Introduction

Aluminum CNC machining is an essential process in many industries, involving the use of advanced computer-controlled machines to shape and finish aluminum parts with high precision. This guide will walk you through the ins and outs of aluminum CNC machining, from its benefits to the types of aluminum alloys used, how the process works, and more. Whether you are in the aerospace, automotive, or medical field, understanding aluminum CNC machining is crucial to producing high-quality, custom parts. Let’s dive into the details!

1. What is Aluminum CNC Machining?

Aluminum CNC machining is a manufacturing process that uses computer-controlled machines to cut, shape, and finish aluminum components. CNC stands for “Computer Numerical Control,” which means the machines follow pre-programmed instructions to perform precise actions. This process is highly efficient and accurate, allowing manufacturers to create complex parts that are used in various industries.

But here’s the kicker: Aluminum is one of the most widely used materials in CNC machining because of its excellent machinability, light weight, and high strength-to-weight ratio. These properties make aluminum an ideal choice for applications where both performance and weight reduction are important.

Aluminum CNC machining can produce a wide variety of parts, ranging from simple structural components to intricate, detailed designs used in high-performance products. The versatility of aluminum makes it a staple in industries such as aerospace, automotive, and electronics.

| Property | Aluminum CNC Machining Benefits |

|---|---|

| Lightweight | Ideal for applications requiring reduced weight |

| Corrosion Resistance | Perfect for components exposed to outdoor or harsh environments |

| Cost-Effective | More affordable compared to other metals like steel and titanium |

2. Why Choose Aluminum for CNC Machining?

Aluminum is an excellent material for CNC machining because of its unique combination of properties, including lightness, durability, and corrosion resistance. These benefits make aluminum the go-to choice for a range of applications across industries.

What’s the real story? Aluminum’s strength-to-weight ratio is one of its biggest advantages. For instance, in the aerospace industry, every gram saved in weight can translate into improved fuel efficiency and performance. Similarly, aluminum’s resistance to corrosion makes it an excellent option for marine and outdoor products.

Let’s explore some specific advantages:

- Lightweight: Aluminum is significantly lighter than other metals like steel, which makes it ideal for applications where weight is critical.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that shields it from rust and corrosion, making it perfect for outdoor and marine applications.

- Machinability: Aluminum is easy to machine, which results in faster production cycles, lower costs, and less wear on tooling.

| Aluminum Alloy Type | Common Applications | Benefits |

|---|---|---|

| 6061 | Aerospace, automotive | Excellent weldability, lightweight |

| 7075 | Aircraft, military applications | High strength, low weight |

| 2024 | Aerospace, high-performance parts | Superior fatigue resistance |

3. What Are the Different Types of Aluminum Used in CNC Machining?

There are many different types of aluminum alloys, and each is suited to different machining applications. Choosing the right alloy for your CNC machining needs depends on factors such as strength, weight, and corrosion resistance.

Ready for the good part? Understanding which alloy to use for your project is key to achieving optimal results in aluminum machining. Here’s a breakdown of the most commonly used aluminum alloys in CNC machining:

- 6061 Aluminum: This is one of the most widely used alloys in CNC machining due to its balanced properties. It has good strength, excellent corrosion resistance, and is easy to machine. It’s often used in aerospace and automotive industries.

- 7075 Aluminum: Known for its high strength and low weight, 7075 aluminum is used in applications where performance is critical, such as in military and aerospace industries. It’s more difficult to machine than 6061 but offers superior strength.

- 2024 Aluminum: With its excellent fatigue resistance, 2024 aluminum is commonly used in aerospace applications. It’s known for its ability to withstand repeated stress, making it ideal for high-performance parts.

| Aluminum Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Common Uses |

|---|---|---|---|

| 6061 | 240 | 205 | Aerospace, automotive |

| 7075 | 570 | 505 | Military, aerospace |

| 2024 | 470 | 325 | Aircraft, aerospace |

4. How Does Aluminum CNC Machining Work?

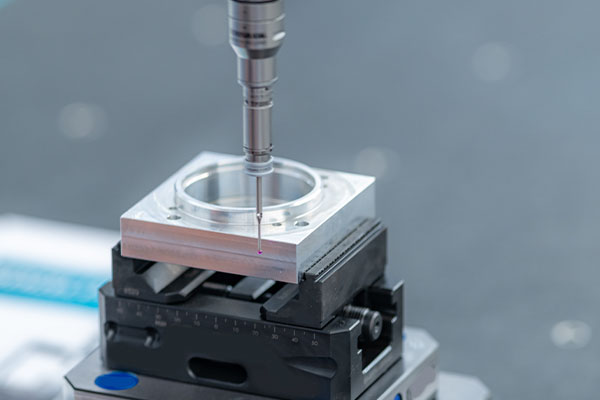

Aluminum CNC machining involves several precise steps, from designing the part to programming the CNC machine and finally machining the aluminum. Here’s how the process works:

This is where it gets interesting: CNC machining of aluminum starts with a digital design. Once the part is designed in CAD (Computer-Aided Design) software, the design is converted into a set of instructions that the CNC machine can follow using G-code.

