Introduction

The artificial intelligence revolution has created unprecedented thermal management challenges for GPU cooling technologies. As AI models grow larger and more complex, the GPUs powering them generate more heat than ever before, pushing traditional cooling solutions to their limits. This comprehensive article explores the cutting-edge innovations in GPU cooling technology that are enabling the future of AI and high-performance computing.

Table of Contents

- The Thermal Challenge of Modern AI GPUs

- Evolution of GPU Cooling Technologies

- Advanced Air Cooling Innovations

- Direct Liquid Cooling Solutions

- Immersion Cooling for Extreme Performance

- Emerging Cooling Technologies

- Selecting the Right Cooling Solution

- Frequently Asked Questions

The Thermal Challenge of Modern AI GPUs

The thermal output of modern AI GPUs has reached unprecedented levels, creating cooling challenges that were virtually nonexistent just a few years ago.

Problem: Today’s AI-focused GPUs generate thermal loads that far exceed what traditional cooling solutions were designed to handle.

Modern AI accelerators like NVIDIA’s H100 or AMD’s MI300 can generate thermal loads exceeding 700 watts per device—more than triple what gaming GPUs produced just a few years ago. This extreme heat concentration creates cooling challenges that traditional solutions struggle to address effectively.

Aggravation: The trend toward higher GPU power consumption shows no signs of abating, with next-generation AI accelerators potentially exceeding 1000W per device.

Further complicating matters, AI workloads typically maintain these devices at near 100% utilization for extended periods—sometimes weeks or months—creating sustained thermal loads fundamentally different from gaming or general computing workloads with their variable utilization patterns.

Solution: Understanding the specific thermal challenges of modern AI GPUs enables more effective cooling solution selection and implementation:

The GPU Power Consumption Trajectory

Tracking the rapid increase in GPU thermal output:

- Historical GPU TDP Progression:

- Early CUDA GPUs (2010-2015): 150-250W TDP

- Early AI-focused GPUs (2016-2018): 250-300W TDP

- Middle AI GPU Era (2019-2021): 300-400W TDP

- Current AI GPU Era (2022-2024): 350-700W TDP

- Projected Next-Gen (2025+): 600-1000W+ TDP

- Factors Driving Increased Power Consumption:

- Larger die sizes and transistor counts

- Higher clock speeds and voltage requirements

- Increased memory bandwidth and capacity

- More specialized compute units

- Performance prioritization over efficiency

- AI Workload Thermal Characteristics:

- Sustained maximum utilization

- Extended run times (days to weeks)

- Minimal idle or low-power periods

- Consistent rather than variable thermal output

- Limited opportunity for thermal recovery

Here’s what makes this fascinating: The thermal output of AI GPUs has grown at approximately 2.5x the rate predicted by Moore’s Law. While traditional computing hardware typically sees 15-20% power increases per generation, AI accelerators have experienced 50-100% TDP increases across recent generations. This accelerated thermal evolution reflects a fundamental shift in design philosophy, where performance is prioritized even at the cost of significantly higher power consumption and thermal output.

Heat Density and Distribution Challenges

Understanding the unique thermal profile of modern GPUs:

- Die-Level Heat Density:

- Modern AI GPUs: 0.5-1.0 W/mm²

- High-end CPUs: 0.2-0.3 W/mm²

- Consumer GPUs: 0.3-0.5 W/mm²

- Hotspot formation and management

- Thermal gradient challenges

- Package-Level Thermal Considerations:

- Multi-chip module complexity

- High-bandwidth memory (HBM) integration

- Interposer and substrate thermal properties

- Power delivery component heat

- Thermal interface material limitations

- System-Level Thermal Interactions:

- Multi-GPU configurations

- Dense server packaging

- Airflow restrictions

- Component proximity effects

- Chassis thermal limitations

But here’s an interesting phenomenon: The thermal profile of AI GPUs represents a fundamental inversion of traditional computing heat patterns. In traditional systems, CPUs typically generate 60-70% of the total heat, with GPUs as secondary contributors. In modern AI systems, GPUs often account for 70-80% of the total thermal output, with CPUs reduced to a secondary heat source despite their own substantial thermal output. This inversion requires a complete rethinking of system thermal design, with cooling resources allocated proportionally to this new heat distribution.

Performance and Reliability Implications

The critical relationship between cooling and GPU effectiveness:

- Thermal Throttling Effects:

- Clock speed reduction under thermal stress

- Performance degradation of 10-30% during throttling

- Training time extension and cost implications

- Inconsistent inference performance

- Reduced return on hardware investment

- Hardware Reliability Considerations:

- Each 10°C increase approximately doubles failure rates

- Thermal cycling creates mechanical stress

- Memory errors increase at elevated temperatures

- Power delivery components vulnerable to thermal stress

- Economic impact of hardware failures and replacements

- Operational Stability Requirements:

- AI workloads require consistent performance

- Reproducibility challenges with variable thermal conditions

- Production deployment stability expectations

- 24/7 operation for many AI systems

- Business continuity considerations

| Impact of Cooling Quality on GPU Performance and Reliability |

| Cooling Quality | GPU Temperature Range | Performance Impact | Reliability Impact | Operational Impact |

|---|---|---|---|---|

| Inadequate | 85-95°C+ | Severe throttling, 30-50% performance loss | 2-3x higher failure rate | Unstable, frequent interruptions |

| Borderline | 75-85°C | Intermittent throttling, 10-30% performance loss | 1.5-2x higher failure rate | Periodic issues, inconsistent performance |

| Adequate | 65-75°C | Minimal throttling, 0-10% performance impact | Baseline failure rate | Generally stable with occasional issues |

| Optimal | 45-65°C | Full performance, potential for overclocking | 0.5-0.7x failure rate | Consistent, reliable operation |

| Premium | <45°C | Maximum performance, sustained boost clocks | 0.3-0.5x failure rate | Exceptional stability and longevity |

Ready for the fascinating part? Research indicates that inadequate cooling can reduce the effective computational capacity of AI infrastructure by 15-40%, essentially negating much of the performance advantage of premium GPU hardware. This “thermal tax” means that organizations may be realizing only 60-85% of their theoretical computing capacity due to cooling limitations, fundamentally changing the economics of AI infrastructure. When combined with the reliability impact, the total cost of inadequate cooling can exceed the price premium of advanced cooling solutions within the first year of operation for high-utilization AI systems.

