---|---|---|---|

| Machinability Rating | สูง | Medium | ต่ำ |

| Surface Finish Quality | ยอดเยี่ยม | ดี | Fair |

| ความต้านทานการกัดกร่อน | สูง | ปานกลาง | ต่ำ |

3. What Are the Properties of Aluminum 6063?

Aluminum 6063 has a unique combination of properties that make it suitable for both structural and aesthetic applications. As mentioned earlier, it’s lightweight yet strong, with excellent resistance to corrosion—especially in harsh environments like marine or industrial settings. This alloy also has good thermal conductivity, which helps in applications requiring heat dissipation. Its high strength-to-weight ratio makes it perfect for use in the aerospace and automotive industries, where minimizing weight without compromising strength is a priority.

So, why does this matter? Well, the ability to easily machine and extrude Aluminum 6063 allows it to be used in intricate designs. Whether it’s for window frames or custom machined parts, the alloy retains its structural integrity even under stress, ensuring long-lasting performance.

Table 3: Key Properties of Aluminum 6063

| คุณสมบัติ | Value |

|---|---|

| Yield Strength | 240 MPa |

| Ultimate Tensile Strength | 250 MPa |

| Hardness (Brinell) | 60 HB |

| Density | 2.70 g/cm³ |

| Melting Point | 650–660 °C |

4. How is Aluminum 6063 Used in Industries?

Aluminum 6063 is used across a wide range of industries. In construction, it’s often employed in architectural frames, railings, and window systems due to its ability to withstand the elements while providing a sleek, polished finish. The alloy’s resistance to corrosion makes it a good choice for applications exposed to harsh weather conditions, like marine environments. In the automotive industry, Aluminum 6063 is used for lightweight structural components, reducing overall vehicle weight and improving fuel efficiency.

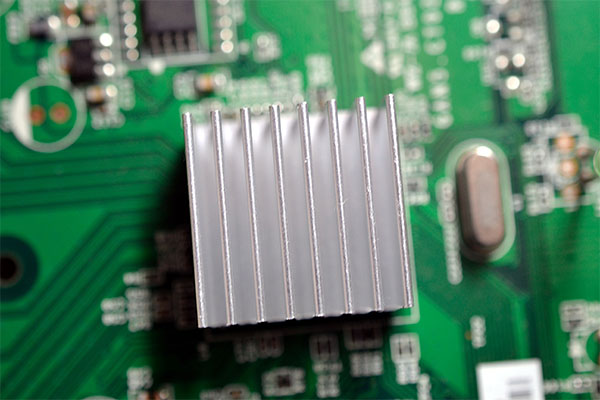

But here’s the deal: aluminum 6063 doesn’t just stop at architecture and transportation. It’s also widely used in electronics, where its thermal conductivity helps dissipate heat from sensitive components. From consumer electronics to industrial machinery, Aluminum 6063 proves itself time and time again as a versatile and reliable material.

Table 4: Common Applications of Aluminum 6063

| อุตสาหกรรม | แอปพลิเคชัน |

|---|---|

| Construction | Window frames, doors, architectural facades |

| ยานยนต์ | Lightweight structural components |

| อิเล็กทรอนิกส์ | Heat sinks, enclosures for electronic devices |

| การบินและอวกาศ | Aircraft structural parts |

5. What Are the Benefits of Using Aluminum 6063 in CNC Machining?

Using Aluminum 6063 in CNC machining comes with numerous benefits, which are why it’s a preferred material for many manufacturing processes. One of the biggest advantages is the material’s workability—Aluminum 6063 is easy to cut, drill, and mill, which allows for high-speed machining and reduces production time. Additionally, this alloy is lightweight, which makes handling and transportation more manageable.

Now here’s the good part—Aluminum 6063 also provides excellent surface finishes. It’s ideal for applications where appearance is crucial, like in architectural elements or consumer electronics. Furthermore, the alloy’s low cost and abundant availability make it a highly cost-effective choice for manufacturers, particularly for large-scale production runs.

Table 5: Advantages of Aluminum 6063 in CNC Machining

| ผลประโยชน์ | คำอธิบาย |

|---|---|

| Excellent Workability | Easy to machine, reducing tool wear |

| Lightweight | Reduces handling and transportation costs |

| Superior Surface Finish | Ideal for aesthetic applications |

| Cost-Effective | Low material cost, ideal for mass production |

6. How Does Aluminum 6063 Compare to Other Aluminum Alloys?

When compared to other aluminum alloys, such as 6061 and 7075, Aluminum 6063 stands out for its excellent machinability, corrosion resistance, and aesthetic properties. While 6061 is stronger and better suited for heavy-duty applications, 6063 excels in environments where a smooth surface finish and corrosion resistance are key. For example, in architectural applications where the visual appearance of the material is as important as its structural integrity, 6063 is the go-to choice.