The CNC machine uses various tools, such as drills, end mills, and lathes, to perform the necessary operations. The machine is controlled by a computer, ensuring that each cut, hole, or mill is made with high precision. Once the part is machined, it undergoes quality control checks to ensure that it meets the required specifications.

- Step 1: Design the part using CAD software.

- Step 2: Program the CNC machine using G-code.

- Step 3: The CNC machine cuts, drills, and mills the aluminum based on the program.

- Step 4: The finished part is inspected for accuracy and quality.

| Step | Description |

|---|---|

| CAD Design | Design the part digitally |

| CNC Programming | Convert the design into machine instructions |

| Machining | CNC machine performs cutting, drilling, and milling operations |

| Quality Control | Inspect the part for specifications and accuracy |

5. What Are the Advantages of Aluminum CNC Machining?

There are many reasons why aluminum is a popular choice for CNC machining, including its versatility, strength, and ease of use. The ability to create highly precise parts is another key advantage.

But here’s the kicker: CNC machining aluminum allows manufacturers to produce complex and intricate parts that are often impossible to make using traditional methods. Aluminum’s properties also allow for high-speed machining, making it ideal for mass production.

Here are the main advantages:

- Precision: CNC machines provide high accuracy, ensuring that parts are produced with exact specifications.

- Efficiency: Aluminum’s machinability allows for faster production speeds, which helps reduce lead times and costs.

- Customization: CNC machining allows manufacturers to produce custom parts that are tailored to the specific needs of the customer.

| Advantage | Description | Impact |

|---|---|---|

| Precision | High accuracy with tight tolerances | Reduced rework and waste |

| Efficiency | Faster production cycles | Lower production costs |

| Customization | Ability to create unique parts | Tailored solutions for clients |

6. What Industries Benefit from Aluminum CNC Machining?

Aluminum CNC machining is used in many industries where precision, light weight, and durability are required. The versatility of aluminum makes it ideal for a wide variety of applications, from aerospace to medical devices.

What’s the real story? The benefits of aluminum CNC machining make it indispensable in industries that need high-quality components produced at a competitive price. Here are some of the key industries that rely on aluminum CNC machining:

- Aerospace: Aluminum’s light weight and strength make it ideal for producing aircraft parts, such as structural components and engine parts.

- Automotive: Lightweight aluminum parts help reduce vehicle weight, improving fuel efficiency and overall performance.

- Medical Devices: Aluminum’s biocompatibility and machinability make it a popular choice for medical devices, including surgical instruments and implants.

| Industry | Benefits | Applications |

|---|---|---|

| Aerospace | Lightweight, corrosion-resistant | Aircraft parts, engine components |

| Automotive | Reduced weight for better fuel efficiency | Engine components, wheels |

| Medical Devices | Precision, durability | Surgical instruments, prosthetics |

7. How Do You Prepare Aluminum for CNC Machining?

Preparing aluminum for CNC machining is crucial to ensuring the best possible outcome. Proper preparation helps prevent problems during machining and guarantees a smooth and accurate process.

What’s the real story? The right preparation ensures that the CNC machine works efficiently, reducing the risk of errors and minimizing wear and tear on tools. Here’s how to prepare aluminum:

- Step 1: Select the right alloy based on the application.

- Step 2: Clean the aluminum to remove any contaminants that could affect the machining process.

- Step 3: Cut the aluminum to the appropriate size for machining.

| Preparation Step | Description |

|---|---|

| Alloy Selection | Choose the correct aluminum alloy |

| Cleaning | Remove dirt, oil, and other contaminants |

| Cutting | Size the aluminum for machining |

8. What CNC Machines Are Best for Aluminum Machining?

When it comes to CNC machining aluminum, choosing the right machine is crucial for achieving the desired results. The type of machine you use will determine how efficiently and accurately you can work with aluminum.

Ready for the good part? Different types of CNC machines are suited to different tasks in the machining process. Some are better for precision milling, while others are ideal for drilling or turning. Here’s a breakdown of the most commonly used CNC machines for aluminum machining:

- Vertical Milling Machines: These are ideal for creating complex shapes and cutting aluminum parts to precise specifications. Vertical mills are excellent for machining flat surfaces, pockets, and other detailed features.

- Horizontal Milling Machines: These machines use a horizontal spindle to remove material from the workpiece. Horizontal mills are often used for larger aluminum parts or when high-volume production is required.

- CNC Lathes: CNC lathes are used to turn aluminum into cylindrical shapes. They are great for creating parts such as shafts, spindles, and bushings.

