Галузі промисловості

CNC precision machining manufacturers make the imagination of every industry become reality through precision manufacturing

Our Service

Precision Solutions for Diverse Industries

Our machining services, as trusted CNC precision machining suppliers, cater to a wide range of industries, delivering high-precision components that meet strict standards and ensure reliable performance across various applications.

Аерокосмічна

Automobile -Manufacturing

Industrial Automation & Robotics

Медичне обладнання

Нова енергія

Напівпровідники

Комунікаційне обладнання

Побутова електроніка

Нафта і газ

Products

High-Quality Precision Products for Every Need

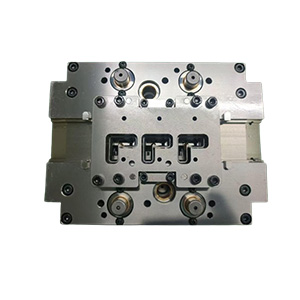

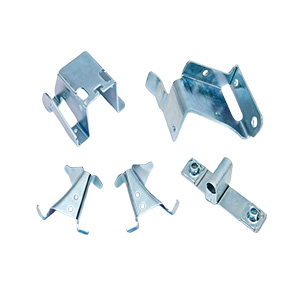

We offer a wide range of precision-engineered products, including Обробка з ЧПУ parts, lathe components, injection molding, die casting, stamping, sheet metal, molds, and surface treatment services, delivering reliable CNC manufacturing solutions for various industries.

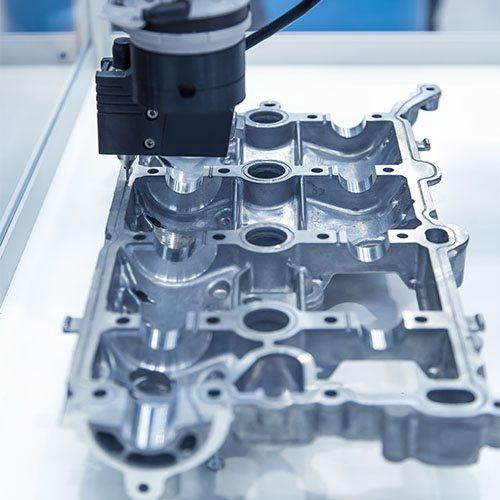

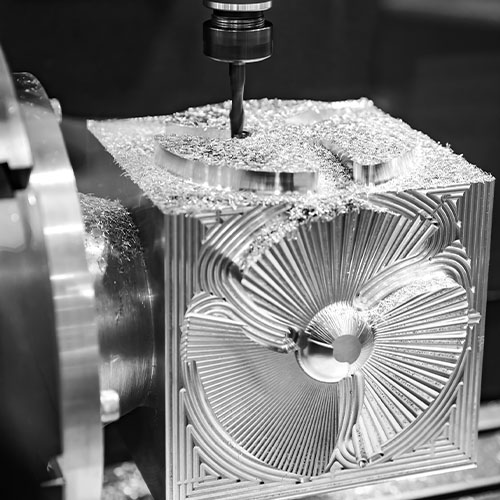

Обробка з ЧПУ

Токарний верстат

Лиття під тиском

цвіль

Punching Part

Листовий метал

Прес-форма для лиття під тиском

Обробка поверхні

Project List

Precision Manufacturing Solutions

Delivering tailored CNC precision machining expertise across industries, from aerospace to robotics, we ensure exceptional quality and innovation in every project, meeting the demands of modern technology and global markets with precision and reliability.

Project #1 Aerospace Industry

Aerospace Industry

Product Demand:

Aerospace components require exceptional precision and durability due to the critical nature of their applications, including turbine blades, landing gear, and avionics parts. Lightweight materials and resistance to extreme conditions are essential.

Client Pain Points:

The aerospace sector struggles with high precision requirements, long lead times, and the need for specialized materials. Additionally, compliance with strict regulatory standards adds complexity to production processes.

Solution:

We specialize in machining high-performance materials such as titanium and aluminum alloys, ensuring precision and durability. Our commitment to stringent quality standards and certifications helps aerospace companies meet regulatory demands, delivering on-time parts with reliable performance.

