Introduction

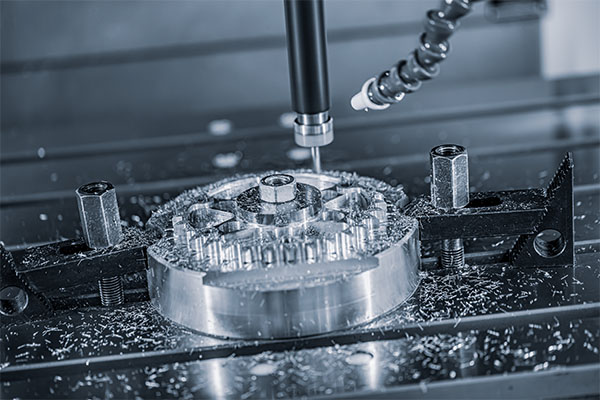

Aluminium CNC machining is an integral part of many industries, including aerospace, automotive, and electronics, due to its ability to produce high-precision parts. However, like any manufacturing process, it comes with its own set of challenges. This article will explore the most common challenges faced in aluminium CNC machining, their impact on operations, and provide practical solutions to overcome them. Whether you’re a manufacturer, operator, or decision-maker, understanding these challenges is key to improving efficiency, reducing costs, and producing high-quality parts.

1. What Are the Common Challenges in Aluminium CNC Machining?

Aluminium CNC machining is known for its versatility and precision, but it’s not without its difficulties. One of the first hurdles encountered is the machining of different aluminium alloys. Each alloy comes with its unique properties, and understanding these is essential for selecting the right machining processes. Not all aluminium alloys are the same, and machinists need to account for variables such as hardness, tensile strength, and corrosion resistance.

Another major challenge is the creation of parts with tight tolerances. While CNC machines are designed for high precision, maintaining accuracy at every stage of the machining process can be difficult. For instance, even slight deviations in the machine’s settings can lead to defective parts.

Then, there’s the issue of tool wear. Aluminium is a relatively soft material, but machining it at high speeds can cause significant wear on tools, especially if the correct cutting parameters are not set. This can lead to reduced tool life, increased downtime, and lower efficiency.

But here’s the kicker: a lack of proper cooling during machining can exacerbate these challenges. Overheating can cause thermal distortion of the material and affect both the final product’s quality and the performance of the CNC machine itself.

Table: Key Challenges in Aluminium CNC Machining

| Challenge | Impact | Solution |

|---|---|---|

| Material Properties | Varies by alloy; affects machining process | Understand alloy properties and adjust parameters accordingly |

| Tight Tolerances | Requires extreme precision | Regular machine calibration and careful programming |

| Tool Wear | Reduces tool life and machine efficiency | Use high-quality tools and monitor wear frequently |

| Cooling and Heat Management | Thermal distortion can ruin parts | Use effective cooling systems and optimize cutting speeds |

2. Why Is Tool Wear a Major Challenge in Aluminium CNC Machining?

Tool wear is one of the most persistent issues in aluminium CNC machining, and it can significantly impact both the quality of the workpiece and the efficiency of the machining process. When tools wear down, they become less effective, leading to poor surface finishes, deviations from required tolerances, and longer machining times.

The main cause of tool wear when machining aluminium is the high cutting speeds required to achieve optimal machining efficiency. At these speeds, the friction between the tool and the material can cause rapid degradation of the tool’s cutting edges.

Another factor that exacerbates tool wear is the lack of effective cooling. Without proper coolant, the temperature of the tool rises, accelerating the wear and tear process. In addition, the type of aluminium alloy being machined plays a role in how quickly tools wear. Softer alloys tend to cause less wear, while harder alloys require more frequent tool changes.

So, what’s the real story? The best way to combat tool wear is by optimizing the cutting parameters, selecting the right tools, and ensuring that cooling systems are operating at maximum efficiency. A combination of these factors can extend the life of your tools and help maintain the high precision of your machining operations.