Evolution of GPU Cooling Technologies

GPU cooling technology has undergone rapid evolution to address the escalating thermal challenges of AI and high-performance computing.

Problem: Traditional GPU cooling approaches were designed for consumer graphics cards with substantially different thermal characteristics than modern AI accelerators.

Conventional GPU cooling was optimized for processors with moderate heat density and variable workloads, while AI accelerators concentrate extreme thermal output with sustained high utilization.

Aggravation: The physical form factors and mounting requirements of data center GPUs differ significantly from consumer cards, complicating cooling design and implementation.

Further complicating matters, data center GPUs feature varying die sizes, component layouts, and mounting patterns across different models and generations, requiring cooling solutions that can adapt to these differences while maintaining optimal performance.

Solution: A new generation of GPU cooling technologies specifically designed for AI accelerators addresses these unique thermal challenges:

Traditional GPU Cooling Approaches

Understanding the foundation of GPU cooling evolution:

- Consumer GPU Cooling Evolution:

- Early passive heatsinks (pre-2000)

- Single fan active cooling (2000-2010)

- Dual and triple fan designs (2010-present)

- Heat pipe implementation (2005-present)

- AIO liquid cooling integration (2015-present)

- Early Data Center GPU Cooling:

- Passive server-grade heatsinks

- High static pressure server fans

- Blower-style coolers for density

- Basic thermal management

- Limited thermal monitoring

- Limitations for AI Workloads:

- Insufficient thermal capacity

- Inadequate for sustained high utilization

- Density and airflow restrictions

- Noise and energy efficiency issues

- Reliability concerns under extreme loads

Here’s what makes this fascinating: The thermal conductivity requirements for AI accelerator cooling exceed those of traditional GPU cooling by 2-3x due to the extreme heat density. While a gaming GPU might generate 0.3-0.5 W/mm², modern AI GPUs can produce 0.5-1.0 W/mm², requiring fundamentally different approaches to heat capture and dissipation. This heat density differential has driven a complete rethinking of GPU cooling design, with solutions that would have been considered excessive for gaming becoming baseline requirements for AI accelerators.

Cooling Technology Transition Points

Identifying when advanced cooling becomes necessary:

- Air Cooling Practical Limits:

- Single GPU: 350-400W practical maximum

- Multi-GPU servers: Challenging above 2-3 GPUs

- Density limitations: 4-6 GPUs per 1U-2U server

- Noise constraints: Significant at maximum capacity

- Energy efficiency: Diminishing returns above 300W

- Liquid Cooling Transition Indicators:

- GPU TDP exceeding 350-400W

- Density requirements above 4-6 GPUs per server

- Performance stability requirements

- Energy efficiency priorities

- Noise constraints in office environments

- Immersion Cooling Consideration Factors:

- Extreme density requirements (8+ GPUs per server)

- Power densities exceeding 50kW per rack

- Maximum performance requirements

- Ultimate energy efficiency priorities

- Specialized facility capabilities

But here’s an interesting phenomenon: The transition point from air to liquid cooling has shifted dramatically over time. In 2018, liquid cooling was typically considered necessary only for GPUs exceeding 300W. By 2020, this threshold had increased to 350W, and by 2022, some advanced air cooling solutions could handle up to 400W. However, this trend has reversed with the latest generation of AI accelerators, with liquid cooling now recommended for GPUs above 350W due to the sustained nature of AI workloads. This “thermal threshold evolution” reflects both advances in air cooling technology and changes in workload characteristics that affect cooling requirements.

Cooling Technology Comparison

Evaluating the relative capabilities of different approaches:

- Performance Comparison:

- Air cooling: Baseline performance

- Direct liquid cooling: 20-40% better thermal performance

- Immersion cooling: 30-50% better thermal performance

- Hybrid approaches: 15-30% improvement over air cooling

- Emerging technologies: Potentially 40-60% improvement

- Density Enablement:

- Air cooling: 4-6 high-power GPUs per server

- Direct liquid cooling: 8-10 high-power GPUs per server

- Immersion cooling: 10+ high-power GPUs per server

- Rack density with air: 20-30kW practical maximum

- Rack density with advanced cooling: 50-100kW+ possible

- Economic Considerations:

- Air cooling: Lowest initial cost

- Direct liquid cooling: 2-3x higher initial cost

- Immersion cooling: 3-5x higher initial cost

- Operational savings with advanced cooling: 30-50%

- Performance benefits: 10-30% effective capacity increase

| GPU Cooling Technology Comparison |

| Technology | Cooling Capacity | Implementation Complexity | Initial Cost | Operational Cost | Best Application |

|---|---|---|---|---|---|

| Advanced Air Cooling | Up to 400W per GPU | Low | $ | $$$ | Entry-level AI, limited density |

| Direct Liquid Cooling | 400-1000W+ per GPU | Moderate-High | $$$ | $ | High-performance AI, production |

| Immersion Cooling | Virtually unlimited | Very High | $$$$$ | $ | Extreme density, maximum performance |

| Hybrid Air/Liquid | 400-600W per GPU | Moderate | $$ | $$ | Transitional deployments, mixed workloads |

| Two-Phase Cooling | 600-1200W+ per GPU | High | $$$$ | $ | Next-gen accelerators, research |

Ready for the fascinating part? The cooling technology landscape for AI GPUs is evolving at an unprecedented pace, with innovation cycles compressed from the historical 5-7 years to just 2-3 years. This accelerated evolution is being driven by the economic value of AI computation, which creates unprecedented incentives for solving thermal limitations that constrain performance. Organizations at the cutting edge are now implementing cooling technology roadmaps that plan for multiple technology transitions within a single hardware generation, fundamentally changing how cooling infrastructure is designed and deployed.

Advanced Air Cooling Innovations

Despite the limitations of air cooling for the highest-power AI GPUs, significant innovations continue to extend its practical capabilities.

Problem: Traditional air cooling approaches are insufficient for modern AI GPUs, but liquid cooling may be impractical in many environments.

Many organizations face facility constraints, operational limitations, or budget restrictions that make liquid cooling challenging to implement, creating demand for enhanced air cooling solutions that can bridge the gap.

Aggravation: The sustained high utilization of AI workloads creates thermal challenges beyond what traditional air cooling was designed to handle.