Project #2 Automotive Industry

Automotive Industry

Product Demand:

The automotive industry requires high-precision, durable, and cost-effective components. These include engine parts, transmissions, suspension systems, and body panels that must meet strict safety standards and performance requirements.

Client Pain Points:

Automotive manufacturers face challenges with tight tolerances, complex designs, and the need for fast production times. There’s also pressure to reduce costs while maintaining quality, as well as to manage supply chain disruptions.

Solution:

We offer precision machining services that deliver consistent, high-quality components on time. With advanced CNC technology and strict quality control processes, we ensure that parts meet all safety and performance standards. Our cost-efficient manufacturing processes help reduce overall production costs while maintaining product integrity.

Project #3 Industrial Automation & Robotics Industry

Industrial Automation & Robotics Industry

Product Demand:

The industrial automation and robotics industry requires precise and durable components for machinery, actuators, sensors, robotic arms, and control systems. These components must function reliably under harsh operating conditions, with minimal downtime.

Client Pain Points:

Clients often face challenges with tight tolerances, high production costs, and the need for rapid scaling of automation systems. Maintaining consistent quality and performance across large batches of components is another common issue.

Solution:

Our precision machining capabilities allow us to produce high-quality parts that meet stringent performance standards. We specialize in fast turnaround times and cost-effective solutions, ensuring that automation systems and robotic components are produced with precision, durability, and reliability.

Project #4 Medical Industry

Medical Industry

Product Demand:

Medical devices and components, such as surgical tools, implants, and diagnostic equipment, demand extreme precision and biocompatibility. These parts must meet strict regulatory standards and ensure patient safety.

Client Pain Points:

Manufacturers face challenges with maintaining sterile conditions, meeting FDA compliance, and ensuring the longevity and reliability of medical components. Time-sensitive orders add to the pressure.

Solution:

We provide high-precision machining services for medical-grade materials, ensuring that all components are produced to the highest standards of safety and quality. Our expertise in regulatory compliance ensures that every product meets necessary certifications, with reliable and timely delivery to meet critical healthcare needs.

Project #5 New Energy Industry

New Energy Industry

Product Demand:

The new energy industry requires specialized components for renewable energy systems such as wind turbines, solar panels, and energy storage devices. Parts need to be lightweight, corrosion-resistant, and capable of withstanding extreme environmental conditions.

Client Pain Points:

The industry often faces issues related to material selection, long lead times, and maintaining low manufacturing costs while ensuring high performance and durability in energy-efficient systems.

Solution:

We offer advanced machining services tailored to the needs of the new energy sector. Our team works with a variety of materials like stainless steel and composite alloys, ensuring that components are high-performing and resilient to harsh environments. With fast delivery times and cost-effective production, we support the growing demand for renewable energy systems.

Project #6 Semiconductors Industry

Semiconductors Industry

Product Demand:

The semiconductor industry requires ultra-precise components for chip production, including wafer stages, photomasks, and specialized tooling. These parts need to be free from defects and highly resistant to contamination.

Client Pain Points:

Semiconductor manufacturers face challenges with maintaining the highest levels of precision, minimizing defects, and meeting tight deadlines for product launches. There is also constant pressure to reduce costs without compromising performance.

Solution:

We specialize in high-precision machining using cleanroom protocols to ensure contamination-free production. Our advanced equipment and quality control systems deliver the fine tolerances and defect-free components needed for semiconductor production, all while reducing manufacturing costs.

Project #7 Communication Industry

Communication Industry

Product Demand:

Communication equipment manufacturers need high-precision parts for devices like antennas, transmitters, and receivers. Components must be durable, reliable, and capable of operating at high frequencies with minimal signal loss.

Client Pain Points:

Challenges include ensuring parts meet rigorous standards for signal integrity, managing costs while maintaining quality, and dealing with the rapid technological advancements in communication systems.

Solution:

We provide high-quality machining services for the communication equipment industry, producing components with precise tolerances and excellent material properties. Our solutions ensure high performance and reliability, helping our clients keep up with the fast-paced demands of the telecommunications sector.