Table: Causes and Solutions for Tool Wear

| Cause | Impact | Solution |

|---|---|---|

| High cutting speeds | Accelerates tool degradation | Reduce speeds, use high-quality tooling |

| Inadequate cooling | Leads to thermal expansion | Use coolants, optimize cutting parameters |

| Harder aluminium alloys | Increases wear rate | Select appropriate tools for alloy type |

3. How Does Material Properties Affect Aluminium CNC Machining?

Understanding the material properties of aluminium is crucial to ensuring efficient CNC machining. Aluminium alloys come in a wide range of grades, each with unique mechanical and chemical properties that influence the machining process. For example, 6061 aluminium is widely used for its excellent weldability and strength, while 7075 aluminium is known for its high strength but is more difficult to machine due to its hardness.

The properties of the aluminium alloy affect several aspects of the machining process, including cutting speed, feed rates, and the type of tooling used. Harder alloys, such as 7075, require slower cutting speeds and more frequent tool changes compared to softer alloys like 1100 or 3003. Additionally, the presence of impurities or elements such as magnesium and silicon can alter the machinability of the material, making it necessary to adjust parameters accordingly.

Ready for the good part? By understanding these material properties, machinists can optimize cutting parameters, tool selection, and coolant usage to achieve the best results. This ensures smoother operations, fewer tool changes, and higher-quality products.

Table: Comparison of Aluminium Alloys and Their Machinability

| Alloy Grade | Strength | Machinability | Common Applications |

|---|---|---|---|

| 6061 | Moderate | Easy to machine | Aerospace, automotive, marine |

| 7075 | High | Difficult to machine | Aircraft, military, high-stress parts |

| 1100 | Low | Very easy to machine | Cooking utensils, heat exchangers |

4. What Role Does Heat Management Play in Aluminium CNC Machining?

Heat management is one of the most critical factors in aluminium CNC machining. The high-speed cutting required to process aluminium generates significant heat. If this heat is not managed correctly, it can lead to thermal distortion of the material, resulting in parts that are out of tolerance and costly to scrap.

Moreover, heat affects the performance of the CNC machine itself. Overheating can cause mechanical components to expand and become misaligned, leading to inaccuracies. The heat can also affect the cutting tools, leading to accelerated wear and potentially damaging the surface finish of the part.

What’s the real story? The solution lies in maintaining an effective cooling system that ensures the temperature of the tool and material remains within the optimal range. Using coolant, controlling cutting speeds, and optimizing tool geometry are all effective ways to manage heat and prevent distortion.

Table: Heat Management Solutions for Aluminium CNC Machining

| Solution | Impact | Benefits |

|---|---|---|

| Use of coolant | Reduces temperature build-up | Prevents thermal distortion and tool wear |

| Optimizing cutting speed | Controls heat generation | Enhances tool life and machining efficiency |

| Tool geometry adjustments | Minimizes heat concentration | Improves precision and surface finish |

5. Why Are Tolerances and Precision Important in Aluminium Machining?

Tolerances and precision are critical in aluminium CNC machining, especially when manufacturing parts that require high accuracy, such as components for the aerospace or medical industries. Tight tolerances ensure that parts fit together correctly in assemblies and function as intended, which is particularly important in high-performance applications.

The challenges in maintaining tight tolerances come from factors such as machine wear, operator skill, and material behavior. Even the smallest deviation from the intended specifications can lead to costly rework or scrapped parts.

So, why does this matter? Achieving precise machining results requires a well-calibrated machine, the right cutting tools, and attention to detail during the machining process. Regular maintenance and calibration can help maintain precision and ensure that parts meet the required tolerances, reducing the likelihood of errors.

Table: Tolerance Standards for Aluminium CNC Machining

| Tolerance Range | Applications | Machining Precision Required |

|---|---|---|

| ±0.005 mm | Aerospace, automotive | High precision for critical components |

| ±0.01 mm | General manufacturing | Moderate precision for most parts |

| ±0.1 mm | Construction, fixtures | Lower precision for less critical applications |

6. What Are the Effects of Chip Removal and Handling in Aluminium CNC Machining?

In aluminium CNC machining, chip removal is crucial for preventing material buildup that can damage the tool or machine and cause surface finish issues. The chips that are removed during the machining process need to be handled properly to avoid clogging the machine and reducing its performance.