But here’s the twist—while 7075 is known for its superior strength, it doesn’t offer the same level of workability as 6063. If you’re looking for an alloy that balances ease of machining with strength and durability, 6063 is the best choice.

Table 6: Aluminum 6063 vs Other Aluminum Alloys

| Alloy | Strength | ความสามารถในการแปรรูป | ความต้านทานการกัดกร่อน | Application Suitability |

|---|---|---|---|---|

| อลูมิเนียม 6063 | ปานกลาง | สูง | สูง | Architecture, Electronics |

| Aluminum 6061 | สูง | ปานกลาง | ปานกลาง | Aerospace, Heavy-duty parts |

| Aluminum 7075 | สูงมาก | ต่ำ | ต่ำ | Military, Aerospace |

7. What Are the Common Challenges When Working with Aluminum 6063 in CNC Machining?

While Aluminum 6063 is a favorite in CNC machining, it does come with its share of challenges. One of the most significant issues is material deformation. Due to its softness and malleability, the alloy can warp or bend under certain machining conditions, especially during high-speed operations. This can lead to dimensional inaccuracies or defects in the finished part.

But here’s the kicker—tool wear is another challenge when machining Aluminum 6063. Although the material is relatively soft, its high silicon content can cause abrasion on the cutting tools over time, requiring more frequent tool changes to maintain machining efficiency. Additionally, the high thermal conductivity of Aluminum 6063 means that it heats up quickly during machining, which can cause issues with thermal distortion and the buildup of material chips. This can affect the surface finish and increase the chances of part defects.

Despite these challenges, these issues can be mitigated with the right machinery, tooling, and machining parameters. By carefully selecting cutting tools, using proper cooling methods, and optimizing cutting speeds, you can achieve high-quality results even with these potential obstacles.

Table 7: Common Challenges and Solutions in CNC Machining of Aluminum 6063

| ท้าทาย | สารละลาย |

|---|---|

| Material deformation | Optimize cutting speeds and feeds, use better clamping |

| Tool wear | Choose appropriate cutting tools with wear-resistant coatings |

| Thermal distortion | Use effective cooling techniques and maintain optimal cutting temperature |

| Chip buildup | Use high-pressure coolant systems to clear chips quickly |

8. How Can You Improve CNC Machining Efficiency with Aluminum 6063?

CNC machining efficiency is crucial for reducing production time and costs, and Aluminum 6063 offers several opportunities for optimization. First, ensuring that your CNC machine is properly calibrated and in optimal working condition can reduce errors and rework. Keeping the machine well-maintained, with proper lubrication and cooling systems, allows for smoother operations and minimizes tool wear.

Ready for the good part? The key to improving efficiency when working with Aluminum 6063 is to optimize cutting speeds and feeds. Since the material is relatively easy to machine, you can increase speeds to reduce cycle times. Additionally, using high-quality cutting tools and maintaining the correct tool geometry can drastically reduce tool wear and improve the precision of the cuts. Another significant factor is the use of automated loading and unloading systems, which can further streamline operations and reduce downtime.

Finally, using advanced CNC programming techniques such as adaptive control and real-time tool condition monitoring can enhance the machining process, allowing for greater flexibility and accuracy.

Table 8: CNC Machining Optimization for Aluminum 6063

| Optimization Area | Recommended Action |

|---|---|

| Cutting speeds | Increase cutting speeds while monitoring tool wear |

| Tool selection | Use carbide tools with wear-resistant coatings |

| การสอบเทียบเครื่องจักร | Ensure accurate machine calibration for precision |

| ระบบอัตโนมัติ | Implement automated loading and unloading systems |

9. How to Maintain CNC Machines When Working with Aluminum 6063?

Proper maintenance of CNC machines is crucial when working with Aluminum 6063 to ensure the longevity of the machine and the quality of the parts produced. One important aspect is regularly cleaning the machine after every shift, especially to remove aluminum chips and debris that can cause machine jams or poor finishes. Failure to clean the machine properly can result in misalignment, tool wear, and operational inefficiencies.