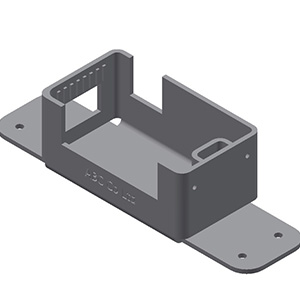

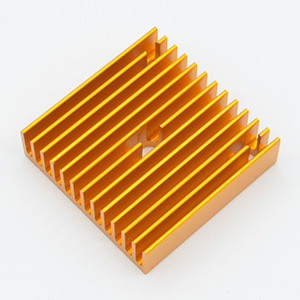

Project #8 Consumer Electronics Industry

Consumer Electronics Industry

Product Demand:

The consumer electronics industry requires a wide range of components, from intricate housings and connectors to durable screens and internal circuitry. Parts need to be aesthetically pleasing, functional, and cost-effective to meet high-volume production needs.

Client Pain Points:

Manufacturers face challenges with balancing quality, cost, and production speed. The need for frequent design changes, rapid product iterations, and maintaining consistency in mass production can also be problematic.

Solution:

We specialize in machining high-quality, cost-effective components for the consumer electronics market. Our efficient production processes and attention to detail ensure that every part meets the required specifications while keeping costs low and delivery times short.

Project #9 Oil and Gas Industry

Oil and Gas Industry

Product Demand:

The oil and gas industry requires robust, high-performance components such as valves, pumps, drilling equipment, and pipeline fittings. These parts need to withstand extreme temperatures, pressure, and corrosive environments.

Client Pain Points:

Clients in the oil and gas industry often struggle with the high cost of materials, the need for specialized components, and the pressure to maintain operations in harsh and challenging conditions. Delays and failures in critical parts can lead to costly downtimes.

Solution:

We provide machining services for the oil and gas industry, specializing in durable, high-performance materials like titanium, stainless steel, and high-alloy steels. Our rigorous quality control ensures that every part is capable of performing under extreme conditions, and we offer fast turnaround times to minimize operational downtime.

BEST SERVICES & TRUSTED

Get premium machining solutions now—quality, price, and service guaranteed. Contact us today!

Our Service From ————

Prototyping to Packing

01 Prototyping

Every great product starts with a solid prototype. We work closely with you to turn ideas into tangible samples that reflect your vision. Our team focuses on precision, ensuring every detail aligns with your requirements. Whether it’s a small adjustment or a complete overhaul, we make sure the prototype sets the foundation for success.

* Accurate product sampling

* Design feasibility testing

* Quick turnaround on prototypes

* Collaborative development process

02 Engineering Validation

Before mass production begins, our experienced engineers step in to ensure every detail is perfect. From material performance to structural integrity, we test, refine, and validate your product thoroughly. This step eliminates risks and guarantees that the final product meets both your standards and industry requirements.

* Performance assessment

* Compliance with global standards

* Detailed engineering analysis

* Risk prevention and refinement

03 Design Solution

Good design isn’t just about looks—it’s about performance, usability, and efficiency. Our design team blends creativity with practicality to develop flooring solutions that not only meet your aesthetic goals but also deliver durability and functionality. We involve you in every step, ensuring your vision becomes reality.

* Customized design solutions

* Balance aesthetics & functionality

* Client collaboration throughout

* Practical and innovative designs

04 Production Control

Our production process is where ideas come to life at scale. Using state-of-the-art machinery and skilled craftsmanship, we produce flooring solutions with precision and care. Every batch undergoes strict monitoring to ensure consistency, efficiency, and quality, delivering products you can rely on.

* Advanced manufacturing technology

* Scalable production capacity

* Strict quality control

* Skilled and dedicated workforce

05 100% Checking

Quality isn’t just a step—it’s a promise. Our checking process ensures every product meets the highest standards before leaving our facility. From material inspection to final checks, we leave no room for error, giving you confidence in every order you receive.

* Multi-stage quality inspection

* Consistency assurance

* Compliance with specifications

* Attention to every detail

06 Customized Packing

The journey doesn’t end until your products arrive safely. Our packing process is designed to protect your flooring from damage during transit. Using durable materials and export-standard packaging techniques, we ensure every product reaches you in perfect condition, ready for your customers.