- CNC Routers: These machines are suitable for cutting and engraving aluminum sheets, typically used for larger, flat parts.

This is where it gets interesting: Choosing the right CNC machine depends on the complexity of your parts and the volume of production. Each machine type offers unique advantages depending on the scope of your project.

| Machine Type | Best For | Benefits |

|---|---|---|

| Vertical Milling | Complex shapes, precise details | High accuracy, versatile |

| Horizontal Milling | Large parts, high-volume production | High production rates |

| CNC Lathe | Cylindrical parts | High precision, perfect for turning |

| CNC Router | Large, flat aluminum parts | Suitable for large sheet metal machining |

9. What Are the Challenges of CNC Machining Aluminum?

While aluminum is one of the easiest metals to machine, there are still several challenges associated with CNC machining. Understanding these challenges can help improve your machining process and prevent costly mistakes.

What’s the real story? The most common challenges in aluminum CNC machining involve managing heat buildup, tool wear, and achieving a perfect surface finish. Overcoming these obstacles requires careful planning and the right tools.

Here are some of the key challenges:

- Tool Wear: Aluminum is a soft metal, but it can still cause wear and tear on CNC tools. Frequent tool changes and the right tool materials can help combat this issue.

- Heat Buildup: CNC machining generates heat, and aluminum’s properties can make it prone to heat buildup, especially when machining at high speeds. Proper coolant use and temperature control are essential.

- Achieving Surface Finish: Aluminum can often have surface irregularities that require additional finishing processes such as polishing or anodizing to achieve the desired smoothness.

| Challenge | Explanation | Solution |

|---|---|---|

| Tool Wear | Frequent cutting can wear out tools | Regular tool maintenance, proper tool selection |

| Heat Buildup | Aluminum generates heat during machining | Use coolant, optimize speeds and feeds |

| Surface Finish | Aluminum can have rough or uneven finishes | Post-machining processes like polishing or anodizing |

10. How Do You Achieve the Best Surface Finish on Aluminum?

Achieving a smooth and high-quality surface finish on aluminum parts is crucial, especially for parts that require a polished or anodized look. The surface finish not only affects the aesthetic quality of the part but also its performance in certain applications.

But here’s the kicker: The surface finish can significantly impact the strength, corrosion resistance, and longevity of aluminum parts. It’s essential to understand the best practices for getting that perfect finish.

Here are some methods for achieving a high-quality surface finish on aluminum:

- Anodizing: Anodizing is a surface treatment that increases the thickness of the aluminum oxide layer, enhancing corrosion resistance and providing a smooth, polished finish.

- Polishing: Polishing aluminum removes imperfections and produces a mirror-like finish. It’s ideal for applications where appearance is critical.

- Sanding and Bead Blasting: For parts that require a matte finish, sanding or bead blasting can be used to create a uniform, non-reflective surface.

| Method | Description | Benefits |

|---|---|---|

| Anodizing | Electrochemical process to thicken oxide layer | Enhanced corrosion resistance, smooth finish |

| Polishing | Abrasive process to remove imperfections | Creates a mirror-like, smooth finish |

| Sanding/Bead Blasting | Abrasive methods for matte finish | Uniform, non-reflective surface |

11. How Can You Improve the Efficiency of Aluminum CNC Machining?

Improving the efficiency of aluminum CNC machining can lead to faster production, lower costs, and higher-quality parts. Several strategies can be employed to optimize the machining process, from tool selection to machine programming.

Here’s the deal: Optimizing cutting speeds, improving tool maintenance, and using automation are some of the best ways to improve machining efficiency.

Here are a few strategies to boost efficiency:

- Optimize Cutting Speeds and Feeds: Selecting the right cutting speeds and feeds for the aluminum material can significantly reduce machining time while maintaining quality.

- Tool Maintenance: Regular tool maintenance and proper selection can prevent tool wear and reduce downtime, improving overall machine efficiency.

- Automation: Automated CNC machines can operate continuously without human intervention, improving production speeds and reducing labor costs.

| Strategy | Explanation | Benefits |

|---|---|---|

| Optimizing Cutting Speeds | Adjusting speeds for efficiency | Reduced machining time, lower costs |

| Tool Maintenance | Regular maintenance to prevent wear | Prolonged tool life, consistent production |

| Automation | Use of automated systems for uninterrupted operation | Higher production rates, reduced labor |

12. What Are Common Applications of Aluminum CNC Machining?

Aluminum CNC machining is used in various industries due to its versatility and the ability to produce custom parts with high precision. From lightweight components for aerospace to sturdy parts for automotive, aluminum is the material of choice.

What’s the real story? The adaptability of aluminum in CNC machining makes it suitable for a wide range of applications, including custom parts that meet specific requirements for various industries.