Further complicating matters, the density requirements of AI deployments often exceed what conventional air cooling can support, creating a need for solutions that enable higher density while remaining air-based.

Solution: Advanced air cooling innovations are extending the practical limits of air-based thermal management for AI GPUs:

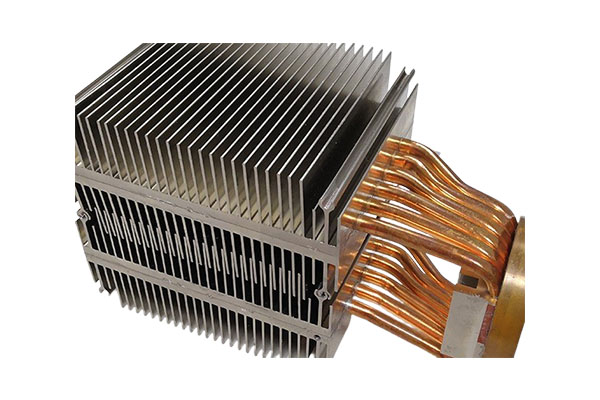

Material and Design Innovations

Pushing the boundaries of air cooling performance:

- Advanced Material Applications:

- Vapor chamber base plates (replacing solid copper)

- Graphene-enhanced heat pipes

- Synthetic diamond heat spreaders

- Carbon nanotube thermal interfaces

- Phase change thermal materials

- Heatsink Design Optimization:

- Computational fluid dynamics optimization

- Variable fin density arrangements

- Turbulence-inducing geometries

- Surface area maximization techniques

- Weight and space optimization

- Manufacturing Technique Advancements:

- Additive manufacturing for complex geometries

- Skived fin production for increased density

- Vapor chamber integration techniques

- Bonding method improvements

- Precision machining advancements

Here’s what makes this fascinating: The thermal conductivity of advanced cooling materials has improved dramatically in recent years. While traditional copper heat pipes offer thermal conductivity around 3,000-4,000 W/m·K, new graphene-enhanced heat pipes can achieve 6,000-8,000 W/m·K—a 2x improvement that directly translates to better cooling performance. Similarly, synthetic diamond heat spreaders offer 5-10x better thermal conductivity than copper, though at significantly higher cost. These material advances are enabling air cooling to handle thermal loads that would have required liquid cooling just a few years ago.

Airflow Optimization Techniques

Maximizing the cooling potential of air:

- Fan Technology Advancements:

- High static pressure fan designs

- Fluid dynamic bearing implementations

- Variable speed control algorithms

- Noise optimization techniques

- Efficiency and reliability improvements

- Airflow Path Engineering:

- Ducted and channeled designs

- Impedance matching with system fans

- Turbulence management features

- Pressure drop optimization

- Recirculation prevention

- System-Level Airflow Integration:

- Server chassis airflow optimization

- Rack-level air management

- Containment system implementation

- Pressure management techniques

- Temperature-based dynamic control

But here’s an interesting phenomenon: The relationship between airflow and cooling performance follows a non-linear curve with diminishing returns. Doubling airflow typically improves cooling by only 30-40% due to the physics of convective heat transfer. This non-linearity creates practical limits for air cooling that cannot be overcome simply by adding more or larger fans. Instead, the most effective advanced air cooling solutions focus on optimizing the entire thermal path from die to ambient air, with innovations at each stage of heat transfer working together to maximize overall performance.

Hybrid and Assisted Air Cooling

Bridging the gap between traditional air and liquid cooling:

- Heat Pipe Advancements:

- Ultra-thin heat pipe designs

- Sintered powder wick implementations

- Variable conductance capabilities

- Multi-pipe arrays (8-12 pipes typical)

- Custom shapes and configurations

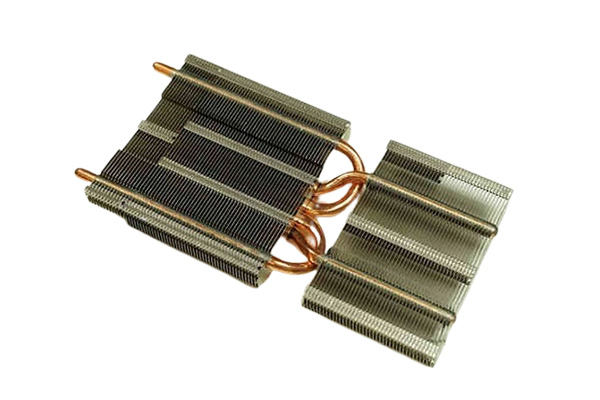

- Vapor Chamber Technology:

- Large surface area implementations

- Custom geometries for GPU dies

- Multi-level vapor chamber designs

- Integration with traditional heat pipes

- Manufacturing technique improvements

- Assisted Air Cooling Approaches:

- Thermoelectric cooling assistance

- Phase change material integration

- Heat pipe to remote radiator designs

- Refrigerant-assisted systems

- Synthetic jet augmentation

| Advanced Air Cooling Technologies for AI GPUs |

| Technology | Cooling Capacity | Key Advantages | Limitations | Cost Premium | Best Applications |

|---|---|---|---|---|---|

| Vapor Chamber | Up to 400W | Excellent heat spreading, low profile | Limited distance heat transfer | 30-50% | High-density servers, limited space |

| Advanced Heat Pipes | Up to 350W | Flexible implementation, proven reliability | Point-to-point transfer limitations | 10-30% | General purpose, cost-sensitive |

| Graphene-Enhanced | Up to 450W | Superior thermal conductivity | Manufacturing complexity, cost | 50-100% | Premium solutions, thermal constraints |

| Synthetic Diamond | Up to 500W | Ultimate thermal conductivity | Extremely high cost | 200-300%+ | Research, specialized applications |

| Thermoelectric Assisted | Up to 450W | Active cooling capability | Power consumption, complexity | 100-150% | Hotspot management, premium solutions |

Case Studies and Real-World Performance

Examining practical implementations of advanced air cooling:

- High-Density Server Implementations:

- 4U server with 8x 350W GPUs

- Vapor chamber and heat pipe combination

- Custom ducting and airflow management

- Temperature results and performance impact

- Density and efficiency achievements

- Workstation-Class Solutions:

- Dual 400W GPU configurations

- Advanced material implementations

- Noise-optimized designs

- Thermal performance under sustained load

- Cost-effectiveness analysis

- Edge AI Deployments:

- Space-constrained implementations

- Passive and semi-passive designs

- Environmental challenge adaptations

- Reliability in variable conditions

- Total cost of ownership considerations

Ready for the fascinating part? The most advanced air cooling solutions are now implementing “intelligent cooling” features that dynamically adapt to changing thermal conditions. These systems use embedded sensors, variable fan curves, and even adjustable heat pipe characteristics to optimize cooling based on real-time workload and environmental factors. Some cutting-edge designs can shift their cooling capacity between multiple GPUs based on utilization, effectively “load balancing” thermal management resources. This adaptive approach can improve cooling efficiency by 15-25% compared to static designs, representing a fundamental shift from passive to active thermal management at the component level.