The challenge with chip removal in aluminium machining is that the material is soft and can generate long, stringy chips that are difficult to handle. These chips can wrap around the tool or clog the coolant system, leading to disruptions in the machining process.

But here’s the kicker: the key to effective chip removal is optimizing the cutting parameters to minimize chip formation and ensuring that the coolant system is functioning properly to carry away the chips. Additionally, using chip breakers or specialized tools can help reduce chip length and improve chip handling.

Table: Chip Removal Strategies for Aluminium CNC Machining

| Strategy | Benefit | Challenges |

|---|---|---|

| Use of chip breakers | Reduces chip length | Requires proper tool selection |

| Optimizing cutting parameters | Minimizes chip formation | May reduce machining speed |

| Effective coolant system | Ensures proper chip removal | Needs regular maintenance |

7. How Does Vibration Affect the Quality of Aluminium CNC Machining?

Vibration is a common problem that can significantly affect the quality of aluminium CNC machining. It occurs when the cutting tool or the machine itself experiences oscillations during the machining process. These vibrations can come from various sources, such as machine misalignment, imbalanced tool holders, or excessive cutting speeds.

The primary impact of vibration is that it reduces the precision of the machining process. When the machine or tool vibrates, it can cause tool deflection, which results in inaccuracies in the part dimensions. Additionally, vibration can lead to poor surface finishes, making the parts unsuitable for applications where smooth finishes are required.

What’s the real story? To combat vibration, it’s crucial to ensure that all parts of the machine, including tool holders and workpieces, are properly secured. Implementing vibration-dampening techniques, such as using vibration-resistant materials, adjusting cutting speeds, or adding more rigid machine structures, can also help. Moreover, the use of damping devices, such as vibration isolators, can reduce the frequency and amplitude of vibrations.

Table: Methods to Reduce Vibration in Aluminium CNC Machining

| Method | Benefit | Challenges |

|---|---|---|

| Proper machine alignment | Reduces tool deflection and inaccuracies | Requires precision setup and regular checks |

| Use of vibration-resistant tools | Minimizes vibrations during cutting | May involve higher tool costs |

| Adjustment of cutting speeds | Reduces vibrations and improves surface finish | Slower speeds may reduce efficiency |

8. What Are the Challenges of Cutting Speed in Aluminium CNC Machining?

Cutting speed plays a pivotal role in aluminium CNC machining. However, choosing the right cutting speed is a balancing act. If the cutting speed is too high, it can cause excessive tool wear and overheating, while if it’s too low, the machining process can be inefficient, taking longer to produce parts and increasing operational costs.

Another issue with cutting speed is the trade-off between speed and quality. Higher cutting speeds tend to produce a rougher surface finish, while slower speeds improve the finish but reduce machining efficiency. The key challenge is finding the optimal speed for a specific alloy and part geometry to maximize both efficiency and part quality.

Ready for the good part? The solution lies in optimizing the cutting parameters for each specific job. Understanding the material properties, the tool type, and the desired outcome can help determine the ideal cutting speed. Regular testing and adjusting of cutting speeds can improve both quality and productivity, leading to more consistent results.

Table: Cutting Speed Optimization for Aluminium CNC Machining

| Factor | Effect of Cutting Speed | Solution |

|---|---|---|

| Material hardness | Affects wear rate and cutting efficiency | Adjust cutting speed based on material hardness |

| Tool material | Determines how high the cutting speed can be | Use suitable tooling for higher speeds |

| Desired surface finish | Higher speeds can reduce finish quality | Balance cutting speed with finishing requirements |

9. Why Is Machine Calibration Crucial in Aluminium CNC Machining?

Machine calibration is a critical step in ensuring that aluminium CNC machining runs smoothly and produces high-quality parts. Over time, CNC machines can experience wear and tear that affects their accuracy. Misalignment of machine components, such as the spindle, tool holder, or the workpiece itself, can cause parts to be machined incorrectly.