But here’s the twist—lubrication is another critical aspect of CNC machine maintenance. Aluminum 6063 generates a lot of heat during machining, and without proper cooling and lubrication, it can cause thermal distortion and lead to poor surface finishes. Ensure that coolant is applied correctly and that the cooling system is functioning at full capacity. Regular checks of the coolant mixture and pump pressure can prevent cooling failures.

Another important consideration is maintaining the tool holders and spindles. These components should be checked regularly for wear and tear, and any misalignment should be addressed immediately to avoid issues during machining.

Table 9: CNC Machine Maintenance for Aluminum 6063

| งานบำรุงรักษา | Recommended Frequency |

|---|---|

| Cleaning machine | After every shift or batch production |

| Checking lubrication | Daily checks on coolant and lubrication levels |

| Tool holder inspection | Inspect tool holders for wear every 500 hours |

| Spindle alignment | Check alignment every 1000 hours of operation |

10. What Are the Best Tools for CNC Machining Aluminum 6063?

Choosing the right tools for CNC machining Aluminum 6063 can significantly impact the quality of the finished product. The alloy’s machinability allows for a wide range of tools to be used, but selecting the best tools depends on the specific machining operation you’re performing.

So, why does this matter? The best tools for machining Aluminum 6063 typically include carbide inserts, which provide long-lasting durability and help in maintaining high cutting speeds. These tools offer excellent wear resistance, reducing the need for frequent tool changes. For drilling, carbide drills are ideal because they maintain sharpness and provide clean holes. Additionally, using tools with proper coatings, such as TiN (Titanium Nitride), can further increase tool life and improve the quality of the surface finish.

Lastly, don’t forget about the importance of tool geometry. For fine cuts and smooth surfaces, use tools with sharp edges and proper angles to minimize burr formation and ensure smooth cuts.

Table 10: Best Tools for CNC Machining Aluminum 6063

| Tool Type | Recommended Features |

|---|---|

| Carbide Inserts | Long-lasting, wear-resistant, ideal for cutting |

| Carbide Drills | Sharp, high-speed cutting, maintains clean holes |

| Coated Tools (TiN) | Increases tool life and improves surface finish |

| Tool Geometry | Use sharp edges and proper angles to reduce burrs |

11. How Does the Surface Finish of Aluminum 6063 Affect CNC Machining?

Surface finish plays a crucial role in the final product when machining Aluminum 6063. This alloy is known for its excellent surface finish, which makes it suitable for applications that require both durability and aesthetics. Whether it’s used in window frames or intricate parts for electronics, the surface quality can directly impact the product’s appearance and functionality.

Now here’s the twist—achieving a high-quality surface finish requires the right machining parameters. For instance, using the correct cutting speed and feed rate can prevent the formation of rough surfaces or unwanted tool marks. Additionally, maintaining clean cutting conditions and using appropriate lubricants can ensure that the surface remains smooth and free of defects.

In many applications, such as in the production of architectural components or high-end consumer goods, a polished surface finish is required. This is where Aluminum 6063 shines—its smooth surface makes it ideal for anodizing and painting, which further enhances its visual appeal.

Table 11: Factors Affecting Surface Finish in CNC Machining Aluminum 6063

| Factor | Impact on Surface Finish |

|---|---|

| Cutting Speed | Higher speeds can result in smoother finishes |

| Feed Rate | Lower feed rates help achieve finer surfaces |

| Lubrication/Coolant | Proper cooling reduces friction and improves finish |

| Tool Condition | Sharp tools minimize defects and roughness |

12. What Are the Environmental Benefits of Using Aluminum 6063?

Aluminum 6063 offers several environmental benefits that make it an attractive choice for sustainable manufacturing. One of the primary benefits is its recyclability. Aluminum, in general, is one of the most recycled materials in the world, and Aluminum 6063 is no exception. The material can be recycled indefinitely without losing its properties, which reduces the need for new raw materials and lowers energy consumption.

What’s the real story? The recycling process for Aluminum 6063 uses only a fraction of the energy required to produce new aluminum, making it an eco-friendly choice for companies looking to reduce their carbon footprint. Furthermore, using aluminum alloys like 6063 in manufacturing processes reduces the demand for heavier, less sustainable materials, helping industries move toward more environmentally responsible practices.