Direct Liquid Cooling Solutions

As AI GPU thermal output continues to increase, direct liquid cooling has become essential for high-performance deployments.

Problem: The thermal output of modern AI GPUs exceeds the practical capabilities of even advanced air cooling, necessitating more effective heat transfer methods.

With thermal densities exceeding 0.5-1.0 W/mm² and total package power reaching 400-700+ watts, modern AI GPUs generate heat beyond what air cooling can effectively dissipate, particularly in dense deployments.

Aggravation: The trend toward higher GPU power consumption shows no signs of abating, with next-generation AI accelerators potentially exceeding 1000W.

Further complicating matters, the computational demands driving GPU power increases continue to grow exponentially with larger AI models, creating a thermal trajectory that will further challenge cooling technologies in coming generations.

Solution: Direct liquid cooling offers significantly higher thermal transfer efficiency, enabling effective cooling of even the highest-power AI GPUs:

Direct-to-Chip Liquid Cooling

Understanding the fundamentals of GPU liquid cooling:

- Operating Principles:

- Direct contact between cold plates and GPU dies

- Liquid circulation through cooling plates

- Heat transfer to facility cooling systems

- Closed-loop vs. facility water implementations

- Temperature, flow, and pressure management

- Cold Plate Design Optimization:

- Microchannel cold plate technology

- Jet impingement implementations

- Pin fin and micro pin fin designs

- Flow distribution optimization

- Contact surface enhancement

- GPU-Specific Design Considerations:

- Die-specific cold plate geometries

- Multi-level contact for die and memory

- Pressure distribution optimization

- Surface flatness and finish requirements

- Thermal interface material selection

Here’s what makes this fascinating: The thermal transfer efficiency of liquid cooling creates a non-linear advantage over air cooling as TDP increases. For 250W GPUs, liquid cooling might offer a 30-40% efficiency advantage. For 500W GPUs, this advantage typically grows to 60-80%, and for 700W+ devices, liquid cooling can be 3-5x more efficient than even the most advanced air cooling. This expanding advantage creates an economic inflection point where the additional cost of liquid cooling is increasingly justified by performance and efficiency benefits as TDP increases.

Liquid Distribution and Management

Implementing effective fluid systems for GPU cooling:

- Distribution Architecture Options:

- Direct facility water connection

- Coolant distribution unit (CDU) implementation

- In-rack distribution systems

- Server-level pumping options

- Hybrid distribution approaches

- Fluid Selection Considerations:

- Water-based solutions

- Water-glycol mixtures

- Dielectric fluids

- Engineered coolants

- Environmental and safety factors

- Flow and Pressure Management:

- Pump selection and redundancy

- Flow balancing techniques

- Pressure regulation approaches

- Temperature control methods

- Monitoring and management systems

But here’s an interesting phenomenon: The reliability of liquid cooling systems follows a distinct bathtub curve that differs from traditional perceptions. While conventional wisdom suggests liquid cooling introduces reliability risks, data from mature implementations shows that after an initial break-in period with higher incident rates, properly designed liquid cooling systems actually experience 30-50% fewer thermal-related failures than air-cooled systems. This reliability crossover typically occurs 6-12 months after implementation, creating a long-term reliability advantage that compounds the performance and efficiency benefits.

Implementation Approaches

Strategies for deploying liquid cooling for GPUs:

- GPU-Focused Liquid Cooling:

- Liquid cooling only for GPUs

- Air cooling for other components

- Simplified implementation

- Targeted cooling resource allocation

- Transitional approach for gradual adoption

- Comprehensive Liquid Cooling:

- Liquid cooling for all major components

- CPU, GPU, memory, and power delivery

- Maximum efficiency and density

- Reduced airflow requirements

- Complete thermal solution

- Manifold and Connection Systems:

- Quick-connect implementation

- Drip-free connection technology

- Manifold design optimization

- Serviceability considerations

- Leak prevention features

| Direct Liquid Cooling Approaches for AI GPUs |

| Approach | Cooling Capacity | Implementation Complexity | Cost Range | Best For | Limitations |

|---|---|---|---|---|---|

| GPU-Only Cooling | 400-800W per GPU | Moderate | $$ | Mixed workloads, transitional | Limited density, partial benefits |

| Comprehensive Cooling | 400-1000W+ per GPU | High | $$$ | High-performance AI, production | Facility requirements, complexity |

| Facility Direct | 600-1000W+ per GPU | Very High | $$ | Large-scale deployments | Facility integration, water quality |

| CDU-Based | 600-1000W+ per GPU | Moderate-High | $$$ | Flexible deployments, retrofits | Additional equipment, efficiency |

| In-Rack Distribution | 600-1000W+ per GPU | Moderate | $$$ | Modular deployments | Rack-level commitment |

Performance and Efficiency Benefits

Quantifying the advantages of liquid cooling for GPUs:

- Thermal Performance Improvements:

- Temperature reduction (20-40°C vs. air cooling)

- Thermal stability enhancement

- Performance consistency improvements

- Throttling elimination

- Overclocking potential

- Energy Efficiency Advantages:

- Pump vs. fan energy comparison

- Higher temperature cooling water potential

- Free cooling opportunity expansion

- Heat reuse possibilities

- Total facility efficiency impact

- Density and Scaling Benefits:

- GPU density improvements (2-3x air cooling)

- Rack density enablement (50-100kW+)

- Facility capacity maximization

- Space utilization optimization

- Growth accommodation

Ready for the fascinating part? The most advanced liquid cooling implementations are achieving remarkable efficiency improvements through high-temperature operation. While traditional data centers typically maintain cold water supply at 10-15°C, advanced liquid cooling systems can operate effectively with supply temperatures of 30-45°C. This temperature increase enables “free cooling” (using ambient air instead of chillers) in most climates year-round, potentially reducing cooling energy consumption by 60-90%. Some implementations are even providing waste heat at temperatures suitable for building heating or domestic hot water, transforming cooling from a pure cost center to a potential value generator.