The impact of poor calibration can be significant. Inaccurate machine settings result in parts that fail to meet tolerances, leading to product defects and potential customer dissatisfaction. Even small deviations can affect assembly processes, making it harder to fit components together.

What’s the real story? Regular calibration and maintenance of CNC machines are key to maintaining precision. It’s crucial to calibrate the machine using high-precision instruments to ensure that all axes are moving in the correct alignment. Also, checking for machine distortion and correcting it before starting a machining job will save time, reduce scrap, and prevent costly errors.

Table: Benefits of Regular Machine Calibration

| Benefit | Impact | Required Actions |

|---|---|---|

| Improved machining accuracy | Reduces errors and defects | Schedule regular machine calibration checks |

| Extended machine lifespan | Prevents unnecessary wear and tear | Implement machine diagnostics and adjustments |

| Consistency in production quality | Ensures uniformity in part dimensions | Maintain alignment and operational parameters |

10. How Can Operator Skill Impact Aluminium CNC Machining?

Operator skill plays a significant role in aluminium CNC machining, as even the best machines can produce subpar results if not operated correctly. Operators must have a thorough understanding of the machine’s capabilities, the materials being used, and the best practices for setting up and running the machine.

A skilled operator can adjust machine settings on the fly, troubleshoot issues, and ensure that the process runs smoothly. On the other hand, a less experienced operator may miss critical adjustments, leading to errors such as incorrect tolerances, tool wear, or even machine damage.

So, why does this matter? Training and experience are essential for minimizing human error and improving machining outcomes. Continuous training programs can keep operators up to date on the latest techniques, software, and machine capabilities, ensuring that the CNC machining process remains efficient, cost-effective, and of high quality.

Table: Importance of Skilled Operators in CNC Machining

| Skill Area | Impact on Machining Process | Solution |

|---|---|---|

| Knowledge of machine settings | Accurate setup leads to precise parts | Ongoing training on machine capabilities |

| Troubleshooting and problem-solving | Reduces downtime and costly errors | Regular skills assessments and feedback |

| Familiarity with materials | Ensures correct tool selection and cutting parameters | Material-specific training programs |

11. What Are the Environmental Factors That Affect Aluminium CNC Machining?

Environmental factors such as temperature, humidity, and air quality can significantly influence the performance of aluminium CNC machining. These factors can cause fluctuations in the material’s properties, affecting its machinability. For example, extreme temperatures may lead to thermal expansion or contraction of the aluminium, which can cause distortion during machining.

Humidity is another factor that can affect the machine’s operation. High humidity can lead to condensation, which may cause rust or corrosion on both the machine and the workpiece. The machine’s electronic components may also be affected by excessive moisture in the air.

What’s the solution? Control of the workshop environment is key to minimizing these issues. By maintaining a stable temperature and humidity level, and investing in proper machine maintenance and protective coatings, these environmental challenges can be reduced. Additionally, using anti-corrosive materials and ensuring that the CNC machine is properly shielded from the elements can further help.

Table: Environmental Factors Affecting CNC Machining

| Factor | Effect | Solution |

|---|---|---|

| Temperature | Can cause thermal expansion of material | Use climate-controlled environments |

| Humidity | May lead to rust and machine malfunctions | Invest in dehumidifiers and protective coatings |

| Air quality | Affects machine electronics and part finishes | Use air purifiers and proper ventilation |

12. How Does Machine Maintenance Prevent Common CNC Machining Issues?

Proper machine maintenance is vital for preventing many common issues encountered in aluminium CNC machining. Over time, machines experience wear and tear, especially when they’re frequently used for high-speed operations. Regular maintenance helps to identify potential issues before they lead to machine failure.

Routine checks for parts such as spindles, bearings, and cooling systems can prevent issues like misalignment, overheating, and excessive tool wear. Not only does this improve the machine’s reliability, but it also reduces downtime and extends the lifespan of the equipment.

What’s the key takeaway here? Regular maintenance can prevent costly repairs, improve operational efficiency, and ensure the quality of the parts being produced. Scheduling regular maintenance and investing in high-quality parts and tools can go a long way in keeping your CNC machining process running smoothly.