Table 12: Environmental Benefits of Recycling Aluminum 6063

| ผลประโยชน์ | คำอธิบาย |

|---|---|

| Energy Savings | Recycling uses only 5% of the energy of new aluminum production |

| Reduces Raw Material Demand | Recycling reduces the need for mining bauxite |

| Lower Carbon Footprint | Less energy consumption results in lower emissions |

13. What Are the Costs Associated with Aluminum 6063 CNC Machining?

The cost of CNC machining Aluminum 6063 depends on several factors, including material costs, machining time, tooling, and labor. Compared to other materials, Aluminum 6063 is relatively inexpensive, especially when bulk quantities are ordered. The low cost of the material makes it an attractive option for manufacturers looking to reduce production expenses.

But here’s the kicker—while the material itself is cost-effective, the cost of machining can vary based on the complexity of the part being produced. The more intricate the design, the higher the machining cost. However, due to its excellent machinability, Aluminum 6063 allows for faster production cycles, which can help offset higher machining costs.

Table 13: Factors Affecting CNC Machining Costs of Aluminum 6063

| Factor | Impact on Cost |

|---|---|

| Material Cost | Relatively low, especially for bulk orders |

| Machining Complexity | More intricate designs lead to higher costs |

| Tooling and Labor Costs | Tool wear and labor time impact overall cost |

| Production Volume | High-volume production can reduce per-unit cost |

14. How to Choose the Right Aluminum 6063 for Your CNC Project?

Choosing the right grade of Aluminum 6063 for your CNC project depends on several factors, including the intended application, mechanical properties, and surface finish requirements. There are different tempers of Aluminum 6063, each offering different strengths and capabilities. For example, the T5 temper provides good strength for structural applications, while the T52 temper offers better resistance to corrosion and is ideal for architectural elements.

What’s the real story? When selecting Aluminum 6063, you should also consider the production process and the specific demands of your project. If you’re working on high-volume machining, it may be worth opting for a higher-strength temper to reduce the risk of deformation. Additionally, if aesthetic quality is crucial, choosing a temper that allows for superior surface finishes may be more appropriate.

Table 14: Different Tempers of Aluminum 6063 and Their Applications

| Temper | Strength | Common Applications |

|---|---|---|

| T5 | ปานกลาง | Structural applications, window frames |

| T52 | สูง | Architectural facades, high-end consumer goods |

| T6 | สูงมาก | Aerospace, heavy-duty structural components |

15. What Are the Latest Innovations in Aluminum 6063 Machining?

The CNC machining of Aluminum 6063 has evolved significantly with advancements in technology. One of the most exciting innovations is the use of advanced coatings and surface treatments that improve the durability and appearance of Aluminum 6063 parts. Anodizing is a common treatment that enhances the material’s corrosion resistance and provides a wide range of color options for architectural components.

Ready for the good part? Additive manufacturing techniques, such as 3D printing with Aluminum 6063, are also gaining popularity. This technology allows for more complex and lightweight designs, which are particularly valuable in industries like aerospace and automotive. These innovations are revolutionizing the way Aluminum 6063 is used in machining and manufacturing, opening up new possibilities for its application.

Table 15: Innovations in Aluminum 6063 Machining

| Innovation | คำอธิบาย |

|---|---|

| Advanced Coatings | Anodizing and other coatings to improve durability and appearance |

| 3D Printing | Additive manufacturing for lightweight and complex designs |

| Laser Machining | Laser cutting for high-precision parts with minimal material loss |

ส่วนคำถามที่พบบ่อย

คำถามที่ 1: What is Aluminum 6063?

Aluminum 6063 is an alloy widely used in CNC machining for its excellent machinability, corrosion resistance, and ability to maintain a smooth surface finish. It’s commonly used in applications requiring both structural strength and aesthetic appeal.

คำถามที่ 2: How does CNC machining work with Aluminum 6063?

CNC machining works effectively with Aluminum 6063 due to its excellent workability. The alloy is easy to cut, drill, and mill, which makes it ideal for high-precision machining applications.

ไตรมาสที่ 3: What are the main applications of Aluminum 6063?

Aluminum 6063 is primarily used in the construction industry for window frames, doors, and other architectural elements. It’s also used in automotive, aerospace, and electronics for lightweight structural components.

ไตรมาสที่ 4: Why is Aluminum 6063 favored over other aluminum alloys in CNC machining?

Aluminum 6063 is favored for its excellent machinability, which allows for high-speed CNC machining. It also offers superior corrosion resistance and a high-quality surface finish, making it ideal for aesthetic applications.

คำถามที่ 5: Can Aluminum 6063 be recycled?

Yes, Aluminum 6063 is highly recyclable. It retains most of its properties after recycling, making it an environmentally sustainable material choice in manufacturing.