Immersion Cooling for Extreme Performance

For the most demanding AI GPU deployments, immersion cooling offers unmatched thermal performance and density capabilities.

Problem: Even direct liquid cooling may be insufficient for the most extreme AI GPU deployments, particularly as power consumption continues to increase.

The highest-density AI clusters with multiple high-power GPUs per server create thermal loads that challenge even advanced direct liquid cooling, particularly when maximum performance and density are required.

Aggravation: The physical constraints of direct liquid cooling, including the need for cold plates and manifolds, create practical limitations for extreme density deployments.

Further complicating matters, the trend toward heterogeneous computing with multiple accelerator types creates complex cooling requirements that may be difficult to address with cold plate-based approaches.

Solution: Immersion cooling offers virtually unlimited thermal capacity by submerging entire systems in dielectric fluid:

Single-Phase Immersion Technology

Understanding the fundamentals of single-phase immersion:

- Operating Principles:

- Complete immersion in non-conductive fluid

- Convection-based heat transfer

- Pump-driven circulation

- Heat exchanger integration

- Facility cooling connection

- Fluid Characteristics and Selection:

- Dielectric properties and requirements

- Thermal capacity and conductivity

- Viscosity and flow characteristics

- Environmental and safety considerations

- Longevity and maintenance factors

- System Design Considerations:

- Tank and containment design

- Fluid circulation optimization

- Heat exchanger selection

- Monitoring and management systems

- Serviceability and maintenance access

Here’s what makes this fascinating: The thermal uniformity achieved with immersion cooling creates significant performance advantages beyond raw cooling capacity. While air cooling typically results in temperature variations of 15-25°C across different GPUs in a system, immersion cooling reduces this variation to just 3-5°C. This thermal consistency enables more predictable performance, reduces throttling events, and allows all GPUs to operate at their maximum potential simultaneously. For large multi-GPU training workloads, this thermal uniformity can improve overall training performance by 5-15% compared to other cooling approaches, even when maximum temperatures are similar.

Two-Phase Immersion Technology

Exploring the ultimate in cooling efficiency:

- Operating Principles:

- Fluid boiling at component surfaces

- Phase-change heat transfer (highly efficient)

- Passive circulation through convection

- Condensation and return

- Extreme cooling capacity

- Fluid Selection Considerations:

- Boiling point optimization

- Latent heat of vaporization

- Environmental impact

- Safety and handling requirements

- Cost and availability factors

- System Design Requirements:

- Condensation surface design

- Vapor containment considerations

- Fluid level management

- Pressure control (if applicable)

- Heat rejection integration

But here’s an interesting phenomenon: The efficiency advantage of two-phase immersion over single-phase immersion varies significantly with deployment density. For moderate-density deployments (15-25kW per rack equivalent), the efficiency difference might be only 10-15%. For extreme density deployments (50+ kW per rack equivalent), the advantage can grow to 30-50%. This variable efficiency delta creates deployment scenarios where single-phase immersion is more economical for moderate deployments while two-phase becomes increasingly advantageous for the highest densities.

Implementation and Deployment Considerations

Practical aspects of immersion cooling deployment:

- Hardware Preparation Requirements:

- Component compatibility verification

- Conformal coating considerations

- Fan removal and modification

- Connector and cabling adaptations

- Testing and validation procedures

- Facility Integration Approaches:

- Space and floor loading requirements

- Fluid handling and storage systems

- Heat rejection integration

- Electrical and safety considerations

- Operational workflow adaptation

- Operational Considerations:

- Immersion-specific maintenance procedures

- Component access and serviceability

- Fluid monitoring and maintenance

- Staff training requirements

- Emergency response planning

| Immersion Cooling Comparison for AI GPUs |

| Characteristic | Single-Phase Immersion | Two-Phase Immersion | Direct Liquid Cooling | Advanced Air Cooling |

|---|---|---|---|---|

| Cooling Capacity | Virtually unlimited | Virtually unlimited | 400-1000W per GPU | Up to 400W per GPU |

| Energy Efficiency | Very High | Extremely High | High | Moderate |

| Density Capability | Very High (50-80kW/rack) | Extreme (80-100kW+/rack) | High (30-50kW/rack) | Moderate (15-25kW/rack) |

| Implementation Complexity | High | Very High | Moderate-High | Low |

| Hardware Compatibility | Requires preparation | Requires preparation | Requires cold plates | Widely compatible |

| Operational Complexity | Moderate-High | High | Moderate | Low |

| Initial Cost | $$$$ | $$$$$ | $$$ | $ |

| Operational Cost | $ | $ | $$ | $$$ |

Performance and Economic Benefits

Quantifying the advantages of immersion cooling:

- Thermal Performance Advantages:

- Temperature reduction and stability

- Elimination of hotspots and gradients

- Performance consistency improvements

- Overclocking potential

- Hardware lifespan extension

- Density and Scaling Benefits:

- Extreme GPU density enablement

- Rack density capabilities (80-150kW+)

- Facility capacity maximization

- Space utilization optimization

- Growth accommodation without constraints

- Total Cost of Ownership Considerations:

- Initial capital investment

- Operational cost savings

- Performance and productivity benefits

- Infrastructure requirement reduction

- Hardware lifespan extension value

Ready for the fascinating part? The most advanced immersion cooling implementations are achieving remarkable density improvements that fundamentally change data center economics. While traditional air-cooled data centers might support 5-10kW per rack and require 8-10 square feet per kW of IT load, immersion-cooled facilities can support 50-100kW per rack and require just 1-2 square feet per kW. This 5-8x improvement in spatial efficiency can reduce data center construction costs by 40-60% per unit of computing capacity, creating compelling economics despite the higher cost of the cooling technology itself. For organizations in space-constrained environments or high-cost real estate markets, this density advantage can be the primary driver for immersion cooling adoption, even before considering the performance and efficiency benefits.

Emerging Cooling Technologies

The landscape of GPU cooling continues to evolve rapidly, with several emerging technologies poised to reshape thermal management approaches.