Table: Benefits of Regular CNC Machine Maintenance

| Benefit | Impact | Action |

|---|---|---|

| Prevents costly repairs | Reduces unexpected machine downtime | Implement preventive maintenance programs |

| Increases machine longevity | Extends the lifespan of equipment | Schedule regular machine checks |

| Improves part quality | Ensures precision and consistent results | Maintain proper tool and spindle conditions |

13. How Can Software and Programming Challenges Be Overcome in Aluminium CNC Machining?

CNC software and programming challenges can significantly affect aluminium machining outcomes. Programming errors, such as incorrect feed rates or tool paths, can lead to costly errors in the machining process. Even minor mistakes in the software can result in poor-quality parts or machine crashes, which may cause downtime or damage to the equipment.

So, what’s the real story? The key to overcoming these challenges lies in using the latest software versions and ensuring that operators are well-trained in the programming tools. Testing the CNC programs through simulations before actual machining can also help detect potential errors.

Table: Overcoming CNC Programming Challenges

| Challenge | Impact | Solution |

|---|---|---|

| Incorrect feed rates | Leads to tool wear, poor surface finishes | Use simulation tools to validate programs |

| Programming errors | Causes machine crashes, part defects | Regular software training for operators |

| Lack of software updates | Reduces machining efficiency | Ensure software is up to date with new features |

14. What Are the Cost Implications of Challenges in Aluminium CNC Machining?

The challenges faced in aluminium CNC machining, such as tool wear, precision issues, and heat management, can have significant cost implications. These issues can increase material waste, require more frequent tool replacements, and lead to costly downtime.

By addressing these challenges through effective process optimization, companies can reduce production costs. Investing in higher-quality tools, advanced machine features, and well-maintained equipment can help mitigate many of these expenses.

Table: Cost Implications of Common CNC Machining Challenges

| Challenge | Impact on Costs | Solution |

|---|---|---|

| Tool wear | Increased tool replacement costs | Use high-quality tools and optimize cutting speeds |

| Heat distortion | Scrapped parts, rework | Implement better cooling and heat management systems |

| Precision issues | Increased scrap rates and rework costs | Invest in regular calibration and high-precision tools |

15. How Can You Improve Aluminium CNC Machining Processes for Better Results?

Improving aluminium CNC machining processes is crucial for enhancing efficiency, reducing costs, and ensuring the production of high-quality parts. This can be achieved by optimizing cutting parameters, using advanced tools, and implementing effective maintenance and calibration schedules.

Additionally, investing in operator training, machine upgrades, and software improvements can help streamline processes. Continually analyzing and refining your machining practices will lead to better outcomes and increased competitiveness in the market.

Table: Strategies for Improving CNC Machining Processes

| Strategy | Benefit | Action |

|---|---|---|

| Optimize cutting parameters | Increases efficiency and quality | Regular testing and adjustment of cutting settings |

| Invest in machine upgrades | Improves precision and reduces downtime | Upgrade to newer, more efficient machines |

| Operator training | Reduces human error and improves productivity | Offer regular training and skill development |

FAQ Section

Q1: What is aluminium CNC machining?

Aluminium CNC machining is a computer-controlled manufacturing process used to produce precise aluminium parts and components, often for industries like aerospace, automotive, and electronics.

Q2: How does tool wear affect aluminium CNC machining?

Tool wear leads to poor surface finishes, lower machining accuracy, and the need for more frequent tool replacements, all of which increase production costs.

Q3: Why is heat management crucial in aluminium CNC machining?

Heat buildup can cause thermal distortion, leading to inaccuracies in the parts and accelerated tool wear, which is why managing heat is vital for maintaining machining quality.

Q4: What is the importance of precision in aluminium CNC machining?

Maintaining tight tolerances is crucial for producing parts that fit together accurately and perform as required, especially in high-performance applications.

Q5: How does chip removal affect aluminium CNC machining?

Improper chip removal can cause machine damage, poor surface finish, and interrupted machining processes. Effective chip handling is essential for smooth operations.