* Durable packaging materials

* Export-standard packing

* Damage-free delivery guarantee

* Safe and secure handling

Go Deep into the Industry and ShareTechnical Insights

1. The Rise of Advanced CNC Machining:

Computer Numerical Control (CNC) machining has revolutionized aerospace manufacturing, enabling intricate designs with micron-level accuracy. This ensures components such as turbine blades, engine parts, and structural elements meet strict performance standards.

2. Additive Manufacturing (3D Printing):

3D printing allows for the creation of complex geometries that were previously impossible to produce. Aerospace companies now use additive manufacturing for lightweight parts, reducing fuel consumption while maintaining strength and durability.

High-Precision Manufacturing Trends in the Aerospace Industry

In the aerospace industry, precision is not just a requirement—it’s a necessity. As technology advances, high-precision CNC machining continues to play a critical role in improving performance, safety, and efficiency in aircraft and spacecraft production.

3. Material Innovation:

High-performance alloys, titanium composites, and carbon-fiber-reinforced polymers are being increasingly used to enhance strength-to-weight ratios and withstand extreme conditions in aerospace environments.

4. Automation and Robotics:

Robotic systems are now integrated into production lines for precision assembly, inspection, and material handling, minimizing human error and boosting efficiency.

Looking ahead, aerospace manufacturing will continue to focus on smarter factories, AI-driven quality control, and greener processes. For stakeholders, investing in high-precision manufacturing technologies means better reliability, lower costs, and enhanced competitive advantages in a rapidly evolving market.

The Impact of New Material Technologies on Medical Equipment Development

Medical technology is advancing at a rapid pace, driven largely by breakthroughs in material science. From surgical tools to implants and diagnostic devices, new materials are transforming how medical equipment is designed, manufactured, and utilized.

1. Biocompatible Materials for Implants:

Innovative materials such as titanium alloys, bioceramics, and bioabsorbable polymers are being widely adopted for implants. These materials not only integrate seamlessly with human tissue but also reduce the risk of rejection and infection.

2. Flexible and Wearable Devices:

Materials like silicone, graphene, and flexible polymers are enabling the creation of wearable medical devices. These devices offer real-time health monitoring and provide better patient comfort during prolonged use.

3. Antimicrobial Surfaces:

Advanced coatings and antimicrobial materials are being used in surgical tools and hospital equipment to minimize bacterial growth, reducing infection rates significantly in medical facilities.

4. Enhanced Imaging Equipment:

Materials with improved radiation shielding and clarity are enhancing the precision of diagnostic tools such as CT and MRI scanners, providing better imaging results for early disease detection.

5. Conclusion

As the medical industry continues to evolve, the adoption of advanced materials will remain at the forefront. For manufacturers and healthcare providers, staying updated on these innovations means better product performance, improved patient outcomes, and a stronger market position in a competitive healthcare landscape.

Precision in Every Detail: Inside Our Advanced Machining Process

Step into our precision CNC machining factory and witness how we achieve unparalleled accuracy and efficiency in every product. With precision machining CNC technology, rigorous quality control, and advanced engineering, we ensure exceptional results at every stage of production. Watch now to see precision manufacturing in action!

Frequently Asked Questions

Have Any Questions

Find quick answers to your key machining questions here.

We work with a wide range of materials, including stainless steel, aluminum, titanium, brass, and specialized alloys. Our advanced equipment ensures precise machining regardless of material complexity, meeting the unique requirements of industries such as aerospace, automotive, and medical devices.

Quality is our top priority. We utilize advanced CNC machinery, strict quality control protocols, and multi-stage inspections throughout the machining process. Each part is checked for accuracy, durability, and compliance with industry standards before delivery.

Absolutely! Our experienced engineering team specializes in customizing machining solutions based on your design drawings and specifications. Whether it’s intricate geometries or tight tolerances, we deliver results tailored to your needs.

With our advanced machinery and efficient workflows, we can handle both small batches and large-scale production orders. Lead times depend on the complexity and volume of the order, but we pride ourselves on fast turnaround and timely delivery to keep your projects on schedule.

Yes, we offer prototyping services to ensure your design meets all specifications before moving to mass production. This allows for adjustments, quality checks, and performance validation, minimizing risks and ensuring optimal results.