Problem: Current cooling technologies may struggle to address the thermal challenges of next-generation AI accelerators and deployment models.

As GPU power consumption potentially exceeds 1000W per device and deployment densities continue to increase, even current advanced cooling technologies will face significant challenges.

Aggravation: The pace of innovation in AI hardware is outstripping the evolution of cooling technologies, creating a growing gap between thermal requirements and cooling capabilities.

Further complicating matters, the rapid advancement of AI capabilities is driving accelerated hardware development cycles, creating a situation where cooling technology must evolve more quickly to keep pace with thermal management needs.

Solution: Understanding emerging cooling technologies enables more future-proof infrastructure planning and technology selection:

Two-Phase Direct Cooling

Bringing phase-change efficiency to direct cooling:

- Operating Principles:

- Direct-to-chip two-phase cooling

- Flow boiling in microchannels

- Refrigerant-based systems

- Enhanced phase change materials

- Compact two-phase solutions

- Implementation Approaches:

- Sealed refrigerant loops

- Engineered fluid systems

- Hybrid air/two-phase solutions

- Server-level integration

- Rack-level distribution

- Performance Capabilities:

- Extreme cooling capacity (800-1200W+ per GPU)

- Superior temperature uniformity

- Reduced pumping requirements

- Potential for facility integration

- Efficiency advantages over single-phase

Here’s what makes this fascinating: Two-phase direct cooling combines the installation simplicity of traditional liquid cooling with the thermal efficiency of phase-change cooling. By using refrigerants or engineered fluids that change phase within the cold plate itself, these systems can achieve 1.5-2x the cooling capacity of single-phase solutions with the same or lower pumping power. This efficiency advantage stems from the physics of phase change, where the latent heat of vaporization provides significantly more cooling capacity than sensible heat transfer alone. The result is a technology that potentially offers the best balance of performance, efficiency, and implementation practicality for next-generation AI accelerators.

Microfluidic and Embedded Cooling

Integrating cooling directly into GPU packages:

- On-Package Fluid Channels:

- Microfluidic cooling integrated into GPU packages

- 3D-printed cooling structures

- Direct die cooling without interfaces

- Targeted hotspot management

- Reduced thermal resistance

- Implementation Approaches:

- Manufacturer-integrated solutions

- Aftermarket adaptation techniques

- Hybrid package/external systems

- Modular connection interfaces

- Serviceability considerations

- Performance Potential:

- Superior thermal performance (potentially 2-3x traditional)

- Dramatic size reduction

- Reduced fluid volume requirements

- Improved reliability through integration

- Next-generation density enablement

But here’s an interesting phenomenon: The integration of cooling directly into semiconductor packages is creating a fundamental shift in the relationship between chip manufacturers and cooling technology. Historically, cooling was entirely separate from chip design and manufacturing. Now, leading semiconductor companies are acquiring cooling technology firms and integrating thermal engineers directly into chip design teams. This convergence is creating a new paradigm where cooling is considered from the earliest stages of chip design rather than as an afterthought, potentially enabling dramatic improvements in both performance and efficiency.

Solid-State Cooling Technologies

Exploring non-fluid approaches to GPU cooling:

- Thermoelectric Cooling Applications:

- Peltier effect utilization

- Targeted hotspot management

- Hybrid thermoelectric/liquid systems

- Efficiency optimization approaches

- Control system integration

- Advanced Material Applications:

- Graphene and carbon nanotube heat spreaders

- Synthetic diamond thermal solutions

- Metal matrix composites

- Anisotropic thermal conductors

- Nano-engineered thermal interfaces

- Emerging Solid-State Approaches:

- Magnetocaloric cooling research

- Electrocaloric material development

- Solid-state heat pumps

- Phononic crystal implementations

- Quantum effects in thermal management

| Emerging GPU Cooling Technologies |

| Technology | Current Status | Potential Impact | Commercialization Timeline | Key Advantages | Primary Challenges |

|---|---|---|---|---|---|

| Two-Phase Direct | Early commercial | Very High | 1-2 years | Efficiency, capacity | Complexity, cost |

| Microfluidic | Advanced R&D | Transformative | 2-4 years | Integration, performance | Manufacturing, reliability |

| Embedded Package Cooling | Early R&D | Revolutionary | 3-5 years | Direct die cooling | Industry adoption, standards |

| Advanced Thermoelectric | Limited commercial | Moderate | 1-3 years | Hotspot management | Efficiency, power consumption |

| Graphene-Based | Early commercial | High | 1-2 years | Conductivity, weight | Cost, manufacturing |

| Synthetic Diamond | Limited commercial | Very High | 2-4 years | Ultimate conductivity | Extreme cost, integration |

Integration and Architectural Trends

Evolving relationships between GPUs and cooling systems:

- Co-Designed Computing and Cooling:

- Cooling requirements influencing GPU design

- Purpose-built cooling for specific accelerators

- Standardized cooling interfaces

- Cooling-aware chip packaging

- Unified thermal-computational optimization

- Disaggregated and Composable Systems:

- Cooling implications of disaggregated architecture

- Liquid cooling for interconnect infrastructure

- Dynamic resource composition considerations

- Cooling for memory-centric architectures

- Heterogeneous system cooling requirements

- Specialized AI Hardware Cooling:

- Neuromorphic computing thermal characteristics

- Photonic computing cooling requirements

- Quantum computing thermal management

- Analog AI accelerator cooling

- In-memory computing thermal considerations

Ready for the fascinating part? The cooling technology innovation cycle is accelerating dramatically. Historically, major cooling technology transitions (air to liquid, liquid to immersion) occurred over 7-10 year periods. Current development trajectories suggest the next major transition (potentially to integrated microfluidic or advanced two-phase technologies) may occur within 3-5 years. This compressed innovation cycle is being driven by the economic value of AI computation, which creates unprecedented incentives for solving thermal limitations that constrain AI performance. Organizations at the cutting edge are now implementing cooling technology roadmaps that plan for multiple technology transitions within a single hardware generation, fundamentally changing how cooling infrastructure is designed and deployed.

Selecting the Right Cooling Solution

Choosing the optimal cooling approach for AI GPUs requires careful consideration of multiple factors beyond raw thermal performance.

Problem: The proliferation of cooling technologies creates complex decision-making challenges for organizations deploying AI infrastructure.