Some common applications of aluminum CNC machining include:

- Aerospace Components: Aluminum’s light weight and strength make it ideal for producing parts like wing structures and fuselage components.

- Automotive Parts: Components such as engine parts, wheels, and structural components benefit from aluminum’s light weight and durability.

- Consumer Electronics: Aluminum is widely used for creating the casings and internal components of electronic devices like smartphones and laptops.

| Industry | Applications | Benefits |

|---|---|---|

| Aerospace | Wing structures, fuselage components | Lightweight, strong, corrosion-resistant |

| Automotive | Engine parts, wheels, body components | Reduced weight, improved fuel efficiency |

| Consumer Electronics | Casings, internal parts | Durable, heat-resistant, lightweight |

13. What Are the Costs Associated with Aluminum CNC Machining?

Understanding the costs of aluminum CNC machining is important for businesses looking to balance quality with cost efficiency. The price of machining aluminum can vary depending on factors such as the type of aluminum used, the complexity of the parts, and the volume of production.

What’s the real story? Aluminum machining tends to be more affordable than machining other metals like titanium or steel. However, several factors can influence the overall cost, and understanding these factors can help businesses save money while ensuring quality.

The main cost factors include:

- Material Cost: The type of aluminum alloy used can affect the cost. High-strength alloys like 7075 aluminum tend to be more expensive than general-purpose alloys like 6061.

- Machining Complexity: More intricate designs that require specialized tools or longer machining times will increase costs.

- Production Volume: High-volume orders can often reduce the per-unit cost due to economies of scale.

| Cost Factor | Impact on Price | Example |

|---|---|---|

| Material Cost | More expensive alloys increase cost | 7075 aluminum is more costly than 6061 |

| Machining Complexity | Complex parts require more time and tools | Intricate parts cost more to machine |

| Production Volume | Higher volume reduces per-unit cost | Bulk orders save on costs |

14. How Do You Choose the Right CNC Machining Service for Aluminum?

Choosing the right CNC machining service for aluminum is crucial to ensuring that your parts are manufactured to the highest standards. The right service can make a significant difference in terms of quality, turnaround time, and cost.

Ready for the good part? Selecting the right CNC service provider involves assessing factors such as machine capabilities, past performance, and customer service.

Here’s how to choose the right CNC machining service for your aluminum needs:

- Evaluate Machine Capabilities: Make sure the service provider has the necessary machines for your specific project.

- Check Reviews and Reputation: Look for companies with strong customer reviews and a solid reputation in the industry.

- Inquire About Lead Times: Ensure that the provider can meet your production deadlines.

| Criteria | Considerations | Impact |

|---|---|---|

| Machine Capabilities | Does the provider have the right equipment? | Ensures the ability to meet project requirements |

| Reputation | Customer reviews, past projects | Indicates reliability and quality |

| Lead Times | Ability to meet deadlines | Timely delivery of parts |

15. What Are the Future Trends in Aluminum CNC Machining?

The world of CNC machining is constantly evolving, and aluminum machining is no exception. Emerging technologies and trends are shaping the future of the industry.

This is where it gets interesting: Automation, 3D printing, and sustainable practices are set to revolutionize aluminum CNC machining in the coming years.

Key future trends include:

- Automation: More manufacturers are incorporating automated CNC systems to improve production rates and reduce labor costs.

- Sustainability: The use of recycled aluminum and energy-efficient machining practices is growing, as businesses look to reduce their environmental footprint.

- Additive Manufacturing: 3D printing is expected to play a bigger role in aluminum machining, offering new possibilities for complex part designs.

| Trend | Explanation | Future Implications |

|---|---|---|

| Automation | Use of automated CNC machines | Faster production, reduced labor costs |

| Sustainability | Use of recycled aluminum, energy-efficient methods | Lower environmental impact |

| Additive Manufacturing | 3D printing of aluminum parts | Enables more complex part designs |

FAQ Section

- Q1: What is Aluminum CNC Machining?

Aluminum CNC machining is a process that uses computer-controlled machines to precisely shape aluminum into desired parts. - Q2: How does aluminum CNC machining work?

Aluminum CNC machining involves using a CNC machine to cut, drill, and mill aluminum parts based on a CAD design, with high precision and efficiency. - Q3: What are the benefits of using aluminum for CNC machining?

Aluminum is lightweight, corrosion-resistant, and easy to machine, making it ideal for applications in industries like aerospace, automotive, and medical devices. - Q4: What industries use aluminum CNC machining?

Industries such as aerospace, automotive, and medical devices use aluminum CNC machining for its strength, light weight, and versatility in producing custom parts. - Q5: How can you improve the efficiency of aluminum CNC machining?

Improving efficiency involves optimizing cutting speeds, selecting the right tools, and maintaining CNC machines to minimize downtime and reduce production costs.