With multiple viable cooling options available, each with different performance characteristics, implementation requirements, and economic implications, organizations struggle to determine the optimal approach for their specific needs.

Aggravation: The rapid evolution of both AI hardware and cooling technology creates a moving target for decision-making.

Further complicating matters, many organizations lack experience with advanced cooling technologies, creating knowledge gaps that make comparative evaluation difficult.

Solution: A structured decision framework enables more effective cooling technology selection based on specific requirements and constraints:

Requirements Analysis

Establishing the foundation for technology selection:

- Thermal Performance Requirements:

- GPU types and thermal output

- Quantity and density of deployment

- Utilization patterns and duration

- Performance stability needs

- Growth and scaling projections

- Facility and Infrastructure Constraints:

- Existing cooling infrastructure

- Space and floor loading limitations

- Power availability and constraints

- Water availability and quality

- Environmental conditions

- Operational Considerations:

- In-house expertise and capabilities

- Maintenance and support resources

- Reliability and availability requirements

- Noise and environmental constraints

- Serviceability and access needs

Here’s what makes this fascinating: The most successful cooling technology selections typically spend 2-3x longer in the requirements analysis phase compared to average implementations. This extended planning process might seem excessive, but research shows it reduces implementation problems by 50-70% and typically results in 10-20% better performance outcomes. This “planning multiplier effect” creates a compelling ROI for thorough assessment and planning despite the additional upfront time investment.

Technology Selection Framework

Developing a structured approach to cooling decisions:

- Decision Criteria Development:

- Performance requirements weighting

- Implementation feasibility assessment

- Economic factor evaluation

- Operational impact consideration

- Future-proofing importance

- Comparative Analysis Methodology:

- Technology capability mapping

- Constraint alignment evaluation

- Total cost of ownership calculation

- Risk assessment and mitigation

- Benefit quantification and comparison

- Selection Process Implementation:

- Stakeholder input gathering

- Decision matrix development

- Scenario-based evaluation

- Sensitivity analysis

- Final recommendation development

But here’s an interesting phenomenon: The optimal cooling technology varies significantly based on scale and growth trajectory. Organizations with smaller, stable AI deployments often benefit most from standardizing on a single advanced cooling approach, while larger or rapidly growing deployments typically achieve better outcomes with a tiered strategy using different technologies for different density requirements. This “scale-dependent optimization” means that cooling strategies should vary based not just on current requirements but on anticipated growth patterns.

Implementation Planning

Creating a practical path from selection to execution:

- Pilot and Proof of Concept Definition:

- Test environment specification

- Success criteria development

- Measurement methodology

- Evaluation timeline

- Scaling consideration analysis

- Deployment Strategy Development:

- Phased implementation planning

- Technology transition timing

- Operational readiness alignment

- Risk management and mitigation

- Success metrics and evaluation framework

- Operational Integration Planning:

- Procedure development requirements

- Training and knowledge transfer

- Monitoring and management integration

- Maintenance program development

- Continuous improvement framework

| Cooling Solution Selection Framework |

| Requirement Category | Air Cooling Best For | Direct Liquid Best For | Immersion Best For | Hybrid Best For |

|---|---|---|---|---|

| GPU Power | Up to 350W per GPU | 350-700W per GPU | 500W+ per GPU | 350-500W per GPU |

| Deployment Scale | Small (10-100 GPUs) | Medium-Large (100-1000+ GPUs) | Large (500+ GPUs) | Small-Medium (50-500 GPUs) |

| Density Requirements | Low-Moderate | Moderate-High | Extreme | Moderate |

| Facility Constraints | Limited modifications acceptable | Water distribution required | Significant modifications acceptable | Minimal modifications preferred |

| Operational Expertise | Limited cooling expertise | Moderate technical capabilities | Advanced technical team | Basic technical capabilities |

| Economic Priority | Lowest initial cost | Balanced TCO | Performance and density | Gradual investment |

| Growth Trajectory | Stable, limited growth | Steady, predictable growth | Rapid, substantial growth | Uncertain, variable growth |

Case Studies and Decision Examples

Learning from real-world cooling selection processes:

- Research Lab Deployment:

- Requirements and constraints

- Technology evaluation process

- Selection rationale

- Implementation approach

- Outcomes and lessons learned

- Enterprise AI Infrastructure:

- Business requirements analysis

- Technology comparison methodology

- Economic evaluation approach

- Deployment strategy

- Performance and operational results

- Cloud Provider Implementation:

- Scale and density considerations

- Technology standardization approach

- Facility integration strategy

- Operational model development

- Efficiency and performance outcomes

Ready for the fascinating part? The most sophisticated organizations are implementing “cooling portfolio strategies” rather than standardizing on a single approach. By deploying different cooling technologies for different workloads and deployment scenarios, these organizations optimize both performance and economics across their AI infrastructure. Some have found that a carefully balanced portfolio approach can improve overall price-performance by 20-40% compared to homogeneous deployments, while simultaneously providing greater flexibility to adapt to evolving requirements. This portfolio approach represents a fundamental shift from viewing cooling as a standardized infrastructure component to treating it as a strategic resource that should be optimized for specific use cases.

Frequently Asked Questions

Q1: How do I determine which GPU cooling technology is most appropriate for my specific AI infrastructure requirements?

Selecting the optimal GPU cooling technology requires a systematic evaluation process: First, assess your thermal requirements—calculate the total heat load based on GPU type, quantity, and utilization patterns. For deployments using high-TDP GPUs (400W+) in dense configurations, advanced cooling is typically essential, while more moderate deployments maintain flexibility. Second, evaluate your facility constraints—existing cooling infrastructure, available space, floor loading capacity, and facility water availability may limit your options or require significant modifications for certain technologies. Third, consider your operational model—different cooling technologies require varying levels of expertise, maintenance, and management overhead that must align with your operational capabilities. Fourth, analyze your scaling trajectory—future expansion plans may justify investing in more advanced cooling initially to avoid disruptive upgrades later. Fifth, calculate comprehensive economics—beyond initial capital costs, include energy expenses, maintenance requirements, density benefits, and performance advantages in your analysis. The most effective approach often involves a formal decision matrix that weights these factors according to your specific priorities. Many organizations find that hybrid approaches offer an optimal balance for initial deployments, with targeted liquid cooling for GPUs combined with traditional cooling for other components. This approach delivers most of the performance benefits of advanced cooling with reduced implementation complexity, while providing a pathway to more comprehensive solutions as density increases.

Q2: What are the most common implementation challenges with liquid cooling for GPUs, and how can they be mitigated?

The most common implementation challenges with liquid cooling for GPUs, and their mitigation strategies: First, facility integration issues—many existing facilities lack appropriate water infrastructure, requiring significant modifications. This can be mitigated through careful planning, phased implementation, and potentially using CDUs with closed-loop systems that minimize facility impact. Second, operational expertise gaps—many IT teams lack experience with liquid cooling technologies. Address this through comprehensive training programs, detailed documentation, and potentially managed services during the transition period. Third, hardware compatibility concerns—not all GPUs and servers are designed for liquid cooling. Mitigate by working closely with vendors to ensure compatibility, potentially standardizing on liquid-cooling-ready hardware platforms, and implementing thorough testing protocols. Fourth, leak risks and concerns—fear of liquid near electronics remains a significant adoption barrier. Address through high-quality components, proper installation validation, comprehensive leak detection, regular preventative maintenance, and appropriate insurance coverage. Fifth, implementation complexity—liquid cooling involves more components and interdependencies than air cooling. Manage this through detailed project planning, experienced implementation partners, thorough commissioning processes, and comprehensive documentation. Sixth, operational transition challenges—procedures developed for air-cooled environments may not translate directly. Develop new standard operating procedures, emergency response protocols, and maintenance schedules specifically for liquid-cooled infrastructure. Organizations that successfully navigate these challenges typically take a methodical, phased approach that includes pilot deployments, staff training, and gradual expansion, rather than attempting wholesale conversion. This measured strategy allows teams to develop expertise and confidence while minimizing risk to production environments.

Q3: How does the choice of cooling technology affect the overall performance and lifespan of AI GPUs?

The choice of cooling technology significantly impacts AI GPU performance and lifespan through several mechanisms: First, operating temperature directly affects performance—modern GPUs automatically reduce clock speeds (thermal throttling) when approaching temperature limits, potentially decreasing performance by 10-30% under heavy loads with inadequate cooling. Advanced cooling technologies that maintain lower operating temperatures can eliminate this performance penalty. Second, temperature stability matters as much as absolute temperature—thermal cycling creates mechanical stress through expansion and contraction, particularly affecting solder joints, interconnects, and packaging materials. Technologies that maintain more consistent temperatures (typically liquid and immersion) can reduce these stresses by 60-80% compared to air cooling with its more variable thermal profile. Third, temperature directly impacts hardware lifespan—research indicates that every 10°C increase approximately doubles semiconductor failure rates. Advanced cooling that reduces operating temperatures by 20-30°C can potentially extend useful life by 40-60%. Fourth, cooling technology affects overclocking potential—better cooling enables higher sustained clock speeds, potentially increasing performance by 5-15% beyond stock specifications. The economic implications are substantial—for high-value AI accelerators costing $10,000-40,000 each, extending lifespan from 3 years to 4-5 years through superior cooling can create $3,000-15,000 in value per GPU. Additionally, the performance benefits directly impact operational costs through faster training completion and higher inference throughput, creating compelling economic justification for advanced cooling investments despite higher initial costs.

Q4: What are the economic considerations when evaluating different GPU cooling technologies?

Economic evaluation of GPU cooling technologies must consider multiple factors beyond initial capital costs: First, implementation costs—while advanced cooling technologies (liquid, immersion) have higher equipment costs (2-5x air cooling), the total implementation cost differential is typically lower (1.5-3x) when considering all factors. Second, operational expenses—advanced cooling typically reduces energy costs by 30-60% compared to air cooling through higher efficiency, potentially saving $500-1,500 per GPU annually depending on energy costs and utilization. Third, performance economics—by eliminating thermal throttling, advanced cooling effectively increases computational capacity by 10-30%, improving hardware utilization and potentially reducing the number of GPUs required for a given workload. Fourth, density benefits—advanced cooling enables 2-5x higher density, reducing data center space requirements and associated costs by 50-80%. Fifth, hardware lifespan extension—better cooling can extend GPU useful life by 1-2 years, reducing replacement frequency and associated capital expenses by 20-40%. Sixth, scaling economics—the cost advantage of advanced cooling increases with scale, with larger deployments (500+ GPUs) typically achieving 20-40% lower total cost of ownership despite higher initial investment. The most sophisticated economic analyses use comprehensive TCO models that incorporate all these factors over a 3-5 year horizon, often revealing that solutions with higher initial costs deliver better long-term economics through efficiency, density, and performance benefits. For high-utilization AI workloads, particularly in regions with high energy or real estate costs, advanced cooling typically achieves ROI within 12-24 months despite the higher initial investment.

Q5: How should organizations plan for the cooling requirements of future GPU generations with potentially higher TDP?

Planning for future GPU cooling requirements requires a forward-looking strategy: First, implement modular and scalable cooling infrastructure—design systems with standardized interfaces and the ability to incrementally upgrade capacity without complete replacement. This approach provides flexibility to adapt as requirements evolve. Second, build in substantial headroom—when designing new infrastructure, plan for at least 1.5-2x current maximum TDP to accommodate future generations. For organizations on aggressive AI adoption paths, 2.5-3x headroom may be appropriate. Third, establish a technology roadmap with clear transition points—develop explicit plans for how cooling will evolve through multiple hardware generations, including trigger points for technology transitions based on density, performance, and efficiency requirements. Fourth, create cooling zones with varying capabilities—designate specific areas for highest-density deployment with premium cooling, allowing targeted infrastructure investment where most needed. Fifth, develop internal expertise proactively—build knowledge and capabilities around advanced cooling technologies before they become critical requirements. The most forward-thinking organizations are implementing “cooling as a service” approaches internally, where cooling is treated as a dynamic, upgradable resource rather than fixed infrastructure. This approach typically involves standardized interfaces between computing hardware and cooling systems, modular components that can be incrementally upgraded, and sophisticated management systems that optimize across multiple cooling technologies. This flexible, service-oriented approach to cooling infrastructure provides the greatest adaptability to the rapidly evolving AI hardware landscape, allowing organizations to incorporate new cooling technologies as they emerge without requiring complete system replacements.